Quando você precisa guardar comida, medicamentos ou produtos biológicos congelados por dias, os pacotes tradicionais de gelo seco ou gel por si só muitas vezes ficam aquém. Pacotes de gelo seco com descongelamento lento misturar dióxido de carbono sólido (gelo seco) com materiais de gel de mudança de fase para manter temperaturas ultra frias para até 72 horas, superando a janela típica de 18 a 24 horas do gelo seco comum. Ao retardar a sublimação do CO₂ e fornecer uma proteção contra picos repentinos de temperatura, esses pacotes híbridos prolongam o tempo de resfriamento e reduzem a quantidade de gelo seco necessária. Este guia completo explica como funcionam as bolsas de gelo seco com descongelamento lento, quando escolhê-los, como embalá-los com segurança e quais tendências estão moldando seu futuro 2025.

O que diferencia uma bolsa de gelo seco de descongelamento lento das tradicionais bolsas de gelo seco ou gel?

Quando você deve escolher bolsas de gelo seco com descongelamento lento em vez de bolsas de gel ou gelo seco puro?

Como você calcula as quantidades de gelo seco e gel para diferentes tamanhos de recipientes?

Quais regras regulatórias e de segurança regem o uso de bolsas de gelo seco híbridas?

Quais inovações e tendências de mercado impactarão as bolsas de gelo seco com degelo lento em 2025?

O que é uma bolsa de gelo seco com descongelamento lento e como funciona?

Uma bolsa de gelo seco com descongelamento lento é uma solução de resfriamento híbrida que combina o frio intenso do gelo seco com o resfriamento constante de bolsas de gel ou materiais de mudança de fase. (PCMs). O gelo seco é dióxido de carbono sólido que sublima diretamente em gás, proporcionando temperaturas em torno de –78°C, mas durando apenas 18–24 horas para cada 2.5 quilogramas usados. Envolvendo pellets ou folhas de gelo seco em camadas de gel ou PCM, o pacote híbrido retarda a sublimação e modera o aumento da temperatura. Os pacotes de gel congelam em 0 °C e descongelar lentamente; folhas de PCM avançadas suportam –12 °C a –18 °C para 48 horas e pode ser reutilizado ao longo 30 ciclos

. O efeito combinado é temperaturas abaixo de zero constantes até 72 horas, liberação reduzida de CO₂ e proteção para mercadorias sensíveis.

Componentes de uma bolsa de gelo seco com descongelamento lento

| Componente do pacote | Função | Beneficiar para você |

| Isolamento VIP ou espuma | Reduz a perda térmica e retarda a sublimação | Prolonga a duração do resfriamento e reduz o consumo de gelo seco |

| Células de gelo seco seladas | Fornece temperaturas ultra frias (< –70ºC) e sublime sem deixar resíduos líquidos | Ideal para vacinas congeladas, carnes e produtos biológicos |

| Pacotes de gel ou PCM | Congele rapidamente e descongele lentamente, mantendo a temperatura constante durante a mudança de fase | Evite picos de temperatura e proteja produtos delicados |

| Configuração híbrida | Combina gelo seco e gel em um pacote | Prolonga o tempo de resfriamento e reduz as emissões de CO₂ |

Uma típica bolsa de gelo seco de degelo lento inclui uma camada de painéis isolados a vácuo (VIPs) ou espuma espessa para retardar a transferência de calor, um núcleo de gelo seco selado e uma camada externa de gel ou pacotes de PCM. Como o gelo seco sublima, o gel absorve parte da energia fria, liberando-o gradualmente em vez de tudo de uma vez. Este design evita o rápido aumento de temperatura que o gelo seco puro pode causar quando embalado diretamente contra os produtos. Também reduz a condensação porque o gás escapa antes da formação de umidade.

Quando você deve escolher uma bolsa de gelo seco com descongelamento lento?

Selecionando entre gelo seco tradicional, pacotes de gel ou um pacote híbrido depende dos requisitos de temperatura, duração da remessa e restrições regulatórias para sua carga.

