إن شحن الأطعمة المجمدة ليس بالأمر السهل مثل وضع بعض الثلج في صندوق. للحفاظ على الجودة والسلامة, أنت بحاجة إلى طريقة التبريد الصحيحة. أ حزمة الثلج الجاف للشحن تحافظ البضائع المجمدة على المنتجات في درجات حرارة أقل من -10 درجة مئوية عن طريق التسامي من ثاني أكسيد الكربون الصلب إلى الغاز. يساعدك هذا الدليل على اختيار واستخدام عبوات الثلج الجاف بشكل فعال, الرسم على 2025 اللوائح وأحدث الابتكارات. بحلول النهاية, ستعرف كيفية حجم الحزم, قم بتعبئة الصناديق بشكل صحيح واتبع قواعد الناقل.

كيف تعمل عبوات الثلج الجاف ولماذا هي أفضل من عبوات الجل للسلع المجمدة.

ما هي كمية الثلج الجاف التي تحتاجها لأحجام ومسارات الصناديق المختلفة.

تعليمات خطوة بخطوة لتعبئة الثلج الجاف والتعامل معه بأمان.

الاختلافات بين الثلج الجاف, عبوات الجل ومواد تغيير الطور ومتى يتم استخدام كل منها.

2025 الاتجاهات في حزم الثلج الجاف, بما في ذلك العزل الصديق للبيئة وأجهزة الاستشعار الذكية.

كيف تحافظ عبوات الثلج الجاف على سلامة البضائع المجمدة أثناء النقل?

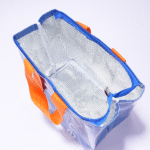

إجابة: تتكون عبوات الثلج الجاف من ثاني أكسيد الكربون الصلب المخزن في أغطية بلاستيكية أو غير منسوجة شديدة التحمل. عند تعرضه للهواء الدافئ, يتسامى ثاني أكسيد الكربون الصلب (يتحول مباشرة إلى غاز) عند حوالي -78.5 درجة مئوية. تمتص هذه العملية الحرارة من المنتجات المحيطة, إبقائها تحت درجة التجمد. يسمح الشاحن المعزول ذو التهوية لغاز ثاني أكسيد الكربون بالهروب بينما يعمل العزل على إبطاء اكتساب الحرارة. لأن الثلج الجاف لا يذوب أبداً, لا يوجد ماء فوضوي, مما يجعلها مثالية للحوم المجمدة, المأكولات البحرية, الآيس كريم والعينات المخبرية.

ممرات التجارة الإلكترونية المجمدة: الجليد الجاف مقابل. هلام وPCM

يلخص الجدول أدناه طريقة التبريد التي تعمل بشكل أفضل مع نطاقات درجات الحرارة المختلفة وحالات الاستخدام النموذجية. يوفر الثلج الجاف أدنى درجات الحرارة ويتفوق على عبوات الجل في وقت الانتظار لكل لتر, خاصة أثناء التأخير بعد الظهر الحار. تعتبر عبوات الجل أكثر أمانًا للسلع المبردة التي لا ينبغي تجميدها, بينما مرحلة تغيير المواد (PCMS) الحفاظ على نطاقات محددة وغالبا ما تكون قابلة لإعادة الاستخدام.

| طريقة التبريد | نطاق درجة الحرارة | تصنيف المخاطر | إعادة الاستخدام | حالات الاستخدام النموذجية |

| حزمة الثلج الجاف | < -70 درجة مئوية | خطرة (و 1845), يتطلب وضع العلامات | استخدام واحد; يمكن دمجه مع عبوات الجل | البيولوجية المجمدة العميقة, بوظة, اللحوم المجمدة |

| حزمة هلام | 0 درجة مئوية إلى 8 درجة مئوية | غير خطرة | الاستخدام الفردي أو إعادة الاستخدام المحدود | اللقاحات التي لا يجب تجميدها, شوكولاتة, المنتجات الطازجة |

| حزمة PCM | 2 درجة مئوية إلى 8 درجة مئوية أو -20 درجة مئوية | غير خطرة | قابلة لإعادة الاستخدام | الأدوية, التجارب السريرية التي تتطلب مراقبة دقيقة |

نصائح عملية:

التحميل العلوي أولاً: ضع أكياس ثلج جاف فوق المنتج حتى يهبط الهواء البارد بشكل طبيعي.

