Como o mercado de biovegetais da cadeia fria está crescendo e o que isso significa para você 2025

O mercado global de biovegetais da cadeia de frio está se expandindo rapidamente à medida que os consumidores preocupados com a saúde exigem produtos frescos, produtos livres de produtos químicos e empresas correm para reduzir resíduos e emissões de carbono. A tecnologia da cadeia de frio mantém os vegetais orgânicos a uma temperatura controlada, desde o campo até à mesa, reduzindo a deterioração e garantindo a qualidade. Em 2024 a indústria mundial da cadeia de frio foi estimada em USD 228.3 bilhão e tem previsão de atingir USD 372 bilhão por 2029 à medida que o comércio eletrônico e as vendas de alimentos processados crescem. Do lado da demanda, o mercado de hortaliças orgânicas foi avaliado em USD 34.26 bilhão em 2024 e poderia superar USD 94.81 bilhão por 2033. Este guia responde às suas perguntas sobre por que as cadeias de frio são importantes, o que impulsiona o crescimento do mercado e como a tecnologia e a sustentabilidade se cruzam 2025.

Por quelogística da cadeia de frio são essenciais para vegetais orgânicos – e como reduzem a perda de alimentos e as emissões de gases com efeito de estufa.

Principais drivers de crescimento nos mercados globais da cadeia de frio e de biovegetais, incluindo comportamento do consumidor e tendências regionais.

Desafios e barreiras de custos como preços premium e custos de certificação.

Tecnologias emergentes como sensores IoT, Otimização de IA e blockchain que estão remodelando as cadeias de frio.

Sustentabilidade e impactos climáticos, além de estudos de caso reais sobre redução de resíduos e emissões.

Por que precisamos de uma cadeia de frio para vegetais biológicos?

Manter os vegetais orgânicos frescos envolve mais do que apenas refrigeração. Sem cadeia de frio, em volta 13 % de todos os alimentos produzidos são perdidos após a colheita, com vegetais perecíveis particularmente vulneráveis. Esta perda poderia alimentar quase 950 milhões de pessoas, e ocorre principalmente porque as temperaturas flutuam durante o armazenamento e transporte. Além da fome, a perda de alimentos é responsável 8 - 10 % das emissões globais de gases com efeito de estufa. Um estudo da Universidade de Michigan descobriu que cadeias de abastecimento totalmente refrigeradas poderiam eliminar 620 milhões de toneladas de desperdício alimentar e corte emissões relacionadas com resíduos por 41 %.

Sistemas de cadeia de frio combinar armazéns refrigerados, caminhões, contêineres e entrega na última milha para manter temperaturas estáveis desde a colheita até o consumidor. Para vegetais orgânicos, onde a deterioração acelera sem conservantes químicos, o controle de temperatura garante a retenção de nutrientes e evita o crescimento microbiano. Os pequenos agricultores também beneficiam: pilotos gostam ColdHubs na Nigéria usar câmaras frigoríficas movidas a energia solar que permitem aos agricultores armazenar produtos por dias em vez de horas, reduzindo perdas e aumentando a renda. Na Índia, refrigeração de bananas reduziu o desperdício em 20 % e triplicou a renda dos agricultores.

Os números por trás do desperdício de alimentos e do impacto da cadeia de frio

| Métrica | Valor | Fonte | O que isso significa para você |

| Perda de alimentos após a colheita devido à cadeia de frio inadequada | 526 milhões de toneladas (≈ 12 % da alimentação mundial) | Relatório PNUMA/FAO | Uma quantidade impressionante de alimentos é deitada fora antes mesmo de chegar aos mercados – cadeias de frio melhoradas poderiam alimentar milhões de pessoas. |

| População estimada que poderia ser alimentada se as perdas globais de alimentos pós-colheita fossem reduzidas | ~1 bilhão de pessoas | PNUMA | Destaca o impacto social; uma melhor infraestrutura da cadeia de frio tem uma ligação direta com a segurança alimentar. |

