Segurança do Chocolate Gourmet da Cadeia de Frio: O que funciona 2025?

Última atualização: dezembro 15, 2025

Segurança do chocolate gourmet na cadeia de frio mantém o chocolate premium brilhante, ágil, e pronto para presente durante o envio. Um alvo inicial confiável é 15–18ºC (59–64°F) com umidade relativa abaixo de ~50%. Mudanças de temperatura e desembalagem úmida podem causar florescimento e cantos suaves. Em 2025, sua melhor vantagem é a repetibilidade: um pacote documentado, embalagem específica para pista, e validação simples. Use este manual para criar uma rotina de segurança para chocolate gourmet na cadeia de frio, não é sorte sazonal.

Este artigo responderá para você:

-

Como a segurança do chocolate gourmet da cadeia de frio mantém a estabilidade temperatura de envio de chocolate gourmet

-

Como evitar o florescimento do chocolate durante o transporte com métodos simples, etapas repetíveis

-

Como controle de umidade para cadeia de frio de chocolate reduz a condensação e a “sudorese”

-

Como escolher embalagens adequadas à faixa sem congelamento excessivo

-

Como um registrador de temperatura para remessas de chocolate transforma esperança em prova

O que realmente significa segurança do chocolate gourmet na cadeia de frio?

A segurança do chocolate gourmet na cadeia de frio significa que você mantém o chocolate em sua “zona de conforto” desde a embalagem até a desembalagem, para que a qualidade e a segurança permaneçam intactas.

cadeia de frio chocolate gourmet sa…

Não se trata de enviar chocolate “o mais frio possível”. Trata-se de enviar chocolate estável, com manuseio limpo e controle correto de alérgenos.

Pense no chocolate como uma vela à luz do sol. Pode não derreter imediatamente, mas o calor muda isso para sempre.

cadeia de frio chocolate gourmet sa…

A segurança do chocolate gourmet da cadeia fria evita danos silenciosos.

Qualidade versus. segurança alimentar: quais riscos você realmente gerencia?

A segurança do chocolate gourmet da cadeia de frio protege a qualidade em primeiro lugar, mas também apoia controlos de segurança alimentar. Chocolate tem pouca umidade, por isso muitas vezes parece “seguro,”mesmo quando algo deu errado. É por isso que você precisa de um plano simples para alérgenos, material estranho, e captação de odores.

| Tipo de risco | Gatilho típico | O que os clientes notam | O que isso significa para você |

|---|---|---|---|

| Defeito de qualidade (florescer) | Ciclagem de umidade ou temperatura | Névoa branca, sensação áspera na boca | Reembolsos, percepção “obsoleta” |

| Defeito de qualidade (amolecimento) | Picos de calor em docas/vans | Você é rude?, manchas | Apresentação quebrada, retorna |

| Transferência de odor | Armazenamento/cargas com cheiro forte | Sabor “desligado” | Danos à confiança premium |

| Erro de alérgeno | Contato cruzado ou troca de etiqueta | Às vezes invisível | Risco de segurança de alto impacto |

| Material estranho | Bandejas ou fragmentos danificados | Contaminação visível | Reclamações imediatas |

Dicas práticas que você pode usar hoje

-

Anote sua “zona de conforto”. Coloque a faixa-alvo em um pôster POP de embalagem para segurança do chocolate gourmet na cadeia de frio.

-

Separe “verificações de qualidade” de “verificações de segurança”. Um é sobre florescer, o outro é sobre risco.

-

Trate chocolates recheados como de maior risco. Eles vazam e se deformam mais cedo do que barras sólidas.

cadeia de frio chocolate gourmet sa…

Caso do mundo real: Uma marca de presentes tinha um produto “seguro”, mas os clientes ainda reembolsaram. O problema era flor e apresentação, não micróbios. Eles consertaram a segurança do chocolate gourmet da cadeia de frio, estabilizando a temperatura e adicionando uma barreira contra umidade. Reclamações retiradas, e repetir pedidos devolvidos.

Qual faixa de temperatura apoia a segurança do chocolate gourmet da cadeia de frio?

Para a segurança do chocolate gourmet na cadeia de frio, apontar para uma temperatura constante de 15–18°C (59–64°F) para a maioria das remessas premium.

cadeia de frio chocolate gourmet sa…

Mantenha a umidade baixa, e evite grandes oscilações durante as transferências. A estabilidade supera “mais frio é melhor,”Porque o resfriamento excessivo pode criar condensação posteriormente.

cadeia de frio chocolate gourmet sa…

O chocolate amolece muito antes de derreter completamente. É por isso que o “frio da geladeira” pode ser uma armadilha. Você não quer uma caixa que chegue gelada, então transpira no ar quente.

