Elementos interativos: Forneça um Ferramenta de seleção de embalagens que pergunta aos usuários sobre o tipo de produto, faixa de temperatura desejada, duração do trânsito e metas de sustentabilidade para recomendar embalagens apropriadas (por exemplo, reutilizável vs descartável, PCM vs gelo seco). Inclua um Questionário de autoavaliação sobre a preparação de embalagens sustentáveis e uma clara Chamada para ação (CTA) solicitando aos usuários que solicitem uma consulta gratuita de embalagem.

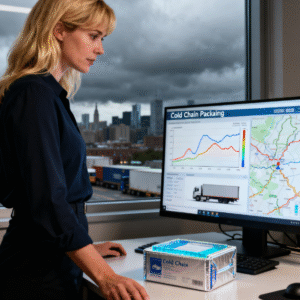

Soluções de embalagem para cadeia fria são recipientes e materiais especializados que protegem produtos sensíveis à temperatura – desde vacinas até frutos do mar – durante o transporte e armazenamento. AS 2024 o mercado global foi avaliado em aproximadamente USD 34.28 bilhão e está projetado para crescer até USD 89.84 bilhão por 2034, ilustrando a crescente demanda por embalagens robustas. Você precisa de embalagens que não apenas mantenham temperaturas adequadas, mas também estejam alinhadas com as metas de sustentabilidade e regulamentações emergentes. Este guia explica os drivers de mercado, explora materiais como poliestireno expandido (EPS), painéis isolados a vácuo (VIPs) e materiais de mudança de fase (PCMs), e mostra como a inovação e as expectativas dos consumidores estão remodelando a maneira como você envia produtos perecíveis.

O que é embalagem para cadeia de frio e por que você precisa dela? Entenda o básico, incluindo faixas de temperatura e materiais.

Qual é o tamanho do mercado e onde ele cresce mais rapidamente? Obtenha números atualizados, insights regionais e segmentos principais.

Quais materiais e tecnologias você deve considerar? Explorar EPS, Pur, VIPs, PCMs, pacotes de gel e rótulos inteligentes.

Como as embalagens sustentáveis podem beneficiar o seu negócio? Aprenda sobre as preferências do consumidor, regulamentos e soluções reutilizáveis.

Quais inovações estão moldando as embalagens em 2025 e além? Descubra a IA, Sensores de IoT, blockchain, e isolamento avançado.

O que é embalagem para cadeia de frio e por que você precisa dela?

Uma definição clara

Embalagem da cadeia de frio refere-se a recipientes e materiais isolados especializados projetados para manter temperaturas seguras para produtos perecíveis durante o transporte e armazenamento. Inclui caixas isoladas, transportadores de paletes, pacotes de gel, tijolos de espuma e materiais de mudança de fase. Essas embalagens protegem itens como alimentos, vacinas, produtos farmacêuticos e biológicos contra calor ou congelamento, garantindo qualidade e segurança. Uma solução de embalagem adequada é essencial porque mesmo uma ligeira variação de temperatura pode comprometer a integridade do produto.

Por que isso importa para você

Sem embalagem adequada, seus frutos do mar congelados podem descongelar ou suas vacinas perderem potência. As embalagens da cadeia de frio mantêm intervalos específicos – congelados (–20 °C a –80 °C), refrigerado (2 °C a 8 °C) ou temperatura ambiente controlada (15 °C a 25 °C). Materiais como espuma de poliestireno, espuma de poliuretano, painéis isolados a vácuo e bioplásticos à base de algas marinhas minimizam a transferência de calor. Pacotes de gel ou PCMs absorvem e liberam calor para estabilizar a temperatura. Escolhendo a solução certa, você protege a qualidade do produto, cumprir os regulamentos e reduzir o desperdício.