Alimentos congelados e kits de refeição: Para carnes, frutos do mar ou refeições preparadas, manter temperaturas abaixo de –20 °C é essencial. O gelo seco tradicional proporciona condições ultra frias, mas sublima rapidamente. Bolsas de gelo seco com descongelamento lento oferecem temperaturas abaixo de zero constantes por 24 a 48 horas; quando revestidos com folhas de gel PCM, eles podem manter o frio por 48 a 72 horas. Se a sua remessa viajar por mais de três dias ou passar por calor extremo, é recomendado combinar pacotes de descongelamento lento com gel extra ou isolamento VIP.

Farmacêuticos e biológicos: Os produtos biofarmacêuticos muitas vezes requerem temperaturas abaixo de –60 °C. Células de CO₂ seladas e géis criogênicos em embalagens híbridas podem manter –60 °C a –40 °C por até 48 horas sem taxas de materiais perigosos. Para vacinas que necessitam de 2–8 °C, pacotes de gel por si só podem ser suficientes; mas manter –12 °C a –18 °C durante 48 horas, combinar gelo seco com folhas de gel PCM oferece flexibilidade.

Mantimentos de comércio eletrônico e kits de refeição: Os serviços de mercearia online devem manter os produtos entre 0–5 °C. Os pacotes de gel congelam rapidamente e descongelam lentamente, tornando-os ideais para manter vegetais frescos por 24 a 48 horas. Quando pedidos mistos incluem itens congelados, como sorvete, uma bolsa de gelo seco de degelo lento com uma camada de gel cria zonas de temperatura separadas, manter o sorvete duro enquanto os vegetais permanecem resfriados.

Amostras de laboratório e ciências da vida: Culturas celulares, plasma e sangue requerem –70 °C ou mais frio. Envolver gelo seco em um pacote de descongelamento lento reduz os riscos de manuseio e aumenta o tempo de espera; o gel amortece os frascos e fornece um tampão de temperatura intermediária. Pacotes híbridos podem ser reutilizados várias vezes, reduzindo desperdícios e garantindo a conformidade com os protocolos de segurança do laboratório.

Entregas ao consumidor e aventuras ao ar livre: Para caixas de carne por assinatura ou acampamentos, pacotes de descongelamento lento oferecem frio duradouro sem a necessidade de luvas especiais ou armazenamento ventilado. Eles podem manter os itens congelados por 48 horas ou mais, tornando-os fáceis de usar para campistas e viagens rodoviárias.

Práticas recomendadas de embalagem para bolsas de gelo seco com descongelamento lento

A embalagem adequada maximiza o desempenho das embalagens híbridas. Siga estas diretrizes para manter um resfriamento consistente e cumprir os regulamentos de segurança.

Use um recipiente isolado de alta qualidade: Painéis isolados a vácuo (VIPs) ou espuma espessa reduz a perda térmica. VIPs são até cinco vezes mais eficientes que a espuma convencional.

Pré-resfrie o recipiente: Pré-resfrie sua caixa de remessa colocando pacotes de gel dentro por pelo menos uma hora antes de carregá-la. Começar com um recipiente frio prolonga o período de resfriamento.

Ventive o contêiner: Nunca feche gelo seco em uma caixa hermética. Sempre inclua orifícios de ventilação ou uma tampa solta para permitir que o gás CO₂ escape e evitar o aumento de pressão. Embalagem ventilada também é necessária para viagens aéreas.

Etiqueta claramente: Marque a embalagem com “Gelo Seco” ou “Dióxido de Carbono, sólido” e indique o peso líquido de CO₂. Mesmo as embalagens híbridas devem ser rotuladas quando contêm células de gelo seco seladas.

Calcular a quantidade de refrigerante: Como regra geral, usar cerca de 2.5 kg de gelo seco por 24 horas de tempo de envio. Pacotes híbridos de sublimação lenta, então menos CO₂ pode ser necessário. Em caso de dúvida, erre pelo lado de mais refrigerante e isolamento.

