As placas de gelo seco estão se tornando cada vez mais essenciais para a logística sensível à temperatura, especialmente em indústrias como farmacêutica, comida, e transporte de amostras biológicas. Understanding how to properly activate dry ice pack sheets ensures maximum performance, enabling you to maintain sub-zero temperatures for longer durations, which is vital for maintaining the integrity of your products during transit.

-

What are dry ice pack sheets and how do they work?

-

How to activate dry ice pack sheets effectively for optimal performance?

-

What factors influence the performance of activated dry ice packs?

-

How long do activated dry ice pack sheets last?

-

How can dry ice pack sheets optimize your cold chain logistics?

O que são folhas de gelo seco e como funcionam?

As folhas de gelo seco são flexíveis, reusable cold packs that use a superabsorbent polymer to absorb water and achieve extremely low freezing temperatures. They are designed to keep perishable goods, Suprimentos médicos, and other temperature-sensitive items cold for extended periods, much longer than regular gel packs.

Quando ativado, these sheets undergo a process where a polymer inside absorbs water and forms a hydrogel, freezing to temperatures as low as -21°C (-40°F), far below traditional ice or gel pack freezing capabilities. This feature makes them ideal for cold chain logistics.

Principais benefícios das folhas de gelo seco:

-

Flexibilidade: These sheets are more adaptable than solid dry ice or gel packs, allowing them to fit into tight spaces and wrap around products for more efficient cooling.

-

Duração de resfriamento mais longa: Uma vez ativado, dry ice sheets last up to 7 times longer than standard ice, making them highly effective for longer transportation times.

-

Reutilizável e econômico: Dry ice sheets can be reused multiple times, reducing the cost and environmental impact of single-use ice packs.

Step-by-Step Guide on How to Activate Dry Ice Pack Sheets

To ensure your dry ice pack sheets perform optimally, follow this simple guide for activation:

Etapa 1: Gather the Necessary Materials

Before starting the activation process, make sure you have the following:

-

Folhas de gelo seco

-

Esquentar (not boiling) água

-

A shallow container or sink

-

A towel for drying

Etapa 2: Immerse the Sheets in Warm Water

-

Submerge the Sheets: Place the dry ice pack sheets into a shallow container or sink filled with warm water. Ensure the sheets are fully submerged.

-

Weigh Down the Sheets: Place an object on top to keep the sheets fully immersed, ensuring even hydration.

Etapa 3: Hidrate as folhas

-

Wait for Absorption: Let the sheets soak in the warm water for approximately 10–15 minutes. Durante este tempo, the polymer inside the sheets will absorb the water and expand, preparing them for freezing.

-

Massage the Sheets: Gently massage the sheets to help air bubbles escape and ensure even hydration.

-

Check the Thickness: The sheets will become thicker and firmer once properly hydrated. Ensure that they are not over-hydrated, as this could affect their performance.

Etapa 4: Dry the Sheets

-

Remove Excess Water: Once the hydration process is complete, remove the sheets from the water.

-

Pat Dry: Use a towel to remove any excess moisture. This step is essential to prevent ice buildup on the exterior during freezing.

Etapa 5: Freeze the Sheets

-

Place in Freezer: Lay the hydrated sheets flat in your freezer, ensuring they do not overlap for even freezing.

-

Optimal Freezing Time: Freeze the sheets for at least 24 hours for maximum cold storage capacity.

Factors That Affect the Performance of Activated Dry Ice Pack Sheets

Understanding the factors that affect the performance of dry ice pack sheets will help you extend their cooling duration and improve overall efficiency during transport:

Qualidade de isolamento

The quality of insulation in your cooler or storage container significantly impacts the effectiveness of dry ice pack sheets. High-quality insulation reduces heat transfer and slows down sublimation, keeping your dry ice colder for longer.

Temperatura Externa

External temperature plays a crucial role in the longevity of dry ice. Higher ambient temperatures increase sublimation rates, meaning dry ice will sublimate faster. In hot conditions, using more dry ice or enhancing your container’s insulation can help mitigate this effect.

