Se você estiver procurando por um fabricante de embalagens de bebidas em gel refrigerante, você está tentando impedir duas falhas dispendiosas: chegadas quentes e congelamento acidental. Some beverage shippers estimate temperature deviations can drive major spoilage and refunds, with figures cited as high as 30% in transit discussions.

A reliable refrigerant gel package beverage manufacturer is not “more gel.” It is a repeatable system: the right gel profile, the right pack-out, e desempenho verificado.

Este artigo irá ajudá-lo a responder:

- How a refrigerant gel package beverage manufacturer protects flavor, carbonation, and labels in real routes

- Which gel temperature profile fits your drink type and hold time, without over-cooling

- How to size gel packs using a simple scoring tool you can apply today

- What quality tests prevent leaks, weak seals, and performance drift

- How to run a remote supplier audit and RFQ that avoids hidden costs

- Qual 2026 sustainability moves reduce waste without raising failures

How does a refrigerant gel package beverage manufacturer support beverage shipping?

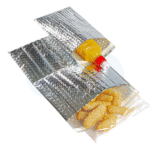

Resposta direta: A refrigerant gel package beverage manufacturer designs gel-based cooling packs that maintain stable temperatures during beverage transport. In typical configurations, gel systems can support 12 para 72 hours of temperature protection, depending on load size and pack-out design.

The goal is controlled cooling that protects product quality without water damage from melting ice.

A strong refrigerant gel package beverage manufacturer builds a system, not a single SKU. That system combines gel formulation, film selection, vedação, and batch controls for repeatable results.

When those parts align, you see fewer hot spots, menos caixas molhadas, and fewer customer complaints. When they don’t, you get uneven cooling and messy leaks that destroy unboxing reviews.

What beverage-specific gel design really means

Beverage shipping is geometry-driven. Packs must fit between bottles and cans, maintain contact, and avoid crushing labels. Beverage-focused solutions are engineered around bottle and can layouts, improving surface contact and airflow balance.

That is why a beverage-experienced refrigerant gel package beverage manufacturer often outperforms a generic ice-pack supplier.

| Beverage type | Typical target range | Gel strategy | O que isso significa para você |

|---|---|---|---|

| Craft beer | 2–6°C | Medium-freeze gel | Protects flavor balance |

| Cold brew / RTD coffee | 2–4 ° C. | Long-duration gel | Reduces warm-taste issues |

| Functional drinks | 4–8 ° C. | Mild-freeze gel | Protects sensitive ingredients |

Dicas práticas que você pode usar imediatamente

- Short distance: Use thinner packs with faster activation.

- Comércio eletrônico: Choose extended-duration gel profiles for longer holds.

- Mixed cartons: Combine top and side placement to reduce hot corners.

Exemplo do mundo real: A regional cold brew brand reported 42% fewer complaints after switching to beverage-specific packs for narrow bottle spacing.

What makes a refrigerant gel package beverage manufacturer different from ice or dry ice?

Resposta direta: A refrigerant gel package beverage manufacturer provides controlled, reusable cooling without melt-water damage or aggressive freezing risk. Gel systems sit between melting ice and dry ice in both behavior and handling.

You get a smoother cooling curve that protects labels, caixas, and customer experience.

Ice can melt quickly and create water damage in cartons. Dry ice can freeze aggressively and demands special handling, especially in mixed DTC networks. Gel releases cooling energy gradually, like a slow-burning candle instead of a flare.

For beverages, que “steady cold” matters more than the coldest possible temperature.

| Método de resfriamento | Controle de temperatura | Operational risk | Best fit for beverages |

|---|---|---|---|

| Gelo | Baixo | Médio (danos causados pela água) | Local delivery only |

| Gelo seco | Muito alto | Low safety margin | Produtos congelados, not chilled drinks |

| Gel refrigerant | Controlado | High predictability | Chilled beverage shipping |

Actionable guidance for beverage teams

- Avoid dry ice for carbonated drinks to reduce pressure and handling risk.

- Use gel packs for both alcohol and non-alcohol beverage programs.

- Ask your refrigerant gel package beverage manufacturer for food-grade material evidence and clear documentation.

Caso prático: If your labels arrive “sweaty,” the fix is often pack placement and moisture control, not colder packs.

How do you choose the right gel temperature profile for drinks in 2026?

Resposta direta: Choose a gel temperature profile that matches your beverage’s quality window and your worst-case route exposure. You are not selecting “ice.” You are selecting temperature behavior over time.

A beverage-ready refrigerant gel package beverage manufacturer can tune freezing points and release rates to avoid “too warm” e “too cold.”

Think of gel profiles like tires. A winter tire is powerful in snow, but wasteful in summer. A deep-freeze gel can be powerful, but risky for sensitive beverages. You want the profile that fits your route, not the strongest option.

This mindset prevents accidental freezing for juices, probiotic drinks, and other delicate products.

Hold time is not just gel weight

Hold time depends on five drivers you can control. If any of these change, performance changes fast.

