Caixa de gelo isolada no atacado: Compre Smart em 2026?

If you buy insulated ice box wholesale, you are not buying “boxes.” You are buying repeatable temperature control em escala. Em 2026, the fastest way to cut cold chain loss is to stop guessing. Lock one lane, validate one pack-out, then reorder the same validated spec with confidence. Many teams also find that reuse (often 50–100 trips) beats one-way cost, once damage and re-ships are counted.

This insulated ice box wholesale guide will help you answer:

-

Como insulated ice box wholesale for seafood shipping reduces leaks, crush damage, and warm arrivals

-

How to set insulated ice box wholesale MOQ and lead time expectations before you commit

-

How to build an insulated ice box wholesale quality inspection checklist that catches failures early

-

Como escolher insulated ice box wholesale materials without overpaying for “extra insulation”

-

How to compare insulated ice box wholesale price using cost per successful delivery, não preço unitário

Recommended reads for insulated ice box wholesale buyers

-

EPP insulated shipping boxes for reusable lanes

-

VIP insulated cold chain shippers for long exposure and tight ranges

-

Gel ice packs for shipping for chilled lanes

-

Dry ice shipping basics for frozen lanes and venting rules

-

Registradores de dados de temperatura to validate hold time

Caixa de gelo isolada no atacado: What Are You Really Buying?

Resposta direta: Insulated ice box wholesale means you buy temperature-controlled containers in volume from a manufacturer or primary distributor, using a defined spec you can repeat. You get a lower unit cost, more stable supply, and better control over performance. Wholesale boxes are built for handling stress, pressão de empilhamento, e tempo de espera previsível, not weekend camping.

When you treat insulated ice box wholesale as a system purchase, you also standardize labor. Your team packs faster because box size, ajuste da tampa, and coolant placement do not change every day.

Explicação expandida: Em pistas reais, cold chain failures often start with small inconsistencies. A lid that flexes, a corner that cracks, or a wall that is thinner than expected can shorten hold time. Insulated ice box wholesale reduces those surprises when you lock one design and enforce quality checks. It also makes training easier, because your pack-out becomes a repeatable routine.

Insulated Ice Box Wholesale for Seafood Shipping: O que muda?

Seafood lanes punish packaging. You deal with moisture, odor risk, e manuseio rude. That means your insulated ice box wholesale spec should prioritize sealing, drainage control, e resistência ao impacto.

| Seafood shipping risk | What changes the risk | What to specify in wholesale | O que isso significa para você |

|---|---|---|---|

| Derreter água | Poor liners or weak seams | Barreira de umidade + drain plan | Fewer soggy cartons |

| Crush damage | Stacking and forklifts | Strong ribs + stack test | Menos reclamações |

| Odor retention | Hard-to-clean surfaces | Washable interior surface | Easier reuse |

| Warm spikes | Long dwell time | Extra coolant buffer + selo | Fewer “arrived warm” |

Practical tips for insulated ice box wholesale today

-

Leak control: Use a liner and a simple drain rule, not “hope it stays dry.”

-

Empilhamento: Test three-high stacks with your real payload, then inspect lid fit.

-

Route honesty: Design for the worst handoff, not the average delivery.

Caso real: A frozen seafood shipper reduced damage claims after switching to a tougher insulated ice box wholesale model and standardizing the liner and gel pack placement.

Insulated Ice Box Wholesale Materials: Which One Fits Your Lane?

Resposta direta: O melhor insulated ice box wholesale material depends on your lane, abuse level, and reuse plan. EPS is often a one-way option. EPP is often chosen for reuse and rough handling. PU foam sits between cost and performance. VIP hybrids are used when you need high performance in thinner walls.

If you choose material by price alone, you usually pay later in breakage, retorna, e deterioração.

Explicação expandida: Think in “cost per trip,” not “cost per unit.” A one-way lane may tolerate lower durability if it stays dry and handled gently. A return loop needs durability, washability, and stable dimensions. For regulated goods, seu insulated ice box wholesale choice should also support documented testing and batch consistency.

EPP vs EPS for insulated ice box wholesale: plain-English rules

EPP behaves like a tough helmet. It bounces back after impacts. EPS behaves more like a fragile cup. It insulates, but chips and cracks more easily.

| Material option | Typical durability | Typical fit | O que isso significa para você |

|---|---|---|---|

| Espuma EPS | Baixo-médio | One-way, pistas curtas | Lower unit cost, higher damage risk |

| Espuma EPP | Alto | Loops de retorno, manuseio brusco | Maior adiantamento, lower replacement rate |

| Espuma PU | Médio-alto | Pistas mais longas, hotter climates | Strong insulation, heavier builds |

| VIP híbrido | Muito alto | High-value pharma, long exposure | Best performance, needs careful handling |

Wholesale sizing: the 3-size rule that speeds packing

If you run insulated ice box wholesale across many orders, too many sizes slow your team. Three sizes often win: pequeno, essencial, and XL. You reduce pick errors, stack cartons better, and negotiate better pricing tiers.

| Size role | Uso típico | Meta de tempo de espera | O que isso significa para você |

|---|---|---|---|

| Pequeno | amostras, add-ons | 24-48h | lower coolant spend |

| Essencial | most orders | 24-72h | fastest packing flow |

| XL | peak season, consolidations | 48–96h | fewer split shipments |

-

Start with your “core” order. Choose one box that fits 60–80% of shipments.

