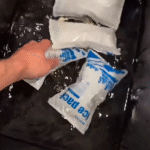

Imagine isso: Uma remessa de vacinas que salvam vidas viajam através de ondas de calor de verão. Viagem de bagas recém -colhidas pelos continentes. Amostras de laboratório críticas de salto entre hubs de trânsito. O que silenciosamente guarda sua integridade? Muitas vezes, it’s an unsung hero – the Saco de gelo seco. Mais do que apenas “pacotes frios,” Esses recipientes especializados aproveitam a extrema sublimação do dióxido de carbono sólido (-78.5° C/-109,3 ° F.) Para se defender contra o abuso de temperatura onde a refrigeração tradicional falha.

Why Dry Ice Bags Are the Cold Chain’s Silent Guardians

In temperature-sensitive logistics, Falha significa bens estragados, receita perdida, e riscos de segurança. Pacotes de gel padrão ou unidades refrigeradas lutam com:

-

Requisitos de temperatura ultra baixa (por exemplo, Vacinas de mRNA a -70 ° C)

-

Long-haul stability excedendo 48 horas

-

Entrega de última milha sem fontes de energia

-

Rapid thermal recovery after door openings

Dry ice bags address these by leveraging CO₂’s phase change energy – absorbing 573 KJ/kg durante a sublimação. Mas pellets de gelo seco cru sublimados muito rápido. Advanced dry ice bags solve this through engineered multi-layer insulation. Studies confirm that strategic placement of folha de alumínio inside packaging boosts thermal retention by 25.39% compared to non-foil designs by reflecting radiant heat2. This transforms dry ice from a short-term coolant into a precision stability tool.

Pacote de gelo seco da Tempk: Where Science Meets Sustainability

Tempk reimagined the dry ice bag not as a commodity, but as a system. Their Dry Ice Packs integrate breakthroughs observed in cold chain research:

-

Smart Layered Architecture: Combinando food-grade inner liners, nano-enhanced insulation cores, e um inner reflective aluminum layer – proven to outperform outer foil positioning by over 21% in thermal retention2. This achieves 72-hour stability in tropical transits.

-

Carbon Footprint Mitigation: Research highlights refrigeration’s massive CO₂ footprint in transport1. Tempk’s packs use co₂ reciclado sourced from industrial byproducts. Their optimized design reduces dry ice consumption by ~30% versus traditional shippers – aligning with low-carbon cold chain models.

-

Phase Change Synergy: Like studies using PCMs (Materiais de mudança de fase) to extend thermal buffers2, Tempk’s optional Painéis híbridos PCM trabalhar com gelo seco, não contra isso. During sublimation plateaus, PCMs absorb excess cold, releasing it when external temps spike – smoothing thermal curves.

Beyond Reliability: The Ripple Effects

Adopting engineered dry ice solutions reshapes logistics economics:

-

Perda reduzida de produto: Maintains product quality by minimizing thermal degradation1

-

Pegada menor: Replaces bulky active refrigeration for air freight

-

Regulatory confidence: Meets IATA, FDA, and EU cold chain protocols

A seafood exporter switching to Tempk’s system reported a 17% drop in rejection rates – proof that thermal stability isn’t theoretical; it’s quantifiable.

The Future Is Adaptive Cold Chains

As predictive logistics AI emerges, dry ice bags won’t stay “dumb.” O roteiro de Tempk inclui Pacotes habilitados para IoT – sensors mapping real-time temperature, taxas de sublimação, e localização. This data stream feeds into platforms that dynamically reroute shipments or trigger replenishment, turning static packaging into responsive nodes.