| Emissões de GEE provenientes da perda de alimentos relacionada com a cadeia de frio | 1 gigatoneladas de CO₂e (~2 % das emissões globais) | PNUMA | Reduzir o desperdício de alimentos reduz a poluição por carbono, alinhamento com metas de sustentabilidade. |

| Participação nas emissões de GEE provenientes da própria cadeia de frio alimentar | ≈ 4 % das emissões globais | PNUMA | Mostra que enquanto a refrigeração consome energia, as emissões de alimentos desperdiçados são ainda maiores; sistemas eficientes são fundamentais. |

| Redução de resíduos quando as cadeias de abastecimento estão totalmente refrigeradas | 620 milhões de toneladas, emissões diminuídas 41 % | Estudo da Universidade de Michigan | Evidências de que o investimento em infraestruturas da cadeia de frio produz benefícios ambientais imediatos. |

Dicas práticas para reduzir o desperdício em casa

Escolha produtos orgânicos locais: Quanto mais curta for a cadeia de abastecimento, menos oportunidades de deterioração. Procure mercados de agricultores ou agricultura apoiada pela comunidade (CSA) caixas.

Aprenda o armazenamento adequado: Mantenha as folhas verdes em sacos respiráveis e as raízes em local fresco, lugares escuros. Muitos varejistas agora fornecem guias de armazenamento.

Planeje refeições: Comprar apenas o que você precisa reduz a chance de os produtos estragarem na sua geladeira.

Apoiar empresas que utilizam cadeia de frio sustentável: Algumas marcas anunciam o uso de energia renovável ou refrigerantes naturais. Suas escolhas de compra incentivam o investimento em sistemas mais ecológicos.

Caso do mundo real: Uma cooperativa de produtores de batata-doce no Quénia fez parceria com uma empresa móvel de armazenamento frigorífico. Alugando pequenas caixas refrigeradas em pontos de coleta, os agricultores prolongaram o prazo de validade de um para cinco dias e negociaram melhores preços nos mercados urbanos.

O que está impulsionando o crescimento no mercado da cadeia de frio?

Várias forças convergentes explicam por que se prevê que a indústria da cadeia de frio cresça a partir de USD 228.3 bilhão em 2024 para USD 372 bilhão por 2029 (Cagr 10.3 %).

Comércio eletrônico e expectativas de entrega: As vendas de alimentos online aumentaram durante a pandemia, e os consumidores agora esperam a entrega de produtos frescos no dia seguinte. A infraestrutura da cadeia de frio garante que os vegetais biológicos cheguem às famílias sem perder a sua integridade orgânica.

Demanda por produtos perecíveis de alto valor: A urbanização e o aumento dos rendimentos na Ásia-Pacífico aumentaram o consumo de carne, laticínio, frutas e vegetais frescos. Os segmentos de panificação e carne processada da China estão em rápida expansão, estimulando investimentos em armazéns e veículos refrigerados.

Regulamentações rigorosas: Leis de segurança alimentar (por exemplo, os EUA. Lei de Modernização da Segurança Alimentar) exigem rastreabilidade e monitoramento de temperatura. A não conformidade leva a recalls, tornando essenciais sistemas robustos de cadeia de frio.

Saúde e sustentabilidade: Os consumidores associam vegetais orgânicos à saúde pessoal e ao impacto ambiental. A maior conscientização sobre resíduos de pesticidas e pegadas de carbono incentiva as marcas a investir em cadeias de frio ecologicamente corretas

Crescimento do mercado visualizado

O gráfico a seguir traça o tamanho projetado do mercado global da cadeia de frio de 2024 para 2029. O crescimento é constante, refletindo o investimento contínuo em toda a cadeia de abastecimento.

Ásia-Pacífico lidera o caminho

O A região Ásia-Pacífico domina o mercado da cadeia de frio, impulsionado pelas crescentes classes médias da China e da Índia. A Europa Ocidental e a América do Norte investem fortemente em automação e refrigerantes naturais, enquanto as economias emergentes se concentram no armazenamento e transporte básicos. As diferenças regionais criam oportunidades para soluções personalizadas.