-

Add small and XL. Only add more sizes if data proves you need them.

-

Match cartons to pallets. Better pallet density cuts freight cost quickly.

Dicas práticas e recomendações

-

One-way parcels: Start with EPS only if lanes are short and cartons stay dry.

-

Loops de retorno: Choose EPP when you already recover packaging from customers.

-

Climas quentes: Run a pilot before upgrading walls or adding premium layers.

Caso real: A meal kit brand improved summer performance by keeping the same box, but switching coolant placement and sealing checks for their wholesale program.

Insulated Ice Box Wholesale Hold Time: How Do You Stop Guessing?

Resposta direta: Stop guessing by defining a pass/fail range and testing one pack-out. Seu insulated ice box wholesale hold time should cover your longest door-to-door hours, mais um buffer de atraso. Then you validate with a pilot test using a simple temperature logger.

This turns “marketing claims” into a number you can reorder.

Explicação expandida: Buyers overspend when they overspec hold time “just in case.” They also lose money when they underspec and shipments arrive warm. The smarter path is simple: define the lane, adicionar um buffer, então teste. Seu insulated ice box wholesale spec becomes a repeatable SOP, não é um palpite.

A 2-Minute insulated ice box wholesale spec builder

Circle your answers, then choose what to test first:

-

Lane type: parcela / local route / exportar

-

Duração desejada: 24h / 48h / 72h+

-

Temperature goal: refrigerado / congelado / controlled room temp

-

Worst ambient: leve / quente / misturado

-

Dwell risk: baixo / médio / alto

Regra simples: If you pick quente + high dwell, increase seal quality and coolant buffer first. Then test.

Quick pack-out math you can actually use

-

Estimate door-to-door hours for your worst lane.

-

Adicionar +20% buffer for delays and doorstep time.

-

Choose a box size that allows coolant on multiple sides.

-

Run a pilot with a temperature logger and record results.

| Pack-out choice | O que muda | What you should do | O que isso significa para você |

|---|---|---|---|

| Colocação do refrigerante | Hot spots form at edges | Place coolant on 2–4 sides | More even temperature |

| Empty air gaps | Air warms fast | Fill gaps with inserts | Menos oscilações |

| Oversized box | More warm air inside | Right-size to payload | Lower coolant cost |

| Weak lid seal | Warm air leaks in | Improve seal checks | Longer stability |

Coolant choices for insulated ice box wholesale: gel, PCM, ou gelo seco?

Your coolant choice changes both performance and workflow. Gel packs are simple for chilled lanes. PCM (material de mudança de fase) packs are more precise for narrow ranges. Dry ice is powerful for frozen lanes, but it needs venting and stricter handling.

| Opção de refrigerante | Melhor para | Cuidados | O que isso significa para você |

|---|---|---|---|

| Pacotes de gel | comida gelada, kits de refeições | needs pre-conditioning | simple operations |

| Pacotes PCM | tight ranges like 2–8°C | higher unit cost | fewer freeze or warm spots |

| Gelo seco | produtos congelados | ventilação + Rotulando SOP | strongest freezing power |

-

Pistas refrigeradas: start with gel packs, then test for 48 horas.

-

Tight ranges: use PCM when overcooling causes damage.

-

Pistas congeladas: use dry ice only with a vented design and trained staff.

Dicas práticas que você pode usar imediatamente

-

Do not stack all coolant on top. Side cooling reduces hot spots.

-

Keep product centered. Edges warm first during spikes.

-

Validate your real payload. “Similar weight” tests mislead you.

Caso real: A grocery shipper hit a 48-hour goal by changing gel pack placement, not by changing their bulk box.

Insulated Ice Box Wholesale Suppliers: How Do You Vet MOQ, Tempo de espera, and QC?

Resposta direta: Um bom insulated ice box wholesale supplier proves three things: performance data, production consistency, e controle de mudança. Price is not enough. You need repeatable materials, stable molding conditions, and a QC plan you can audit.

If your supplier cannot explain their test method in plain language, treat claims as marketing.

Explicação expandida: Most failures start in the RFQ. Vague specs create vague results. Your RFQ must describe use, faixa, faixa de temperatura, and pass/fail targets. Then you validate samples and early batches with a checklist. That is how insulated ice box wholesale becomes predictable.

