Para logística alimentar perecível, temperature deviations exceeding ±3°C can trigger microbial growth (FDA, 2021). Pacotes de gelo seco provide consistent -78.5°C protection through sublimation (transição sólida para gás), Eliminando o escoamento líquido que compromete a integridade da embalagem-tornando-os indispensáveis para remessas congeladas de alto valor.

Why Food Logistics Choose Dry Ice Packs

| Advantage | Food Industry Impact |

|---|---|

| Extended Thermal Buffer | Maintains ≤-18°C for 48-96 hours – exceeds standard frozen transit windows |

| Zero Moisture Exposure | Prevents soggy packaging, Formação de cristal de gelo, and label damage |

| Space Efficiency | 1kg dry ice = 4L cooling volume (vs 8l água gelo) – 50% space savings |

| Regulatory Compliance | Meets HACCP/FDA frozen storage requirements with auditable temperature control |

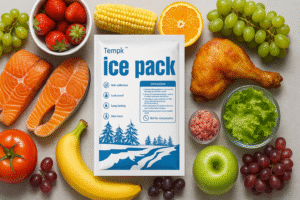

Food-Specific Applications

High-Risk Perishables

→Frutos do mar: Maintains -30°C for premium tuna/salmon exports

→Meat/Poultry: Impede “abuso de temperatura” during multi-stop deliveries

→Ice Cream: Evita a separação de gordura & texture damage from partial thawing

Last-Mile Solutions

• Meal kit ingredient freshness

• Gourmet chocolate protection

• Frozen bakery transport

Tempk’s Food-Grade Dry Ice Pack Innovations

✓ Precision Performance: Mantém <-20°C paraMais de 96 horas (validated per ISTA-7D)

✓ Structural Integrity: Triple-layer laminate resists punctures during palletized transport

✓ Custom Configuration:

Conclusão: Transform Food Safety Margins

Dry ice packs cut food spoilage rates by 19-34% (IATA Cold Chain Data 2023) versus gel alternatives. By combining deep-freeze reliability with moisture-free operation, Tempk’s solutions empower:

•Exporters to access premium markets

•E-commerce to guarantee “fresh-frozen” delivery promises

•Processors to pass FDA/USDA audits

Upgrade your cold chain defense with engineered dry ice protection – where product integrity becomes profit protection.