Sugestões centradas no usuário

Para produtores: Considere investir em pré-resfriamento e refrigeração na fazenda para manter a qualidade logo após a colheita. Unidades movidas a energia solar estão se tornando mais acessíveis.

Para gerentes de logística: Use a otimização de rotas por IA para reduzir o tempo de transporte e o uso de combustível. Integre sensores IoT que monitoram temperatura e umidade em tempo real.

Para formuladores de políticas: Fornecer subsídios ou incentivos fiscais para infraestruturas sustentáveis da cadeia de frio. Apoiar programas de treinamento para pequenos agricultores adotarem tecnologias de refrigeração.

Caso do mundo real: Durante um piloto na Índia, uma cadeia de fornecimento de kiwis usava caixas equipadas com sensores que transmitiam dados de temperatura para um painel central. Quando as temperaturas subiram acima de um limite, alertas permitiram intervenção rápida, evitando a deterioração e mantendo a firmeza da fruta.

Mercado de Bio Vegetais: Demanda, Prêmios e Desafios de Certificação

Vegetais orgânicos são sinônimo de saúde e sustentabilidade, mas eles vêm com preços mais altos e padrões complexos. De acordo com o Relatório de insights de crescimento global, o mercado de vegetais orgânicos ficou em USD 34.26 bilhão em 2024 e está projetado para atingir USD 38.36 bilhão em 2025 e USD 94.81 bilhão por 2033, com um taxa composta de crescimento anual de 11.97 %. No nível da fazenda, prevê-se que o segmento de agricultura orgânica de hortaliças cresça de USD 10.69 bilhão em 2024 para USD 14.24 bilhão por 2029.

Por que os consumidores estão se tornando orgânicos

Consciência de saúde: Os consumidores preocupam-se com resíduos de pesticidas e desreguladores hormonais em produtos convencionais. Vegetais orgânicos são vistos como mais limpos e nutritivos.

Preocupação ambiental: A agricultura biológica evita fertilizantes sintéticos e promove a biodiversidade, atraente para compradores preocupados com o meio ambiente.

Sabor e qualidade percebidos: Muitas pessoas acreditam que os produtos orgânicos têm melhor sabor e textura superior, justificando o prêmio de preço.

Alinhamento de estilo de vida: Alimentos naturais se alinham com veganos, estilos de vida vegetarianos e focados no bem-estar. Geração Y, em particular, estão impulsionando o crescimento; 33 % classifique os vegetais orgânicos como prioridade máxima.

Prêmios de preço: Os custos de se tornar orgânico

Os vegetais cultivados organicamente muitas vezes carregam um 25 - 40 % prêmio de preço devido à agricultura intensiva em mão-de-obra, rendimentos mais baixos, custos de certificação e requisitos rigorosos da cadeia de frio. A certificação pode ser particularmente onerosa para pequenos produtores em regiões de baixa renda: alguns relatórios observam que as taxas de certificação podem exceder 50 % da renda anual de uma fazenda.

Exemplos de preço premium

| Vegetal | Preço Orgânico Premium | Implicações para os consumidores |

| Alface americana | 179.3 % premium sobre o convencional | Mais que dobrando o preço, refletindo a alta demanda e a oferta limitada. |

| Couve de Bruxelas | 126.8 % prêmio | Mostra diferença significativa de custo; comprar opções orgânicas locais sazonais pode mitigar custos. |

| Maçãs Vovó Smith | 123.3 % prêmio | Enfatiza o valor agregado atribuído à fruta orgânica; pode encorajar os consumidores a priorizar tipos de produtos. |

| Cenouras | 62.1 % prêmio | Salienta que nem todos os vegetais biológicos têm prémios extremos; o preço varia de acordo com a cultura e a região. |

Desafios de certificação

A certificação orgânica envolve auditorias rigorosas, manutenção de registros e conformidade com padrões nacionais ou internacionais. Os pequenos agricultores nos países em desenvolvimento enfrentam barreiras como:

Altas taxas e burocracia: Organismos de certificação exigem registros detalhados de insumos e processos, consumindo tempo e dinheiro.

