Embalagem de sorvete seco é essencial para garantir que suas guloseimas congeladas permaneçam frias e frescas durante o trânsito. Se você está enviando sorvete para varejo ou entregar aos clientes diretamente, A embalagem de gelo seco é uma solução confiável para manter a temperatura adequada. Neste artigo, Exploraremos os benefícios do uso de embalagens de sorvete seco e como funciona para preservar a qualidade de seus produtos congelados.

Este artigo responderá às principais perguntas sobre:

-

O que é embalagem de sorvete seco, E como funciona?

-

Por que o gelo seco é essencial para embalar sorvete para envio?

-

Quais são as principais características da embalagem de sorvete seco?

-

Como garantir um envio seguro e eficiente com gelo seco?

O que é embalagem de sorvete seco, E como funciona?

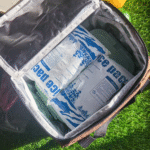

A embalagem de sorvete seco envolve usar gelo seco Para manter o sorvete em sua temperatura congelada ideal durante o envio. Gelo seco tem um ponto de sublimação de -78.5°C (-109.3°F), tornando -o perfeito para garantir que os bens congelados, como sorvete, Fique abaixo do congelamento durante o trânsito. O gelo seco é colocado dentro de um pacote isolado com o sorvete, impedir o produto de descongelar e manter sua frescura.

As embalagens de sorvete seco são usadas principalmente para Remessas de longa distância onde o gelo regular pode não ser suficiente para manter a temperatura necessária.

Principais benefícios da embalagem de sorvete seco

-

Duração estendida de resfriamento: O gelo seco dura mais do que o gelo tradicional, manter o sorvete congelado para até 72 horas.

-

Sem umidade: Ao contrário do gelo regular, Gelo seco não derrete na água, que poderia danificar a embalagem ou o sorvete.

-

Controle de temperatura confiável: A embalagem garante que o gelo seco permaneça contido e impeça flutuações de temperatura que possam afetar a qualidade do produto.

| Aplicativo | Faixa de temperatura | Duração do resfriamento | Principais benefícios |

|---|---|---|---|

| Sorvete & Guloseimas congeladas | -18° C a -20 ° C. | Até 72 horas | Mantém sorvete congelado, preserva textura e sabor |

| Produtos farmacêuticos | -20° C a -70 ° C. | 24-72 horas | Mantém a eficácia durante o envio |

| Amostras de biotecnologia | -20° C a -70 ° C. | 12-48 horas | Preserva a integridade de materiais biológicos |

Por que o gelo seco é essencial para a embalagem de sorvete?

Usar gelo seco para embalagem de sorvete garante que o produto permaneça congelado durante o envio, impedindo que ele derrete e rebante, que poderia alterar a textura e a qualidade. O gelo seco mantém temperaturas abaixo de zero por períodos mais longos, Tornando-se a solução ideal para transporte de sorvete de longa distância ou internacional.

-

Resfriamento sustentado: Gelo seco mantém sorvete a uma temperatura congelada constante, mesmo durante longos tempos de trânsito.

-

Sem danos causados pela água: Como o gelo seco não derrete na água, elimina o risco de embalagens encharcadas e produtos danificados.

-

Versatilidade: A embalagem de gelo seco funciona bem para diferentes métodos de envio, incluindo terra, ar, e frete oceano.

Comparando embalagens de gelo seco com métodos tradicionais

| Recurso | Embalagem de gelo seco | Pacotes de gelo tradicionais |

|---|---|---|

| Eficiência de resfriamento | High - mantém os produtos abaixo de zero | Moderado - pode não manter temperaturas baixas por tempo suficiente |

| Duração do resfriamento | 24-72 horas | 12-48 horas |

| Sem umidade | Sim | Não |

Principais características da embalagem de sorvete seco

Ao escolher embalagens de sorvete seco, Procure esses recursos essenciais para garantir o transporte seguro de produtos congelados:

-

Embalagem Isolada: A embalagem deve incluir isolamento de alta qualidade para impedir que o calor entre.

-

Vedação adequada: Certifique -se de que a embalagem seja selada firmemente para manter o gelo seco e o sorvete seguro.