تنفيس الغطاء: لا تغلق أبدًا ثاني أكسيد الكربون; استخدم غطاءًا أو صدعًا مزودًا بفتحات تهوية للسماح بخروج الغاز.

تقليص الفراغ: قم بتقليل المساحة الفارغة باستخدام الإدخالات لإبطاء عملية الإحماء.

لف الحمولة: الأغطية الرقيقة تمنع الصقيع وتحافظ على نظافة الصناديق الكرتونية.

اختبار المسار الخاص بك: استخدم مسجل بيانات منخفض التكلفة للتحقق من صحة الوصفات قبل القياس.

حالة حقيقية: تحولت إحدى العلامات التجارية المتخصصة في المأكولات البحرية إلى عبوات الثلج الجاف المحملة من الأعلى وأضافت أ 15 % المخزن المؤقت للتأخير في عطلة نهاية الأسبوع. انخفض معدل مطالباتهم الصيفية من 6.4 % ل 1.9 % عبر ثلاث مناطق, بينما ظلت تجربة فتح الصندوق متسقة.

الفيزياء وراء التسامي

تكمن ميزة الثلج الجاف في التسامي. عندما يتحول ثاني أكسيد الكربون من الحالة الصلبة إلى الحالة الغازية, فهو يمتص حرارة كبيرة تقريبًا 571 كيلوجول/كجم - دون ترك الماء السائل. يحافظ هذا الامتصاص على تجميد المنتجات القريبة ويزيل الرطوبة, تثبيط نمو البكتيريا. درجة الحرارة المنخفضة للغاية (-78.5 درجة مئوية) يسمح بأوقات تعليق تتراوح من 24 إلى 96 ساعة عند دمجه مع عزل عالي القيمة R. للتجارة الإلكترونية, يضمن المشتت الحراري العالي لكل لتر بقاء البضائع مجمدة حتى أثناء إعادة توجيه الناقل أو ازدحام المركز.

| ميزة | وظيفة | فائدة |

| قلب بارد جدًا (-78.5 درجة مئوية) | يحافظ على الحمولات تحت درجة التجمد | فترات حفظ أطول; مناسبة للقاحات, البيولوجية والأطعمة المجمدة |

| تسامي (لا سائل) | يتحول ثاني أكسيد الكربون الصلب إلى غاز, امتصاص الحرارة | يقلل من التلوث وتلف التغليف |

| طبقات خارجية متينة | مواد متعددة الطبقات تقاوم الثقوب وتنظم إطلاق الغاز | يمنع التسربات ويقلل من خطر تلف المنتج |

| تصميم خفيف الوزن | كثافة أقل من جليد الماء | يوفر المساحة وتكاليف الشحن; المزيد من البضائع لكل شحنة |

| أشكال قابلة للتخصيص | كتل, الكريات أو الصفائح تناسب الحاويات المختلفة | المرونة للطرود, المنصات والأطقم السريرية |

نصائح واقتراحات المستخدم

تسليمات محلية قصيرة: استخدم عبوات الثلج الجاف من مصادر محلية للتوصيل في نفس اليوم; فهي تتسامى بشكل أبطأ وتقلل من انبعاثات وسائل النقل.

الهجين الطبقات: لمواسم الكتف, الجمع بين 70-85 % ثلج جاف مع PCM صغير بدرجة حرارة −10 درجة مئوية لمنع التجمد الزائد.

مراقبة الشحنات: أضف مسجل درجة الحرارة أو المستشعر لتتبع الظروف في الوقت الفعلي.

