Como os blocos de gelo seco e as bolsas de gelo seco transformam o transporte da cadeia de frio?

Se você enviar alimentos congelados, vacinas ou amostras de laboratório, você provavelmente já ouviu falar blocos de gelo seco e bolsas de gelo seco. Ambos mantêm as remessas frias, aproveitando o frio extremo do dióxido de carbono sólido, no entanto, eles atendem a necessidades diferentes. Neste guia você aprenderá o que são blocos e embalagens de gelo seco, quando escolher cada, e como 2025 inovações estão remodelando a logística da cadeia de frio. O gelo seco sublima a cerca de -78,5 °C (−109°F), proporcionando condições ultra frias sem deixar resíduos de água, tornando-o indispensável na logística da cadeia de frio. Continue lendo para descobrir como esses heróis da cadeia de frio podem ajudar seu negócios.

O que diferencia os blocos de gelo seco e as bolsas de gelo seco? Saiba mais sobre tamanhos, taxas de sublimação e melhores aplicações.

Quando você deve escolher blocos versus pacotes? Entenda como a temperatura precisa, a duração e a sensibilidade do produto influenciam sua escolha.

Como você pode usar gelo seco com segurança e eficiência? Obtenha dicas práticas sobre embalagem, manuseando e calculando a quantidade certa.

Quais são as últimas tendências para 2025? Descubra bolsas de gelo seco reutilizáveis, sensores inteligentes e sistemas híbridos que combinam gelo seco com materiais de mudança de fase.

O que são blocos de gelo seco e bolsas de gelo seco e como funcionam?

Resposta direta

Blocos de gelo seco e bolsas de gelo seco são formas sólidas de dióxido de carbono (Co₂) projetado para manter os produtos extremamente frios, sublimando diretamente de um sólido para um gás. Os blocos são grandes lajes retangulares que sublimam lentamente e proporcionam resfriamento duradouro, enquanto os pacotes podem ser pellets, fatias ou folhas projetadas para conveniência e resfriamento mais rápido. Sua extrema frieza (em torno de -78,5 °C) e a propriedade de sublimação os tornam ideais para o envio de produtos congelados sem deixar sujeira molhada.

Como o gelo seco é feito e por que é especial

O gelo seco é produzido pela compressão e resfriamento do CO₂ gasoso até que ele se liquefaça, então permitindo que ele se expanda rapidamente, formando um sólido semelhante a neve que pode ser prensado em blocos ou extrudado em pellets. Porque o gelo seco sublima em vez de derreter, absorve o calor do ambiente sem criar água, que evita caixas encharcadas e protege produtos sensíveis à umidade. Esta propriedade também significa que você precisa de menos peso para obter o mesmo efeito de resfriamento: o gelo seco tem cerca de três vezes a eficiência de resfriamento do gelo de água.

Formulários, tamanhos e mecanismos de resfriamento

O gelo seco vem em vários formatos para atender às diferentes necessidades logísticas:

Blocos: Grande, lajes densas que duram dias. Os blocos sublimam mais lentamente que os pellets devido à menor área de superfície, tornando-os adequados para remessas de longa duração.

Pellets ou arroz: Pequenas peças cilíndricas (1⁄8–3⁄8 pol.) que proporcionam resfriamento preciso e são fáceis de embalar em torno dos produtos; frequentemente usado em jateamento com gelo seco, processamento de alimentos e remessas médicas.

Fatias e pepitas: Peças de tamanho médio utilizadas em laboratórios ou embalagens pequenas onde o espaço é apertado.

As bolsas de gelo seco industriais normalmente consistem em pellets ou fatias de gelo seco encerradas em recipientes ventilados., embalagem isolada. Essas embalagens liberam gás CO₂ à medida que aquecem e são colocadas em cima ou ao redor da remessa para que o ar frio penetre nos produtos. Blocos maiores esfriam por mais tempo, mas mais lentamente, enquanto pellets menores esfriam rapidamente, mas precisam ser reabastecidos mais cedo.