Requisitos estimados de gelo seco e folha híbrida

| Volume do contêiner | CO₂ sugerido (Pellets) | Número de folhas de embalagem híbrida | Tempo de espera esperado |

| 10 L | 0.75–1kg | 1 planilha híbrida | ≈ 12 horas |

| 20 L | 1.5–2kg | 2 folhas híbridas | ≈ 24 horas |

| 30 L | 2.5–3kg | 3–4 folhas híbridas | ≈ 36 horas |

| 40 L | 4–5kg | 4–5 folhas híbridas | ≈ 48–72 horas |

Use esta tabela como ponto de partida, ajuste para temperatura ambiente, espessura do isolamento e massa térmica do produto. Sempre pré-resfrie o recipiente e monitore a temperatura interna para verificar o desempenho.

Estratégia de embalagem

Hidrate e congele as folhas corretamente: Algumas placas de gelo seco requerem hidratação. Mergulhe a folha em água fria por 3–5 minutos para permitir que as células absorvam água, em seguida, congele a –20 °C ou mais frio por pelo menos 24 horas.

Posicionamento estratégico: Posicione embalagens híbridas ao redor do produto e não apenas na parte inferior. Combine produtos sensíveis com plástico bolha ou inserções acolchoadas para evitar danos.

Monitorar temperatura: Inclui um registrador de temperatura NFC ou Bluetooth dentro da embalagem para rastrear desvios e fornecer rastreabilidade. Sensores inteligentes estão se tornando padrão em 2025

Equipamento de segurança e manuseio

Sempre trate gelo seco e embalagens híbridas com respeito. Use luvas isoladas e óculos de segurança durante o manuseio para evitar queimaduras pelo frio. Evite armazenar gelo seco em geladeiras fechadas; O gás CO₂ pode deslocar o oxigênio e se acumular em espaços confinados. Depois de desembalar, recupere gelo seco ou pacotes não utilizados com pinças e coloque-os em um refrigerador ventilado para reutilização dentro de dois a três dias. Não congele novamente gelo seco sublimado; uma vez que se foi, não pode ser regenerado. Doe o excesso de gelo seco para um laboratório ou restaurante local para minimizar o desperdício.

Considerações de segurança e conformidade regulatória

Embora os pacotes híbridos mitiguem alguns riscos, o manuseio de qualquer forma de gelo seco exige conformidade com os regulamentos de segurança e transporte. O gelo seco causa queimaduras graves por contato e pode atingir –60 °C mesmo quando envolto em gel. O gás CO₂ é mais pesado que o ar e pode acumular-se em espaços mal ventilados. Siga estas diretrizes:

Requisitos de ventilação: Os regulamentos de transporte internacional exigem ventilação adequada para que o gelo seco libere gás CO₂. Certifique-se de que seu recipiente tenha orifícios de ventilação ou microporos; as transportadoras podem recusar pacotes que não cumpram.

Rotulagem e documentação: O gelo seco é classificado como um Aula 9 material perigoso sob UN1845. As remessas em aeronaves de passageiros estão limitadas a 2.5 kg por pacote e deve ser ventilado e rotulado. Pacotes híbridos com menos de 2.5 kg de CO₂ pode estar isento de alguns requisitos de rotulagem perigosa, mas sempre confirme com sua operadora. A embalagem deve exibir “Gelo Seco” ou “Dióxido de Carbono, sólido” e o peso líquido.

Exposição ao congelamento e ao CO₂: Embora o CO₂ esteja selado, a superfície externa pode estar extremamente fria. Use luvas e óculos criogênicos ao embalar e desembalar. Nunca armazene embalagens híbridas em salas fechadas ou em geladeiras domésticas; O gás CO₂ pode acumular-se.

Descarte e impacto ambiental: Os componentes do pacote de gel são frequentemente biodegradáveis e podem ser recongelados dezenas de vezes. Depois que o gelo seco tiver sublimado completamente, você não pode reconstituí-lo; descarte sobras de pacotes de gel ou PCM de forma responsável. Escolha fornecedores que capturem CO₂ de fontes renováveis, como fermentação de etanol.