Por que a estabilidade bate “o mais frio possível”

A segurança do chocolate gourmet da cadeia de frio falha quando você cria um ciclo quente → frio → quente. Esse ciclismo empurra gorduras ou açúcares para a superfície. Pode parecer mofo, mesmo quando não é.

Use esta regra simples: Se o seu refrigerante estiver muito mais frio do que o seu alvo, você aumenta o risco de condensação na entrega.

cadeia de frio chocolate gourmet sa…

| Tipo de produto | Banda alvo prática | Por que isso ajuda você |

|---|---|---|

| Barras de chocolate amargo | Frio estável na zona de 15–18°C | Mais tolerante, menos surpresas de textura |

| Chocolate ao leite/branco | Mesma banda, estabilidade mais rígida | Mais sensível a excursões e floração |

| Bombons/pralines recheados | Mesma banda + manuseio rigoroso | As obturações se deformam e vazam com oscilações |

| Sortimentos de presentes | Mesma banda + proteção contra umidade | A apresentação é o “produto” |

Dicas práticas que você pode usar hoje

-

Pré-condicionar produto e embalagem à mesma temperatura alvo antes de embalar.

cadeia de frio chocolate gourmet sa…

-

Evite contato direto entre chocolate e embalagens muito frias.

-

Planeje suas transferências. As docas de carregamento são onde ocorrem a maioria dos picos.

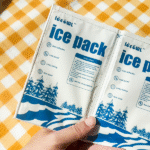

Caso do mundo real: Um chocolateiro usou pacotes de gel congelado “por segurança”. As caixas chegaram frias, então floresceu durante a noite no balcão do cliente. Eles mudaram para uma abordagem de controle de 15–18°C e as reclamações de “névoa branca” diminuíram rapidamente.

cadeia de frio chocolate gourmet sa…

Como evitar o florescimento do chocolate durante o transporte com a segurança do chocolate gourmet da cadeia de frio?

A segurança do chocolate gourmet da cadeia de frio evita o florescimento ao controlar dois inimigos: picos de calor e ciclos de temperatura.

cadeia de frio chocolate gourmet sa…

Bloom geralmente é um problema de qualidade, mas os clientes consideram isso “não novo”. Isso torna a prevenção da floração uma prioridade empresarial.

Você está lutando contra dois tipos de flores:

-

Flor gorda: causada por oscilações de temperatura que movem os cristais de manteiga de cacau.

-

Flor de açúcar: causada pela umidade e condensação que dissolvem o açúcar, então seque.

Os quatro gatilhos comuns (e o que fazer)

A tabela abaixo transforma a segurança do chocolate gourmet na cadeia de frio em ações claras.

cadeia de frio chocolate gourmet sa…

| Gatilho de risco | O que acontece | O que fazer | O que isso significa para você |

|---|---|---|---|

| Pico quente | Amolecimento, manchando, florescer mais tarde | Adicionar isolamento + refrigerante apropriado para a pista | Menos reembolsos de “cantos derretidos” |

| Ciclagem de temperatura | Névoa de flor gorda | Escolha um controle estável de 15–18°C | Mantém brilho e estalo |

| Refrigeração excessiva | Condensação → flor de açúcar | Use PCM de média temperatura, não gel gelado | Impede superfícies “empoeiradas” |

| Desembalagem úmida | Sudorese e caixas pegajosas | Adicionar saco de barreira + Controle de umidade | Melhor apresentação de presentes |

Verificação rápida do ponto de orvalho (sem ansiedade matemática)

A condensação acontece quando o chocolate frio encontra o quente, ar úmido. Se o seu chocolate estiver mais frio que o “ponto de orvalho,”a umidade pode aparecer rapidamente.

| Quarto RH (a ~20°C) | Ponto de orvalho aproximado | O que isso significa para você |

|---|---|---|

| 40% | ~6°C | Baixo risco de condensação |

| 50% | ~9°C | Assista ao aquecimento rápido |

| 60% | ~12°C | Provável condensação se estiver muito frio |

| 70% | ~14°C | Alto risco sem barreiras |

| 80% | ~16°C | Risco muito alto durante a desembalagem |

Dicas práticas que você pode usar hoje

-

Reduza o espaço aéreo vazio. O ar aquece rapidamente e provoca oscilações.

