Como embalar sorvete com gelo seco 2025

Você quer cervejas sólidas na porta, não lama. Aqui está como embalar sorvete com gelo seco da maneira certa — métodos passo a passo, matemática exata do gelo, e etiquetas compatíveis – para que sua remessa mantenha 0°F (-18 °C) por 24 a 72 horas sem desperdício. A maioria dos pequenos refrigeradores precisa 5–10 lb de gelo seco por 24 horas; isolamento mais espesso e rotas quentes precisam de mais.

-

Como colocar litros e gelo seco em camadas para um frio uniforme em rotas de 24 a 72 horas

-

Quanto gelo seco usar com um simples, calculadora testável

-

Qual remetente isolado (EPS, Pur, VIP) cabe no tempo e no orçamento

-

Como etiquetar e ventilar pacotes para conformidade com USPS/UPS/FedEx

-

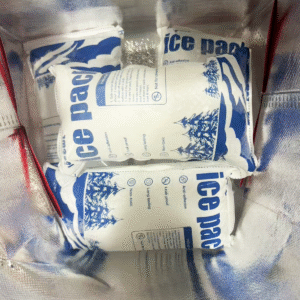

Quando os pacotes de gel ajudam – e quando o gelo seco deve liderar

Como embalar sorvete com gelo seco passo a passo?

Resposta rápida: Canecas pré-congeladas, pré-condicionar o expedidor, linha com um saco poli, adicione uma camada base de gelo seco, embale os litros com força, carregue mais gelo seco, preencher todos os vazios, mantenha as aberturas de ventilação abertas, e rotule corretamente. Não sele hermeticamente; CO₂ deve escapar. Plano 5–10 libras de gelo seco por 24 horas para refrigeradores pequenos; aumento para paredes finas ou ondas de calor.

Por que funciona: O gelo seco está a -109°F (-78,5°C). Pisos de gás frio. Colocando mais gelo acima os litros alimentam o frio para baixo e retardam o ganho de calor. Um “sanduíche” (gelo base → litros → gelo superior) uniformiza as temperaturas e evita empenamento da tampa. A ventilação evita o aumento de pressão e mantém os manipuladores seguros.

Qual remetente isolado você deve escolher para embalar sorvete com gelo seco?

Escolha a espessura da parede por tempo de trânsito. Usar ~1,5″ EPS por 24–48 horas. Aproxime-se 1.75–2,25″ EPS ou PUR/VIP para 48+ h ou pistas quentes. PUR isola melhor que EPS; VIP oferece a maior retenção no menor espaço ocupado.

| Escolha de embalagem | Especificação típica | Melhor para | O que isso significa para você |

|---|---|---|---|

| 1.5″ EPS | Espuma econômica | 24–36 h | Bom para pernoite; adicione gelo tampão |

| 1.75–2,25″ EPS | Espuma espessa | 36–48 h | Rotas de dois dias; calor moderado |

| PUR ou VIP | Valor R mais alto | 48–72h+ | Caixa menor, Menos gelo, preço premium |

Dicas práticas que você pode usar hoje

-

Condição prévia o remetente em um freezer por 1–2 horas.

-

Misture blocos + Pellets: últimos blocos, pellets preenchem lacunas.

-

Elimine o headspace: preenchimento de vazios de papel supera o ar quente.

Caso real: Um laticínio enviado 12 litros no verão usando 1,75″ Remetente EPS e 18 lb de gelo seco misto com um layout pesado. Entrega em 46 horas: os litros chegaram sólidos como uma rocha; tampas intactas.

Quanto gelo seco você precisa ao embalar sorvete com gelo seco?

Regra geral: Comece em 5–10 lb por 24 h para pequenos refrigeradores bem isolados. Escala para paredes mais espessas, tamanho da carga útil, e clima. Por 36–48 horas, 12 canecas geralmente precisam 15–22 lb. em 1,75–2,25″ EPS. Sempre valide com um teste de pista.

Torne-o previsível: A sublimação depende do isolamento, massa, e fluxo de ar. Use um estimador simples, em seguida, adicione um buffer para estação de calor (+20% nos meses quentes). Mantenha a maior parte do gelo acima dos litros. Para pistas longas ou ondas de calor, atualize para PUR/VIP para reduzir a massa de gelo necessária e o risco.

Estimador de gelo seco (copiar/colar no Planilhas)

-

Rate_lb_per_day: comece em 7.5 (ponto médio de 5-10).

-

Fator_Rota: 1.0 legal / 1.2 ombro / 1.4 quente.

-

Fator_Caixa: 0.9 PUR/VIP; 1.0 para 1,75–2,25″ EPS; 1.2 para 1,0–1,5″ EPS.

Exemplo: 36 h, rota quente (1.4), 1.5″ EPS (1.2) → =ROUNDUP((36/24)*7.5*1.4*1.2,0) → 19 Libra gelo seco.

| Carga útil (litros) | Tipo de caixa | Janela | Leste . gelo seco | Sua lição |

|---|---|---|---|---|

| 6–8 | 1.5″ EPS | 24–36 h | 8–12 lb. | Pernoite mais buffer |

| 12 | 1.75–2,25″ EPS | 36–48 h | 15–22 lb. | Rotas de dois dias em clima quente |

| 18–24 | 2.25″ EPS / Pur | 48–60 h | 25–35 lb. | Saltos de zona longos; O fim de semana segura |

Layout que mantém os litros congelados

-

Camada base: 0.5–1″ pelotas embrulhadas em papel.

-

Zona de carga útil: linhas apertadas; sem lacunas.

-

Cavidades laterais: 0.5–1″ sacos de pellets em paredes “quentes”.

-

Camada superior: 1–2″ blocos + Pellets.