القضية الفعلية: تستخدم إحدى شركات تقديم الطعام التي تقدم المقبلات المجمدة في جميع أنحاء المدينة عبوات ثلج جاف محلية طازجة مع أكياس معزولة. يؤدي ملء المساحة الفارغة بالورق المجعد وإضافة حوالي 5 كجم من الثلج الجاف إلى الحفاظ على الجودة وتجنب التغليف المبلّل.

ما هي كمية الثلج الجاف التي تحتاجها لشحن البضائع المجمدة؟?

إجابة: تعتمد كمية الثلج الجاف على حجم الصندوق الداخلي, درجات الحرارة المحيطة ووقت العبور. للطرق الدافئة (20-30 درجة مئوية), يخطط 1.1– 1.5 كجم من الثلج الجاف لكل 10 لتر من الحجم الداخلي لكل 24 ساعات. يستخدم 0.8-1.0 كجم للطرق المعتدلة (10-20 درجة مئوية) و 1.5-1.9 كجم للطرق الساخنة (30-40 درجة مئوية). أضف 10-20 % المخزن المؤقت لحساب التأخير.

طريقة خطوة بخطوة لتقدير الثلج الجاف

قياس الحجم الداخلي: احسب الطول × العرض × الارتفاع للمساحة المعزولة باللتر.

حدد نطاق المسار: تحديد ما إذا كانت الشحنة الخاصة بك تنتقل عبر الضوء (10-20 درجة مئوية), دافيء (20-30 درجة مئوية) أو ساخنة (30-40 درجة مئوية) شروط.

استخدم جدول الأسعار: اضرب المعدل المختار كجم/10 لتر/24 ساعة بحجم الصندوق وعدد الأيام.

إضافة المخزن المؤقت: زيادة بنسبة 10-20 % لتغطية التأخير غير المتوقع.

توثيق الوزن: قم بجمع الكيلوجرامات الصافية من الثلج الجاف وتسجيلها على الملصق.

| فرقة الطريق | الملف الشخصي المحيط | كجم لكل 10 لام ل 24 ح | ماذا يعني لك |

| خفيف | 10-20 درجة مئوية | 0.8-1.0 كجم | انخفاض الحمل الحراري; أبطأ التسامي |

| دافيء | 20-30 درجة مئوية | 1.1-1.5 كجم | طرق التجارة الإلكترونية النموذجية وقمم بعد الظهر |

| حار | 30-40 درجة مئوية | 1.5-1.9 كجم | يسكن طويلا, التعرض للشمس وموجات الحر |

مثال: أ 24 L الشاحن على طريق دافئ ل 48 ساعات يحتاج تقريبا 7.1 كجم من الجليد الجاف. ابدأ مع 1.3 كجم × (24 لام ÷ 10) × 2 أيام = 6.2 كجم; ثم أضف أ 15 % المخزن المؤقت للوصول 7.1 كجم.

الجدول المرجعي للكمية

ترتبط كمية الثلج الجاف أيضًا بوزن الحمولة. يوفر الجدول أدناه مرجعًا سهلاً لـ a 10 رطل (≈4.5 كجم) حمولة:

| مدة الشحن | يوصى بالثلج الجاف | مثال (10 رطل الحمولة) | ماذا يعني لك |

| 24 ساعات (بين عشية وضحاها) | 0.5 × وزن الحمولة | ~5 رطل من الثلج الجاف | مثالية لعمليات التسليم المحلية أو خدمة البريد السريع في اليوم التالي |

| 48 ساعات | 1 × وزن الحمولة | ~ 10 رطل من الثلج الجاف | مناسبة للشحنات الإقليمية أو عبر البلاد |

| 72 ساعات+ | 1.5 × وزن الحمولة | ~ 15 رطلاً من الثلج الجاف | مطلوب لمسافات طويلة أو الشحن الدولي |

ضبط دقيق بدون عمليات حسابية معقدة

حماية الحافة: إذا ذوبان الحواف قبل القلب, أضف شرائح ضيقة من الثلج الجاف على طول الجوانب.

