Como embalar gelo seco para enviar carne congelada com segurança?

O envio de carne congelada sem comprometer a qualidade requer controle preciso de temperatura, especialmente ao usar gelo seco. É crucial compreender as quantidades certas de gelo seco, os melhores materiais de embalagem, e os regulamentos que você deve seguir para garantir que os produtos cárneos permaneçam congelados durante o transporte e cheguem em perfeitas condições. Neste guia, we’ll cover the essentials of how to pack dry ice to ship frozen meat com segurança, ajudando você a permanecer em conformidade com 2025 diretrizes enquanto otimiza o processo de envio.

-

Quanto gelo seco você precisa em 24 a 72 horas para o transporte seguro de carne congelada?

-

Quais regras de design de embalagem e ventilação você deve seguir para conformidade?

-

Como você coloca o isolamento em camadas, carne, e gelo seco para manter a temperatura?

-

Que rotulagem regulatória, documentação, e precauções de segurança são necessárias?

-

Quais tendências estão surgindo na logística da cadeia de frio de 2025?

How Much Dry Ice Should You Use to Ship Frozen Meat Over 1–3 Days?

Resposta central:

You should estimate 5–10 lbs of dry ice per 24 hours for typical shipping conditions. No entanto, this amount may need adjustment depending on the duration of the shipment, temperatura ambiente, e isolamento usado.

Explicação:

Dry ice sublimates at approximately 5–10 lbs per 24 horas, depending on the shipping conditions and the quality of insulation. Por exemplo, ao enviar 10 libras de carne, you may need around 7 lbs of dry ice per day for a short transit. In warmer weather or longer distances, você vai precisar de mais. Testing your shipment with temperature loggers helps ensure optimal results.

| Duração da remessa | Typical Dry Ice Amount | Risk of Underestimating | Aplicação prática |

|---|---|---|---|

| 1 dia (durante a noite) | 5–8 libras (2.3–3.6 kg) | Partial thaw, warm edges | Local shipments |

| 2 dias | 10–15 libras (4.5–6,8 kg) | Meat warms or partially thaws | Cross-state shipments |

| 3 dias | 15–20 libras (6.8–9 kg) | Full thaw, perda de qualidade | Long-distance or remote areas |

Dica: For longer transit times or in hot climates, it is advisable to increase the dry ice load by 20% or use thicker insulation materials to slow down sublimation.

What Packaging Design & Venting Rules Must You Follow?

Resposta central:

Your packaging must always allow CO₂ gas to vent, Nunca sele hermeticamente, and should include the necessary labels: "Gelo seco" ou "dióxido de carbono, Sólido," E 1845, and net dry ice weight in kg.

Explicação:

À medida que o gelo seco sublima, libera gás CO₂. Se a embalagem for hermética, the pressure can build up and rupture the container. Para evitar isso, the outer packaging must have vents, and the inner cooler must not be sealed tightly. Packaging materials should comply with hazardous materials guidelines to ensure safety.

Required Labels:

-

"Gelo seco" ou "dióxido de carbono, Sólido"

-

Número da ONU: E 1845

-

Peso líquido de gelo seco (kg)

-

Aula 9 etiqueta de material perigoso

-

Remetente & recipient addresses

Packaging Process:

-

Caixa Externa: Use a corrugated fiberboard or durable plastic box.

-

Isolamento: Add EPS foam panels or rigid insulation around the meat and dry ice.

-

Ventilação: Ensure the package can vent CO₂ by not sealing the inner cooler too tightly.

How to Layer Insulation, Carne & Dry Ice for Temperature Control?

Resposta central:

When packing frozen meat with dry ice, the dry ice should surround the meat on all sides and be placed on top to ensure the cold air sinks through the product. Insulation should be used to slow down heat ingress, and all voids should be filled with packing materials.

Explicação:

-

Meat Placement: Place vacuum-sealed meat in the center of the cooler to minimize air exposure.

-

Colocação de gelo seco: Place dry ice on top and around the sides of the meat, but avoid direct contact with the meat to prevent freezer burn. Ensure that the dry ice is not tightly packed and can sublimate without restriction.

-

Isolamento: Use foam or other insulating materials to fill gaps and reduce the chances of temperature fluctuations.

Packaging Layering Example:

-

Vacuum-seal meat and place it in the center.