Tipos de embalagem e zonas de temperatura

| Tipo de embalagem | Faixa de temperatura típica | Melhores casos de uso | O que isso significa para você |

| Recipientes de espuma EPS ou PUR | 2 °C–8 °C | Produção fresca, laticínio, vacinas | Leve, baixo custo e amplamente disponível; bom para remessas curtas. |

| Painéis isolados a vácuo (VIPs) | –20 °C a –80 °C | Carne congelada, Biologics | Fornece isolamento superior com paredes finas; ideal para viagens longas, mas mais caro. |

| Pacotes de gel e tijolos de espuma | Mantenha as condições ambientais ou refrigeradas | Kits de refeições, produtos farmacêuticos | Fornece resfriamento flexível; pode ser reutilizável e combinado com isolamento. |

| Material de mudança de fase (PCM) pacotes | 2 °C–8 °C ou –20 °C a –25 °C | Vacinas, Biologics, reagentes | Pacotes reutilizáveis que absorvem e liberam calor em pontos específicos; não perigoso. |

| Embalagem de gelo seco | Abaixo de –70 °C | Produtos biológicos ultracongelados, células congeladas | Embalagem descartável que fornece temperaturas ultrabaixas, mas sujeita a regulamentações de materiais perigosos. |

Dicas e conselhos práticos

Combine a faixa de temperatura do seu produto com a embalagem certa: Use embalagens de PCM para produtos biológicos que requerem 2–8 °C ou –20 °C, e gelo seco para remessas ultrafrias, como materiais CRISPR.

Considere a duração da remessa: Pacotes de gel e PCM funcionam bem para remessas sob 72 horas. Para viagens além 96 horas em congelamento profundo, gelo seco ou sistemas híbridos podem ser necessários.

Planeje a reutilização: Escolha embalagens PCM duráveis ou recipientes isolados para reduzir o desperdício e cortar custos a longo prazo.

Exemplo de caso: Uma empresa de biotecnologia que envia vacinas para clínicas rurais adotou embalagens de PCM dentro de contêineres VIP. A solução manteve 2–8 °C durante 72 horas sem refrigeração ativa, redução do uso de gelo seco e manuseio perigoso. Como resultado, as perdas de produtos caíram 20%, e os custos de envio caíram devido às embalagens reutilizáveis.

Qual é o tamanho do mercado de embalagens da cadeia fria e onde ele está crescendo?

Tamanho e crescimento do mercado

O mercado de embalagens da cadeia de frio está em expansão. Towardspackaging relata que a indústria estava avaliado em USD 34.28 bilhão em 2024 e espera-se que alcançar USD 89.84 bilhão por 2034, crescendo em um CAGR de 11.3 %. O relatório indica que a América do Norte dominou o mercado em 2024, enquanto a Ásia-Pacífico está preparada para um crescimento significativo. Poliestireno expandido (EPS) liderou o segmento de materiais, contêineres isolados liderados por tipo de produto, e peixe, carne e frutos do mar dominaram o segmento de uso final.

Nos Estados Unidos, o tamanho do mercado era USD 7.97 bilhão em 2024, e prevê-se que cresça a um ritmo 15.6 % CAGR de 2025 para 2030. Recipientes e caixas isolados mantidos 55.2 % da participação nas receitas em 2024 devido à crescente demanda por produtos sensíveis à temperatura. Materiais isolantes representados 58.1 % de participação na receita. Espera-se que as bolsas frias cresçam em 17.6 % Cagr impulsionado pela entrega de kits de refeição e compras on-line.

Drivers e dinâmicas regionais

A expansão do mercado é alimentada pelo aumento da demanda por alimentos congelados, produtos farmacêuticos, e entregas de mantimentos de comércio eletrônico. O domínio da América do Norte decorre de fortes remessas farmacêuticas e de redes de distribuição avançadas, Considerando que o crescimento da Ásia-Pacífico é impulsionado pelo aumento dos rendimentos e das exportações biofarmacêuticas. A Europa está a investir em embalagens neutras em carbono para cumprir os objetivos de sustentabilidade da UE. Enquanto isso, América Latina e Oriente Médio & África está a reforçar a logística da cadeia de frio para apoiar as exportações de alimentos e produtos farmacêuticos de alto valor. Em muitas economias emergentes, lacunas de infraestrutura, os elevados custos de energia e a conformidade regulamentar continuam a ser desafios.

Tendências por segmento

Os EUA. mercado revela tendências interessantes de subsegmentos:

Tipos de produtos: Recipientes e caixas isolados detêm a maior participação (55.2 %). Bolsas frias e blocos de gel estão ganhando popularidade devido às entregas de kits de refeição e remessas de alimentos para casa.

Tipos de materiais: Materiais isolantes como espuma de poliuretano e captura de VIPs 58.1 % de receita graças ao alto desempenho térmico. Refrigerantes reutilizáveis, como PCMs e embalagens de gel, estão surgindo como alternativas sustentáveis.