Atualizações de infraestrutura: Os agricultores biológicos podem necessitar de armazenamento e transporte separados para evitar contaminação, adicionando custos à cadeia de frio.

Acesso ao mercado: Sem certificação, os agricultores não podem rotular seus produtos como orgânicos, limitando o acesso aos mercados premium.

Alfabetização digital: Muitos sistemas de certificação dependem de ferramentas de rastreabilidade digital; agricultores em áreas remotas podem não ter acesso confiável à Internet.

Tendências de consumo e varejo

As estatísticas mostram a adopção generalizada de vegetais orgânicos nos mercados desenvolvidos: 61 % dos EUA. famílias compram vegetais orgânicos, 45 % das redes de varejo alocam espaço nas prateleiras para produtos orgânicos, e 29 % dos vegetais orgânicos são comprados online. Os varejistas estão expandindo as assinaturas de entrega em domicílio e embalagem ecológica para atrair compradores ambientalmente conscientes. Enquanto isso, a ascensão da agricultura vertical e da agricultura ambiental controlada traz abastecimento durante todo o ano e reduz as distâncias de transporte.

Visualizando o crescimento do mercado orgânico

O gráfico abaixo ilustra o crescimento projetado do mercado global de vegetais orgânicos de 2024 através 2033. A tendência ressalta o forte apetite por alimentos sustentáveis.

Orientação Prática para Consumidores

Procure rótulos confiáveis: Na América do Norte, USDA Organic garante conformidade com os padrões federais. Na Europa, procure o símbolo Euroleaf. A certificação garante que os requisitos da cadeia de frio sejam atendidos.

Compre sazonal e local: Os vegetais orgânicos sazonais são muitas vezes mais baratos porque se alinham com os ciclos naturais de colheita e requerem menos energia para refrigeração.

Junte-se a um CSA ou compartilhamento de fazenda: Esses programas oferecem caixas semanais de produtos orgânicos frescos, muitas vezes a um custo menor do que comprar individualmente.

Compare varejo vs.. on-line: As plataformas online podem oferecer melhores ofertas ou assinaturas, mas verifique as condições de entrega para garantir a refrigeração adequada.

Drivers de custos e barreiras no mercado de biovegetais da cadeia fria

Embora a demanda seja forte, o mercado de biovegetais da cadeia de frio enfrenta vários obstáculos:

Consumo de energia: A refrigeração utiliza energia significativa e, se alimentado por combustíveis fósseis, contribui para as emissões. No entanto, a energia renovável e as tecnologias energeticamente eficientes estão a reduzir este fardo.

Lacunas de infraestrutura: Os países em desenvolvimento carecem de armazéns refrigerados e transporte suficientes. O Relatório PNUMA/FAO observa que se os países em desenvolvimento tivessem a mesma capacidade de cadeia de frio que os países industrializados, eles poderiam salvar 144 milhões de toneladas de alimentos.

Altos custos de capital: A construção de instalações de armazenamento refrigerado e a compra de veículos refrigerados exigem um grande investimento inicial. Opções de financiamento como parcerias público-privadas e microarrendamento para agricultores são soluções emergentes.

Complexidade regulatória: Diferentes países têm definições variadas de “orgânico” e diferentes padrões de cadeia de frio, complicando o comércio transfronteiriço.

Sensibilidade ao preço ao consumidor: Nem todos podem comprar produtos orgânicos premium; colmatar esta lacuna requer maior eficiência para reduzir custos sem comprometer a qualidade.

Mesa: Principais fatores de custo vs.. Soluções

| Gerador de custos | Desafio | Soluções potenciais | Beneficiar para você |

| Uso de energia | Alta demanda de eletricidade para refrigeração | Adoção de painéis solares, sistemas de recuperação de calor e refrigerantes de baixo GWP | Custos operacionais mais baixos e pegada de carbono reduzida |

| Lacunas de infraestrutura | Falta de armazenamento refrigerado, especialmente nas áreas rurais | Câmaras frigoríficas móveis, micro armazéns e centros de frio comunitários | Redução das perdas pós-colheita e melhoria da renda do agricultor |

