Dry Ice Foam Dry Ice Pack: How to Ship Overnight

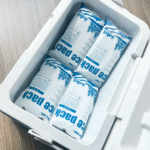

UM dry ice foam dry ice pack keeps products hard‑frozen across an overnight lane when it’s sized, ventilado, and packed correctly. You’ll match foam insulation to your route, calculate a realistic dry ice load, and add porch‑time buffer. Expect 24–36 hours of hold when you right‑size the cube and place dry ice above and around the payload. This guide shows practical steps you can apply today.

-

Quanto dry ice foam dry ice pack you need for typical weights and climates

-

Which foam (EPS/EPP/VIP) makes your dry ice foam dry ice pack lighter and safer

-

How to label, ventilação, and document a dry ice foam dry ice pack para conformidade

-

How to cut CO₂ usage and freight using hybrid PCM + dry ice foam dry ice pack

-

O que 2025 trends change how you design a dry ice foam dry ice pack

What is a dry ice foam dry ice pack and when should you use it?

Resposta direta

A dry ice foam dry ice pack is a foam‑insulated shipper loaded with dry ice to keep payloads frozen for about one day. Use it for frozen foods, premium meats, sobremesas, Biologics, and research samples when delivery is guaranteed within 24–36 hours and you need a clean, water‑free cold source.

Explicação expandida

The foam shell slows heat; dry ice handles the heavy lifting by sublimating at −78.5 °C. Escolha o dry ice foam dry ice pack when speed and certainty matter more than long buffer windows. It’s ideal for overnight air, regional ground, and hot‑to‑mild lanes with predictable handoffs. Place dry ice above the product so cold CO₂ gas “falls” and blankets the payload. Add a small data logger if you need proof for audits or customer support.

How much dry ice does a dry ice foam dry ice pack need?

Detalhes

Start with 15–25% of payload weight in dry ice for a dry ice foam dry ice pack, then test across your hottest lane. Increase the dose for summer, tarmac risk, and porch dwell; decrease if you upgrade insulation or reduce headspace. Denser foods hold cold longer, so a protein bundle needs less per kilogram than airy bakery items.

| Packout Scenario | Payload Mass | Dry Ice Mass (Começar) | What It Means For You |

|---|---|---|---|

| Meal kit sampler | 1–2 kg | 1–2 kg | Simples dry ice foam dry ice pack with small foam cube keeps entrées rock hard |

| Premium steaks | 4–5kg | 3–4kg | Extra top slab for tarmac heat and late porch delivery |

| Amostras de laboratório | 8–10kg | 6–8kg | Larger dry ice foam dry ice pack with rigid dividers stabilizes vials |

| Ice cream pints | 3–4kg | 2–3kg | Dense payload lets you trim ice by 10–20% after lane testing |

| PCM híbrido + gelo | 4–6kg | 1–2 kg + PCM | PCMs tame short spikes; dry ice holds deep‑freeze core |

Practical tips for a dependable dry ice foam dry ice pack

-

Top layer matters: Always keep some dry ice above the payload; cold gas sinks.

-

Tight voids: Fill gaps with liners or kraft—less air equals less heat gain.

-

Porch buffer: Add 1–2 kg for summer afternoons or “driver behind schedule” alerts.

-

Pré -Chill: Comece frio; don’t ask your dry ice foam dry ice pack to fix warm product.

-

Data loop: One logger per lane pays for itself by cutting guesswork.

Caso do mundo real: A dessert brand swapped to a narrower dry ice foam dry ice pack with a top slab and side pellets, cutting soft‑serve complaints by half in July while shaving 12% off freight due to a smaller cube.

How do you size a dry ice foam dry ice pack for overnight lanes?

Resposta direta

Estimate heat load from surface area, insulation value, e condições ambientais, then choose a dry ice mass that covers 24–36 hours with buffer. A quick model gets you within 10–20% before live tests.

Explicação expandida

Heat sneaks through foam walls. The colder the inside and the hotter the day, the faster it leaks. Dry ice absorbs that heat as it turns to gas. With a simple calculation, you can choose a starting dose for your dry ice foam dry ice pack and then tune it per lane.

