O gelo seco cria pressão e estoura pacotes?

Gelo seco, a forma sólida de dióxido de carbono (Co₂), presents unique shipping challenges, especially when packed in sealed containers. Como se sublima, ele se transforma diretamente em gás, and this transition can create high pressure in confined spaces. This pressure buildup can cause containers to burst, potentially damaging contents and violating shipping regulations. Neste artigo, we will dive into why dry ice causes pressure, how to avoid package ruptures, and the best practices for complying with 2025 regulations to ensure safe and efficient shipping.

-

Gelo seco sublima -se em gás, increasing internal pressure in sealed packaging.

-

Embalagem adequada with ventilation prevents pressure buildup and package rupture.

-

2025 regulamentos como IATA PI 954 e 49 CFR demand vented packaging for air and sea transport.

-

Seguir melhores práticas for labeling, materiais de embalagem, and compliance to avoid rejection during transport.

Why Does Dry Ice Create Pressure in Packages?

Resposta Direta: Sim, dry ice can create dangerous pressure in sealed packages. This is because as dry ice sublimates, it turns from solid CO₂ into gas. In an airtight environment, the gas rapidly accumulates, causing pressure to rise quickly. Sem ventilação adequada, this buildup can lead to ruptured packages or even explosions.

How Dry Ice Sublimates and Causes Pressure

Dry ice is unique because it doesn’t melt into a liquid. Em vez de, it sublimates—changing directly from solid CO₂ into gas at a temperature of −78.5°C (−109,3 ° F.). For each kilogram of dry ice, aproximadamente 500-550 liters of CO₂ gas are produced at room temperature. Em um recipiente selado, this large volume of gas has nowhere to escape, resulting in dangerously high internal pressure. This is why IATA, 49 Cfr, and other regulations mandate that packaging must allow gas release to prevent pressure buildup.

Packaging Regulations and Safety Standards

To mitigate the risk of bursting packages, air and sea shipments containing dry ice must follow certain packaging standards. Os principais regulamentos incluem:

-

Aqui está Pi 954: Requires packages to allow CO₂ gas to escape to prevent pressure buildup and rupture. This is checked during the acceptance process.

-

49 CFR §173.217: Mandates that packaging used for dry ice shipments must be designed to permit CO₂ release, and net dry ice mass must be clearly marked.

-

FedEx/UPS: Both major carriers emphasize that dry ice packages must be vented, as they will reject airtight builds during acceptance.

Best Packaging Practices to Prevent Dry Ice Packages from Bursting

To avoid package rupture, consider these best practices for packaging dry ice shipments safely:

1. Use Vented or Loosely Sealed Packaging

-

Embalagem externa: Use corrugated fiberboard or similar materials that are strong and allow for venting.

-

Inner Packaging: Use insulating materials like Styrofoam or other foam-based products that do not form an airtight seal. Ensure the packaging has venting pathways to allow CO₂ gas to escape.

Dica: Avoid using airtight seals like tape or fully closed gaskets. A vented design will allow gas to dissipate, evitando o acúmulo perigoso de pressão.

2. Ensure Proper Labeling and Documentation

All shipments containing dry ice must include clear and accurate labeling. Required labels include:

-

“Gelo Seco” ou “Dióxido de carbono, Sólido”.

-

E 1845 (Para gelo seco).

-

Aula 9 Etiqueta de perigo.

-

Peso líquido de gelo seco em quilogramas.

Dica: Double-check your labeling to avoid non-compliance, which could lead to shipment delays or rejection. Use job aids from FedEx/UPS to ensure accuracy.

3. Ensure Adequate Ventilation During Transport

Even if packaging is correctly designed, ventilation is crucial during transport. Ao lidar com gelo seco, make sure that the transport vehicles and storage areas are well-ventilated. CO₂ can accumulate quickly in confined spaces, creating an asphyxiation risk.

Dica: Never store dry ice shipments in sealed trunks or small, poorly ventilated rooms. Always ensure airflow to safely dissipate the gas.

4. Test Packaging for Performance

To avoid unexpected failures, always test your packaging design under the expected shipping conditions:

-

Pressure Build-Up Simulation: Test a sample package under a dry ice load to measure how it responds to pressure over time.

-

Temperature Cycling: Assess how the package performs under both cold and warmer temperatures during shipping and handling.

-

Seal Integrity: Verify that all seals and closures on your packaging can handle the pressure and allow gas release.

Dica: Conduct these tests with various amounts of dry ice and across different temperature ranges to ensure your packaging can handle real-world conditions.

Chave 2025 Dry Ice Shipping Regulations

To meet the latest standards, adhere to these 2025 rules for dry ice packaging:

1. Vented Packaging is Mandatory

Packaging must be constructed to allow CO₂ gas release. This includes avoiding completely sealed packages and using materials like foam or fiberboard that can safely vent the gas.

2. Maximum Dry Ice Limits

-

Aqui está Pi 954 permite até 200 kg de gelo seco por pacote.

-

Airline-specific limits: Some airlines may set lower limits than IATA PI 954. Always check your carrier’s guidelines before shipping.

Dica: Make sure that net dry ice mass is clearly marked on the package. This is a requirement for air transport and helps prevent fines or delays.

3. Proper Training and Documentation

To comply with safety regulations, personnel must be trained on how to handle, pacote, and ship dry ice safely. Adicionalmente, ensure that all required documentation is provided, incluindo:

-

Shipping manifest or waybill indicating the presence of dry ice.

-

Safety protocols for handling CO₂ exposure.

Dica: Regularly audit your dry ice shipments to ensure compliance with evolving regulations and minimize the risk of accidents.

Real-World Examples of Dry Ice Package Failures

No passado, packages containing dry ice have exploded due to improper sealing. Por exemplo, a shipping container with a tightly sealed screw-cap lid exploded when dry ice gas pressure exceeded the container’s structural integrity. This can happen when packaging materials like plastic or metal containers trap gas with no escape routes.

Exemplo: A healthcare shipper used heat-sealed liner bags in their dry ice shipments. The boxes bulged during sorting, and one split during handling. After switching to a fold-closed liner and adding a vent spacer, they reduced rejections to zero.

Conclusão: How to Avoid Dry Ice Package Rupture

By following best practices for dry ice packaging, you can safely prevent pressure buildup and avoid ruptured packages. Ensure your packaging is vented, your labels are accurate, and your team is trained on the latest regulatory requirements. With the right preparation, you can safely ship temperature-sensitive goods without compromising safety.

Plano de ação:

-

Audit your dry ice shipments for vented packaging.

-

Train your packaging teams on IATA PI 954 e o mais recente 2025 regulamentos.

-

Run real-world packaging tests to ensure safety and compliance.

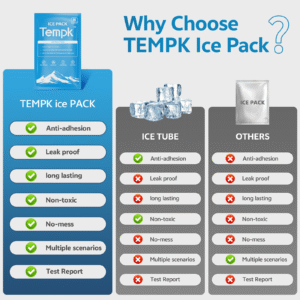

Sobre Tempk

No Tempk, we specialize in cold chain packaging solutions designed for dry ice shipments. Our packaging is engineered for compliance with IATA, UPS, and FedEx standards, ensuring safe and efficient transport of temperature-sensitive goods. Explore our vented dry ice shipping solutions and learn how we can help your team reduce rejections and improve reliability.