Comparação das principais propriedades

| Propriedade | Blocos de gelo seco | Pacotes de gelo seco (pellets/fatias) | Significado prático |

| Temperatura típica | ≈ –78,5 °C (–109 ° F.) | ≈ –78,5 °C (–109 ° F.) | Ambos mantêm condições ultra frias para produtos congelados. |

| Taxa de sublimação | Lento (dura 48–72 horas em armazenamento isolado) | Mais rápido (12–24 horas por pacote) | Os blocos são ideais para viagens longas; pacotes de terno mais curtos, remessas de alta rotatividade. |

| Eficiência de resfriamento | Alto; grande massa absorve mais calor | Alto, mas requer substituição mais frequente | O gelo seco é cerca de três vezes mais eficiente que o gelo de água, reduzindo peso e custo de envio. |

| Lidando com dificuldade | Mais pesado e difícil de levantar | Mais fácil de manusear e organizar os produtos | Os blocos precisam de um manuseio mais cuidadoso; pellets ou fatias são flexíveis e podem preencher lacunas. |

| Melhores usos | Envios de longa distância, refrigeração a granel, eventos criando efeitos de neblina | Pequenas remessas, resfriamento preciso, laboratórios médicos, explodindo | Combine o formulário com a duração do envio e restrições de espaço. |

Dicas e conselhos práticos para o usuário

Para viagens longas e cargas pesadas: Use blocos de gelo seco ou grandes embalagens industriais. Sua sublimação lenta pode manter a carga congelada por dias, reduzindo o número de substituições.

Para embalagens de precisão ou pequenas: Use pellets ou fatias para preencher espaços e garantir um resfriamento uniforme. Os pellets são ideais para amostras de laboratório ou pacotes que exigem temperatura uniforme.

Combine formulários quando necessário: Para remessas mistas (por exemplo, carne congelada mais vegetais resfriados), combine blocos de gelo seco em um compartimento e pacotes de gel ou PCM em outro para manter diferentes temperaturas.

Caso do mundo real: Um exportador de frutos do mar substituiu o gelo de água por pequenas fatias de gelo seco em caixas isoladas. Ventilando as caixas e usando o posicionamento adequado, a empresa reduziu o peso da remessa em 30% e manteve os filés de peixe congelados por 48 horas sem vazamento.

Quando você deve usar blocos de gelo seco versus bolsas de gelo seco na logística da cadeia de frio?

O agente refrigerante certo para sua remessa

Escolha blocos de gelo seco ou embalagens grandes quando precisar manter produtos completamente congelados em longas distâncias ou em climas quentes. O gelo seco é excelente para manter temperaturas abaixo de –70 °C e, portanto, é ideal para o transporte de sorvetes, carnes congeladas e amostras biológicas que não toleram qualquer descongelamento. Pacotes de gel ou materiais de mudança de fase são melhores para produtos que devem permanecer resfriados, mas não congelados (2–8 ° C.), como produtos frescos ou certos produtos farmacêuticos.

Em termos práticos, os blocos mantêm a temperatura por mais tempo devido à sua massa e menor área de superfície, enquanto pellets ou embalagens são adequados para viagens mais curtas ou remessas que precisam de rápida redução de temperatura. Por exemplo, peso igual de gelo seco e carga útil pode manter os itens congelados por até 48 horas, e 1.5 vezes o peso do gelo seco pode ser necessário para remessas de 72 horas.

Fatores que influenciam sua escolha

Requisitos de temperatura do produto. Produtos congelados como carne, frutos do mar ou vacinas exigem condições ultrafrias. A sublimação do gelo seco a –78,5 °C garante que esses itens permaneçam congelados e seguros durante o transporte. Itens resfriados que devem permanecer acima do ponto de congelamento, como chocolates ou medicamentos injetáveis que requerem 2–8 °C, deve usar pacotes de gel ou PCMs.