Este “poço frio” equilibra as temperaturas e prolonga o tempo de espera.

Como você mantém a conformidade ao embalar sorvete com gelo seco?

Faça isso sempre: Marca “Gelo seco” ou “Dióxido de carbono, sólido,UN1845, lista Peso da rede de gelo seco, use o Aula 9 rótulo (ar), e ventilação o pacote - sem partes internas herméticas. USPS permite gelo seco no mercado interno com limites de ar; internacional via USPS é proibido. UPS/FedEx seguem IATA PI 954 para o ar.

Por que isso importa: O gás CO₂ deve escapar para evitar o aumento de pressão e o deslocamento de oxigênio. Etiquetas adequadas mantêm seu pacote em movimento e protegem os manipuladores. O ar do USPS tem um 5 limite de lb por correspondência; o solo pode exceder, mas deve permanecer na superfície. As remessas internacionais exigem transportadoras privadas e marcação em conformidade com a IATA.

Lista de verificação de rotulagem sobre como embalar sorvete com gelo seco

-

Nome de envio adequado: Gelo seco / Dióxido de carbono, sólido

-

UN1845 claramente marcado

-

Peso líquido de gelo seco (kg ou lb) do lado de fora

-

Aula 9 Etiqueta de perigo (100 milímetros) para remessas aéreas

-

Embalagem ventilada; não sele o revestimento hermeticamente

| Operadora / Modo | Limite de chave | Marcas obrigatórias | Notas |

|---|---|---|---|

| USPS (Ar) | ≤5 libras de gelo seco | UN1845 + Aula 9 + Peso líquido | Somente doméstico; internacional proibido |

| USPS (Chão) | Sem limite fixo | “Dióxido de carbono, sólido" + Peso líquido | Apenas transporte de superfície |

| UPS/FedEx (Ar) | Aqui está Pi 954 | UN1845 + Aula 9 + Peso líquido | As regras de aceitação da estação variam |

Gelo seco é sempre melhor, ou quando os pacotes de gel ajudam?

O gelo seco é o apenas maneira de manter um verdadeiro congelamento para sorvete. Os pacotes de gel são para intervalos refrigerados. UM híbrido (gelo seco superior + gel lateral) pode amortecer litros delicados ou cargas mistas e reduzir o empenamento da tampa em pistas longas. Para alvos de 0°F, mantenha o gelo seco primário.

2025 tendências que moldam como embalar sorvete com gelo seco

Instantâneo da tendência: As marcas estão mudando do EPS padrão para PUR/VIP para diminuir o tamanho da caixa e a massa de gelo seco enquanto aumenta o tempo de espera. Registradores de dados de baixo custo simplifique a qualificação da pista. Os expedidores estão “dimensionando corretamente” o gelo seco com calculadoras validadas em vez de regras práticas, reduzindo desperdícios e custos.

Último progresso em um olhar

-

VIP se torna popular: Maior durabilidade em caixas menores; menos reembalagens.

-

Monitoramento mais inteligente: Registradores habilitados para API comprovam conformidade e reduzem reclamações.

-

Uso mais ecológico de CO₂: Uma melhor modelagem evita o excesso de gelo sem risco de descongelamento.

Insight de mercado: A demanda por embalagens da cadeia de frio continua aumentando com sobremesas DTC e mercearia eletrônica. Camadas de EPS mais espessas e adoção VIP suportam janelas de 48 a 72 horas sem serviços premium – fundamental para margem.

Perguntas frequentes

Por quanto tempo o gelo seco manterá o sorvete congelado?

Sobre 24–72 horas dependendo do isolamento e da massa de gelo. Comece com 5–10 lb por 24 h e valide na sua pista.

Quanto gelo seco para 12 litros, 36–48 h?

Plano 15–22 lb. em 1,75–2,25″ EPS com um layout pesado; adicionar 20% em ondas de calor.

Posso enviar internacionalmente com USPS?

Não. USPS proíbe gelo seco no correio internacional. Use transportadoras privadas com rótulos compatíveis com IATA.

Onde deve ficar o gelo seco?

Majoritariamente acima as canecas; adicione sacos laterais de pellets em paredes quentes para uniformizar as temperaturas.

A ventilação é obrigatória?

Sim. O revestimento interno e a embalagem externa devem permitir que o CO₂ escape; Nunca sele hermeticamente.

Resumo & Recomendações

Pontos -chave: Você aprendeu como embalar sorvete com gelo seco usando um layout em camadas, gelo do tamanho certo (5–10 lb/24 h como linha de base), isolamento mais espesso para rotas mais longas, e marcação compatível (UN1845, Aula 9 para o ar). Valide com um navio de teste por pista e um registrador antes do dimensionamento.

PRÓXIMOS PASSOS (plano de ação):

-

Qualifique sua pista: Execute um teste com um registrador temporário.

-

Escolha a embalagem: 1.75–2,25″ EPS por 36–48 horas; PUR/VIP por 48–72 horas.

-

Calcular gelo: Use o estimador, em seguida, adicione buffer sazonal.

-

Rótulo & ventilação: UN1845, Peso líquido, Aula 9 (ar), Sem focas herméticas.

Sobre Tempk

Projetamos embalagens congeladas validadas por pista – expedidores isolados, gráficos de gelo seco do tamanho certo, e POPs simples – para que suas cervejas cheguem congeladas sem gastar demais com gelo ou atualizações de serviço. Nossos kits incluem rótulos compatíveis e fluxos de trabalho de registrador, apoiado por técnicos que enviaram milhões de unidades. Vamos personalizar um pacote adequado às suas rotas e ao seu orçamento.

CTA: Pronto para eliminar o risco de seus lançamentos congelados? Entre em contato com a Tempk para uma revisão da embalagem em 15 minutos.