Folhas de gelo seco para catering: A solução definitiva para transporte seguro e eficiente da cadeia de frio

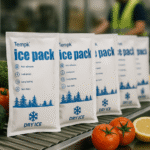

Manter a qualidade e segurança dos alimentos perecíveis durante o transporte é crucial na indústria da restauração. Folhas de gelo seco para catering estão se tornando cada vez mais a solução ideal para manter frescos os alimentos sensíveis à temperatura. Estas folhas fornecem um ultra-frio, solução seca, oferecendo uma maneira conveniente e econômica de garantir que os alimentos permaneçam congelados ou resfriados durante o transporte de longa distância. Neste artigo, exploraremos como funcionam as placas de gelo seco, os benefícios que eles oferecem, e as melhores práticas para usá-los para manter a qualidade dos alimentos.

-

O que são placas de gelo seco para catering e como funcionam?

-

Por que são a melhor escolha para serviços de catering?

-

As vantagens do uso de gelo seco no transporte.

-

Como escolher o tamanho e a quantidade certos para suas necessidades.

-

Tendências no transporte marítimo da cadeia de frio e inovações em 2025.

O que são folhas de gelo seco para catering e como funcionam?

As folhas de gelo seco para catering são flexíveis, cobertores multicelulares cheios de dióxido de carbono de alta pureza (Co₂). Essas folhas são projetadas para manter temperaturas ultrabaixas, sublimando o CO₂ do sólido para o gasoso, que absorve o calor sem deixar nenhum resíduo de umidade. Isso os torna ideais para uso em catering, pois evitam que os alimentos fiquem encharcados - ao contrário das bolsas de gelo tradicionais que derretem e criam escoamento de água.

Como funciona a sublimação:

O processo de sublimação envolve a transição do CO₂ diretamente de um sólido para um gás, absorvendo calor no processo. Isso resulta em resfriamento sem a necessidade de gelo ou água volumosos. O gelo seco atinge temperaturas tão baixas quanto -78.5°C (-109.3°F), tornando-o eficaz para manter alimentos congelados e perecíveis na temperatura ideal durante transporte ou eventos.

Principais recursos:

-

Temperatura ultrabaixa: O gelo seco pode manter temperaturas bem abaixo de zero, tornando-o adequado para alimentos congelados como sorvete, carnes, e frutos do mar.

-

Nenhum resíduo líquido: Ao contrário do gelo tradicional, gelo seco sublima diretamente no gás, não deixando resíduos de água que possam danificar os alimentos ou embalagens.

-

Design Flexível: A estrutura da manta multicelular se adapta a refrigeradores e bandejas, fornecendo cobertura total para vários tamanhos de recipientes e produtos.

Por que as folhas de gelo seco para catering são a melhor escolha para serviços de catering?

Para fornecedores, garantir que os alimentos cheguem frescos e seguros é fundamental. As placas de gelo seco para catering costumam ser a melhor escolha devido a diversas vantagens em relação aos métodos tradicionais de resfriamento, como bolsas de gel ou gelo de água..

Duração estendida de resfriamento:

O gelo seco pode fornecer resfriamento para 24-48 horas, significativamente mais longo do que os pacotes de gel, que normalmente dura 6-12 horas. Isto é crucial para transporte de longa distância ou eventos prolongados onde a refrigeração pode não estar disponível.

Eficiência de custo:

Embora o gelo seco possa parecer uma opção mais cara inicialmente, economiza dinheiro a longo prazo, preservando a qualidade dos alimentos e reduzindo a deterioração. O risco reduzido de deterioração dos alimentos também significa menos perdas de produtos.

Ecologicamente correto:

O gelo seco é feito de dióxido de carbono reciclado, que é capturado durante processos industriais. Como resultado, usar gelo seco para transporte de alimentos pode ser considerado uma opção mais sustentável do que o gelo tradicional ou refrigerantes sintéticos.

As vantagens de usar folhas de gelo seco para catering no transporte

Usando folhas de embalagens de gelo seco na restauração oferece diversas vantagens que vão além de apenas manter os alimentos frescos. Estas folhas melhoram a qualidade geral do seu serviço de catering, abordando questões críticas como danos causados pela umidade, deterioração, e custo-efetividade.

Principais benefícios:

-

Duração de resfriamento mais longa: O gelo seco mantém seu efeito de resfriamento por até 48 horas, tornando-o perfeito para eventos, locais remotos, ou remessas noturnas.

-

Sem danos causados pela água: Ao contrário do gelo tradicional, Gelo seco não derrete na água, garantindo que sua embalagem de alimentos permaneça intacta e seus produtos secos.