-

Surround the meat with approximately 10 libras de gelo seco.

-

Usar 2 inches of foam insulation around the dry ice.

-

Fill any voids with crumpled paper or cellulose insulation to prevent shifting.

-

Ensure the cooler lid is slightly open or has vent holes to allow gas to escape.

What Regulatory Labeling, Documentação & Safety Steps Are Required?

Resposta central:

Complying with regulations is essential when shipping dry ice. This includes labeling the package properly and ensuring it is handled by certified personnel familiar with hazardous materials shipping protocols.

Explicação:

Dry ice is considered a Class 9 materiais perigosos, and shipping it requires careful attention to regulatory guidelines to ensure safety and compliance.

Key Documentation & Segurança:

-

Rotulagem adequada: Always label the outer box with “Dry Ice” or “Carbon Dioxide, Sólido,” include the UN number, and the net dry ice weight.

-

Declaração do remetente: For air shipments of more than 5.5 libras (2.5 kg), include a shipper’s declaration for dangerous goods.

-

Manuseio de precauções: Always handle dry ice with insulated gloves and work in well-ventilated areas to avoid CO₂ buildup.

Dicas de conformidade:

-

Never seal the package airtight. Ensure that CO₂ can vent freely.

-

Verify that the packing and labeling meet carrier-specific rules (por exemplo, FedEx, UPS, USPS).

-

Use temperature data loggers to monitor internal conditions during transit.

2025 Trends in Dry Ice Shipping and Cold Chain Innovations

Visão geral das tendências:

Em 2025, o setor de logística da cadeia de frio está evoluindo, with a focus on smarter packaging, monitoramento de temperatura em tempo real, and the use of eco-friendly materials to improve efficiency and reduce costs.

Últimas inovações:

-

Monitoramento de temperatura inteligente: IoT-connected sensors alert you if the temperature deviates from the desired range during transit.

-

Materiais ecológicos: High-performance, sustainable materials such as VIP liners are becoming more common, providing better insulation while reducing environmental impact.

-

AI-powered Route Optimization: Delivery platforms are using artificial intelligence to optimize routes based on temperature conditions, minimizing transit times and reducing dry ice usage.

Insights de mercado:

As consumer demand for direct-to-consumer frozen meat shipments grows, it’s essential to adopt these innovations to improve reliability, reduzir o desperdício, e construir a confiança do cliente. Brands that optimize their dry ice packing methods while embracing sustainability will gain a competitive edge.

Perguntas frequentes (Perguntas frequentes)

Q1: How much dry ice do I need to ship frozen meat for 48 horas?

You typically need 10–15 lbs (4.5–6,8 kg) de gelo seco para 48 horas, dependendo da qualidade do isolamento e da temperatura ambiente. Always perform a test with temperature loggers.

Q2: Can I seal the shipping box tightly?

Não, the box must allow for venting to prevent pressure buildup from the CO₂ gas. A tightly sealed box can rupture during transit.

Q3: What if my shipment is delayed and dry ice runs out?

To mitigate this risk, always include a buffer (gelo extra seco), choose fast transit routes, and work with carriers who can replenish dry ice if needed.

Resumo & Recomendações

Takeaways -chave:

To pack dry ice for shipping frozen meat safely, sempre garanta ventilação adequada, accurate labeling, and the right amount of dry ice. Use insulated packaging to maintain low temperatures and follow regulatory guidelines to ensure compliance. Test shipments with temperature loggers to adjust dry ice quantities.

Próximas etapas para você:

-

Audit your packaging to ensure it’s optimized for your specific shipping conditions.

-

Implement a dry ice calculator for better load estimation.

-

Train your team on handling dry ice and understanding the required regulations.

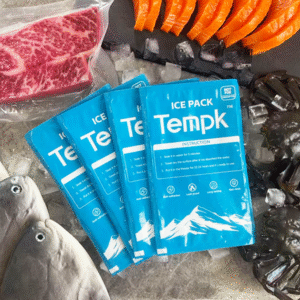

Sobre Tempk

We specialize in providing cold-chain solutions for the shipping industry, particularly in the transportation of frozen food and biothermal products. Our innovative, eco-friendly packaging options, combined with our expertise in temperature management, ensure that your products arrive safely and on time. Whether you need a tailored cold-chain plan or advice on regulatory compliance, Tempk está aqui para ajudar.