| Investimento de capital | Alto custo de construção de ativos da cadeia de frio | Modelos de locação, logística compartilhada, subsídios governamentais | Mais jogadores podem entrar no mercado, aumentando a concorrência e reduzindo os preços |

| Custos de certificação | A conformidade com os padrões orgânicos é cara | Esquemas de certificação de grupo, plataformas de rastreabilidade digital | A partilha de custos reduz a carga sobre os agricultores individuais |

| Acessibilidade do consumidor | Prêmios de preços elevados para vegetais orgânicos | Melhorias de eficiência, redução de desperdício, escala de produção | Preços mais acessíveis para você sem sacrificar a qualidade |

Sugestões para diferentes partes interessadas

Agricultores: Colaborar com cooperativas para compartilhar os custos de certificação e armazenamento refrigerado. Explore a certificação de grupo para reduzir taxas e adote a manutenção de registros digitais para auditorias mais fáceis.

Varejistas: Diversifique sua linha de produtos orgânicos com opções acessíveis. Oferecer produtos orgânicos “imperfeitos” a preços mais baixos para reduzir o desperdício.

Consumidores: Esteja aberto a vegetais orgânicos disformes ou manchados; muitas vezes têm o mesmo sabor e custam menos. Apoiar marcas que divulgam as suas práticas na cadeia de abastecimento e investem em soluções sustentáveis de cadeia de frio.

Caso do mundo real: No Vietnã, um grupo de pequenos produtores de vegetais orgânicos reuniu recursos para comprar um caminhão refrigerado. Com o apoio de ONGs locais, eles negociaram custos de certificação mais baixos e obtiveram acesso direto a supermercados urbanos, aumentando suas margens de lucro.

Tendências tecnológicas moldando cadeias de frio e vegetais biológicos em 2025

O setor de biovegetais da cadeia de frio está a adotar a digitalização e a sustentabilidade. Estas inovações não só reduzem o desperdício, mas também melhoram a transparência e a confiança do consumidor.

Internet das coisas (IoT) e sensores

Dispositivos IoT rastreiam a temperatura, umidade, vibração e localização em toda a cadeia de abastecimento. Sensores sem fio enviam dados para plataformas em nuvem, permitindo monitoramento e alertas em tempo real. Esta transparência ajuda os gestores de logística a reagir rapidamente aos desvios, prevenir a deterioração e manter os requisitos de certificação orgânica.

Inteligência artificial (IA) e análise preditiva

A IA usa dados históricos e aprendizado de máquina para otimizar rotas de entrega e gerenciamento de estoque, reduzindo o tempo de viagem e o consumo de combustível. Modelos preditivos prevêem a demanda e recomendam os melhores tempos de colheita e envio para minimizar o uso de energia e a deterioração. Algumas empresas usam IA para prever a maturação e ajustar automaticamente as configurações de refrigeração.

Blockchain e rastreabilidade

Blockchain fornece um ambiente seguro, livro razão à prova de adulteração de cada transação e leitura de temperatura. Os consumidores podem escanear um código QR para visualizar a origem da fazenda, status de certificação e toda a jornada de seus vegetais orgânicos. Isso promove a confiança e impede a fraude, o que é crucial quando os consumidores pagam um prémio.

Automação e Robótica

Armazéns frigoríficos estão adotando empilhadeiras autônomas, selecionadores robóticos e sistemas de armazenamento automatizados. Essas tecnologias aceleram o manuseio, reduzir os custos trabalhistas e minimizar o erro humano. Drones estão sendo testados para inspeção remota de temperatura em grandes instalações de armazenamento.

Energia Renovável e Refrigerantes Naturais

Para reduzir as emissões de gases com efeito de estufa, empresas estão instalando painéis solares, turbinas eólicas e armazenamento de energia térmica em instalações de armazenamento refrigerado. Refrigerantes naturais como amônia e CO₂ substituem hidrofluorocarbonetos de alto GWP. Materiais de mudança de fase e isolamento a vácuo reduzem a energia necessária para manter baixas temperaturas.