Indústrias de uso final: Peixe, carne & os frutos do mar dominam devido aos rigorosos requisitos de controle de temperatura. Os produtos farmacêuticos e biológicos representam uma grande parcela na Europa e na América do Norte.

O que isso significa para você

Os números mostram que a embalagem não é mais uma reflexão tardia; é um investimento estratégico. Com a expansão do comércio global de produtos alimentares e farmacêuticos, as empresas precisam de embalagens que possam ser dimensionadas entre regiões e que cumpram as regulamentações locais. Compreender quais segmentos estão crescendo mais rapidamente ajuda você a alocar recursos de maneira eficaz. Por exemplo, se você atende o mercado de kits de refeição, invista em compressas frias leves; se você enviar produtos biológicos, considere VIPs e PCMs.

Quais materiais e tecnologias impulsionam as soluções de embalagem para cadeia fria?

Materiais tradicionais: EPS, PUR e VIPs

Poliestireno expandido (EPS) e espuma rígida de poliuretano (Pur) são os burros de carga das embalagens da cadeia de frio. Eles fornecem peso leve, isolamento econômico e dominou a participação do material em 2024. O EPS é frequentemente utilizado em remessas de peixes e frutos do mar devido ao seu baixo custo e isolamento eficaz. A espuma PUR oferece benefícios semelhantes, mas pode ser mais durável. Painéis isolados a vácuo (VIPs) fornecer isolamento superior com paredes finas, tornando-os ideais para produtos farmacêuticos e biológicos de alto valor. No entanto, VIPs são mais caros e exigem manuseio cuidadoso.

Materiais de mudança de fase (PCMs) versus gelo seco

PCMs absorvem e liberam calor em temperaturas específicas, mantendo faixas estáveis (como 2–8 °C ou –20 °C). Eles são reutilizáveis, não perigoso e simplificar a conformidade. Gelo seco, dióxido de carbono sólido, sublima a –78,5 °C para fornecer condições ultrafrias para produtos biológicos ultracongelados. O gelo seco é barato por remessa, mas deve ser reabastecido e manuseado de acordo com os regulamentos de materiais perigosos. Os sistemas PCM exigem maior investimento inicial, mas oferecem vários ciclos de reutilização, reduzindo o desperdício e os custos a longo prazo.

Embalagem inteligente e integração IoT

Tecnologias como indicadores de temperatura de tempo, Etiquetas RFID e sensores IoT estão cada vez mais incorporados nas embalagens para monitorar as condições em tempo real. A embalagem inteligente permite que você e seus clientes verifiquem o histórico de temperatura por meio de códigos QR, garante a conformidade com as diretrizes da FDA e da OMS, e aciona alertas se um pacote se desviar de sua faixa-alvo. Análise preditiva pode prever falhas de equipamentos e sugerir rotas alternativas. Visão computacional alimentada por IA inspeciona a embalagem em busca de vazamentos ou danos, e drones avaliam as condições do armazém. A embalagem inteligente não só melhora a segurança, mas também reduz as verificações manuais e acelera a tomada de decisões.

Materiais emergentes e opções sustentáveis

A sustentabilidade está a provocar uma mudança dos plásticos derivados de combustíveis fósseis para alternativas biodegradáveis e recicláveis. Materiais como bioplásticos à base de algas marinhas, espuma de amido de milho e fibra de madeira fornecem isolamento enquanto reduzem o impacto ambiental. As embalagens derivadas de algas marinhas estão ganhando força porque formam filmes comestíveis ou solúveis em água, não deixando microplásticos. Papelão e papel reciclado são usados para embalagens externas e fornecem suporte estrutural. Algumas empresas estão experimentando soluções híbridas combinando PET reciclado com VIPs para melhorar o desempenho térmico e a reciclabilidade. Drenar géis refrigerantes seguros, evitar produtos químicos nocivos e podem ser descartados com segurança.

