Caixa de espuma EPP ecológica: Como escolher em 2025?

Última atualização: dezembro 15, 2025

Um eco-friendly EPP foam box is a smart 2025 escolha apenas when you can reuse it reliably and retire it responsibly. You’re not just buying a box. You’re building a simple loop: return, limpar, inspecionar, reutilizar, and eventually recycle. Na Europa, packaging pressure is rising fast, e 2025 rules are pushing companies toward real recyclability and proof—not slogans.

Este artigo irá ajudá-lo a entender:

-

How to define “eco-friendly” for an eco-friendly EPP foam box without greenwashing

-

How to compare eco-friendly EPP foam box vs EPS cooler using a simple decision table

-

How to run a washable eco-friendly EPP foam box reuse loop without slowing operations

-

How to build an eco-friendly EPP foam box recycling program that works in real life

-

How to prove your reuse claim in 2025 with simple, auditable metrics

What makes an eco-friendly EPP foam box truly eco-friendly?

Resposta principal: An eco-friendly EPP foam box is “eco-friendly” when it is reused enough times and has a clear end-of-life path. If your boxes don’t come back, the “eco” claim collapses. If cleaning is slow, the loop jams. Think of it like a refillable bottle: the bottle matters, but the refill habit matters more.

eco-friendly EPP foam box

Em termos simples, you’re choosing both a material e a sistema. EPP is a closed-cell foam, meaning it has sealed bubbles that resist soaking up water. It stays light, difícil, and stable through repeat handling. Some EPP structures are about 95% air and 5% polymer, which helps explain why insulation can be strong without heavy weight.

eco-friendly EPP foam box

EPP basics in plain English: what are you buying?

You’re buying forma + espessura da parede + qualidade de fechamento, not just foam. Density matters because it changes strength, empilhamento, e peso.

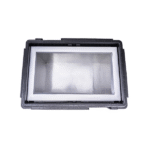

eco-friendly EPP foam box

| Escolha de design | Lower density EPP | Higher density EPP | O que isso significa para você |

|---|---|---|---|

| Peso | Isqueiro | Mais pesado | Lower freight cost vs stronger structure |

| Feel | Softer | Firmer | Better cushioning vs better stacking strength |

| Durabilidade | Bom | Excelente | More reuse cycles with tougher designs |

| Isolamento | Often strong | Still strong | Lane length decides what’s “enough” |

Dicas práticas para você

-

Set a reuse target first: Decide the minimum trips your eco-friendly EPP foam box must reach.

-

Match the box to your real process: A perfect box fails if nobody returns it.

-

Define end-of-life now: “Recyclable” is not the same as “recycled in your region.”

eco-friendly EPP foam box

Exemplo do mundo real: One repeat-route distributor standardized packing faster after switching to reusable EPP boxes.

eco-friendly EPP foam box

Eco-friendly EPP foam box vs EPS cooler: o que você deve escolher?

Resposta principal: Choose an eco-friendly EPP foam box when you can run a return loop. Choose EPS (muitas vezes de uso único) when returns are unrealistic and you need low upfront cost. But beware: “easy today” can become “wasteful tomorrow” if damage, deterioração, or rule pressure increases.

This decision is not about insulation alone. It’s about operations: retorna, tempo de limpeza, taxa de perda, e intensidade de manuseio.

Comparison table you can use in sourcing meetings

| Recurso | Eco-friendly EPP foam box | Refrigerador EPS | O que isso significa para você |

|---|---|---|---|

| Potencial de reutilização | Alto | Baixo a médio | EPP supports circular systems better |

| Resistência ao impacto | Forte | More brittle | Fewer corner breaks in rough handling |

| Water resistance | Forte | Varia | Less soggy packaging in wet lanes |

| Temperature support | Forte | Forte | Design matters as much as material |

| End-of-life | PP-based route possible | Region-dependent | Both depend on local acceptance |

Practical choice rules (simple and honest)

-

Choose eco-friendly EPP foam box when: you have repeat routes, retail returns, or scheduled backhauls.

-

Avoid eco-friendly EPP foam box when: you can’t recover boxes and can’t store returns.

-

Run a 2-week pilot: Track return rate, taxa de dano, and packing time before scaling.

eco-friendly EPP foam box

Exemplo do mundo real: A frequent-lane distributor improved outcomes after switching to a simpler latch design.

eco-friendly EPP foam box

How does an eco-friendly EPP foam box improve temperature control?

