Como negociar bolsas de gelo seco com segurança e lucratividade em 2025

Se você enviar produtos congelados, você deve negociar pacotes de gelo seco o caminho certo. Em poucos minutos, bom dimensionamento e rotulagem podem evitar deterioração, tarifas, e incidentes de segurança. Este guia mostra como lidar com bolsas de gelo seco para proteger a margem, atender às regras UN1845, e mantenha as equipes seguras - com alcances práticos, estimadores rápidos, e camadas de embalagem que você pode usar hoje. Você receberá etapas em inglês simples que reduzem os riscos sem retardar as operações.

-

Métodos de embalagem mais seguros que negociar pacotes de gelo seco para confiabilidade no envio de congelados

-

Regras de dimensionamento rápido e um estimador baseado em faixa para negociar pacotes de gelo seco com precisão

-

2025 Etiqueta UN1845 e documentos essenciais quando você negociar pacotes de gelo seco

-

Quando mudar de gelo seco para PCM ou gel para reduzir custos e CO₂

Como você deve negociar bolsas de gelo seco para remessa de congelados?

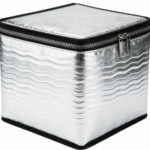

Coloque o gelo seco por cima, ventile a caixa, e mantenha as luvas calçadas – essa é a maneira mais rápida de manter temperaturas congeladas e evitar problemas de pressão de CO₂. Na maioria dos pequenos expedidores, a perda diária é de 5 a 10 libras; planeje massa suficiente, distribuir pacotes no topo, e nunca sele o gás. Quando você vende bolsas de gelo seco para rotas de comércio eletrônico, adicione um amortecedor fino na lateral da tampa e bloqueie bolsas de ar.

Comece com um objetivo simples: produtos congelados permanecem ≤ −20°C da doca à porta. Porque o dióxido de carbono afunda, gelo seco acima do produto espalha ar frio para baixo. Ventile pequenos canais para que o gás escape; nunca carregue frascos herméticos ou sacos de forro. Para a maioria dos volumes de 20 litros, você precisará de cerca de 1,5–2,5 kg por 24 horas, em seguida, ajuste para isolamento e clima. Armazenar em isolado, áreas bem ventiladas – não freezers selados – para retardar a sublimação e proteger a equipe. Nos meses quentes, lidar com pacotes de gelo seco aumentando a massa e melhorando a espessura da parede em pistas longas.

Gelo seco vs gel/pcm: que protege o orçamento e o produto?

O gelo seco mantém a faixa mais fria (até -78,5°C) para sorvete, carnes, e amostras clínicas. Os pacotes de gel estabilizam de 0 a 5°C para produtos agrícolas e de 2 a 8°C para produtos biológicos. PCMs podem atingir -5°C, 0°C, +5°C, ou faixas de temperatura ambiente por até 72 horas e evite rótulos de materiais perigosos. Se você vende bolsas de gelo seco para alimentos frágeis, combine-os com barreiras de umidade para evitar queimaduras de congelamento.

| Método de resfriamento | Temperatura alvo | Duração típica | O que isso significa para você |

|---|---|---|---|

| Pacotes de gelo seco | ≤ −20°C a −78,5°C | 24–48 h (mais tempo com paredes mais grossas) | Congelamento rápido; requer rotulagem e ventilação UN1845. |

| Pacotes de gel | −5°C a +5°C | 12–24 h | Bom para produtos refrigerados; retornos mais simples; sem materiais perigosos. |

| Blocos PCM | Personalizado (−25°C a +25°C) | Até 72 h | Reutilizável; escolha a temperatura da fase que corresponda às necessidades do produto. |

Dicas práticas

-

Antes de você negociar pacotes de gelo seco, pré-congelar a carga para que o gelo resfrie o remetente, não o produto.

-

Preencher vazios; o ar vazio acelera o aquecimento.

-

Mantenha gelo seco no topo; Produto para pias e cobertores de CO₂.

-

Use isolado, armazenamento ventilado; nunca recipientes herméticos.

Caso real: Um laboratório mudou para uma tabela fixa de “gelo seco por hora” e pacotes carregados na parte superior. Faixas de vacinação de dois dias mantidas ≤ −70°C com 5 quilogramas totais, reduzindo eventos de perda a zero.

Como você dimensiona e distribui bolsas de gelo seco por faixa?