تقليل الاتصال المباشر: ضع رفًا مموجًا رفيعًا بين الثلج الجاف والحمولة لتجنب كرتون هش.

وصفة هجينة: في مواسم الكتف, استخدم 70-85 % الثلج الجاف بالإضافة إلى بلاط PCM عند -10 درجة مئوية لتخفيف ارتفاع درجات الحرارة.

مثال العالم الحقيقي: قام أحد موزعي المأكولات البحرية باستبدال عبوات الجل بأكياس ثلج جاف شديدة التحمل لمدة 48 ساعة للتوصيل عبر البلاد. يؤدي استخدام وزن متساوٍ من الثلج الجاف والحمولة إلى تقليل التلف الناتج عن ذلك 12 % ل 1 % وحفظها $50,000 سنويا.

كيفية تعبئة عبوات الثلج الجاف والتعامل معها بشكل آمن للشحنات المجمدة

إجابة: التعبئة والتعامل الآمن يقللان من المخاطر مثل تراكم الضغط, إزاحة الأكسجين وقضمة الصقيع. يضمن إجراء التشغيل المعياري (SOP) المنظم إمكانية التكرار عبر فريقك والامتثال للوائح.

التعبئة خطوة بخطوة SOP

مرحلة ما قبل الصندوق: ضع وسادة سفلية وإدراج زاوية لتقليل دوران الهواء.

إعداد الأساسية ملفوفة: لف المنتجات بطبقة واقية رقيقة وقم بإزالة الهواء الزائد.

ملاءمة جانبية ضيقة: أدخل وسادات جانبية حتى لا يتحرك القلب.

تحميل العبوات من الأعلى: قم بتكسير كتل الثلج الجاف الكبيرة إلى قطع أصغر ووضعها فوق القلب.

تنفيس والتسمية: استخدم غطاءً مزودًا بفتحات تهوية وضع علامة "الثلج الجاف". (و 1845)"بالكيلوغرام الصافي من ثاني أكسيد الكربون.

وزن وتسجيل: سجل الوزن الإجمالي, صافي ثاني أكسيد الكربون ومعرف الباكر.

اختبار الهز النهائي: إذا تحركت المحتويات, أضف فرشًا خفيفًا حتى يصبح دافئًا.

إرشادات الامتثال والسلامة

التسمية الصحيحة: العبوات الملصقة "الثلج الجاف" أو "ثاني أكسيد الكربون"., "صلب" بالوزن الصافي والرقم الأممي (و 1845).

تهوية: لا تغلق أبدًا ثاني أكسيد الكربون; استخدم أغطية تنفيس أو مسارات الغاز.

التوافق المادي: اختر البطانات والمواد اللاصقة التي تتحمل -78.5 درجة مئوية.

التوثيق: يجب أن تشير بوليصة الشحن الجوي إلى الثلج الجاف وكميته.

معدات الوقاية الشخصية والتدريب: توفير القفازات والتدريب للرازمين والمستقبلين.

تجنب الحاويات المغلقة: لا تقم بتخزين الثلج الجاف في مجمدات أو مبردات محكمة الإغلاق لمنع انفجارات الضغط.

معدات الحماية: ارتداء القفازات المعزولة وحماية العين; الاتصال بالثلج الجاف يمكن أن يسبب قضمة الصقيع في الأسفل 30 ثوان.

قائمة التحقق من التعامل الآمن

قم بتخزين ثاني أكسيد الكربون في مناطق جيدة التهوية، وليس في غرف مغلقة أو صناديق السيارات.

احتفظ بالقفازات الحرارية في محطة التعبئة.

تجنب المبردات محكمة الغلق; قم دائمًا بتهوية الغطاء.

اطلب من المستقبلين فتح العبوات في أماكن جيدة التهوية وتجنب ملامسة الجلد.

قم بتوفير رقم هاتف الطوارئ على الملصق للأسئلة أثناء الولادة.