Gêmeos Digitais e Simulação

Um gêmeo digital é uma réplica virtual de um sistema físico. Na cadeia de frio, gêmeos digitais simulam condições de armazém, rotas de transporte e uso de energia. Isso ajuda os planejadores a identificar gargalos e testar melhorias sem arriscar remessas reais.

Edge Computing e conectividade 5G

Dispositivos de borda processam dados de sensores localmente, permitindo decisões rápidas mesmo quando a conectividade da rede é instável. 5As redes G fornecem informações confiáveis, comunicação de alta largura de banda para rastreamento em tempo real através de fronteiras e áreas remotas.

Dicas para adotar tecnologia

Comece pequeno: Experimente uma tecnologia, como sensores IoT, antes de escalar para automação total.

Escolha sistemas interoperáveis: Garanta que novos dispositivos possam ser integrados ao seu software e equipamento existente.

Invista em treinamento: A equipe precisa entender as ferramentas digitais; considere parcerias com fornecedores de tecnologia que oferecem treinamento e suporte.

Priorize a segurança dos dados: Os sistemas Blockchain e em nuvem devem cumprir os regulamentos de privacidade; trabalhar com fornecedores que atendam aos padrões internacionais.

Caso do mundo real: Uma empresa de logística na Espanha implementou caminhões refrigerados movidos a energia solar com otimização de rotas por IA. Dentro de seis meses, eles relataram economia de combustível de 18 %, menores custos de manutenção e maiores taxas de entrega no prazo.

Sustentabilidade e Impacto Climático

Os vegetais biológicos da cadeia de frio proporcionam benefícios à saúde, mas também levantam questões de sustentabilidade. A perda e o desperdício de alimentos representam 8 - 10 % das emissões globais de gases com efeito de estufa. Ao mesmo tempo, a própria refrigeração produz emissões. O desafio é reduzir o desperdício e, ao mesmo tempo, minimizar a energia e os refrigerantes utilizados.

Compensações de emissões

Embora a melhoria das cadeias de frio possa reduzir o desperdício alimentar, também consomem eletricidade e muitas vezes dependem de refrigerantes com elevado potencial de aquecimento global (PAGs). Felizmente, avanços tecnológicos - energia renovável, recuperação de calor, refrigerantes naturais – permitem a expansão da cadeia de frio sem aumentar proporcionalmente as emissões.

Iniciativas políticas e industriais

Compromisso Global de Metano: Alguns governos pretendem reduzir para metade as emissões de metano provenientes do desperdício alimentar antes de 2030, pressionando por uma infraestrutura melhorada da cadeia de frio.

Acordo Verde da UE e CBAM: O Mecanismo Europeu de Ajuste de Carbono nas Fronteiras tributará os bens importados com base na sua intensidade de carbono. Isto poderia incentivar os exportadores a adotar cadeias de frio mais ecológicas.

Programa de Cadeias de Frio Alimentares Sustentáveis: PNUMA e FAO incentivam os países em desenvolvimento a modernizarem as cadeias de frio com tecnologias de baixas emissões. Projetos na Nigéria e na Índia demonstram como o armazenamento refrigerado moderno reduz o desperdício e melhora os meios de subsistência.

Como você pode contribuir

Reduza o desperdício de alimentos em casa: Planeje refeições, use sobras de forma criativa e faça compostagem de sobras.

Escolha marcas com embalagens e transporte sustentáveis: Alguns produtores utilizam embalagens biodegradáveis e investem em logística verde.

Mudança de política de apoio: Defende subsídios para refrigeração renovável e infraestrutura melhorada nos países em desenvolvimento.

Eduque sua rede: Partilhar informações sobre os impactos ambientais do desperdício alimentar e a importância das cadeias de frio.

Caso do mundo real: Numa parceria público-privada na África Oriental, pequenos pescadores ganharam acesso a câmaras frigoríficas movidas a energia solar em barcos. Deterioração caiu de 25 % para 5 %, os rendimentos aumentaram e as comunidades reduziram a dependência do gelo produzido com geradores a diesel.

