Transportar o gelato exige precisão e cuidado para manter sua textura cremosa e sabor. Equipamentos eficientes de cadeia de resfriamento de gelatos são essenciais para preservar sua qualidade durante o transporte, garantindo que a temperatura perfeita seja mantida desde a produção até a entrega. Neste artigo, we will explore the latest advancements in corrente legal technology for gelato, focando em equipamentos que otimizam o controle de temperatura.

Pontos -chave:

-

Importância de Equipamentos Eficientes para Envio de Gelato: Learn why maintaining the right temperature is crucial for preserving gelato’s texture and flavor.

-

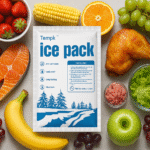

Componentes principais do equipamento de remessa de gelato: Conheça o equipamento que mantém seu gelato fresco, incluindo recipientes isolados, pacotes de gel, e dispositivos de monitoramento de temperatura.

-

Sustentabilidade e Eficiência de Custos: Entenda como as tecnologias modernas de cadeia de resfriamento contribuem para a economia de energia e a sustentabilidade ambiental.

Por que equipamentos eficientes são essenciais para o envio de gelatos?

O gelato é um produto delicado que deve ser mantido em temperatura estável, baixa temperatura para preservar sua textura cremosa. Equipamentos eficientes de cadeia de frio garantem que a cadeia de frio permaneça intacta, preventing melting, degradação de textura, or contamination during transit. This equipment includes insulated containers, pacotes de gel, and sophisticated temperature monitoring devices.

Core Components of Cool Chain Gelato Equipment

-

Recipientes Isolados: These specially designed boxes maintain the required low temperature during transport.

-

Pacotes de gel e gelo seco: Used to keep gelato frozen during shipment, ensuring it stays at the optimal temperature.

-

Dispositivos de monitoramento de temperatura: These sensors and real-time tracking systems ensure the gelato is always stored at the correct temperature, providing alerts if conditions change.

How Does Insulation Affect Gelato Quality During Shipping?

Proper insulation is crucial for maintaining gelato’s texture and preventing unwanted temperature fluctuations. High-quality insulation prevents gelato from melting or forming ice crystals, which could ruin its smooth, creamy consistency.

Types of Insulated Packaging for Gelato Shipping

-

VIP (Painéis isolados a vácuo): Offers superior insulation and long-term temperature stability, ideal for extended transit times.

-

PPE (Polipropileno Expandido): Leve, durável, and perfect for short-term transport.

-

Espuma de poliuretano: A reliable option for standard shipping but bulkier than VIP and EPP solutions.

Exemplo do mundo real: A major gelato producer switched to VIP insulation for shipments and experienced a 30% reduction in temperature-related complaints, melhorando significativamente a satisfação do cliente.

The Role of Temperature Monitoring Systems in Gelato Shipping

Temperature monitoring systems are vital for ensuring that gelato stays at the correct temperature throughout its journey. These systems allow shippers to track temperature fluctuations in real-time and intervene when necessary, preventing spoilage and ensuring that gelato arrives at its destination in perfect condition.

| Dispositivo | Função | Benefício para o usuário |

|---|---|---|

| Sensores IoT | Tracks temperature in real-time | Garante controle preciso da temperatura |

| Registradores de dados | Records temperature over time | Provides transparency and compliance |

| GPS-Enabled Tracking | Monitors location and conditions | Reduces errors and ensures timely delivery |

How Does Efficient Equipment Contribute to Sustainability?

Many modern cool chain solutions are designed with sustainability in mind. Por exemplo, EPP insulated boxes are made from recyclable materials, while energy-efficient temperature control systems minimize the carbon footprint. Investing in eco-friendly equipment reduces waste and supports a sustainable business model.

Practical Tips for Gelato Shipping Efficiency

-

Use multi-use insulation systems: Embalagens reutilizáveis reduzem desperdício e custos.

-

Implement real-time tracking: Stay on top of temperature changes and avoid spoilage.

-

Store gelato at the right temperature before shipping: Ensure your gelato is pre-cooled and ready for transport.

What Are the Latest Innovations in Cool Chain Gelato Equipment?

Em 2025, gelato shipping technology continues to evolve with innovations that improve efficiency, sustentabilidade, and product integrity. Algumas tendências principais incluem:

-

Resfriamento Inteligente: Adaptive cooling systems adjust to fluctuations in temperature to maintain optimal conditions.

-

AI-Driven Packaging Solutions: Packaging materials that automatically adjust to external conditions to maintain the ideal internal temperature.

-

Biodegradable Insulation: Materials that naturally break down, reduzindo o impacto ambiental.

How Does AI Improve Gelato Shipping?

AI is transforming the cold chain industry, and gelato shipping is no exception. AI-driven systems optimize cooling by adjusting temperature settings based on real-time data, improving product quality while reducing energy consumption.

Exemplo: A gelato distributor adopted AI-powered temperature adjustments, which led to improved product quality and reduced energy use.

Perguntas frequentes

What is the ideal temperature for shipping gelato?

The ideal temperature is -20°C (-4°F) or lower to prevent melting and preserve the gelato’s texture.

How long can gelato stay frozen during shipping?

With proper equipment, gelato can stay frozen for up to 72 horas, depending on insulation and cooling methods.

Conclusão

Efficient cool chain gelato equipment is essential for ensuring the highest quality during transport. By using advanced technologies such as insulation, monitoramento de temperatura em tempo real, and eco-friendly solutions, businesses can preserve the quality of gelato while reducing their environmental footprint. Stay ahead of the curve by integrating these technologies into your shipping processes to deliver fresh, high-quality gelato every time.

Recomendações acionáveis:

-

Invest in smart temperature monitoring systems to ensure proper cooling and avoid temperature fluctuations.

-

Mudar para reutilizável, Embalagens ecológicas to reduce waste and improve sustainability.

-

Adopt AI-driven cooling systems for dynamic temperature adjustments during shipping.