Resposta principal: An eco-friendly EPP foam box slows heat transfer and stabilizes internal temperature during handling and last-mile delivery. That matters most when doors open, pallets wait, or drivers hit delays. Even short temperature spikes can reduce product quality.

Because EPP traps air evenly, insulation performance can remain consistent even after repeated use.

eco-friendly EPP foam box

Thermal performance compared simply

| Tipo de embalagem | Insulation stability | Caso de uso típico | O que isso significa para você |

|---|---|---|---|

| Cartão + forro | Baixo | Curto, low-risk trips | Baixo custo, maior variabilidade |

| Espuma EPS | Médio | One-way shipments | Bom isolamento, brittle risk |

| Eco-friendly EPP foam box | Alto | Reusable cold chain | More consistent holds across trips |

| Sistemas VIP | Muito alto | Longo curso, prêmio | Best performance, higher system cost |

Dicas práticas para você

-

Pack cold-to-cold: Don’t use the box to “fix” warm product.

-

Minimize lid-open time: Write one simple rule and train it.

-

Use inserts for fragile goods: Less breakage means less waste and fewer reships.

Exemplo do mundo real: Teams often see fewer complaints when insulation stays stable through rough last-mile handling.

eco-friendly EPP foam box

How many reuses make an eco-friendly EPP foam box worth it?

Resposta principal: There is no single number. Break-even depends on return rate, washing cost, damage/loss rate, and what single-use packaging you replace. The simplest truth is this: every additional reuse spreads the “make” impact across more deliveries.

eco-friendly EPP foam box

Quick reuse break-even calculator (fill-in tool)

Use this simple model:

Reusable cost per shipment = (Box cost ÷ Expected rotations) + Cleaning/return cost per trip + Loss allowance per trip

Break-even happens when reusable cost per shipment ≤ your single-use packaging cost per shipment.

Preencha:

-

Single-use packaging cost per shipment = $UM

-

Eco-friendly EPP foam box purchase cost = $B

-

Expected rotations (average trips per box) = R

-

Limpeza + return handling per trip = $C

-

Loss/damage allowance per trip (small buffer) = $D

Então:

-

Reusable cost per shipment = (B ÷ R) + C + D

Fast decision shortcut: If you can’t track rotations, you can’t prove the win.

| Rotations (R) | B ÷ R (box cost per trip) | What usually happens in real life | O que isso significa para você |

|---|---|---|---|

| 1–3 | Alto | Feels like expensive single-use | Don’t scale yet |

| 5–10 | Médio | Pilot becomes meaningful | Improve returns + limpeza |

| 20+ | Baixo | Reuse program starts “printing savings” | Padronizar + track IDs |

Practical tips to increase rotations fast

-

Standardize sizes: Fewer SKUs means fewer packing errors.

-

Design for stacking: Lower damage reduces early retirement.

-

Use a simple retirement rule: If the latch fails, aposentar.

eco-friendly EPP foam box

Exemplo do mundo real: Meal-prep style routes often win quickly because boxes return daily on repeat lanes.

eco-friendly EPP foam box

How do you clean and reuse an eco-friendly EPP foam box fast?

Resposta principal: Cleaning is the hidden make-or-break step for an eco-friendly EPP foam box. You need a routine that is fast, seguro, e consistente. If cleaning becomes complicated, training fails. If drying is skipped, odor and label failure follow.

Think of it like dishwashing in a busy restaurant. If it slows down, everything backs up.

eco-friendly EPP foam box

A simple 6-step reuse SOP you can implement

-

Collect: Schedule pickups or capture returns at delivery points.

-

Sort: Separate “ready to wash” from “needs inspection.”

-

Lavar: Use a consistent detergent and time setting.

-

Seco: Dry fully to prevent odor and mold issues.

-

Inspecionar: Check cracks, hinge zones, and lid fit.

-

Re-issue: Return to inventory with a visible “ready” status.

eco-friendly EPP foam box

| Etapa | Time goal | Falha comum | O que isso significa para você |

|---|---|---|---|

| Inspecionar | 15–30 seg. | Nobody checks lids | Hidden failures repeat every trip |

| Lavar | Curto + repetível | Over-complicated chemicals | Training becomes impossible |

| Seco | Must be complete | Wet stacking | Odor, risco de mofo, label loss |

| Re-issue | Simple labeling | No status control | Dirty boxes slip into use

eco-friendly EPP foam box |

Practical tips to prevent cleaning bottlenecks

-

Create a drying zone: A basic rack speeds turnaround.