cadeia de frio chocolate gourmet sa…

-

Evite docas e vans quentes. Um pequeno atraso pode ser um grande problema.

cadeia de frio chocolate gourmet sa…

-

Use uma breve nota de desembalagem. “Descanse 20 a 30 minutos antes de desembrulhar” apoia a segurança do chocolate gourmet na cadeia de frio e evita o suor.

cadeia de frio chocolate gourmet sa…

Caso do mundo real: Uma marca adicionou um forro de barreira e uma nota de desembalagem de uma linha. Tampas pegajosas e bandejas suadas caíram, mesmo com a mesma operadora e faixa.

Quais camadas de embalagem proporcionam segurança de chocolate gourmet na cadeia de frio em grande escala?

A embalagem é a primeira defesa física na segurança do chocolate gourmet da cadeia de frio. Retarda o ganho de calor e protege contra umidade durante atrasos. Se a embalagem for fraca, A “perfeição” logística não salvará o produto.

Use uma pilha simples de quatro camadas:

-

Proteção primária: envoltório interno selado e bandeja.

-

Umidade + barreira contra odores: um saco ou forro selado.

-

Isolamento: remetente do tamanho certo para a pista.

-

Controle de temperatura: refrigerante que corresponda à sua faixa alvo.

Pacotes de gel vs PCM vs gelo seco: o que cabe no chocolate?

Para a maioria dos chocolates premium, gelo seco geralmente é a ferramenta errada. Está extremamente frio e pode resfriar demais o produto, aumentando o risco de condensação posteriormente.

cadeia de frio chocolate gourmet sa…

O controle de temperatura média geralmente é a melhor opção para a segurança do chocolate gourmet da cadeia de frio.

| Escolha do refrigerante | Comportamento típico | Chocolate em forma | O que isso significa para você |

|---|---|---|---|

| Pacotes de gel congelado | Muito frio no início, aquece de forma desigual | Arriscado para floração/condensação | Pode criar problemas de “suor”

cadeia de frio chocolate gourmet sa… |

| PCM de média temperatura (15–18ºC) | Mantém-se perto do alvo por mais tempo | Excelente combinação | Chegadas mais consistentes

cadeia de frio chocolate gourmet sa… |

| Pacotes de gel refrigerados | Mais perto do alvo, retenção mais curta | Bom para pistas curtas | Menor custo, menor risco

cadeia de frio chocolate gourmet sa… |

| Gelo seco | Extremamente frio | Geralmente mau ajuste | Super-resfriamento + risco de condensação

cadeia de frio chocolate gourmet sa… |

Uma ferramenta de decisão de embalagem em 3 minutos (escolha sua pista)

Responda três perguntas para escolher a construção certa para segurança do chocolate gourmet da cadeia de frio:

-

Qual é o comprimento da sua pista? (≤24h, 24-48h, 48-72h)

cadeia de frio chocolate gourmet sa…

-

Quão quente é o pior dia? (Abaixo de 20°C, 20–28ºC, acima de 28°C)

cadeia de frio chocolate gourmet sa…

-

O que você está enviando? (bares, caixas de presente, sortimentos preenchidos)

cadeia de frio chocolate gourmet sa…

Agora combine suas respostas com uma construção:

| Realidade da pista | Abordagem de embalagem | Seu benefício prático |

|---|---|---|

| ≤24h, clima ameno | Isolamento leve + pacotes de gel refrigerados | Simples, baixo risco |

| 24-48h, clima misto | Melhor isolamento + PCM de média temperatura + saco de barreira | Menos reclamações de saúde |

| 48-72h, clima quente | Alto isolamento + PCM de média temperatura + registrador | Entrega estável com prova |

| Sortimentos preenchidos, qualquer pista | Adicionar bandejas + proteção contra esmagamento + barreira | Melhor apresentação e menos vazamentos |

Dicas práticas que você pode usar hoje

-

Caixas de presente: priorize amortecimento e proteção de apresentação.

cadeia de frio chocolate gourmet sa…

-

Barras: priorize a estabilidade da temperatura e a proteção dos cantos.

cadeia de frio chocolate gourmet sa…

-

Sortimentos: trate-os como frágeis, com bandejas e resistência ao esmagamento.

cadeia de frio chocolate gourmet sa…

Caso do mundo real: Uma equipe de atendimento reduziu os erros de embalagem ao mudar de “qualquer pacote congelado” para um pacote rotulado., kit de refrigeração específico da pista. A segurança do chocolate gourmet da cadeia de frio melhorou porque o processo se tornou consistente.

cadeia de frio chocolate gourmet sa…

Como você valida a segurança do chocolate gourmet da cadeia de frio antes da alta temporada?