Worked example you can adapt

-

Foam shipper external area: 0.32 m²

-

U‑value: 0.8 W/m²·K (EPS 25–30 mm with tight joints)

-

ΔT: 30 K (−20 °C interior vs +10 °C truck to +35 °C porch)

-

t: 30 h (pickup + hub + porch buffer)

-

Q ≈ 0.8 × 0.32 × 30 × 108000 / 1000 ≈ 829 kJ

-

Dry ice ≈ 829/571 ≈ 1.45 kg → Round to 2 kg for a safer dry ice foam dry ice pack

| Input | Valor | Por que isso importa | Sua ação |

|---|---|---|---|

| U‑value | 0.8 | Lower is better insulation | Upgrade foam or add VIP facing hottest wall |

| Area | 0.32 m² | Bigger box, more heat | Downsize cube; alvo <15% Headspace |

| ΔT | 30 K | Hotter lanes need more | Boost dose in heat waves |

| Tempo | 30 h | Includes porch | Use AM delivery to trim 10% |

Which foam and insulation work best for a dry ice foam dry ice pack?

Resposta direta

Use EPS or EPP at 25–38 mm for most routes, and add VIP panels for hot lanes or high‑value goods. Joints and lid fit matter as much as thickness for a dry ice foam dry ice pack.

Explicação expandida

-

EPS (poliestireno expandido): Cost‑effective, previsível, easy to recycle in many regions. Great for standard dry ice foam dry ice pack kit sizes.

-

PPE (polipropileno expandido): Tougher and springier; better for reuse loops. Slightly pricier, but resists dents and lid creep.

-

XPS (extruded polystyrene): Smooth skins, useful for custom inserts, though less common for full shippers.

-

VIP (painéis isolados a vácuo): Much lower U‑value at low mass, ideal to slim dry ice mass or cube. Protect VIPs with corrugate sleeves.

EPS vs EPP vs VIP—when to switch in a dry ice foam dry ice pack

-

Stay with EPS if failure rate is already low and freight costs are acceptable.

-

Move to EPP when shippers re‑circulate or you see crush damage on returns.

-

Add VIP on lanes with long porch dwell or frequent weather delays; you can often trim dry ice by 10–25% while maintaining the same hold.

| Material | Typical Thickness | Strength Trait | Meaning for Your Pack |

|---|---|---|---|

| EPS | 25–38 mm | Luz, econômico | Padrão dry ice foam dry ice pack linha de base |

| PPE | 25–38 mm | Impact‑resistant | Lower breakage in reuse; stable lid fit |

| VIP + EPS | VIP 10–15 mm + EPS 12–25 mm | Very low U‑value | Downsize cube or cut dry ice mass |

Fit and seal: the quiet killers

Lid gaps, misaligned corners, and cracked edges are silent heat leaks. Tape can’t fix a bad fit. Por um dry ice foam dry ice pack, pick shippers with tongue‑and‑groove lids or compression gaskets and verify lid creep under load with a 15‑minute bench test.

How do you comply with rules using a dry ice foam dry ice pack?

Resposta direta

Ventilação, rótulo, and disclose net dry ice weight. Seu dry ice foam dry ice pack must show “Carbon dioxide, sólido,UN1845, e permitir que o gás escape. Staff need gloves and eye protection during packout.

Explicação expandida

Dry ice vents CO₂ gas. Never seal a dry ice foam dry ice pack hermeticamente. Mark the outside with UN1845 and the net dry ice weight. Follow your carrier’s current instructions for air transport (por exemplo, packing instructions specific to dry ice) and standard workplace safety guidance for handling CO₂ and frostbite risks. Store dry ice in ventilated areas, not in sealed rooms or walk‑ins.