- Pre-conditioning time (how long packs are fully conditioned)

- Desempenho de isolamento (shipper design and thickness)

- Colocação do pacote (principal, lado, enrolar, layered)

- Temperatura da carga útil (pre-chilled vs warm product)

- Exposição ambiental (doorstep heat and depot delays)

Matching table you can share with your team

| Beverage type | Temperature goal | Best gel approach | Why it protects you |

|---|---|---|---|

| Cold brew / RTD coffee | Cold and steady | Médio, long-release gel | Reduces warm spikes |

| Craft beer | Legal, não congelado | Moderate profile gel | Protects flavor balance |

| Fresh juice | Mais frio, estável | Higher safety-window gel | Reduces separation risk |

Simple manufacturer selection rules

- Ask for thermal test data, not only product specs.

- Request beverage-specific validation, not generic claims.

- Confirm batch consistency to avoid performance variation.

Insight de caso: A kombucha distributor improved stability by choosing a higher freezing point gel profile.

Quantos pacotes de gel você precisa? A decision tool for refrigerant gel package beverage manufacturer buyers

Resposta direta: Start with a structured estimate, then validate with a short pilot. Most cost overruns happen when you guess gel quantity instead of sizing it.

Your refrigerant gel package beverage manufacturer should support a sizing method that your team can repeat.

Below is a decision tool that gives you a starting configuration. You can refine it after a one-week pilot.

Use it to standardize decisions across SKUs, seasons, and fulfillment shifts.

Ferramenta de decisão rápida: Gel pack sizing for beverage shipping

Answer five questions and score A=1, B=2, C=3.

- Transit time you must survive: UM) ≤24h B) 24–48h C) 48-72h

- Ambient risk on the route: UM) Low B) Medium C) Alto

- Temperatura inicial do produto: UM) Fully pre-chilled B) Partly chilled C) Temperatura ambiente

- Shipper insulation: UM) High-performance B) Standard EPS C) Thin or budget

- Peso da carga útil: UM) Light B) Medium C) Pesado

Scoring guide

| Pontuação total | Starting configuration | O que isso significa |

|---|---|---|

| 5–7 | Light gel load | Espera curta, ambiente controlado |

| 8–11 | Medium gel load | Balanced protection |

| 12–15 | Heavy gel load | Espera longa, high ambient risk |

What quality tests should you run before choosing a refrigerant gel package beverage manufacturer?

Resposta direta: Run simple, repeatable tests that catch leaks, weak seals, and performance drift before you commit to volume orders.

Você não precisa de um laboratório. You need discipline and a short checklist.

Pre-pilot quality checklist

| Teste | O que você faz | O que você aprende |

|---|---|---|

| Inspeção visual | Verifique os selos, edges, fill uniformity | Manufacturing consistency |

| Weight check | Pesar 5 pacotes, compare to spec | Fill accuracy |

| Freeze-thaw cycle | Congelar, descongelamento, repeat 3× | Seal durability |

| Drop test | Drop from 1m onto hard surface | Resistência ao impacto |

| Squeeze test | Apply firm pressure to seams | Seal strength |

| Hold duration | Monitor temp over time in shipper | Lane fit |

| Leak check | Place on paper, check for wet spots | Integridade do selo |

How do you run a remote supplier audit for a refrigerant gel package beverage manufacturer?

Resposta direta: Use a structured checklist and video calls to verify production controls, batch records, and change management without traveling.

Remote audits are now standard practice. The key is asking the right questions and requesting the right evidence.

Remote audit checklist

- Request a video walkthrough of the production line

- Ask for batch records from the last 3 meses

- Confirm QC test methods and pass/fail criteria

- Ask about change notification policy (materiais, fornecedores, processos)

- Request references from beverage customers

What RFQ fields prevent hidden costs when sourcing from a refrigerant gel package beverage manufacturer?

Resposta direta: A clear RFQ prevents mismatched samples, confusing pricing, and painful re-qualification.

RFQ template for beverage gel packs

| RFQ field | Seu valor | What the supplier must confirm |

|---|---|---|

| Faixa de temperatura alvo | por exemplo, 2–8 ° C. | Gel profile and conditioning guidance |

| Hold time required | por exemplo, 48 horas | Pack-out recommendation |

| Pack size and weight | por exemplo, 200g, 400g | Available SKUs and MOQs |

| Food-grade certification | Obrigatório | Certificate and test reports |

| Leak rate acceptance | Zero tolerance | Test method and batch records |

| Rastreabilidade | Batch codes required | Code format and retention policy |

O que 2026 sustainability moves reduce waste without raising failures?

Resposta direta: Focus on reusable packs, filmes recicláveis, and right-sizing to reduce waste without compromising performance.

Sustainability options to discuss with your manufacturer

- Reusable gel packs with return programs

- Recyclable film materials (check local recycling compatibility)

- Right-sizing to reduce gel weight and shipping costs

- Bio-based gel formulations (verify performance equivalence)

Conclusão

Choosing a refrigerant gel package beverage manufacturer is not about finding the cheapest supplier. It is about finding a partner who can deliver repeatable performance, support your specific beverage types, and help you avoid costly failures. Use this guide to build a structured selection process that protects your products and your brand.