Use um estimador rápido: horas de trânsito × 0.25 ≈ libras de gelo seco, Em seguida, adicione 30% para pistas quentes e 20% para aberturas planejadas. Arredondar para o próximo 2 lb para corresponder aos tamanhos de embalagem comuns. A sublimação típica do dia a dia é de 5 a 10 lb em um refrigerador padrão, portanto, uma pista de 36 horas geralmente precisa de cerca de 9 a 12 libras. Documente como você distribui bolsas de gelo seco para que as equipes embaladas repitam as vitórias.

Mantenha-o simples e repetível. Pré-congelar o produto, minimizar lacunas de ar, e isolamento do tamanho certo. Para cargas úteis de 20 litros, uma linha de base de 1,5–2,5 kg por 24 horas funciona bem; pistas mais longas ou paredes finas exigem mais. Divida o gelo seco em vários pacotes para evitar cantos quentes e coloque-os acima da carga para ficar ainda mais frio. Quando você distribui bolsas de gelo seco em grande escala, publicar tabelas de rotas e adicioná-las aos SOPs para que os novatos acertem no primeiro dia.

| Cenário de pista | Tamanho do remetente | Leste . gelo seco | Por que funciona |

|---|---|---|---|

| 24 metrô, verão | Espuma pequena, 1–2 em paredes | 8–10 lb. | Cobre perdas diárias com margem. |

| 48 h regional | Uretano médio, 2 nas paredes | 18–22 lb. | Paredes mais espessas prolongam o tempo de espera. |

| 72 h remoto | EPS qualificado, 2.5 nas paredes | 26–30 libras | Maior massa + amortecedor de isolamento. |

Como você rotula e distribui bolsas de gelo seco sob UN1845?

Marque um rosto com “UN 1845, Gelo Seco, líquido X kg,” adicione a classe 9 diamante, e manter os detalhes do expedidor/destinatário fora da etiqueta de perigo. Quando o gelo seco apenas resfria mercadorias não perigosas, a maioria das transportadoras ignora uma Declaração do Remetente DG completa – mas as marcações e o peso preciso ainda são obrigatórios. Treine equipes para lidar com bolsas e rótulos de gelo seco em conjunto como uma lista de verificação.

As regras postais e do integrador diferem. NÓS. o ar postal geralmente limita o gelo seco a 5 lb por pacote e bloqueia correio internacional. Operadoras publicam listas de verificação de aceitação, incluindo tamanho e posicionamento da etiqueta. Pese novamente um pouco antes do concurso para que o rótulo NET KG corresponde ao que resta após qualquer sublimação pré-embalada. Se você costuma negociar bolsas de gelo seco para devolução, pré-imprimir etiquetas e adicionar espaços em branco de kg líquido.

Quando você deve distribuir bolsas de gelo seco – ou mudar para PCM?

Mude quando a faixa segura for ≥ −5°C ou 0°C e o trânsito for ≤ 72 horas; mantenha gelo seco para resultados congelados duros. PCMs evitam o manuseio de materiais perigosos, reduzir retornos, e pode ser reutilizado. Seu custo total de entrega geralmente cai, mesmo que o preço do pacote seja mais alto. Se você ainda vende bolsas de gelo seco nessas pistas, você provavelmente está gastando demais.

Escolha temperaturas de fase que correspondam ao seu produto: −5°C para ultracongelados, +5°C para produtos biológicos de 2–8°C, +18–25°C para proteção térmica no verão. Adicione uma camada fina de PCM a 0°C sob a tampa como um buffer de atraso, mesmo quando você usa gelo seco. Rastreie devoluções e crie um ciclo simples de reutilização para obter economias e reduzir desperdícios. Documente quando não negociar bolsas de gelo seco para que os compradores escolham automaticamente o PCM para pistas adequadas.

Autoavaliação rápida: gelo seco ou PCM?

Responder sim/não. Se você marcar 3+ sim, escolha PCM/gel; de outra forma, Use gelo seco.

-

O seu produto é seguro a ≥ −5°C?

-

Você envia rotas abaixo 72 horas com atrasos frequentes na última milha?

-

Você usa correio aéreo ou transfronteiriço que não gosta de materiais perigosos??

-

Você irá recuperar e reutilizar pacotes no destino?

-

Você quer etiquetas mais simples e menos pacotes rejeitados?

Como você mantém as equipes seguras ao distribuir bolsas de gelo seco?

CO₂ alvo ≤ 5,000 ppm (8média de horas) e ≤ 30,000 ppm para rajadas curtas; use escapamento de baixo nível e nunca ande com caixas em cabines seladas. Use luvas térmicas ou de couro, evite recipientes herméticos, e ventilar áreas de preparação. Quando você vende bolsas de gelo seco em vans ou walk-ins, monitorar CO₂ na altura da respiração.