Considerações sobre custos e sustentabilidade

Mudar para bolsas de gelo seco com descongelamento lento envolve investimento inicial, mas traz benefícios de longo prazo para o orçamento e o meio ambiente.

Reduza os custos de embalagem ao longo do tempo: Embora o gelo seco seja barato por quilograma, taxas de materiais perigosos, custos de treinamento e embalagens descartáveis aumentam as despesas. Pacotes híbridos podem ser reutilizados 30 ciclos, reduzindo os gastos com embalagens em até 75 %. Porque os pacotes de gel mantêm temperaturas constantes, você pode usar quantidades menores de gelo seco, reduzindo custos de matéria-prima. Em um estudo de caso de Los Angeles, uma empresa de sobremesas trocou pellets de gelo seco soltos por folhas de descongelamento lento; tempos de trânsito estendidos de 36 para 60 horas, O consumo de CO₂ caiu 20 % e as reclamações dos clientes sobre queimaduras no freezer quase desapareceram.

Melhor qualidade do produto e satisfação do cliente: As embalagens híbridas minimizam as oscilações de temperatura que danificam os produtos. A sublimação controlada evita queimaduras de congelamento e preserva a eficácia de vacinas e produtos biológicos. Melhor qualidade do produto reduz devoluções e promove a fidelidade do cliente, compensando o custo inicial mais alto.

Sustentabilidade e pegada de carbono: As embalagens híbridas usam menos CO₂ em geral, combinando gelo seco com géis de mudança de fase. Muitos géis são biodegradáveis ou recicláveis, reduzindo o impacto ambiental. Os fabricantes também estão adquirindo CO₂ de matérias-primas de base biológica, redução das emissões de gases com efeito de estufa. Ao estender os tempos de espera, embalagens híbridas reduzem o número de remessas e a necessidade de refrigeração com uso intensivo de energia, reduzindo sua pegada de carbono.

2025 Tendências e inovações em bolsas de gelo seco com descongelamento lento

A indústria da cadeia fria está evoluindo rapidamente. Por 2025 várias inovações estão remodelando a forma como as bolsas de gelo seco com descongelamento lento são projetadas e usadas, melhorando o desempenho, sustentabilidade e conformidade regulatória

Visão geral das tendências

Embalagem híbrida e multizona: A combinação de gelo seco e materiais PCM em um único pacote cria múltiplas zonas de temperatura, permitindo que uma remessa transporte produtos congelados e refrigerados

Folhas de gel avançadas: As novas folhas de gel suportam –12 °C a –18 °C por até 48 horas e pode ser reutilizado ao longo 30 ciclos, tornando-os uma alternativa econômica ao gelo seco puro

Sensores inteligentes: A integração de registradores de temperatura NFC ou Bluetooth fornece monitoramento em tempo real e alertas para variações de temperatura

Materiais ecológicos: Os fabricantes estão desenvolvendo isolamento biodegradável e materiais PCM para reduzir o desperdício e a poluição

- . O CO₂ usado na produção de gelo seco é cada vez mais capturado de fontes renováveis

Atualizações regulatórias: A Lei de Modernização da Segurança Alimentar (FSMA) e outras regulamentações incentivam os transportadores a adotar soluções que reduzam os riscos e garantam a rastreabilidade

Últimos desenvolvimentos de vista

Desafios de fornecimento de CO₂: A demanda por gelo seco está crescendo cerca de 5 % por ano enquanto a oferta de CO₂ aumenta apenas 0.5 %, levando a aumentos de preços de até 30 % em 2024. Pacotes híbridos ajudam a mitigar a escassez

Classificação não perigosa: Alguns pacotes de substituição híbridos encerram CO₂ em células seladas, limitando sua liberação e isentando-os de Classe 9 rotulagem

Folhas de embalagem reutilizáveis: As modernas placas de gelo seco com células flexíveis fornecem –40 a –20 °C por 36–48 horas e são reutilizáveis