القضية الفعلية: قام موزع حقيقي للمأكولات البحرية بطباعة ملاحظة "التهوية قبل الفتح" داخل الغطاء وأضاف رقم هاتف الطوارئ. أدت هذه الخطوة البسيطة إلى تقليل شكاوى المتلقي وتحسين الامتثال للسلامة.

الجليد الجاف مقابل. حزم هلام مقابل. مواد تغيير الطور: وهو الأفضل?

تتطلب السلع المختلفة استراتيجيات تبريد مختلفة. يوفر الثلج الجاف أبرد درجة حرارة, لكن عبوات الجل وأجهزة PCM لها نقاط قوتها الخاصة وغالبًا ما تكون غير خطرة.

جدول المقارنة والاختلافات الرئيسية

| طريقة التبريد | التحكم في درجة الحرارة | خطر & وضع العلامات | رُطُوبَة | التأثير البيئي | إعادة الاستخدام |

| حزمة الثلج الجاف | درجة حرارة منخفضة للغاية (< -70 درجة مئوية) | خطرة (و 1845); يتطلب وضع العلامات والتوثيق | يتسامى إلى غاز, ترك العبوة جافة | التسامي يطلق ثاني أكسيد الكربون; لا النفايات المادية | استخدام واحد; يمكن دمجه مع عبوات الجل |

| حزمة هلام | يبقي البضائع مبردة بالقرب 0 درجة مئوية | غير خطرة | يذوب في الماء; قد يسبب التعبئة والتغليف مندي | يمكن أن يكون لها واجهات خارجية قابلة للتحلل; توجد خيارات قابلة لإعادة الاستخدام | في كثير من الأحيان قابلة لإعادة الاستخدام أو إعادة استخدام محدودة |

| حزمة PCM | يحافظ على نطاقات محددة (على سبيل المثال, 2-8 درجة مئوية أو -20 درجة مئوية) | غير خطرة | لا يوجد سائل مجاني; يحدث تغيير الطور عند درجة حرارة محددة | قابلية إعادة الاستخدام العالية; تحتوي بعض أجهزة PCM على مكونات قابلة لإعادة التدوير | قابلة لإعادة الاستخدام ومناسبة للأدوية |

التوصيات

الشحنات المجمدة (>72 ساعات): استخدم عبوات الثلج الجاف شديدة التحمل. لفترات طويلة, يُمزج مع عبوات الجل لإبطاء التسامي والحفاظ على مناطق درجات الحرارة المتعددة.

شحنات مبردة (0-8 درجة مئوية): اختر عبوات الجل; فهي فعالة من حيث التكلفة وغير خطرة.

احتياجات باردة أو قابلة لإعادة الاستخدام معتدلة: استخدم PCMs للأدوية والتجارب السريرية; أنها توفر تحكمًا دقيقًا ويمكن إعادة استخدامها.

تجنب التجميد: عند شحن الشوكولاتة أو غيرها من البضائع التي يجب ألا تتجمد, تجنب الثلج الجاف. استخدم عبوات الجل وصندوق معزول للحفاظ على درجة الحرارة من 4 إلى 8 درجات مئوية.

مؤشر عملي: للشحنات المختلطة التي تحتوي على مواد مجمدة ومبردة, ضع حاجزًا داخل الصندوق وضع الثلج الجاف فقط حول البضائع المجمدة أثناء استخدام عبوات الجل للحجرة المبردة.

2025 الاتجاهات في عبوات الثلج الجاف والشحن المجمد

نظرة عامة على الاتجاه: تتطور الخدمات اللوجستية لسلسلة التبريد بسرعة. في 2025, تستمر عبوات الثلج الجاف في العمل كمعيار متجمد, ولكن هناك تحول نحو الصناديق الأخف ذات قيم R الأعلى, بطانات صديقة للبيئة وتطبيقات تعبئة أكثر ذكاءً. تنمو استراتيجيات PCM الهجينة في مواسم الكتف والشبكات ذات القيود المفروضة على ثاني أكسيد الكربون. ويشهد السوق أيضًا تتبعًا محسّنًا وموادًا صديقة للبيئة.