A validação torna a segurança do chocolate gourmet da cadeia de frio previsível em vez de esperançosa.

cadeia de frio chocolate gourmet sa…

Você não precisa de um laboratório. Você precisa de um teste repetível que diga se a caixa permanece dentro do alcance.

Use este plano de validação em cinco etapas:

-

Crie um remetente de teste exatamente como a produção.

cadeia de frio chocolate gourmet sa…

-

Coloque um registrador ao lado do produto, não ao lado do refrigerante.

cadeia de frio chocolate gourmet sa…

-

Simule sua pior exposição ao calor para a pista.

cadeia de frio chocolate gourmet sa…

-

Abra e inspecione após um período de descanso.

cadeia de frio chocolate gourmet sa…

-

Repita com uma alteração de cada vez.

cadeia de frio chocolate gourmet sa…

Autoteste interativo: Pontuação de segurança do chocolate gourmet da cadeia fria

Use esta pontuação rápida para decidir quão sério seu redesenho precisa ser.

cadeia de frio chocolate gourmet sa…

1) Pico de temperatura externa na rota

-

Abaixo de 20°C: +1

-

20–28ºC: +3

-

Acima de 28°C: +5

2) Tempo total de trânsito

-

Menos de 24h: +1

-

24-48h: +3

-

48-72h: +5

3) Estratégia de refrigeração

-

Controle de temperatura média perto de 15–18°C: +1

-

Pacotes de gel refrigerados: +3

-

Pacotes congelados / gelo seco: +5

4) Controles de umidade

-

Barreira + nota de desembalagem: +1

-

Apenas barreira: +2

-

Nenhum: +4

5) Monitoramento

-

Registrar em cada teste de pista + verificações pontuais: +1

-

Uso ocasional de registrador: +2

-

Sem monitoramento: +4

Sua pontuação e o que isso significa

-

5–8 (Baixo risco): A segurança do chocolate gourmet da cadeia de frio é provavelmente estável.

-

9–14 (Risco médio): Melhorar o posicionamento do refrigerante, Controle de umidade, ou isolamento.

-

15+ (Alto risco): Redesenhe a embalagem ou a política de faixas antes de dimensionar.

Dicas práticas que você pode usar hoje

-

Teste antes das semanas mais movimentadas. A alta temporada esconde erros até que seja tarde demais.

-

Escreva limites de aprovação/reprovação. Sua equipe precisa de uma definição simples de “sim/não”.

-

Mantenha um registro de falhas. Corrija as duas principais causas primeiro.

Caso do mundo real: Uma marca registrou dez remessas de verão e descobriu que a maioria das falhas aconteceu nas últimas seis horas. Eles melhoraram os buffers de última milha e obtiveram os maiores ganhos.

Entrega de última milha: onde a segurança do chocolate gourmet da cadeia de frio geralmente quebra

A entrega na última milha é o curinga na segurança do chocolate gourmet da cadeia de frio. A caixa pode ficar em um saguão, em uma varanda, ou dentro de um armário de pacotes. Até mesmo o controle perfeito do movimento da linha pode ser perdido na linha de chegada.

Projetar para a realidade, não para um timing perfeito. Seu tempo de reserva faz parte da segurança do chocolate gourmet da cadeia de frio.

O manual da última milha (simples, repetível)

-

Enviar no início do dia. O parto matinal reduz a exposição ao calor.

-

Evite esperas no fim de semana. Envie no início da semana para reduzir o tempo de “travamento”.

-

Use embalagens externas “à prova de sol”. Uma capa reflexiva ganha tempo.