Crescimento do mercado: O mercado global de logística da cadeia de frio deverá se expandir de US$ 268,5 bilhões em 2023 para US$ 647,47 bilhões por 2028 em um taxa composta de crescimento anual de 15.1 %

- . A crescente demanda por alimentos perecíveis e produtos farmacêuticos está estimulando a inovação em embalagens

Insights de mercado

A ascensão de comércio eletrônico, kits de refeição e produtos biológicos alimentou a demanda por soluções confiáveis de cadeia de frio. Os consumidores esperam que mantimentos e medicamentos frescos sejam entregues com segurança, e as empresas querem reduzir a deterioração e os riscos regulatórios. Bolsas de gelo seco com descongelamento lento apoiam essas tendências, fornecendo resfriamento prolongado, reduzindo o uso de CO₂ e melhorando a sustentabilidade. Eles também ajudam as empresas a atender aos requisitos da FSMA para monitoramento de temperatura e manutenção de registros.

Perguntas frequentes

Q1: Quanto tempo dura uma bolsa de gelo seco com descongelamento lento? Um pacote híbrido pode manter temperaturas abaixo de zero por 36–72 horas, dependendo da quantidade de CO₂ e PCM utilizados. Isso é mais longo do que o gelo seco tradicional sozinho, que normalmente dura 18–24 horas para 2.5 kg. Pré-resfriar seu contêiner e usar um bom isolamento prolonga a duração do resfriamento.

Q2: Uma bolsa de gelo seco com descongelamento lento é segura para o transporte de alimentos?? Sim. Envolver gelo seco em células seladas e envolvê-lo com gel reduz o risco de congelamento e evita o contato direto com os produtos. Porque o CO₂ sublima diretamente em gás, nenhum resíduo de água permanece para danificar a embalagem. Sempre forneça ventilação e rotule a embalagem adequadamente.

Q3: Posso reutilizar uma bolsa de gelo seco com descongelamento lento? Muitos pacotes híbridos são projetados para reutilização. Folhas de gel de alta qualidade podem ser congeladas novamente 30 ciclos com menos de 10 % perda de capacidade. O gelo seco não pode ser recongelado depois de sublimado, mas você pode reutilizar o pacote flexível e recarregá-lo com novo CO₂.

Q4: Qual é a diferença entre uma bolsa de gel e uma bolsa de gelo seco com descongelamento lento? Os pacotes de gel congelam rapidamente e descongelam lentamente, mantendo temperaturas próximas 0 °C. Eles são ideais para manter produtos entre 2 e 8 °C e não exigem rotulagem de materiais perigosos. Um pacote híbrido combina um pacote de gel com gelo seco para atingir temperaturas mais baixas (< –20 °C) e durações mais longas.

Q5: Como descarto os restos de CO₂ e gel após a chegada da minha remessa? Deixe sobras de gelo seco sublimar ao ar livre ou em uma área ventilada; nunca jogue no lixo. Os pacotes de gel muitas vezes podem ser reutilizados ou descartados no lixo geral se não forem tóxicos. Se a embalagem contiver PCM especializado, siga as diretrizes de descarte do seu fornecedor. Doar sobras de CO₂ para um laboratório ou restaurante local é uma opção sustentável.

Q6: Os pacotes de gelo seco com degelo lento são permitidos em aviões?? Em voos de passageiros, o TSA e a FAA permitem que você traga até 2.5 kg (5.5 Libra) de gelo seco por passageiro na bagagem de mão ou despachada, desde que o recipiente seja ventilado e claramente rotulado. As remessas de carga seguem os Regulamentos de Mercadorias Perigosas da IATA, exigindo classe 9 etiquetas de perigo e entradas de conhecimento de embarque. Os pacotes de gel por si só não estão sujeitos a esses limites.

Dicas e conselhos práticos

Escolha o pacote certo para o trabalho: Use pacotes de gel para remessas abaixo 24 horas ou produtos que necessitam de 2–8 °C. Para viagens mais longas ou temperaturas abaixo de –20 °C, selecione pacotes híbridos de degelo lento.