2025 Desenvolvimentos e Tendências

Ficar à frente da curva significa estar atento a novos desenvolvimentos. Aqui estão as últimas tendências que moldam o mercado de biovegetais da cadeia de frio em 2025:

Tecnologia & Inovação

Nanoembalagens: Filmes biodegradáveis infundidos com nanopartículas prolongam a vida útil e sinalizam deterioração através de mudanças de cor.

Veículos de entrega autônomos: Projetos piloto utilizam vans elétricas e drones equipados com compartimentos refrigerados para distribuição de última milha.

Sensores avançados: Os sensores da próxima geração não apenas medem a temperatura, mas também detectam gás etileno e contaminação microbiana, permitindo intervenções preditivas.

Cadeia de frio como serviço (CCaaS): Start ups oferecem armazenamento refrigerado e transporte por assinatura, reduzindo a barreira à entrada de pequenos produtores.

Mercado & Comportamento do Consumidor

Nutrição personalizada: Aplicativos baseados em IA analisam dados de saúde individuais e recomendam caixas personalizadas de vegetais orgânicos, entregue através de logística com temperatura controlada.

Comércio eletrônico transfronteiriço: Mais consumidores encomendam vegetais orgânicos especiais do exterior, crescente demanda por redes de cadeia de frio contínuas que atendam a vários padrões regulatórios.

Embalagem de economia circular: Empresas adotam contêineres reutilizáveis com sistemas de depósito; consumidores devolvem embalagens para higienização e reutilização.

Política & Regulamento

Rotulagem de carbono: Alguns supermercados agora exibem pegadas de carbono nos rótulos dos produtos. Vegetais orgânicos transportados através de cadeias de frio ecológicas apresentam menor pegada, apelando para compradores conscientes.

Zonas de emissão zero: Cidades como Londres e Amsterdã restringem veículos movidos a combustíveis fósseis; fornecedores de logística implantam caminhões frigoríficos elétricos para cumprir.

Leis aprimoradas de rastreabilidade de alimentos: Os governos exigem registos digitais de temperatura e localização para alimentos de alto risco, acelerando a adoção de IoT e blockchain.

Desenvolvimentos da Indústria

Integração vertical: Grandes varejistas adquirem fazendas e empresas de logística da cadeia de frio para controlar a qualidade e garantir o abastecimento durante todo o ano.

Plataformas logísticas colaborativas: Agricultores, atacadistas e varejistas compartilham recursos de transporte para maximizar a utilização da carga, reduzindo custos e emissões.

Insights de mercado

Os analistas prevêem a consolidação contínua entre os fornecedores da cadeia de frio à medida que as economias de escala reduzem os custos. No entanto, também há espaço para players de nicho especializados em produtos orgânicos locais ou premium. Ásia-Pacífico continuará a ser o maior mercado, enquanto Europa Ocidental espera-se que veja a adoção mais rápida de tecnologias sustentáveis de cadeia de frio. O crescimento também é impulsionado pela crescente disponibilidade de vegetais orgânicos através de canais on-line, com plataformas de comércio eletrônico que oferecem caixas de assinatura e sortimentos personalizados.

Perguntas frequentes

Pergunta 1: O que significa “cadeia de frio” para vegetais orgânicos?

A cadeia de frio é um sistema de abastecimento com temperatura controlada que mantém os vegetais orgânicos frescos desde a colheita até o consumo. Inclui refrigeração em todas as fases – pré-resfriamento, armazenar, transporte e varejo – para manter a qualidade e a segurança. Sem isso, produtos orgânicos estragam rapidamente, aumentando resíduos e emissões.

Pergunta 2: Por que os vegetais orgânicos são mais caros?

A agricultura biológica utiliza práticas intensivas em mão-de-obra, proíbe pesticidas sintéticos e muitas vezes produz menos produtos do que os métodos convencionais. Os custos de certificação e os requisitos mais rigorosos da cadeia de frio aumentam as despesas, resultando em um 25 - 40 % prêmio. No entanto, o aumento da demanda e a melhoria da logística estão reduzindo gradualmente os preços.