Escolhendo a solução certa

| Material ou Tecnologia | Características principais | Casos de uso adequados | Vantagens |

| EPS/PUR | Painéis de espuma rígida; baixo custo; isolamento moderado | Remessas de alimentos de curta distância, kits de refeições | Acessível, amplamente disponível, fácil de reciclar (com infraestrutura). |

| VIPs | Painéis de vácuo com isolamento fino | Produtos farmacêuticos, Biologics, bens de alto valor | Excelente desempenho térmico, reduz tamanho e peso. |

| Pacotes PCM | Pacotes reutilizáveis que derretem/solidificam em temperaturas definidas | Vacinas, kits de ensaios clínicos | Mantenha intervalos específicos; não perigoso; vários ciclos de reutilização. |

| Gelo seco | CO₂ sólido; sublima a –78,5 °C | Terapias genéticas, células congeladas | Fornece ambiente ultra frio; amplamente disponível. |

| Espuma à base de algas marinhas | Biodegradável, compostável | Kits de refeição ecológicos, frutos do mar | Reduz o uso de plástico; dissolve em água; apelo amigável ao consumidor. |

| Sensores inteligentes & rótulos | RFID, indicadores de temperatura de tempo, Códigos QR | Todas as remessas de alto valor | Monitoramento em tempo real, integração blockchain, análise preditiva. |

Melhores práticas e recomendações

Equilibre desempenho e custo: Use espuma ou papelão ondulado para remessas de baixo risco; invista em VIPs e PCMs para produtos farmacêuticos de alto valor e tempos de trânsito estendidos.

Integrar monitoramento: Adicione sensores ou etiquetas inteligentes a qualquer embalagem de cadeia de frio. Dados em tempo real garantem detecção precoce de variações de temperatura e conformidade regulatória.

Adote embalagens reutilizáveis: Recipientes duráveis e embalagens PCM reduzem custos a longo prazo e ajudam a cumprir metas de sustentabilidade.

Avalie a infraestrutura local de reciclagem: Selecione materiais que possam realmente ser reciclados na região do destinatário; considerar programas de retomada se faltar infraestrutura.

Exemplo de caso: Uma empresa de kits de refeição trocou EPS por papel reciclável e embalagens de espuma à base de amido. A nova solução manteve temperaturas refrigeradas durante 24 horas e reduziu o volume de embalagens em 30 %. A satisfação do cliente melhorou, e a empresa economizou em taxas de descarte de resíduos, alinhando-se com os compromissos de sustentabilidade.

Como as embalagens sustentáveis podem beneficiar o seu negócio?

Preferências do consumidor e pressões regulatórias

Embalagens sustentáveis para a cadeia de frio não são mais algo agradável de se ter – são obrigatórias. De acordo com tecnologias de cadeia fria, 79 % dos consumidores mudam as preferências de compra com base no impacto social ou ambiental; 67 % dizem que serão mais cautelosos em relação à escassez de recursos devido à crise da COVID 19. Os governos também estão elevando a fasquia: Os estados membros da UE devem pagar 0,80€ por quilograma de embalagem de plástico não reciclado, e o Reino Unido impõe um imposto sobre embalagens com menos de 30 % conteúdo reciclado. A Diretiva Europeia de Embalagens e Resíduos de Embalagens determina que 65 % de todos os resíduos de embalagens sejam reciclados 2025, com metas mais altas 2030. Nos EUA, responsabilidade estendida do produtor (Epr) leis em estados como Califórnia e Maine exigem que as empresas financiem programas de reciclagem, impulsionando a adoção de soluções recicláveis e reutilizáveis.

Tipos de embalagens sustentáveis e seus benefícios

As soluções sustentáveis da cadeia de frio enquadram-se em diversas categorias:

Materiais recicláveis: Cartão, polietileno e papel são cada vez mais usados em revestimentos isolados e caixas externas. Esses materiais podem ser processados e reutilizados, reduzindo resíduos em aterros.

Embalagem reutilizável: Pacotes de gel duráveis, contêineres isolados e transportadores de paletes podem ser reutilizados diversas vezes, reduzindo o custo por remessa e o desperdício. Prevê-se que o mercado de embalagens reutilizáveis da cadeia de frio cresça de USD 4.97 bilhão em 2025 para USD 9.13 bilhão por 2034.

Materiais biodegradáveis: Espuma de amido de milho, fibra de madeira, bioplásticos de algas marinhas e isolamento de algodão se decompõem naturalmente e reduzem o impacto ambiental.

Refrigerantes ecológicos: Pacotes de gel seguros para drenagem e géis biodegradáveis substituem refrigerantes nocivos e podem ser descartados com segurança.