Quantidade de gelo seco

Using a larger quantity of dry ice will prolong the cooling duration. When shipping goods over longer distances, calculating the right amount of dry ice is crucial to ensure consistent temperatures.

Cooler Opening Frequency

Every time a cooler is opened, entra ar quente, accelerating the sublimation process of dry ice. Limiting access to the cooler will help maintain lower temperatures for longer periods.

How Long Do Activated Dry Ice Pack Sheets Last?

The duration that dry ice pack sheets remain effective depends on various factors such as insulation, temperatura externa, and how much dry ice is used. Tipicamente, activated dry ice pack sheets can last anywhere from 18 para 48 horas:

| Isolamento mais frio | Duração estimada | Impacto na duração do resfriamento |

|---|---|---|

| Well-insulated | 24–48 horas | Duração de resfriamento mais longa |

| Moderately insulated | 12–24 horas | Moderate cooling time |

| Poorly insulated | 6–12 horas | Curto tempo de resfriamento, sublimação rápida |

Melhores práticas para uso de gelo seco na logística da cadeia de frio

To get the most out of your dry ice pack sheets, follow these best practices in cold chain logistics:

-

Properly Seal the Cooler: Use tight-fitting lids or seals to minimize the entry of warm air, which will speed up the sublimation of dry ice.

-

Place Dry Ice on Top: Air frio afunda, so placing dry ice on top of items ensures optimal temperature maintenance.

-

Regular Temperature Monitoring: Use temperature monitoring devices inside the cooler to ensure the contents stay within the required temperature range.

2025 Tendências no uso de gelo seco para logística de cadeia de frio

Em 2025, the cold chain logistics industry continues to evolve, and so does the technology around dry ice. As principais tendências incluem:

-

Alternativas ecológicas: The shift towards sustainable packaging and cooling options, such as biodegradable alternatives, está acelerando.

-

Tecnologias de envio inteligentes: Real-time temperature tracking and data logging are improving the management of dry ice and the cold chain process.

-

Tecnologias de isolamento aprimoradas: Advancements in insulation are helping extend the effectiveness of dry ice packs, ensuring more reliable and efficient transportation of sensitive goods.

Perguntas comuns sobre placas de gelo seco

How Long Does It Take for Dry Ice Pack Sheets to Activate?

The activation process typically takes 10–15 minutes, during which the sheets absorb water and begin to expand.

Can I Use Dry Ice Pack Sheets for Long-Term Storage?

Dry ice pack sheets are ideal for short-term use (até 48 horas). Para armazenamento a longo prazo, additional cooling methods may be required.

Are Dry Ice Pack Sheets Reusable?

Sim, dry ice pack sheets can be reused multiple times. Após cada uso, they need to be properly rehydrated and frozen.

Conclusão e insights acionáveis

Activating dry ice pack sheets is a simple process, but understanding how to properly use them is essential for ensuring their effectiveness in cold chain logistics. By following the steps outlined in this guide, you can ensure the longevity of your dry ice packs and maintain the safety of your temperature-sensitive shipments.

PRÓXIMOS PASSOS:

-

Follow the correct hydration and freezing steps for optimal performance.

-

Implement best practices for storage and transport to extend the cooling duration.

-

Fique atualizado com 2025 industry trends and technologies to enhance your cold chain logistics.

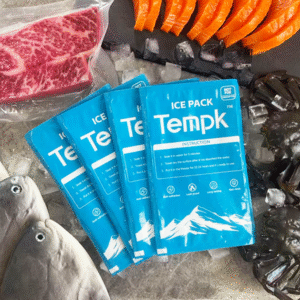

Sobre Tempk

Tempk é líder em soluções de cadeia fria, specializing in advanced dry ice pack sheets, cooling systems, and insulated containers for industries like food, produtos farmacêuticos, e pesquisa. Our products are designed to meet the highest standards of efficiency and reliability.

Contact us today for expert advice on optimizing your cold chain logistics.