-

Use visual status tags: “clean / segurar / retire” stops confusion.

-

Don’t debate broken hardware: Retire fast and keep performance consistent.

eco-friendly EPP foam box

Exemplo do mundo real: Adding a drying rack and a quick inspection routine often stabilizes reuse loops immediately.

eco-friendly EPP foam box

How to build an eco-friendly EPP foam box recycling program that works

Resposta principal: “Recyclable” must mean recyclable in practice. For an eco-friendly EPP foam box, that means the box is collected, kept clean, densified when possible, and sent to a real partner or take-back route.

eco-friendly EPP foam box

You don’t need a perfect network. You need a repeatable plan that your team can actually follow.

Eco-friendly EPP foam box recycling program: 5 passos

| Etapa | O que você faz | O que você rastreia | O que isso significa para você |

|---|---|---|---|

| Coleção | Return bin / pallet position | Taxa de retorno (%) | Return rate drives “eco” fast |

| Classificando | Keep EPP clean + separar | Contamination notes | Clean material is easier to process |

| Densifying | Compactar / bale if possible | Volume reduction | Lowers transport + storage pain |

| Partnering | Recycler or take-back loop | Proof of recycling | Stronger compliance story |

| Opinião | Review monthly | Fail reasons | Fix the process, not the box

eco-friendly EPP foam box |

Practical tips that make recycling realistic

-

Label for your team, not marketing: “Return to Dock A” wins every time.

-

Avoid mixed-material add-ons: Fewer glued layers means fewer recycling headaches.

-

Treat damage as data: Cracked corners show where lanes need reinforcement.

eco-friendly EPP foam box

Exemplo do mundo real: Deposit-style internal policies can raise return rates because the rule is simple.

eco-friendly EPP foam box

Reusable EPP cooler box for cold chain: which specs matter most?

Resposta principal: Choose the specs that prevent failure, not the specs that look premium. If teams can’t close the lid correctly every time, insulation performance drops. If latches frustrate operators, compliance drops.

Focus on what changes outcomes: encerramento, wall thickness matched to lane, limpeza fácil, and tracking surfaces.

eco-friendly EPP foam box

Buyer checklist (simples, operator-friendly)

| Especificações | O que procurar | Por que isso importa | O que isso significa para você |

|---|---|---|---|

| Vedação da tampa | Ajuste apertado, repeatable closure | Reduces warm air exchange | Longer hold time with less coolant |

| Espessura da parede | Matched to lane duration | Equilibra o peso + isolamento | Avoid overpaying on short routes |

| Travas | Glove-friendly, simples | Prevents “half-closed” lids | Fewer temperature surprises |

| Drainage/cleaning | Smooth corners, low traps | Faster wash + seco | Less labor, less odor retention |

| Label zone | Painéis planos, scannable IDs | Enables tracking | Better returns + prova

eco-friendly EPP foam box |

Dicas práticas para você

-

Ask “how many handlings per trip?” It clarifies stacking and drop needs.

-

Pick the simplest latch teams will use correctly. Fancy latches fail under rush.

-

Plan basic tracking from day one. Even simple IDs improve return rates.

eco-friendly EPP foam box

Exemplo do mundo real: A simple latch swap can reduce closure errors quickly on high-volume lanes.

eco-friendly EPP foam box

How do you prove eco-friendly EPP foam box claims in 2025?

Resposta principal: Em 2025, “eco-friendly” is moving from marketing to auditable proof. You prove an eco-friendly EPP foam box claim with reuse data, material clarity, and end-of-life documentation. EU packaging policy updates in 2025 are pushing companies toward stronger lifecycle accountability.

eco-friendly EPP foam box

eco-friendly EPP foam box

The “proof folder” checklist you can keep simple

-

Taxa de retorno: % of shipments where the box comes back

-

Average rotations per box: trips per box (even estimates help at first)

-

Taxa de perda: boxes missing per month

-

Taxa de dano: retirements per 100 viagens

-

End-of-life path: where retired boxes go and what happens next

eco-friendly EPP foam box

Practical tips to avoid greenwashing

-

Say what you can prove: “Reusable in our program” beats “planet-saving.”