-

Confiabilidade: Folhas de gelo seco para catering oferecem desempenho de resfriamento consistente, dando aos fornecedores a tranquilidade de que seus produtos chegarão nas melhores condições possíveis.

| Solução de resfriamento | Duração do resfriamento | Aplicações ideais | Benefícios |

|---|---|---|---|

| Catering para placas de gelo seco | 24-48 horas | Frutos do mar, carnes, Alimentos congelados | Resfriamento mais longo, Sem resíduos de água, alta confiabilidade |

| Pacotes de gel | 12-24 horas | Laticínio, frutas | Flexível, reutilizável, econômico |

| Pacotes de gelo tradicionais | 6-12 horas | Envio de curta distância | Barato, amplamente disponível |

Que tipos de alimentos se beneficiam mais com folhas de gelo seco para catering?

Nem todos os alimentos precisam do mesmo nível de resfriamento. Folhas de gelo seco para catering são particularmente benéficas para certos tipos de alimentos. Estes incluem:

Alimentos Congelados:

O gelo seco garante que os alimentos congelados, como sorvete, carnes congeladas, e aves, permanecem nas baixas temperaturas exigidas durante o transporte.

Frutos do mar:

Frutos do mar frescos são especialmente sensíveis às mudanças de temperatura, e gelo seco ajuda a prevenir o descongelamento, garantindo que os frutos do mar permaneçam frescos, seguro, e livre de crescimento bacteriano.

Produtos lácteos:

Queijos, leite, e outros produtos lácteos precisam ser mantidos em temperaturas específicas para evitar deterioração. O gelo seco ajuda a manter a qualidade desses produtos, mesmo durante o transporte de longa distância.

Melhor dica para fornecedores:

Para uma variedade de alimentos, considere usar gelo seco para itens perecíveis como carne e frutos do mar, e pacotes de gel para itens menos sensíveis, como frutas ou certas sobremesas. Este método híbrido otimiza o custo e a eficácia do resfriamento.

2025 Tendências na logística da cadeia fria

À medida que nos mudamos para 2025, inovações no setor de logística da cadeia de frio estão moldando o futuro dos serviços de catering. Aqui está uma olhada nas principais tendências a serem observadas:

Logística Inteligente e Monitoramento de Temperatura:

Dispositivos de monitoramento de temperatura em tempo real estão se tornando padrão, permitindo que os fornecedores monitorem a condição de suas mercadorias durante o trânsito.

Embalagem sustentável:

Há um foco cada vez maior em materiais de embalagem biodegradáveis e recicláveis para complementar as soluções de resfriamento com gelo seco. Esta tendência é impulsionada por crescentes preocupações ambientais.

Automação em logística da cadeia fria:

Os sistemas de embalagem automatizados estão se tornando mais avançados, reduzindo custos de mão de obra e erros humanos, melhorando ao mesmo tempo a eficiência no processo de embalagem.

Considerações de segurança para placas de gelo seco para catering

Embora o gelo seco seja altamente eficaz, requer manuseio adequado. Siga estas práticas de segurança para evitar acidentes:

Melhores práticas de segurança:

-

Ventilação: Certifique-se sempre de que os recipientes usados com gelo seco tenham aberturas adequadas para permitir a saída do gás.

-

Luvas e pinças: Sempre use luvas isoladas ao manusear gelo seco para evitar queimaduras pelo frio.

-

Evite recipientes herméticos: Nunca sele gelo seco em recipientes herméticos, pois isso pode causar acúmulo perigoso de pressão.

-

Rotulagem: Rotular adequadamente os recipientes com “Gelo Seco (E 1845)” e o peso líquido para cumprir os regulamentos de segurança.

Perguntas frequentes

1. Quanto tempo duram as placas de gelo seco para catering?

As placas de gelo seco normalmente duram entre 24 para 48 horas, dependendo de fatores como isolamento e temperatura ambiente.

2. Posso usar gelo seco para enviar todos os tipos de alimentos?

Sim, o gelo seco é adequado para transportar uma ampla variedade de alimentos, particularmente aqueles que precisam permanecer congelados ou em baixas temperaturas.

3. É seguro manusear gelo seco?

Sim, mas sempre manuseie o gelo seco com cuidado. Use luvas, trabalhar em áreas bem ventiladas, e nunca feche-o em recipientes herméticos.

Conclusão e recomendações

Folhas de gelo seco para catering são confiáveis, eficaz, e solução ecológica para manter os alimentos frescos durante o transporte. Seu poder de resfriamento duradouro, versatilidade, e os benefícios ambientais os tornam essenciais para empresas de catering. Quer você esteja transportando alimentos congelados, frutos do mar, ou laticínios, o gelo seco garante que suas mercadorias cheguem em ótimas condições.

PRÓXIMOS PASSOS:

-

Avalie seus métodos de transporte atuais e considere mudar para placas de gelo seco para alimentos sensíveis à temperatura.

-

Invista em ferramentas de monitoramento de temperatura para garantir condições ideais durante o transporte.

-

Adote soluções de embalagens sustentáveis para aprimorar suas práticas ecológicas e atrair clientes ambientalmente conscientes.