12 RFQ questions for insulated ice box wholesale suppliers

Ask these in writing:

-

What material and density are you proposing, e por quê?

-

What wall thickness options exist for this design?

-

How does the lid seal work, and how is it tested?

-

What temperature range is the design intended for?

-

What thermal test method can you provide (lab or lane)?

-

What is MOQ for no logo, 1-cor, and full customization?

-

What is lead time for samples, then mass production?

-

How do you pack and palletize for export shipping?

-

What are the most common failures (rachaduras, warping, vazamentos)?

-

What QC checks happen in-process and at final inspection?

-

Can you provide cleaning guidance for reusable models?

-

How do you handle batch traceability if defects appear?

A Practical Quality Inspection Checklist

Use this on samples and early production:

-

Lid closes evenly and stays closed under light pressure

-

Seal contact line looks consistent around the full rim

-

Corners have no thin spots or soft zones

-

Walls feel uniform, not “hollow” in one area

-

Box stays stable when stacked with real payload

-

Interior has no sharp edges and no strong odor

| QC check | O que medir | Pass/fail rule | O que isso significa para você |

|---|---|---|---|

| Lid fit | Gap size + latch force | No visible gaps | Fewer warm swings |

| Espessura da parede | Corner and hinge zones | Within tolerance | Menos rachaduras |

| Compressão | Stack with payload | No deformation | Menos reclamações |

| Superfície | Edges and burrs | No sharp points | Manuseio mais seguro |

Scorecard do fornecedor (quick version)

Give each item 0–2 points:

-

Process control: are molding settings recorded?

-

Medição: are lid fit and thickness measured each batch?

-

Rastreabilidade: can they trace a shipment to a lot?

-

Corrective action: can they show a real fix, não é uma promessa?

-

Capacidade: can they support peak season without shortcuts?

Score 8–10: menor risco. Score 5–7: piloto primeiro. Pontuação <5: expect surprises.

Caso real: A distributor stopped lid-warp complaints after adding a simple lid-fit gauge to incoming checks for their wholesale batches.

Insulated Ice Box Wholesale Price: What Drives Total Cost?

Resposta direta: O melhor insulated ice box wholesale price is the lowest custo por entrega bem-sucedida. Unit price is only one line item. Real cost includes coolant, trabalho, dano, reembolsos, and disposal or return handling.

A slightly higher unit price can be cheaper if it reduces failures.

Explicação expandida: Think in five buckets: custo da caixa, coolant cost, labor time, failure cost, and lifecycle cost. Your job is to reduce failures first, then optimize materials and sizing. When you standardize your insulated ice box wholesale SKUs, you also concentrate volume and unlock better tiers.

Insulated ice box wholesale price drivers you should watch

| Pricing driver | What changes the cost | What changes outcomes | Your practical move |

|---|---|---|---|

| Espessura da parede | More material | Maior tempo de espera | Match to lane, não é hábito |

| Lid seal design | Better parts | Menos oscilações | Ask for seal evidence |

| Densidade / rigidity | Stronger structure | Less cracking | Request handling samples |

| Custom logo & cor | Configurar + rejects | Brand consistency | Piloto, então dimensione |

| Accessories | Adds unit cost | Embalagem mais rápida | Add only what saves labor |

Lifecycle cost comparison (simple view)

| Fator de custo | One-way boxes | Reusable wholesale boxes | O que isso significa para você |

|---|---|---|---|

| Unit price | Mais baixo | Médio | Not the full story |

| Trips per box | 1 | Often 50–100 | Cost per trip drops |

| Taxa de dano | Mais alto | Mais baixo | Menos reclamações |

| Waste handling | Mais alto | Mais baixo | Lower disposal burden |

Practical negotiation tips

-

Ask for two quotes: “base” and “performance” on the same size.

-

Separate tooling from unit price to see payback clearly.

-

Tie the price to the agreed performance test result.

Caso real: A shipper paid more per box but reduced refunds enough to lower total cost in their insulated ice box wholesale programa.

Insulated Ice Box Wholesale Compliance: Comida, Farmacêutico, and Dry Ice Basics

Resposta direta: Compliance is a document pack, não é uma promessa. Para insulated ice box wholesale programas, you should request material declarations, thermal evidence, and change notifications. If you use dry ice for frozen lanes, you also need venting and consistent labeling procedures.

This protects you during audits, comentários de clientes, and claims disputes.

Explicação expandida: Food lanes care about cleanliness and food-contact suitability. Pharma lanes care about temperature evidence and traceability. Dry ice lanes add safety and transport rules because CO₂ gas must vent. Seu insulated ice box wholesale spec should support these needs without adding unnecessary complexity.