Simple compliance checklist (copiar/colar)

-

Carton is ventilado, Não é hermético

-

Exterior shows UN1845 e “Dióxido de carbono, sólido"

-

Rede de gelo seco da rede written clearly

-

Gloves and eye protection available at the station

-

No sealed glass or pressure‑tight containers inside

-

Earliest available durante a noite service selected

-

Packout SOP posted at the bench

Passo a passo: pack a dry ice foam dry ice pack like a pro

Resposta direta

Pré -Chill, bottom layer, side fill, top slab, Fechar o revestimento, rótulo, and ship early. That sequence produces the most reliable dry ice foam dry ice pack ao longo das estações.

Explicação expandida

Cold product multiplies your margin. Place a thin bottom layer of pellets or a scored slab. Center the payload, fill sides hard, then cap with a top slab. Close the inner liner but keep a vent path. Weigh the net dry ice, write it on the box, and stage for the first outbound truck.

Two‑minute bench test method

-

Assemble the dry ice foam dry ice pack empty and close it.

-

Shine a bright light around seams; look for light leaks.

-

Press on corners—if lids lift, add a strap or switch models.

-

With a tiny dry ice piece inside, confirm gas exits at intended vents.

| Etapa | Ação | Tempo | Por que isso importa |

|---|---|---|---|

| 1 | Pre‑chill product & remetente | 20–60 min | Gains 1–3 hours hold |

| 2 | Bottom pellet layer | 30 s | Keeps base rigidly cold |

| 3 | Center and side fill | 60–90 s | Reduces air gaps |

| 4 | Top slab | 15–30 s | Maintains surface freeze |

| 5 | Close liner & ventilação | 15 s | Evita o acúmulo de pressão |

| 6 | Rótulo & pesar | 30 s | Compliance and QC proof |

How to cut costs with a dry ice foam dry ice pack?

Resposta direta

Shrink the cube, upgrade insulation only where it pays back, and use hybrid PCM with a modest dry ice reduction. Freight and CO₂ mass fall together when your dry ice foam dry ice pack fits tightly.

Explicação expandida

Every cubic centimeter costs money. Downsize to the smallest inner volume that still allows top and bottom layers. A one‑step insulation upgrade can cut ice by more than the added box cost. Hybrid PCM tiles tame heat spikes near 0 °C so your dry ice foam dry ice pack doesn’t overshoot. Prioritize hot lanes and porch‑heavy zips for upgrades; leave mild zones on the simpler spec.

Quick ROI levers

-

Right‑size cube: Objetivo para <15% headspace—smaller box, less heat load

-

Smart insulation: Use VIP only on lanes with late porch risk

-

Hybrid core: Two PCM tiles near doors; dry ice on top and sides

-

Route engineering: AM delivery windows often justify −10% dry ice

-

Order bundling: Combine two small orders into one dry ice foam dry ice pack

Quality control for your dry ice foam dry ice pack

Resposta direta

Golden samples, simple loggers, and pass/fail charts keep results consistent. Visual SOPs help every packer execute the same dry ice foam dry ice pack toda vez.

Explicação expandida

Create a master packout per SKU and lane. Photograph each step and mount it at the station. Add a sticker for net dry ice mass. Pull one box per pallet for logging. Build a red/amber/green chart for porch outcomes and adjust the dose the same day. Fast feedback reduces refunds.

Station playbook

-

Golden sample photos posted at eye level

-

Net dry ice sticker on each carton

-

Random open‑box checks hourly

-

Exceptions logged and reviewed at shift end

Sustainability choices around the dry ice foam dry ice pack

Resposta direta

Use recycled‑content corrugate, reclaim foam where available, and cut CO₂ mass with better fit and hybrid cooling. Many customers notice cleaner, tighter dry ice foam dry ice pack desenhos.

Explicação expandida

Foam gets a bad rap when cubes are bigger than needed. Shrinking the box lowers materials and freight. Where local programs accept EPS, bundle and return shippers; EPP supports reuse loops for nearby deliveries. Share a simple “How to dispose of dry ice safely” card and a note on recycling locations. Small steps add up across thousands of boxes.