أحدث التطورات في لمحة

بطانات عاكسة من الألياف: يعمل العزل الورقي مع الأفلام العاكسة الدقيقة على تضييق فجوة الأداء مع الرغوة مع تحسين إمكانية إعادة التدوير.

مسجلات البيانات المصغرة تحت $20: تساعد أجهزة تسجيل Bluetooth أو NFC ذات الأسعار المعقولة في التحقق من صحة ممرات الشحن الجديدة قبل موسم الذروة.

التجهيز المدرك للطريق: تختار تطبيقات التعبئة الخفيفة تلقائيًا, وصفات دافئة أو ساخنة في المحطة بناء على توقعات الطقس.

الاستراتيجيات الهجينة: يؤدي الجمع بين الثلج الجاف ووحدات PCM إلى تقليل التجاوز واستخدام ثاني أكسيد الكربون.

التركيز على الاستدامة: يلتقط الموردون ثاني أكسيد الكربون الصناعي لصنع الثلج الجاف ويقدمون عبوات هلامية قابلة للتحلل بيولوجيًا. PCMs قابلة لإعادة الاستخدام وتقلل من النفايات.

رؤى السوق

العلامات التجارية التي تحافظ على جودة المنتج المجمد تشهد معدلات شراء متكررة أعلى. انخفاض نقطة واحدة في المطالبات يمكن أن يمول وصفات ثلج جاف أقوى لفصل الصيف بأكمله. عن طريق تحديد حجم العبوة الصحيح وتعديل الوصفات موسميًا, يمكن للشركات تقليل كتلة الجليد الجاف بنسبة 10-15 %. يمكن للحلول الهجينة تقليل استخدام ثاني أكسيد الكربون بنسبة 10 تقريبًا % في حين تجانس ارتفاع درجات الحرارة. مع اشتداد المنافسة في 2025, إن الاستثمار في عزل أفضل وتسجيل البيانات يؤتي ثماره من خلال تقليل المبالغ المستردة وزيادة ولاء العملاء.

الأسئلة المتداولة

س 1: إلى متى سيبقي الثلج الجاف شحنتي مجمدة؟?

أ: للطرق الدافئة, خطة 1.1-1.5 كجم من الثلج الجاف لكل 10 لام ل 24 ساعات; تحتاج الطرق الساخنة إلى 1.5-1.9 كجم. قم بتهوية الغطاء والتحميل العلوي لتجنب عمليات الإحماء المبكرة.

Q2: هل يسمح بالشحن الجوي مع الثلج الجاف?

أ: نعم. ضع علامة على العبوة "الثلج الجاف (و 1845)بالكيلوغرامات الصافية واتباع قواعد شركات الطيران والاتحاد الدولي للنقل الجوي. يجب أن تشير بوليصة الشحن الجوي إلى الكمية, وقد تطلب شركات النقل رقم اتصال.

س 3: كم عدد العبوات التي يجب أن أستخدمها في 15 صندوق L ل 48 ساعات?

أ: على طريق دافئ, الهدف حوالي 3.5-4.2 كجم إجماليًا, مقسمة على عبوات أصغر من أجل التسامي المتساوي.

س 4: هل يمكنني مزج الثلج الجاف مع عبوات الجل?

أ: نعم. يمكن أن يقلل الهجين من التجاوز ويثبت المناطق الهامشية; ضع الجل أسفل الحمولة أو بجانبها واحتفظ بالثلج الجاف في الأعلى.

س 5: ما هي الطريقة الأكثر أمانًا للتخلص من بقايا الثلج الجاف؟?

أ: دع ثاني أكسيد الكربون المتبقي يتسامى في منطقة جيدة التهوية; الابتعاد عن الأطفال والحيوانات الأليفة. لا تحبسه أبدًا في حاويات أو مصارف مغلقة.

س6: هل هناك حدود لكمية الثلج الجاف?