Materiais de isolamento inovadores: A reciclagem de fibras de papelão pós-industriais em isolamento de alto desempenho reduz o desperdício e oferece excelente desempenho térmico.

Dados que apoiam a sustentabilidade

O blog de Taylor relata que 43 % dos consumidores consideram o impacto ambiental das embalagens ao tomar decisões de compra. O mercado de embalagens reutilizáveis para produtos de beleza e cuidados pessoais cresceu 65 % de 2020 para 2021. 74 % dos americanos têm interesse em comprar produtos em embalagens recarregáveis, mostrando a aceitação geral de modelos de reutilização. Oferta de PET reciclado cresceu sobre 4 % anualmente na última década, refletindo o aumento da demanda por materiais reciclados.

Desafios e como superá-los

Apesar desses benefícios, adoção de embalagens sustentáveis enfrenta obstáculos:

Custo: Projetando, adquirir e produzir embalagens sustentáveis pode ser mais caro do que o EPS convencional. No entanto, compra em massa, parcerias com fornecedores e análises de custos do ciclo de vida muitas vezes revelam economias a longo prazo.

Gestão de mudanças: A troca de materiais exige comprometimento de toda a organização e ajustes de processos. Projetos piloto e treinamento de funcionários podem facilitar a transição.

Confiar: As partes interessadas podem duvidar que os novos materiais ofereçam proteção adequada. Valide soluções por meio de testes térmicos, certificações e estudos de caso.

Infraestrutura: Pode faltar infraestrutura de reciclagem ou compostagem. Considere esquemas de devolução, programas de embalagens reutilizáveis ou parcerias locais para garantir a recuperação no final da vida útil.

Disponibilidade: Materiais sustentáveis podem ser escassos, causando problemas na cadeia de suprimentos. Diversificar fornecedores e manter estoque regulador para reduzir riscos.

Exemplo de caso: Um distribuidor farmacêutico substituiu caixas EPS descartáveis por um conjunto de expedidores VIP reutilizáveis e embalagens PCM. Embora os custos iniciais tenham sido mais elevados, a empresa reduziu o desperdício de embalagens em 70 %, economizou dinheiro ao longo de três anos e atendeu aos novos requisitos de EPR. Os clientes apreciaram o esforço de sustentabilidade, aumentando a reputação da marca.

Quais inovações estão moldando as embalagens da cadeia de frio 2025 e além?

IA, IoT e análise de dados

A inteligência artificial e os sensores IoT estão transformando as embalagens. Etiquetas inteligentes registram o histórico de temperatura e fazem a varredura por meio de aplicativos de smartphone. Plataformas alimentadas por IA detectam padrões em dados de sensores e prevêem quando uma unidade de armazenamento pode falhar. A integração com blockchain fornece registros de temperatura imutáveis e automatiza o pagamento quando as remessas atendem às condições especificadas. Empresas como Flexport e Shipwell usam IA para analisar o clima, disponibilidade de tráfego e instalações para otimizar rotas e reduzir o consumo de combustível.

Sistemas reutilizáveis e modulares

Embalagens reutilizáveis estão ganhando força. Towards Packaging prevê que o mercado de embalagens reutilizáveis da cadeia de frio crescerá para USD 9.13 bilhão por 2034. Sistemas modulares com componentes empilháveis permitem que as transportadoras ajustem a capacidade e reduzam o espaço vazio. Os programas de reutilização geralmente incluem rastreamento digital para garantir retornos e saneamento. As empresas estão explorando programas de depósito onde os clientes pagam uma taxa reembolsada na devolução da embalagem.

Isolamento avançado e materiais sustentáveis

Novos materiais de isolamento incluem bioplásticos à base de algas marinhas e espuma reciclada que proporcionam desempenho térmico comparável ao EPS, reduzindo ao mesmo tempo o impacto ambiental. Painéis isolados a vácuo estão se tornando mais finos e acessíveis, tornando-os acessíveis a expedidores mais pequenos. Materiais de mudança de fase estão sendo projetados com pontos de fusão precisos e maior capacidade de calor latente para ampliar o controle de temperatura sem aumentar o peso. Embalagem híbrida que combina gelo seco e PCMs oferece compartimentos multitemperatura para remessas mistas.