Reuse and reclaim ideas

-

Use EPP shippers with return labels for subscription customers

-

Offer a take‑back day at retail partners once per quarter

-

Switch to VIP only on failure‑prone lanes to avoid over‑engineering

2025 trends in dry ice foam dry ice pack solutions

Visão geral da tendência

O dry ice foam dry ice pack is getting lighter and smarter in 2025. You’ll see slimmer VIP panels for standard boxes, tiny QR‑loggers that render phone‑friendly graphs, and hybrid PCM cores that shave dry ice mass without losing freeze assurance. Carriers expand morning windows and carbon tracking, while brands push regional fulfillment to shorten lanes.

Últimos desenvolvimentos de vista

-

Hybrid cooling kits: PCM tiles plus a smaller dry ice foam dry ice pack dose to smooth spikes

-

Edge analytics: Low‑cost loggers with QR download for instant cold‑chain proof

-

Slim VIP overlays: Drop‑in panels sized for common 10–20 L shippers

Insights de mercado

Frozen DTC and e‑grocery drive volume on overnight lanes. Customers reward cleaner unboxing and compact cubes. Expect more porch‑safe packaging and proactive SMS alerts to reduce refunds. Teams that tune doses by zip code and season see fewer failures and lower CO₂ use.

Perguntas frequentes (Perguntas frequentes)

Q1: How long will a dry ice foam dry ice pack keep items frozen?

Most dry ice foam dry ice pack setups hold 24–36 hours when sized and vented well. Add buffer for summer or late porch drop; verify with a simple logger.

Q2: Can gel packs replace a dry ice foam dry ice pack?

Gel packs keep items cold, not hard‑frozen. Use gels for 0–8 °C. For deep freeze, stick with a dry ice foam dry ice pack or a hybrid where dry ice maintains the freeze core.

Q3: Como devo descartar o gelo seco restante?

Let it sublimate in a ventilated area away from people and pets. Never place dry ice in sinks, sealed bins, or walk‑ins.

Q4: What size pellets or slabs work best in a dry ice foam dry ice pack?

Pellets fill gaps and cool faster; slabs last longer and resist tarmac heat. Many teams use a top slab plus side pellets inside the dry ice foam dry ice pack.

Q5: Is a dry ice foam dry ice pack allowed by major carriers?

Sim, with correct labels, aberturas, and net mass markings. Some aircraft compartments limit total dry ice mass; check the latest carrier rules each season.

Q6: How do I prevent freezer burn inside a dry ice foam dry ice pack?

Use moisture‑safe wrap, minimize headspace in inner bags, and keep product from directly touching dry ice using a thin barrier.

Q7: Will a dry ice foam dry ice pack damage packaging or labels?

It can crack thin plastics or make labels brittle if unprotected. Add a liner and choose adhesives rated for cold.

Q8: What if my lane sometimes takes two days?

Upgrade to VIP overlays or add porch buffer to your dry ice foam dry ice pack. Better yet, split shipments to regional hubs to shorten routes.

Resumo e recomendações

Takeaways -chave

UM dry ice foam dry ice pack works when cube and dose match the lane. Put dry ice above and around the payload, mantenha as aberturas de ventilação abertas, and label UN1845 with net mass. Upgrade insulation only where it pays back. Close the loop with quick data and a golden sample SOP.

Plano de ação

-

Map hot lanes and porch windows by zip.

-

Build two dry ice foam dry ice pack tests per SKU.

-

Log five boxes; adjust dose ±10–20%.

-

Add PCM tiles where porch dwell is frequent.

-

Publish a one‑page SOP at every station.

CTA: Want a ready‑to‑ship kit? Ask for a lane review and a custom dry ice foam dry ice pack spec.

Sobre Tempk

Quem somos

We build practical cold‑chain solutions backed by testing and simple playbooks. Our ready kits combine tight foam fit, smart insulation, and clear labels. Customers report fewer returns and smaller cubes with our dry ice foam dry ice pack desenhos.

Próximo passo

Request a quick consult. We’ll size, teste, and ship a pilot dry ice foam dry ice pack for your hottest lane.