Considere seu impacto ambiental: Opte por fornecedores que oferecem folhas de gel reutilizáveis e obtêm CO₂ de matérias-primas renováveis. Reutilizando embalagens híbridas até 30 vezes reduz o desperdício e o custo.

Implementar monitoramento inteligente: Use sensores de temperatura NFC ou Bluetooth em suas remessas para registrar dados em tempo real e reagir rapidamente a desvios

- . Esses dados podem ajudar a melhorar os métodos de embalagem e cumprir os requisitos de manutenção de registros da FSMA.

Eduque sua equipe: Treine a equipe sobre o manuseio adequado – use luvas, pacotes de ventilação, rotular corretamente e seguir as regras de descarte. Um bom treinamento reduz acidentes e penalidades regulatórias.

Exemplo do mundo real: Uma empresa de sobremesas em Los Angeles trocou pellets de gelo seco soltos por embalagens híbridas de degelo lento com géis de PCM. Os tempos de trânsito aumentaram de 36 horas para 60 horas, O consumo de CO₂ caiu 20 % e as reclamações dos clientes sobre queimaduras no freezer quase desapareceram. A empresa também economizou em taxas de materiais perigosos e melhorou a sustentabilidade.

Resumo e recomendações

Resumindo, bolsas de gelo seco com descongelamento lento mesclam gelo seco e tecnologia de gel para proporcionar longa duração, resfriamento sem umidade para remessas da cadeia de frio. Ao retardar a sublimação e criar múltiplas zonas de temperatura, essas embalagens mantêm os produtos congelados e refrigerados seguros por até 72 horas. Isolamento adequado, ventilação e cálculos precisos de refrigerante são essenciais para maximizar o desempenho. Siga sempre as orientações de segurança – use luvas, ventile os pacotes e rotule-os corretamente - para se proteger e cumprir os regulamentos. Ao investir em embalagens híbridas reutilizáveis, você reduz taxas de materiais perigosos, reduzir o uso de CO₂ e apoiar as metas de sustentabilidade.

Plano de ação

Avalie suas necessidades de remessa: Determinar os requisitos de temperatura, duração do trânsito e restrições regulatórias. Use a tabela de refrigerante acima para estimar o número de folhas de embalagem híbrida.

Escolha o pacote certo: Selecione um design de descongelamento lento que corresponda à sua categoria de produto (alimentos congelados, produtos farmacêuticos ou produtos mistos). Para remessas sob 24 horas, pacotes de gel podem ser suficientes; para remessas mais longas ou ultra frias, pacotes híbridos ou sistemas multizona são recomendados.

Siga as melhores práticas: Pré-resfrie seus recipientes, calcule com precisão as quantidades de gelo seco e gel, fornecer ventilação e monitorar temperaturas durante o trânsito.

Envolva-se com fornecedores: Pergunte sobre a reutilização do pacote, Certificações de fornecimento e conformidade de CO₂. Procure materiais ecológicos e sensores inteligentes para preparar sua cadeia de frio para o futuro.

Mantenha-se informado: Regulamentações e tecnologia evoluem rapidamente. Marque este guia como favorito e fique por dentro das novas inovações e atualizações regulatórias.

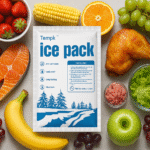

Sobre Tempk

Nós somos Tempk, pioneira em soluções de embalagem para cadeia de frio. Nossa equipe combina décadas de experiência no setor com pesquisa e desenvolvimento para projetar sistemas de refrigeração híbridos avançados. Oferecemos bolsas térmicas médicas com materiais de mudança de fase, recipientes isolados a vácuo e bolsas de gelo seco com descongelamento lento que atendem às diretrizes GMP e GDP. Nossos produtos são reutilizáveis, ambientalmente amigável e fornecer desempenho consistente.

Pronto para atualizar sua cadeia de frio? Contate-nos para aconselhamento personalizado e escolha a melhor bolsa de gelo seco com descongelamento lento para sua aplicação específica.