Duração e distância do envio. Envios de longa distância (>48 horas) ou rotas através de climas quentes favorecem os blocos de gelo seco porque duram mais. Entregas curtas ou distribuição local podem contar com pacotes de gel ou pacotes menores de gelo seco.

Manuseio e conformidade regulatória. O gelo seco é classificado como um material perigoso (E 1845) e remessas superiores 5.5 lb deve estar em conformidade com os EUA. Título CFR 49 e regras IATA. Os pacotes de gel não são regulamentados e são mais fáceis de manusear pelos clientes.

Custo e sustentabilidade. O gelo seco é perecível e deve ser reabastecido a cada remessa; bolsas de gelo são mais baratas e reutilizáveis. No entanto, bolsas de gelo seco reutilizáveis surgindo em 2025 pode ser recarregado e reutilizado centenas de vezes, economizando até 20% em custos de refrigeração.

Experiência do cliente. Se os clientes não estiverem familiarizados com o manuseio de gelo seco, pacotes de gel podem ser mais seguros e simples de descartar. Forneça instruções e rótulos claros sempre que enviar gelo seco aos usuários finais.

Comparando agentes de resfriamento: bolsas de gelo seco vs bolsas de gel

| Atributo | Pacotes de gel | Pacotes de gelo seco | Impacto em você |

| Faixa de temperatura | Aproximar 0 °C (32 °F) | Cerca de –78,5 °C (–109 ° F.) | Use pacotes de gel para itens resfriados; gelo seco para produtos congelados. |

| Duração | 12–24 horas para pacotes de gel padrão | 12–24 horas por pacote; mais tempo com blocos maiores | O gelo seco pode durar mais em recipientes isolados. |

| Resíduo | Derrete em água | Sublimados ao gás | Gelo seco evita embalagens encharcadas. |

| Manuseio | Não perigoso | Requer luvas e ventilação | Gelo seco exige treinamento e equipamento de proteção. |

| Regulamento | Não regulamentado | Aula 9 materiais perigosos | Você deve seguir a embalagem, regras de rotulagem e transporte para gelo seco. |

Cenários práticos

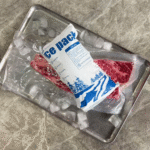

Carne congelada em todo o país: Use blocos de gelo seco iguais ao peso da carne para manter o congelamento por até 48 horas. Adicione mais blocos ou pacotes suplementares para viagens de 72 horas.

Kits de refeição com conteúdo misto: Compartimentos separados podem combinar bolsas de gelo seco para carnes congeladas e bolsas de gel para vegetais, garantindo que cada produto permaneça dentro de sua faixa de temperatura adequada.

Amostras farmacêuticas: Para produtos biológicos que requerem –70 °C, escolha pacotes de gelo seco com monitoramento em tempo real. Algumas transportadoras agora oferecem contêineres que reabastecem o gelo seco automaticamente quando os sensores detectam aquecimento.

Exemplo prático: Uma pequena empresa de kits de refeição usa uma abordagem híbrida: bolsas de gelo seco para proteínas congeladas e bolsas de gel para vegetais. Essa combinação manteve as remessas intactas e reduziu a confusão do cliente.

Manuseio seguro, Embalagem e descarte: Práticas recomendadas

Por que a segurança é importante

O gelo seco é extremamente frio e libera grandes volumes de gás CO₂ quando sublima. O contato direto com a pele pode causar queimaduras graves, e o acúmulo de CO₂ em espaços confinados pode levar à asfixia. Portanto, embalagem adequada, manuseio e descarte são críticos.

Precauções de segurança e considerações regulatórias

Use equipamento de proteção. Sempre use luvas isoladas, óculos de proteção e sapatos fechados ao manusear gelo seco.

Garanta ventilação. Trabalhe em áreas bem ventiladas e evite armazenar gelo seco em espaços confinados. Meio quilo de gelo seco libera cerca de 250 litros de gás CO₂.

Use recipientes ventilados. Nunca coloque gelo seco em recipientes herméticos; o aumento de pressão pode causar explosões. O isopor dentro de uma caixa de papelão oferece isolamento e permite que o gás escape.