أ: اللوائح تحد من الثلج الجاف إلى 200 كجم لكل طرد للطائرات, مع إعفاءات للحزم تحت 2.5 كجم (5.5 رطل). تحقق من قواعد مشغل شبكة الجوال الخاصة بك لمعرفة الحدود المحددة.

س7: هل أحتاج إلى تدريب خاص لشحن الثلج الجاف؟?

أ: نعم. ويجب تدريب الشاحنين واعتمادهم للتحضير, تعبئة وتوثيق شحنات الثلج الجاف. مطلوب التعبئة والتغليف والوثائق الواقية.

ملخص وتوصيات

يتطلب الحفاظ على البضائع المجمدة سليمة أثناء الشحن استخدام المبرد المناسب, التحجيم الدقيق والالتزام بقواعد السلامة. حزم الثلج الجاف توفر درجات حرارة شديدة البرودة تدوم أكثر من عبوات الجل وأجهزة PCM. لتقدير الكمية, استخدم 0.8-1.9 كجم لكل 10 لام ل 24 ساعات حسب درجة حرارة الطريق وأضف 10-20 % المخزن المؤقت. قم بتعبئة الصناديق وفقًا لإجراءات التشغيل القياسية (SOP).: التفاف المنتجات, تقليل مساحة الفراغ, قم بتحميل الثلج الجاف من الأعلى وقم بفتح الغطاء. قم بتسمية العبوات بشكل صحيح وتأكد من استخدام فريقك للقفازات والتدريب على السلامة. فكر في الاستراتيجيات الهجينة أو PCMs عندما لا يجب تجميد البضائع أو عندما تكون الاستدامة أولوية.

الخطوات التالية القابلة للتنفيذ

تدقيق التعبئة والتغليف الخاصة بك: قياس الكميات الداخلية وتسجيل نطاقات المسار لكل SKU. قم بإنشاء بطاقات وصفات تشير إلى عدد كيلوغرامات الثلج الجاف التي سيتم استخدامها لكل صندوق.

قم بتنفيذ الإجراء التشغيلي الموحد (SOP).: تدريب الموظفين على طريقة التعبئة خطوة بخطوة. ضع أغطية ذات فتحات تهوية, الملصقات والقفازات في محطات التعبئة. قم بإجراء اختبارات الاهتزاز بشكل منتظم.

استخدم مقدرًا سريعًا: قم بتطوير جدول بيانات أو آلة حاسبة بسيطة باستخدام جدول الأسعار لتحديد الثلج الجاف المطلوب. اختبر بعض الشحنات باستخدام مسجلات البيانات للتحقق من أوقات الانتظار.

الحجم الصحيح والتهجين: تقليل مساحة الفراغ الداخلي بنسبة 10-15 %, اضبط الوصفات موسميًا وفكر في إضافة PCMs لخفض استهلاك ثاني أكسيد الكربون.

التواصل مع العملاء: قم بتضمين ملاحظة "التهوية قبل الفتح" وتعليمات للتعامل الآمن. توفير رقم اتصال في حالات الطوارئ للأسئلة أثناء الولادة.

حول Tempk

شركة Tempk متخصصة في حلول سلسلة التبريد القابلة لإعادة الاستخدام والاستخدام الفردي للأغذية, المستحضرات الصيدلانية والتكنولوجيا الحيوية. نقوم بتطوير الصناديق المعزولة, عبوات هلامية وحزم ثلج جاف مصممة للقاء 2025 اللوائح وأهداف الاستدامة. لدينا ص&يركز D على الخطوط ذات القيمة العالية R, مواد صديقة للبيئة وأجهزة استشعار متكاملة. من خلال الشراكة مع Tempk, يمكنك الوصول إلى الوصفات المختبرة, الدعم الفني والتعبئة المخصصة التي تحافظ على سلامة المنتجات مع تقليل التأثير البيئي.

دعوة إلى العمل: للحصول على إرشادات شخصية حول اختيار عبوات الثلج الجاف, اتصل بخبرائنا. سنساعدك على تصميم حل لسلسلة التبريد مصمم خصيصًا لمنتجك ومسارك.