-

Adicione um buffer de porta. Crie um tempo de espera de 1 a 2 horas ao ar livre.

| Cenário da última milha | Risco | Consertar | Seu benefício |

|---|---|---|---|

| Varanda ao sol | Pico de calor | Exterior reflexivo + melhor isolamento | Melhor aparência |

| Atrasos na retirada do lobby | Imersão quente | Design de maior tempo de espera | Menos peças macias |

| Armários de encomendas | Efeito de caixa quente | Evite armários nas pistas de verão | Menos reembolsos |

| Atrasos na van de entrega | Ciclismo | Controle de temperatura média + saco de barreira | Menos flor |

Um script de unboxing amigável ao cliente (reduz o suor)

Use um cartão simples dentro da caixa:

-

““Mantenha a caixa lacrada por 20 a 30 minutos após o parto.”

cadeia de frio chocolate gourmet sa…

-

“Então abra a embalagem interna e divirta-se.”

-

“Se a caixa estiver quente, refrigerar depois desembrulhando e selando novamente.”

Isto apoia a segurança do chocolate gourmet da cadeia de frio sem confundir os clientes.

Caso do mundo real: Uma marca DTC mudou o envio para evitar os picos da tarde e adicionou um rótulo “não deixe ao sol”. Reclamações de verão caíram sem alteração de receitas ou transportadoras.

Controles de saneamento e alérgenos na segurança do chocolate gourmet da cadeia de frio

A segurança do chocolate gourmet da cadeia de frio não é apenas a temperatura. Também inclui saneamento para alimentos com baixo teor de umidade e gerenciamento de alérgenos. Em janeiro 2025, os EUA. A FDA emitiu um projeto de orientação sobre programas de saneamento para alimentos prontos para consumo com baixo teor de umidade, e chocolate está listado como uma categoria de exemplo.

cadeia de frio chocolate gourmet sa…

A baixa umidade retarda o crescimento bacteriano, mas não elimina o risco. Pesquisa mostra que Salmonella pode persistir no chocolate por longos períodos, então a prevenção é importante.

cadeia de frio chocolate gourmet sa…

A segurança do chocolate gourmet da cadeia de frio deve, portanto, incluir um zoneamento limpo, controle de embalagem, e ações corretivas claras.

Controle de alérgenos que você não pode ignorar no chocolate gourmet

O chocolate costuma compartilhar linhas com leite e nozes, e inclusões adicionam complexidade. FDA lista os principais alérgenos alimentares como leite, ovos, peixe, Marisco crustáceo, nozes, amendoim, trigo, soja, e gergelim.

cadeia de frio chocolate gourmet sa…

Um envoltório interno errado pode transformar um problema de qualidade em um incidente de alto impacto.

Etapas práticas de alérgenos e higienização para seu SOP

-

Separação física: armazenar inclusões de alérgenos separadamente, rotular claramente.

cadeia de frio chocolate gourmet sa…

-

Agendamento de linha: execute primeiro o antialérgico, alérgeno mais tarde, ou use linhas dedicadas.

cadeia de frio chocolate gourmet sa…

-

Validação de limpeza: verifique com cotonetes onde for importante, não “em todos os lugares”.

cadeia de frio chocolate gourmet sa…

-

Verificação de etiqueta: use uma verificação de duas pessoas em cada mudança de SKU.

cadeia de frio chocolate gourmet sa…

-

Proteja o rótulo: um produto “seguro” com um rótulo de alérgeno danificado ainda é um risco comercial.

cadeia de frio chocolate gourmet sa…

Essas verificações pertencem ao seu POP de segurança de chocolate gourmet da cadeia de frio, mesmo para pistas curtas.

Caso do mundo real: Uma barra escura “sem laticínios” gerou reclamações porque o rótulo externo estava correto, mas o invólucro interno foi trocado. Os controles de alérgenos incluem o controle de embalagens – não apenas receitas.

cadeia de frio chocolate gourmet sa…

2025 últimas tendências em segurança de chocolate gourmet na cadeia de frio

Em 2025, A segurança do chocolate gourmet na cadeia de frio está passando de soluções reativas para controle previsível. Os clientes compartilham fotos rapidamente, então pequenos defeitos viajam mais longe do que nunca. As marcas estão melhorando os sistemas de qualidade, não apenas embalagem.

Últimos desenvolvimentos que você deve assistir

-

O controle de temperatura média torna-se o padrão. 15O controle de –18°C reduz a floração e o suor.

cadeia de frio chocolate gourmet sa…

-

Monitoramento mais barato torna normal o teste de pista. Os registradores agora fazem parte do controle de qualidade padrão.

-

A pressão da sustentabilidade remodela as embalagens. Isolamento mais leve e transportadores reutilizáveis estão crescendo.

-

Processo supera o heroísmo. POPs claros reduzem os erros de embalagem em “dias agitados”.