Evite materiais incompatíveis. Use apenas recipientes classificados para gelo seco. Metais, plásticos ou vidro podem rachar sob o frio extremo.

Rotular pacotes. Marque remessas com “Gelo Seco (Dióxido de Carbono Sólido) UN 1845” e especifica o peso líquido do gelo seco para cumprir os regulamentos DOT e IATA.

Treinar manipuladores e clientes. Forneça instruções para uso seguro, armazenamento e descarte.

Calculando a quantidade certa de gelo seco

O cálculo adequado da quantidade garante um resfriamento adequado sem desperdício:

Diretriz geral: Use 1–2 lb de gelo seco para cada 3–4 lb de produto.

24hora de voo: 15 lb de gelo seco pode manter condições de –70 °C para uma remessa de 24 horas, conforme demonstrado por um laboratório de biotecnologia que usou recipientes pré-resfriados e orifícios de ventilação para evitar o acúmulo de pressão.

Razões de peso: Para remessas noturnas, embale metade do peso da carga útil em gelo seco. Peso igual mantém o congelamento por 48 horas, e 1,5× peso pode ser necessário para 72 horas.

Dicas de embalagem e isolamento

Pré-condicionar recipientes. Resfrie as caixas antes de adicionar gelo seco para retardar a sublimação.

Camada corretamente. Coloque gelo seco acima dos produtos para que o ar frio desça, e separe-o de produtos sensíveis ao frio extremo com papelão ou acolchoamento.

Minimize o espaço vazio. Preencha as lacunas com materiais isolantes (espuma, pelotas ou enchimento) para evitar bolsas quentes.

Escolha uma embalagem externa robusta. Caixas de papelão ondulado ou plástico proporcionam resistência; evite tambores de aço ou recipientes de plástico selados.

Erros comuns para evitar

Selando o recipiente completamente. Isso retém o gás CO₂ e pode causar explosões.

Subestimando a quantidade. Muito pouco gelo seco leva ao descongelamento. Ajustar quantidades para temperaturas ambientes e tempo de viagem.

Deixar o gelo seco entrar em contato com a água. A água acelera a sublimação; mantenha as embalagens secas.

Descarte inadequado. Permitir que o gelo seco sublime em espaços abertos; nunca despeje em pias ou ralos.

Ignorando o treinamento. Pessoal não treinado pode manusear mal o gelo seco, arriscando congelamento ou asfixia.

Como as bolsas de gelo seco reutilizáveis e a tecnologia inteligente estão se transformando 2025 Logística da Cadeia Fria

Visão geral de 2025 inovações

O panorama da cadeia de frio está a evoluir rapidamente em resposta aos objetivos de sustentabilidade, restrições de oferta e progresso tecnológico. Pacotes de gelo seco reutilizáveis, sensores inteligentes, sistemas híbridos de temperatura e isolamento aprimorado são tendências-chave que moldam 2025.

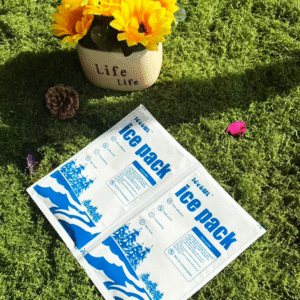

Pacotes de gelo seco reutilizáveis

As bolsas de gelo seco tradicionais são descartáveis; uma vez que o gelo seco sublima, você deve descartar a embalagem e comprar novos pacotes. Em 2025, os fabricantes oferecem durabilidade, recipientes isolados que podem ser recarregados com CO₂ sólido e usados repetidamente. Essas embalagens reutilizáveis mantêm temperaturas ultra frias (−78,5°C) e evitar danos causados pela água porque o gelo seco sublima em gás. As empresas que adotam embalagens reutilizáveis economizaram até 20 % nos custos de refrigeração dentro de meses, reduzindo simultaneamente os resíduos de plástico e melhorando os relatórios de sustentabilidade.