Pergunta 3: Como a IoT e o blockchain melhoram a cadeia de frio?

Sensores IoT monitoram temperatura e umidade em tempo real, enviando alertas se os limites forem violados. Blockchain registra esses pontos de dados em um livro-razão seguro, garantindo que ninguém possa adulterar as informações. Esta transparência ajuda os retalhistas e os consumidores a confiar que os vegetais biológicos permanecem em conformidade com os padrões de qualidade e certificação..

Pergunta 4: A melhoria das cadeias de frio pode reduzir as alterações climáticas?

Sim. O desperdício de alimentos produz metano e é responsável por 8 - 10 % das emissões globais de GEE. A refrigeração adequada reduz a deterioração, impedindo a liberação de metano da decomposição de alimentos. Embora a refrigeração consuma energia, a adoção de energia renovável e refrigerantes naturais pode minimizar o impacto climático líquido.

Pergunta 5: Existem formas acessíveis para os pequenos agricultores participarem na cadeia de frio??

Centros de frio comunitários, armazenamento móvel e logística cooperativa permitem que pequenos agricultores compartilhem custos. Unidades movidas a energia solar e modelos pré-pagos reduzem as barreiras de entrada. A certificação de grupo e as plataformas digitais também podem reduzir os encargos administrativos, permitindo que pequenos agricultores tenham acesso aos mercados orgânicos.

Resumo e recomendações

Resumindo, o mercado de biovegetais da cadeia de frio está preparado para uma expansão significativa. Uma cadeia de frio robusta reduz o desperdício de alimentos, aumenta a segurança alimentar e apoia a crescente procura de vegetais biológicos. A indústria global da cadeia de frio deverá crescer até USD 372 bilhão por 2029, enquanto o mercado de vegetais orgânicos poderia exceder USD 94 bilhão por 2033. Consumidores, reguladores e empresas estão impulsionando a mudança através da demanda por alimentos mais saudáveis, compromissos de sustentabilidade e inovações digitais. No entanto, os desafios permanecem: altos custos, lacunas de infraestrutura e processos de certificação complexos podem dificultar o acesso. Para ter sucesso, as partes interessadas devem investir em tecnologias energeticamente eficientes, colaborar na logística e defender políticas de apoio. Cadeias de fornecimento transparentes e opções orgânicas acessíveis conquistarão a confiança dos clientes e acelerarão o crescimento.

Plano de Ação para Leitores

Apoie marcas sustentáveis: Escolha produtos de empresas que utilizam cadeias de frio com energia renovável e cadeias de abastecimento transparentes.

Eduque você e sua comunidade: Compartilhe informações sobre a ligação entre o desperdício de alimentos, cadeias de frio e mudanças climáticas.

Defensor da mudança de política: Incentivar os governos locais a financiar infra-estruturas da cadeia de frio e a simplificar a certificação orgânica.

Mantenha-se informado: Fique de olho nas novas tecnologias como IA e blockchain que tornarão os vegetais orgânicos mais acessíveis e baratos.

Considere sua própria pegada: Reduzir o desperdício alimentar pessoal, compre produtos orgânicos sazonais e restos de compostagem.

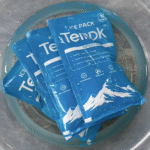

Sobre Tempk

A Tempk é fornecedora líder de tecnologia de cadeia de frio e serviços de consultoria. Somos especializados em projetar soluções de armazenamento e transporte refrigerado com eficiência energética, ajudando os agricultores, operadores logísticos e varejistas entregam produtos frescos, produtos orgânicos aos consumidores. Nossas soluções incorporam Monitoramento da IoT, Otimização de IA e refrigerantes naturais, garantindo a conformidade com as mais recentes regulamentações e metas de sustentabilidade. Trabalhando com Tempk, você obtém acesso a inovações de ponta e orientação especializada adaptada à sua cadeia de suprimentos.

Pronto para melhorar sua cadeia de frio? Contacte-nos para uma avaliação personalizada e descubra como as nossas soluções podem reduzir o desperdício, reduza custos e melhore a qualidade de seus vegetais orgânicos.