Informações de mercado nas quais você pode agir

Compradores de chocolate premium esperam perfeição em nível de loja em casa. A segurança do chocolate gourmet da cadeia de frio torna-se uma vantagem competitiva quando você consegue oferecer consistência. As marcas que vencem não são as que enviam mais frio. Eles são os que enviam com mais firmeza.

Sugestões de links internos

Use texto âncora descritivo e mantenha links em seu próprio site:

-

Modelo SOP de pacote de segurança para chocolate gourmet de cadeia fria

-

Faixa de temperatura para envio de chocolate gourmet (15–18ºC)

-

Como prevenir o florescimento do chocolate durante o transporte

-

Lista de verificação de testes de pista: Colocação do registrador de temperatura

-

Controle de temperatura de última milha para alimentos premium

Perguntas frequentes

Q1: Qual a melhor faixa de temperatura para entrega de chocolate gourmet?

Para a segurança do chocolate gourmet na cadeia de frio, comece com 15–18ºC e evite oscilações.

cadeia de frio chocolate gourmet sa…

A estabilidade é mais importante do que “frio extra”.

Q2: Como evitar o florescimento do chocolate durante o transporte no verão?

Use isolamento, controle de temperatura média, e uma barreira de umidade. Evite docas quentes e reduza o tempo de exposição da última milha.

cadeia de frio chocolate gourmet sa…

Q3: Preciso de gelo seco para remessas de chocolate gourmet?

Geralmente não. O gelo seco é extremamente frio e pode aumentar o risco de condensação posteriormente.

cadeia de frio chocolate gourmet sa…

PCM de temperatura média é uma combinação melhor para a maioria das pistas.

Q4: Por que o chocolate chega com uma névoa branca se não derreteu?

Essa neblina geralmente surge devido ao ciclo de temperatura ou à condensação. A segurança do chocolate gourmet da cadeia de frio evita oscilações, não só derretendo.

Q5: Devo usar um registrador de temperatura para remessas de chocolate??

Sim para testes de pista e verificações pontuais. Um registrador ao lado do produto mostra o que o chocolate experimentou.

cadeia de frio chocolate gourmet sa…

Q6: Qual é o maior risco de última milha para caixas de chocolate premium?

Exposição ao calor na porta. Projete um buffer, adicione embalagem à prova de sol, e inclua uma breve nota de descanso de desembalagem.

Resumo e recomendações

A segurança do chocolate gourmet da cadeia de frio é um sistema repetível, não é um resultado de sorte. Mantenha o chocolate firme por perto 15–18ºC, controlar a umidade, e evite um aquecimento rápido.

cadeia de frio chocolate gourmet sa…

Combine a embalagem com a sua pista, em seguida, valide com um teste simples de logger. Quando você reduz os picos, ciclismo, e condensação, você protege o brilho, foto, e confiança na marca.

O que você deve fazer a seguir (plano simples)

-

Defina sua faixa-alvo para a segurança do chocolate gourmet da cadeia de frio.

-

Escolha isolamento específico da pista e controle de temperatura média.

-

Adicione um saco de barreira e uma nota de descanso para desembalagem de 20 a 30 minutos.

cadeia de frio chocolate gourmet sa…

-

Correr 10 testes de pista com um registrador ao lado do produto.

-

Padronize a embalagem para que cada caixa corresponda à sua melhor construção.

Sobre Tempk

Tempk (Xangai Huizhou Industrial Co., Ltda.) é uma empresa de embalagens para cadeia de frio estabelecida em 2011. Nós nos concentramos em R&D, produção, e serviços para produtos da cadeia de frio. Nossas ofertas incluem materiais de armazenamento refrigerado com mudança de fase, soluções de embalagem de cadeia fria, e serviços de verificação de controle de temperatura, além de produtos como bolsas de gelo em gel, Pacotes de gelo seco, sacos isolados, e caixas isoladas EPP/VIP.

cadeia de frio chocolate gourmet sa…

Aplicamos princípios de segurança do chocolate gourmet da cadeia de frio no design e verificação de embalagens.

Próximo passo: Compartilhe sua pista (origem → destino, tempo de trânsito, temperaturas máximas de verão, e tipo de produto). Podemos ajudá-lo a transformar a segurança do chocolate gourmet da cadeia de frio em uma especificação de embalagem de uma página e um plano de teste de aprovação/reprovação adaptado à sua rota.