The simple document pack to request

-

Material declaration (resin type and additives)

-

Region-specific food-contact declarations (when relevant)

-

Thermal test report that matches your lane profile

-

QC plan (entrada, em processo, final inspection)

-

Change notification rule (no silent material changes)

-

Coolant SDS sheets (gel, PCM, or dry ice handling guidance)

Gelo seco: three rules that prevent expensive mistakes

-

Ventive o pacote: Gelo seco libera gás CO₂. Do not fully seal it.

-

Label consistently: “Dry ice” and UN1845 are commonly required in air workflows.

-

Control quantity: Stay within carrier and route limits, then document net weight.

Practical tips you can apply

-

Build a one-page SOP for pack-out and labeling, then train your team once.

-

Keep a version log of each insulated ice box wholesale design revision.

-

Treat any material change as a new validation trigger.

Caso real: An ice cream shipper reduced rejects after switching to a vented insulated ice box wholesale design and tightening dry ice handling rules.

2026 Insulated Ice Box Wholesale Trends You Should Plan For

Visão geral da tendência: Em janeiro 2026, buyers are asking for proof, não promessas. They want reusable options, clearer material documentation, and easier-to-run pack-outs. They also want fewer SKUs and more repeatability, so teams pack faster and make fewer mistakes.

This shifts insulated ice box wholesale from “box shopping” to “delivery outcome management.”

Instantâneo do progresso mais recente

-

More reuse loops: Returnable packaging reduces waste and stabilizes cost per trip.

-

More measurement: Temperature loggers and lane tests become normal, não opcional.

-

More standardization: Three sizes beat ten sizes for speed and accuracy.

-

More system thinking: Caixa, refrigerante, forro, and SOP are tested together.

Insight de mercado: The teams that win in 2026 build one validated program, then scale it. They do not chase a new “best box” every quarter. A stable insulated ice box wholesale spec also improves supplier leverage and reduces stockouts.

Interactive self-check: are you ready to place a wholesale PO?

Pontue cada item 0 (não), 1 (partly), ou 2 (sim). Total your score.

-

You defined a target temperature range and the longest lane time.

-

You fixed a pack-out diagram (coolant placement + conta).

-

You wrote a pass/fail rule (exemplo: “2–8°C for 48 hours”).

-

You requested a test report or ran a pilot that matches your profile.

-

You selected your 3 box sizes and forecast volumes by size.

-

You agreed on incoming QC checks (ajuste da tampa, rachaduras, dimensões).

-

You confirmed dry ice venting and labeling needs (se aplicável).

-

You set a reorder point and safety stock rule.

Guia de pontuação

-

0–8: run a small pilot first.

-

9–12: place a limited order and track damage and temperature results.

-

13–16: you are ready to scale your insulated ice box wholesale programa.

Perguntas frequentes

Q1: What MOQ should I expect for insulated ice box wholesale MOQ and lead time?

MOQ depends on size and customization. Start with a pilot batch, then scale after your lane test proves results.

Q2: Is insulated ice box wholesale for seafood shipping different from meal kits?

Sim. Seafood needs leak control and rough-handling protection. Meal kits often prioritize weight and packing speed.

Q3: How do I lower insulated ice box wholesale price without losing performance?

Standardize SKUs first. Then improve carton density and negotiate tiered volume pricing on a validated spec.

Q4: Is EPP insulated ice box wholesale always better than EPS?

Nem sempre. EPP fits reuse and abuse. EPS can work for short, one-way lanes if cartons stay dry.

Q5: What is the simplest way to improve hold time without changing the box?

Improve pack-out. Reduce air gaps, reposition coolant, and add a realistic delay buffer.

Q6: Do I need thermal test reports for insulated ice box wholesale?

If temperature matters, sim. A repeatable test and pass/fail range protect you when lanes get rough.

Resumo e recomendações práticas

Takeaways -chave: Insulated ice box wholesale works when you treat it as a repeatable system. Defina sua pista, set a temperature-and-time target, and validate one pack-out. Choose material based on reuse reality, não preço unitário. Protect the program with supplier questions, incoming QC, e controle de mudança. Then standardize sizes so your team packs faster and makes fewer mistakes.

O que você deve fazer a seguir: Write your lane spec today. Order samples from 2–3 suppliers. Run a pilot with a temperature logger. Lock your QC checklist and reorder point. Then scale your insulated ice box wholesale purchase with confidence.

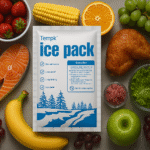

Sobre Tempk

We build temperature-controlled packaging for food, médico, and industrial cold chains. We focus on durable designs, consistent manufacturing, and pack-outs you can repeat at scale. If you share your lane time, temperatura alvo, and shipment size, we can recommend a practical insulated ice box wholesale starting spec you can validate quickly.

CTA: Send your target temperature range, longest lane time, and box size needs. We’ll help you design a pilot pack-out you can measure and reorder.