O gás residual pode substituir rapidamente o oxigênio em vans, visitantes, ou quartos pequenos. Quebrar portas durante o carregamento, adicione monitores simples com alarmes próximos de 5.000–8.000 ppm, e treinar equipes para carregar pacotes superiores. Armazene as caixas em local fresco, zonas ventiladas e evite porões ou cabines de veículos onde o gás pode acumular. Adicione uma atualização de “pacotes de gelo seco” à integração para que os bons hábitos permaneçam.

2025 tendências que moldam a forma como você lida com bolsas de gelo seco

A sustentabilidade e a telemetria continuam a remodelar o planeamento da cadeia de frio em 2025. PCMs reutilizáveis, filmes recicláveis, e as previsões de rota e sublimação baseadas em IA estão se tornando predominantes. Espere um controle de qualidade de rótulo mais rígido nas transportadoras e uma demanda mais constante à medida que o comércio eletrônico de alimentos e ciências biológicas se expande. Equipes que negociar pacotes de gelo seco com SOPs e calculadoras, vemos menos pacotes rejeitados.

Resumo das novidades

-

Controle de qualidade de etiqueta mais rápido: As operadoras reforçaram as listas de verificação de tipografia e aceitação; adicionar uma verificação de etiqueta de embalagem.

-

Segurança CO₂ facilitada: Monitores acessíveis simplificam o treinamento e as verificações da área de preparação.

-

Crescimento do PCM: Programas de reutilização reduzem pontos de contato com materiais perigosos e rejeições de última milha.

Insight de mercado: a demanda por entrega congelada e refrigerada está crescendo constantemente. Planeje oscilações periódicas nos preços do gelo seco e considere embalagens híbridas que misturem PCM com gelo seco para evitar atrasos. Se você atualmente negociar pacotes de gelo seco em cada pista, segmentar por necessidade de temperatura e mudar de 2 a 8°C para PCMs.

Perguntas frequentes

Quanto tempo duram os pacotes de gelo seco?

Planeje 24 a 48 horas dependendo do isolamento e da carga; a perda diária é normalmente de 5 a 10 libras. Quando você negociar pacotes de gelo seco, tamanho para o maior tempo de trânsito realista.

Posso reutilizar uma bolsa de gelo seco?

Sim – se a barreira externa estiver intacta e não contaminada; sempre inspecione antes de reutilizar. Para equipes que negociar pacotes de gelo seco semanalmente, crie uma lista de verificação simples de aprovação/reprovação.

Onde os pacotes devem ficar na caixa?

No topo da carga útil, o frio afunda sobre o produto; dividido em vários pacotes para evitar cantos quentes. Treinar equipes para negociar pacotes de gelo seco consistentemente.

Posso colocar gelo seco em um recipiente ou frasco selado?

Não. O gás residual pode criar pressão e romper recipientes. Ventile um pouco e nunca sele o gás. Isso se aplica sempre que você negociar pacotes de gelo seco.

Preciso de uma declaração DG?

Geralmente não quando o gelo seco apenas resfria conteúdos não perigosos, mas marcações e kg líquido são obrigatórios. Adicione isso ao seu “como nós negociar pacotes de gelo seco”SOP.

Resumo e recomendações

Para lidar bem com bolsas de gelo seco, carga superior e ventilação, tamanho certo por pista, etiqueta UN1845 com kg líquido, e mude para PCMs sempre que o alcance seguro permitir. Publique tabelas de pacotes para que as equipes negociar pacotes de gelo seco da mesma maneira todas as vezes.

PRÓXIMOS PASSOS: execute o estimador rápido nas três pistas principais, adicione uma etiqueta na etapa de controle de qualidade na embalagem, e pilotar um ciclo de reutilização de PCM para produtos de 2–8°C. Se você ainda negociar pacotes de gelo seco nessas pistas biológicas, teste a alternativa PCM esta semana.

Sobre Tempk

Projetamos embalagens práticas de cadeia de frio e POPs para expedidores de alimentos e ciências biológicas. Nossos engenheiros qualificam embalagens, otimizar pacotes, e crie calculadoras de pista que ajudam você negociar pacotes de gelo seco ou mude para PCMs com confiança. Dois pontos fortes: tabelas de embalagem validadas e fluxos de trabalho rápidos de controle de qualidade de etiquetas. Fale conosco para avaliar suas rotas e aumentar a confiabilidade da entrega congelada.