Refrigerantes sustentáveis e géis ecológicos

Géis seguros para drenagem e refrigerantes biodegradáveis estão substituindo os pacotes de gel convencionais, reduzindo o impacto ambiental. Algumas empresas estão usando refrigerantes à base de PCM derivados de óleos vegetais ou extratos vegetais. Estão em andamento pesquisas sobre solventes eutéticos naturais que podem ser ajustados a temperaturas específicas e reutilizados muitas vezes.

Blockchain e contratos inteligentes

A tecnologia Blockchain garante a integridade dos dados e suporta contratos inteligentes para conformidade e pagamentos automatizados. Quando integrado com sensores IoT, blockchain registra todas as leituras de temperatura em um livro-razão à prova de adulteração. Essa transparência gera confiança entre os remetentes, operadoras e reguladores. Os contratos inteligentes liberam pagamentos ou cobertura de seguro somente se a remessa permanecer dentro das faixas de temperatura especificadas, reduzindo disputas e despesas administrativas.

O papel da regulação e da padronização

Governos e grupos industriais estão a desenvolver normas para embalagens reutilizáveis, calibração de sensores e compartilhamento de dados. Por 2025, 74 % espera-se que os dados logísticos sejam padronizados. Essa normalização permitirá a troca contínua de informações entre parceiros e apoiará iniciativas de economia circular. Órgãos reguladores como o FDA, A EMA e a OMS estão a atualizar as diretrizes para o envio de produtos biológicos, exigindo embalagens validadas e monitoramento digital.

Exemplo de caso: Uma startup europeia de biotecnologia adotou bolsas isoladas à base de algas marinhas com etiquetas RFID incorporadas. A embalagem manteve 2–8 °C durante 48 horas e era compostável após o uso. Com integração blockchain, a empresa forneceu aos reguladores registros de temperatura verificáveis, acelerar o desalfandegamento transfronteiriço e reforçar as suas credenciais de sustentabilidade.

Quais são os desafios e as melhores práticas para implementar soluções de embalagens para cadeia fria?

Principais desafios

Pressões de custos: Isolamento avançado e sistemas reutilizáveis têm custos iniciais mais elevados. Determine o custo total de propriedade considerando os ciclos de reutilização, eliminação de resíduos e multas de conformidade.

Complexidade e treinamento: Novos materiais e tecnologias exigem treinamento para embalagem, monitoramento e devolução de contêineres. Sem procedimentos adequados, os funcionários podem fazer uso indevido de componentes ou ignorar alertas.

Conformidade regulatória: Os padrões variam de acordo com o país e a categoria do produto. A embalagem deve cumprir regras como FDA 21 Parte cfr 11 para registros eletrônicos, Regulamentos de mercadorias perigosas da IATA para gelo seco e leis locais de reciclagem.

Logística reversa: Gerenciar a devolução e higienização de embalagens reutilizáveis requer infraestrutura e colaboração com transportadoras e clientes. A perda ou roubo de recipientes reutilizáveis pode prejudicar a economia de custos.

Segurança e integração de dados: O compartilhamento de dados de sensores entre parceiros exige sistemas e acordos seguros. Silos de dados podem prejudicar a visibilidade e a resposta.

Melhores práticas

| Desafio | Prática recomendada | Como isso ajuda |

| Custo | Conduza uma análise de custos do ciclo de vida e negocie contratos plurianuais com fornecedores de embalagens | Ajuda a quantificar a economia com a reutilização, redução de resíduos e redução de deterioração. |

| Complexidade | Fornece treinamento prático e manuais digitais; comece com projetos piloto | Aumenta a confiança dos funcionários e identifica problemas antes da implementação completa. |

| Conformidade regulatória | Mantenha-se atualizado sobre as regulamentações globais e locais; faça parceria com fornecedores de embalagens que fornecem sistemas validados | Reduz o risco de multas e perda de produtos; garante que a documentação atenda aos requisitos de auditoria. |

| Logística reversa | Configure pontos de coleta e rastreie contêineres com códigos QR; projetar embalagens fáceis de limpar | Melhora as taxas de retorno e garante o saneamento, preservando a vida útil da embalagem. |

| Segurança de dados | Use transmissão de dados criptografados e blockchain; estabelecer acordos claros de compartilhamento de dados | Protege informações confidenciais e cria confiança entre parceiros. |

Conselhos práticos

Comece pequeno: Experimente uma solução de embalagem sustentável em uma única linha ou rota de produto antes de ampliar. Colete dados sobre o desempenho da temperatura, feedback do cliente e logística de devolução.