-

Avoid absolute claims: “100% recycled” is risky without verified data.

-

Track “recycled in practice”: Can you actually collect and process it locally?

eco-friendly EPP foam box

Exemplo do mundo real: Programs get stronger when recycler receipts and return-rate KPIs are part of audits.

eco-friendly EPP foam box

Ferramenta de decisão: Is an eco-friendly EPP foam box right for you?

Pontue cada linha 0–2 (0 = não, 1 = parcialmente, 2 = sim).

-

You can recover boxes on at least 60% de remessas (0–2)

-

You have a place to clean and fully dry caixas (0–2)

-

Your routes repita (mesmos clientes, same lanes) (0–2)

-

Your team can inspect and retire damaged boxes fast (0–2)

-

You have a recycling or take-back option for retired EPP (0–2)

-

You can track box IDs, even simply (0–2)

eco-friendly EPP foam box

Interpretação:

-

0–4: Fix returns and cleaning first.

-

5–8: Pilot-ready (uma pista, one design).

-

9–12: Scale-ready (standardize sizes + monitorando).

eco-friendly EPP foam box

2025 eco-friendly EPP foam box trends and what to do next

Em 2025, the biggest shift is simple: buyers want proof, não promessas. That means rotation tracking, end-of-life planning, and documented cleaning routines.

eco-friendly EPP foam box

Latest developments you’ll see more in 2025

-

Improved foam density: Better insulation without extra weight

-

Modular designs: Easier stacking and storage

-

Tracking-ready surfaces: Label zones built for IDs and scanning

eco-friendly EPP foam box

Informações de mercado nas quais você pode agir

Reusable packaging wins when it reduces labor. If packing becomes faster and damage drops, adoption becomes easy. If cleaning is slow and returns are messy, the system collapses.

Perguntas frequentes

Q1: Is an eco-friendly EPP foam box biodegradable?

Não. Its sustainability comes from long reuse e end-of-life recycling paths, not biodegradation.

eco-friendly EPP foam box

Q2: Can I recycle an eco-friendly EPP foam box in curbside bins?

Sometimes no. Local acceptance varies, so many programs require drop-off or take-back partners.

Q3: How long can an eco-friendly EPP foam box be reused?

Com manuseio adequado, pode ser reutilizado dozens or even hundreds of times. Inspect regularly to protect insulation performance.

eco-friendly EPP foam box

Q4: What’s the biggest operational risk with an eco-friendly EPP foam box?

Returns and cleaning. If boxes don’t come back—or come back wet and dirty—benefits drop quickly.

eco-friendly EPP foam box

Q5: Is an eco-friendly EPP foam box safe for food delivery?

Muitas vezes sim, but “safe” depends on intended use, POP de limpeza, and supplier documentation. Align it with your hygiene plan.

eco-friendly EPP foam box

Q6: What should I track to prove my eco-friendly EPP foam box program works?

Taxa de retorno, rotations per box, taxa de perda, taxa de dano, and where retired boxes go. Simple data beats perfect claims.

eco-friendly EPP foam box

Resumo e recomendações

Um eco-friendly EPP foam box is worth it when you can reuse it many times, clean it quickly, e retire it responsibly. Your biggest wins come from higher return rates, fewer damaged shipments, and more repeatable packing. Comece com uma pista, one box size, and a simple cleaning + inspection SOP. Then scale only after your loop stays stable for several weeks.

Seus próximos passos (rápido e prático)

-

Escolha one repeat lane for a 2-week pilot.

-

Escolher one eco-friendly EPP foam box size with a simple latch.

-

Acompanhar taxa de retorno + damage rate daily.

-

Fix cleaning and drying flow before expanding.

eco-friendly EPP foam box

Sobre Tempk

E tempk, we focus on eco-friendly EPP foam box solutions designed for real cold chain operations. We help you balance insulation performance, durabilidade, and sustainability without adding unnecessary complexity. We also support practical rollout steps like size selection, reuse-loop planning, and simple inspection rules.

eco-friendly EPP foam box

Próximo passo: Compartilhe a duração da sua pista, tamanho da carga útil, and return scenario, and we’ll recommend a practical eco-friendly EPP foam box approach you can pilot quickly.