Uma análise comparativa mostra que bolsas de gelo seco reutilizáveis oferecem estabilidade de temperatura consistente, evitar danos causados pela água, usam menos espaço e têm menor impacto ambiental do que as tradicionais bolsas de gelo ou gel. As empresas que mudaram para embalagens reutilizáveis não só pouparam dinheiro, mas também reduziram os resíduos em aterros e as pegadas de carbono.

Sensores inteligentes e monitoramento de temperatura

Sensores IoT integrados e etiquetas sensíveis à temperatura agora fornecem dados em tempo real durante o trânsito. Pacotes inteligentes de gelo seco podem monitorar temperaturas internas e alertar os transportadores quando as temperaturas ultrapassam os limites seguros. Alguns recipientes reabastecem automaticamente o gelo seco a partir de cartuchos integrados quando os sensores detectam aquecimento. Estas tecnologias permitem uma intervenção proativa, reduzindo o risco de deterioração do produto e melhorando a conformidade regulatória.

No nível macro, provedores de logística operam torres de controle onde a IA analisa dados de temperatura de remessas em todo o mundo. Algoritmos prevêem possíveis variações de temperatura com base no histórico de rotas, atrasos climáticos e de envio, permitindo que a equipe adicione refrigerante extra ou ajuste rotas. Essa abordagem preditiva melhora a integridade do produto e reduz o desperdício.

Sistemas híbridos e isolamento melhorado

2025 também vê o aumento de sistemas híbridos de cadeia de frio que combinam gelo seco com materiais de mudança de fase (PCMs) ou pacotes de gel. A embalagem híbrida mantém múltiplas zonas de temperatura no mesmo recipiente, ideal para remessas contendo produtos congelados e refrigerados. Materiais de mudança de fase absorvem e liberam calor em temperaturas específicas (por exemplo, 2–8 °C ou –20 °C) e são reutilizáveis. O gelo seco proporciona condições ultra frias abaixo de –70 °C. Soluções híbridas permitem que os expedidores equilibrem o frio extremo e a simplicidade regulatória: PCMs evitam rótulos perigosos, enquanto o gelo seco garante capacidade de congelamento profundo para materiais sensíveis.

Painéis de isolamento a vácuo (VIPs) e embalagens isoladas de alto desempenho também estão melhorando a retenção de frio. VIPs reduzem significativamente a transferência de calor, permitindo que os remetentes usem menos gelo seco e ainda mantenham as temperaturas exigidas. Combinado com embalagens reutilizáveis, VIPs reduzem peso e desperdício.

Dinâmica de mercado e sustentabilidade

O mercado global de gelo seco deverá crescer de USD 1.54 bilhão em 2024 para USD 2.73 bilhão por 2032, uma taxa composta de crescimento anual de cerca de 7.4%. O crescimento é impulsionado pelo transporte de alimentos, Biologics, distribuição de vacinas e usos industriais como limpeza. No entanto, O fornecimento de CO₂ é limitado; a demanda por gelo seco aumenta aproximadamente 5 % por ano, enquanto a oferta cresce apenas 0.5 %, causando escassez periódica e aumentos de preços até 300%. Isso ressalta a necessidade de embalagens reutilizáveis, isolamento eficiente e refrigerantes alternativos.

As pressões de sustentabilidade também estão moldando o mercado. Grande parte do CO₂ usado para gelo seco vem de processos de combustíveis fósseis. As empresas estão explorando a captura de CO₂ de base biológica em usinas de bioetanol para criar uma cadeia de abastecimento mais circular. Inovações como revestimentos biodegradáveis em bolsas de gelo seco e materiais recicláveis reduzem o impacto ambiental.

Último progresso em um olhar

Pacotes de gelo seco reutilizáveis: Recarregável, recipientes isolados fornecem condições ultrafrias consistentes e podem ser usados centenas de vezes, reduzindo custos e desperdícios de refrigeração.