Envolva os fornecedores desde o início: Trabalhe com fabricantes de embalagens para personalizar soluções para seus produtos e rede de distribuição. Solicite dados de desempenho térmico e certificações de sustentabilidade.

Monitore e ajuste: Use sensores IoT para coletar dados em tempo real sobre o desempenho das embalagens e ajustar seus protocolos adequadamente. Ao longo do tempo, você pode reduzir materiais tampão e peso.

Exemplo de caso: Uma empresa de comércio eletrônico de frutos do mar testou um programa de caixas isoladas retornáveis. Eles forneceram aos clientes etiquetas de devolução pré-pagas e ofereceram pontos de fidelidade para a devolução de caixas. O piloto alcançou um 60 % taxa de retorno, reduziu o desperdício de embalagens pela metade e melhorou a retenção de clientes.

2025 Últimos desenvolvimentos e tendências em embalagens para cadeia fria

Visão geral da tendência

O cenário global de embalagens da cadeia de frio em 2025 é moldado pela sustentabilidade, tecnologia inteligente e regulamentações em evolução. As empresas devem se adaptar a metas de reciclagem mais rígidas, demanda dos consumidores por opções ecológicas e regras de controle de temperatura mais rigorosas. Ao mesmo tempo, inovações como embalagens habilitadas para IA, refrigerantes híbridos e blockchain estão elevando o nível de confiabilidade e eficiência.

Último progresso em um olhar

Expansão do mercado reutilizável: O mercado de embalagens reutilizáveis da cadeia de frio deverá crescer de USD 4.97 bilhão em 2025 para USD 9.13 bilhão por 2034. Empresas dos setores alimentício e farmacêutico estão investindo em transportadores duráveis e esquemas de depósito.

Monitoramento orientado por IA: Sensores inteligentes e análises preditivas estão se tornando padrão. As soluções de embalagem agora incluem registradores de dados integrados, Etiquetas RFID e códigos QR para fornecer visibilidade em tempo real e apoiar a manutenção preditiva.

Ascensão do isolamento biodegradável: Materiais derivados de algas marinhas, amido de milho e fibras de madeira estão sendo comercializados, oferecendo desempenho térmico comparável e ao mesmo tempo atendendo às expectativas dos consumidores em relação a embalagens sem plástico.

Refrigerantes híbridos: As empresas estão combinando PCMs com gelo seco em embalagens modulares para suportar faixas mistas de temperatura em uma única remessa. Soluções híbridas reduzem remessas perigosas e aumentam a flexibilidade.

Harmonização regulatória: Organizações internacionais como a Associação Internacional de Transporte Aéreo (IATA), Organização Marítima Internacional (OMI) e Organização Mundial da Saúde (QUEM) estão alinhando padrões de controle de temperatura e documentação, simplificando a conformidade transfronteiriça.

Insights de mercado

A consolidação do mercado está aumentando. Grandes players como Cold Chain Technologies, Sonoco Thermosafe e CSafe investem em embalagens inteligentes e materiais sustentáveis. Parcerias entre fornecedores de logística e empresas de embalagens são comuns à medida que as empresas procuram integrar soluções de monitoramento e embalagem. O financiamento de capital de risco está fluindo para startups de embalagens sustentáveis, particularmente aqueles que produzem isolamento biodegradável e rótulos inteligentes.

Perguntas frequentes

O que são materiais de mudança de fase, e como eles diferem dos pacotes de gel ou gelo seco?

Materiais de mudança de fase (PCMs) são compostos que armazenam e liberam calor em temperaturas específicas, manter condições estáveis dentro de um pacote. Ao contrário dos pacotes de gel, que simplesmente retém frio ou calor, PCMs passam por uma transição de fase (sólido para líquido ou vice-versa), absorver ou liberar calor latente para manter a temperatura desejada. O gelo seco proporciona condições ultra frias (< –70 °C) por sublimação, mas é de uso único e regulamentado como material perigoso. PCMs são reutilizáveis e mais fáceis de manusear, tornando-os ideais para vacinas e produtos biológicos que requerem faixas de 2–8 °C ou –20 °C.

Como posso decidir entre embalagens reutilizáveis e descartáveis?