-

Design à prova de vazamentos: O recipiente deve ser capaz de conter o gelo seco sem vazamento para manter o efeito de resfriamento pelo maior tempo possível.

Dicas para escolher a melhor embalagem de gelo seco

-

Para remessas curtas, Opte por pacotes menores com isolamento adequado para manter a temperatura.

-

Para remessas longas, Use pacotes maiores com isolamento mais espesso para evitar qualquer flutuação de temperatura ao longo do tempo.

Como garantir um envio seguro e eficiente com gelo seco?

Para maximizar a eficácia da embalagem de gelo seco, Siga estas melhores práticas para remessa segura e eficiente:

-

Embalagem pré-escolar: Antes de colocar o gelo seco e o sorvete dentro, Pré-escreva o pacote para garantir o controle ideal da temperatura.

-

Ventilação adequada: O gelo seco sublima em gás dióxido de carbono, Portanto, verifique se a embalagem permite a ventilação segura durante o trânsito.

-

Monitoramento de temperatura: Use madeireiros de temperatura para rastrear a temperatura dentro da embalagem para garantir que ela permaneça dentro da faixa necessária.

Como maximizar a eficiência da embalagem de gelo seco

-

Use isolamento espesso Para manter o gelo seco mais frio por mais tempo e evitar a sublimação precoce.

-

Prenda o gelo seco dentro da embalagem para impedir que ela mude durante o transporte.

Exemplo do mundo real: Um fabricante de sorvete Utilizou embalagens de gelo seco para enviar sobremesas congeladas internacionalmente. A embalagem manteve o sorvete congelado para 72 horas, garantindo que chegasse intacto e fresco, preservando a textura e o gosto pelos clientes.

2025 Tendências e inovações em embalagens de sorvete seco

À medida que nos mudamos para 2025, A embalagem de sorvete seco está evoluindo com a introdução de Materiais de embalagem sustentáveis e Monitoramento de temperatura inteligente. Essas inovações não apenas aumentam o desempenho do gelo seco, mas também reduzem o impacto ambiental.

Últimos desenvolvimentos em embalagens de gelo seco

-

Materiais sustentáveis: Muitas empresas estão explorando materiais ecológicos para isolamento, reduzindo sua pegada ambiental.

-

Embalagem inteligente: Alguma embalagem de sorvete seco agora inclui sensores de temperatura e Monitoramento em tempo real Para rastrear a temperatura interna durante o envio, garantindo a segurança do produto.

Insights de mercado

A crescente demanda por envio sensível à temperatura em indústrias como comida e produtos farmacêuticos está dirigindo o mercado para embalagens de sorvete seco. À medida que mais empresas se envolvem no comércio global, a necessidade de eficaz, confiável, e soluções de transporte sustentável estão aumentando.

Perguntas frequentes

Quanto tempo pode secar o gelo manter o sorvete congelado?

O gelo seco pode manter o sorvete congelado para até 72 horas, dependendo da quantidade de gelo seco e isolamento usado na embalagem.

A embalagem de gelo seca pode ser reutilizada?

Sim, desde que a embalagem esteja intacta e não seja danificada, A embalagem de gelo seco pode ser reutilizada para remessas futuras.

É seguro de gelo seco para enviar comida?

Sim, Gelo seco é seguro para enviar comida, desde que esteja devidamente contido em embalagens isoladas para manter uma temperatura consistente.

Resumo e recomendações

A embalagem de sorvete seco é uma solução confiável e eficaz para o envio de produtos congelados. Usando a embalagem certa e seguindo as melhores práticas, Você pode garantir que seu sorvete permaneça congelado e fresco durante o trânsito.

PRÓXIMOS PASSOS: Avalie seus requisitos de envio, Escolha a embalagem de gelo seco direito com base no tamanho, isolamento, e duração do transporte, e garantir o monitoramento adequado da temperatura ao longo da jornada.

Sobre Tempk

E tempk, Somos especializados em fornecer Soluções de remessa controladas por temperatura Para as indústrias alimentares e farmacêuticas. Nossa embalagem de sorvete seco, junto com outras soluções isoladas, garante que seus produtos cheguem em segurança e mantenham sua qualidade durante o trânsito.

Contate-nos Para saber mais sobre nossas soluções de embalagem personalizadas projetadas para atender às suas necessidades específicas.