Sensores inteligentes: Dispositivos IoT integrados monitoram a temperatura e enviam alertas em tempo real; alguns sistemas reabastecem o gelo seco automaticamente quando os sensores detectam aumento de temperatura.

Soluções híbridas: A combinação de gelo seco com PCMs ou pacotes de gel proporciona múltiplas zonas de temperatura, garantindo que itens congelados e resfriados viajem juntos com segurança.

Painéis de isolamento a vácuo: VIPs reduzem a transferência de calor, permitindo que os remetentes usem menos gelo seco e mantenham as temperaturas frias por mais tempo.

CO₂ de base biológica e sustentabilidade: Empresas estão capturando CO₂ de usinas de bioetanol, desenvolvendo revestimentos biodegradáveis e medindo emissões para reduzir pegadas de carbono.

Insights de mercado e setor

A demanda por gelo seco continua a crescer em todos os setores:

Processamento de alimentos e carnes: O gelo seco fatiado ou peletizado resfria rapidamente os produtos nas linhas de processamento, enquanto os blocos mantêm o frio em remessas a granel. Um melhor isolamento prolonga os tempos de espera e reduz a sublimação.

Farmacêuticos e laboratórios: O monitoramento em tempo real e as tecnologias de barreira retardam a liberação de CO₂ e garantem a integridade da carga útil. Remetentes de PCM reutilizáveis estão ganhando força para medicamentos menos críticos em termos de temperatura.

Limpeza industrial e soldagem: O jateamento com gelo seco usa pellets para remover contaminantes sem deixar resíduos. A volatilidade da oferta leva as empresas a garantir contratos de longo prazo ou a investir em capacidade local de pelotização.

FAQ – Suas perguntas respondidas

Pergunta 1: As bolsas de gelo seco são seguras para o envio de vacinas??

Sim. As bolsas de gelo seco mantêm temperaturas ultra frias em torno de –78,5 °C, que é necessário para certas vacinas e produtos biológicos. Certifique-se de usar recipientes ventilados e seguir os regulamentos de materiais perigosos. Para vacinas que requerem 2–8 °C, materiais de mudança de fase ou pacotes de gel podem ser mais apropriados.

Pergunta 2: Quanto tempo duram os blocos de gelo seco em trânsito?

Em recipientes bem isolados, blocos de gelo seco podem durar de 48 a 72 horas. Fatores como temperatura ambiente, o isolamento do recipiente e a quantidade de gelo seco influenciarão a duração real.

Pergunta 3: Posso reutilizar pacotes de gelo seco?

Bolsas de gelo seco descartáveis devem ser descartadas após a sublimação. No entanto, bolsas de gelo seco reutilizáveis disponíveis em 2025 usar durável, recipientes isolados que podem ser recarregados com CO₂ sólido e usados várias vezes. Esses pacotes reduzem o desperdício e economizam dinheiro ao longo do tempo.

Pergunta 4: Qual é a diferença entre bolsas de gelo seco e bolsas de gel?

As bolsas de gelo seco proporcionam temperaturas ultra frias e sublimes sem deixar líquido, tornando-os ideais para produtos congelados. Os pacotes de gel mantêm temperaturas próximas 0 °C e são melhores para produtos refrigerados que não devem congelar. Os pacotes de gel não são perigosos e são mais fáceis de manusear, enquanto as bolsas de gelo seco exigem equipamentos de proteção e rotulagem de perigo.

Pergunta 5: Como calculo quanto gelo seco usar?

Uma regra geral é usar 1–2 lb de gelo seco para cada 3–4 lb de produto. Para remessas de 48 horas, peso de gelo seco igual à carga útil é recomendado. Ajuste a quantidade com base na temperatura ambiente, qualidade do isolamento e duração da viagem.

Pergunta 6: O gelo seco pode danificar meus produtos?

Sim, gelo seco extremamente frio pode congelar itens sensíveis ao congelamento (por exemplo, Frutos do mar frescos, flores, certos produtos farmacêuticos). Mantenha o gelo seco separado de tais produtos com divisórias ou almofadas e considere usar pacotes de gel ou PCMs.