Considere a frequência de envio, distância, valor do produto e metas de sustentabilidade. As embalagens reutilizáveis têm custos iniciais mais elevados, mas proporcionam poupanças a longo prazo através de múltiplos ciclos. É ideal para envios frequentes e logística de devolução estabelecida. As embalagens descartáveis podem ser mais práticas para remessas únicas ou destinos sem infraestrutura de retorno.

Os materiais biodegradáveis são robustos o suficiente para aplicações na cadeia de frio??

Sim, quando projetado corretamente. Espumas biodegradáveis e plásticos à base de algas marinhas são projetados para fornecer isolamento comparável ao EPS, ao mesmo tempo que se decompõem naturalmente após o uso. No entanto, você deve validar seu desempenho com testes térmicos e garantir que eles atendam aos requisitos de peso e tamanho do seu produto.

As etiquetas inteligentes e os sensores IoT aumentam significativamente os custos de embalagem?

Embora as etiquetas inteligentes aumentem os custos, eles reduzem a perda de produtos e problemas de conformidade, fornecendo visibilidade em tempo real. Muitos expedidores descobrem que as poupanças resultantes de evitar desperdícios e atrasos compensam as despesas adicionais. Comece com remessas críticas e aumente gradualmente.

Como os regulamentos diferem para remessas de gelo seco e PCM?

O gelo seco é classificado como material perigoso e deve estar em conformidade com a IATA, Regulamentações do DOT e da ONU. As remessas exigem rotulagem especial, ventilação e treinamento. As remessas de PCM geralmente não são perigosas, mas ainda assim devem atender aos requisitos de registro e validação de temperatura, como FDA 21 Parte cfr 11.

Resumo & Recomendações

O mercado de embalagens de cadeia fria está passando pelo rápido crescimento, projetado para subir de USD 34.28 bilhão em 2024 para USD 89.84 bilhão por 2034. Recipientes isolados, pacotes de gel e materiais avançados como VIPs e PCMs são componentes-chave desta expansão. A dinâmica do mercado varia por região: América do Norte lidera devido à forte demanda farmacêutica, enquanto a Ásia-Pacífico está a recuperar rapidamente. As pressões da sustentabilidade estão remodelando as embalagens, com consumidores e reguladores exigindo recicláveis, soluções reutilizáveis e biodegradáveis. Inovações como monitoramento habilitado por IA, sistemas de embalagens reutilizáveis e refrigerantes híbridos dominarão 2025 e além.

Etapas de ação:

Avalie seus requisitos de produto e rota escolher materiais de embalagem e refrigerantes apropriados. Use ferramentas de decisão para combinar a faixa de temperatura e o tempo de trânsito.

Invista em embalagens inteligentes com sensores e registro de dados para remessas de alto valor para evitar deterioração e comprovar conformidade.

Transição para embalagens sustentáveis integrando soluções recicláveis ou reutilizáveis. Avalie o custo do ciclo de vida e estabeleça parcerias com fornecedores que ofereçam opções ecológicas.

Inovações piloto como pacotes de PCM e espuma biodegradável em pistas selecionadas antes de aumentar a escala; coletar dados sobre desempenho e feedback do cliente.

Mantenha-se informado sobre os regulamentos em relação aos impostos sobre embalagens e metas de reciclagem para evitar penalidades e atender às expectativas dos clientes.

Sobre Tempk

No Tempk, projetamos e fabricamos embalagens inteligentes para cadeia de frio que mantêm seus produtos seguros e suas metas de sustentabilidade no caminho certo. Nosso portfólio inclui contêineres VIP reutilizáveis, Pacotes PCM e caixas isoladas ecológicas feitas de materiais reciclados. Integramos sensores IoT e análises em nuvem para fornecer visibilidade em tempo real e relatórios de conformidade. Com uma rede global de parceiros, entregamos soluções customizadas para alimentos, indústrias farmacêuticas e de biotecnologia. Estamos empenhados em reduzir o desperdício e a pegada de carbono através de um design inovador e práticas de economia circular.

Pronto para transformar sua embalagem? Entre em contato com a Tempk hoje para uma consulta gratuita sobre como adaptar soluções de embalagens de cadeia de frio sustentáveis e confiáveis às suas necessidades. Vamos manter seus produtos seguros, seus clientes felizes e nosso planeta saudável.