Pergunta 7: O gelo seco é ecologicamente correto?

O próprio gelo seco é essencialmente CO₂ reciclado; libera o mesmo gás durante a sublimação. O impacto ambiental vem do fornecimento de CO₂, muitas vezes a partir de processos de combustíveis fósseis. Usar a quantidade certa de gelo seco e adotar embalagens reutilizáveis ou CO₂ de base biológica pode reduzir a pegada de carbono.

Pergunta 8: Quais são as alternativas mais recentes ao gelo seco?

Materiais de mudança de fase (PCMs) oferecer estável, resfriamento reutilizável a 2–8 °C ou –20 °C e evita regulamentações sobre materiais perigosos. Recipientes de refrigeração mecânica ou painéis de isolamento a vácuo podem prolongar a retenção de frio, embora com custo mais elevado. Os sistemas híbridos que combinam gelo seco com PCMs estão ganhando popularidade para remessas que exigem múltiplas zonas de temperatura.

Takeaways -chave

Blocos de gelo seco e bolsas de gelo seco são ferramentas indispensáveis na logística da cadeia de frio. Blocos de gelo seco oferecem condições ultra frias prolongadas, sublimando lentamente para manter os produtos congelados seguros durante remessas longas. Pacotes de gelo seco, incluindo pellets e fatias, fornecem posicionamento flexível e resfriamento mais rápido, mas exigem reabastecimento para viagens mais longas. O gelo seco sublima sem deixar água e tem aproximadamente três vezes a eficiência de resfriamento do gelo de água. Ao escolher entre blocos e pacotes, considere os requisitos de temperatura, Duração da remessa, sensibilidade do produto, conformidade regulatória e experiência do cliente.

Ações recomendadas para suas operações de cadeia de frio

Avalie as necessidades de temperatura do seu produto. Use gelo seco para itens que requerem temperaturas abaixo de zero e pacotes de gel ou PCMs para produtos refrigerados.

Calcule a quantidade apropriada. Aplique a diretriz de 1–2 lb de gelo seco por 3–4 lb de produto e ajuste para trânsito mais longo ou climas mais quentes.

Escolha o formulário certo. Os blocos são ideais para remessas de longa distância; pellets e fatias funcionam melhor para viagens mais curtas ou resfriamento preciso.

Implementar procedimentos de manuseio seguro. Treine a equipe, usar equipamento de proteção, ventile os recipientes e rotule os pacotes claramente.

Explore soluções reutilizáveis e inteligentes. Pacotes de gelo seco reutilizáveis, sensores inteligentes e sistemas híbridos podem reduzir custos, obstáculos de desperdício e conformidade.

Plano para a sustentabilidade. Considere fontes de CO₂ de base biológica, revestimentos de embalagens biodegradáveis e painéis de isolamento a vácuo para atender às metas ambientais.

Sobre Tempk

Tempk é especializada em embalagens para cadeia de frio e soluções de refrigeração para alimentos, indústrias farmacêuticas e de biotecnologia. Nós fornecer uma ampla variedade de bolsas de gelo seco reutilizáveis, pacotes de gel, materiais de mudança de fase e recipientes isolados projetados para atender a requisitos rigorosos de temperatura. Nosso R&A equipe D desenvolve produtos ecologicamente corretos, incluindo revestimentos biodegradáveis e embalagens inteligentes com sensores IoT, para ajudar os clientes a reduzir custos e pegadas de carbono. Escolhendo Tempk, você ganha acesso a tecnologia de ponta, fornecimento confiável e orientação especializada para todas as suas necessidades de cadeia de frio.

Chamado à ação: Pronto para atualizar sua cadeia de frio? Entre em contato com os especialistas da Tempk para uma consulta personalizada e descubra como nossas bolsas de gelo seco reutilizáveis e sistemas híbridos podem proteger suas remessas e apoiar suas metas de sustentabilidade.