Keeping frozen goods intact during transit doesn’t have to drain your wallet. أ cheap dry ice wrap for food combines reflective insulation with a solid carbon dioxide coolant to deliver sub zero temperatures for one to three days. Retail dry ice typically costs between $1 و $3 لكل رطل, and many shippers can reduce the per pound rate by buying in bulk. By pairing the right amount of ice with high quality insulation, you can preserve meat, seafood or desserts without paying premium overnight fees. This article demystifies cost factors, sizing rules and safety practices for 2025 so you can confidently ship frozen food without overspending.

What defines a cheap dry ice wrap for food? Learn what materials and mechanisms make these wraps effective at keeping frozen goods safe during transit.

How much dry ice do you need and how much does it cost? Understand per pound pricing, carrier surcharges and sizing formulas to avoid overspending.

When should you choose gel packs or PCM over a dry ice wrap? Explore temperature ranges, reusability and regulatory considerations.

What are the key safety rules and labeling requirements? Stay compliant with UN1845 and IATA regulations while protecting handlers.

What trends in 2025 can lower costs further? Discover innovations like smart sensors, better insulation and bio based CO₂ sources that reshape the frozen shipping landscape.

Practical tips and real world examples. Use our step by step guides and case studies to plan your next shipment.

What Is a Cheap Dry Ice Wrap for Food?

Definition and working principle

A cheap dry ice wrap for food combines an insulated wrap with solid dry ice to create an affordable, moisture free cold chain solution. الثلج الجاف هو ثاني أكسيد الكربون الصلب الذي يتسامي عند 78.5 درجة مئوية, absorbing heat as it changes directly from solid to gas. Unlike gel packs that thaw into water, dry ice produces no liquid; the wrap’s reflective liner contains the cold gas while allowing venting. Many wraps use super absorbent polymer layers that hydrate and freeze around dry ice pellets, maintaining structural flexibility even when frozen. Because the ice sublimates rather than melts, your products stay dry and safe from moisture damage.

Cheap dry ice wraps are available as scored sheets, small pellets in perforated bags or larger slabs. Score lines let you cut the sheet to fit irregular items, while pellets can be poured into tight spaces for faster cooling. Slabs release CO₂ more slowly and are ideal for long duration shipments. The reflective wrap around the ice reduces radiant heat gain, and the vented design prevents pressure build up.

Advantages vs other refrigerants

Cheap dry ice wraps offer several benefits over traditional gel or water packs:

| فائدة | Cheap Dry Ice Wrap | Impact for You |

| نطاق درجة الحرارة | Maintains −78 °C to −10 °C, keeping goods frozen for 24–72 h | Suitable for meat, seafood and ice cream that must stay below freezing. |

| Flexible and space saving | Modern wraps remain somewhat flexible even when frozen, conforming to product contours | Minimises empty air gaps, improving heat transfer and reducing required ice mass. |

| Clean and residue free | Dry ice sublimates directly into CO₂ gas | Leaves no water mess, protecting packaging and product integrity. |

| خفيف الوزن | Many wraps use lightweight materials and absorbent polymer gel | Lower dimensional weight reduces shipping costs, especially with carrier surcharges based on size. |

| Environmental options | New formulations use biodegradable films and capture CO₂ from industrial processes, and bioethanol plants capture high purity CO₂ | Cuts waste and carbon footprint while maintaining performance. |

Dry ice wraps aren’t perfect. They are single use and require careful handling: the extreme cold can cause frostbite and CO₂ gas must be vented. Prices fluctuate because dry ice consumption grows about 5 % annually while CO₂ supply increases just 0.5 %, leading to price spikes up to 300 % during shortages. The next sections explain how to size your wrap efficiently and when to consider alternatives.

Practical tips and case example

Pre chill your load: Freeze or chill foods to their intended shipping temperature before adding the wrap. Pre chilled contents reduce the heat load and reduce the amount of dry ice needed.

Choose the right format: Use slabs for trips longer than 48 ساعات, pellets for quick initial cooling, or scored sheets for irregular shapes.

Ventilation matters: Always leave 10–15 % headspace and never seal the package airtight. CO₂ expands by roughly 541 L per kilogram, so vented packaging prevents explosions.

Bulk buying: Pair with a neighbouring business to purchase 100 lb of dry ice and cut the per pound rate; retail dry ice runs between $1.60 و $3.00 لكل رطل.

Real world case: A West coast bakery replaced gel packs with a 6 lb dry ice wrap in an EPS cooler for two day air shipments and cut spoilage claims by 30 % without increasing base rates.

How to Size and Budget a Cheap Dry Ice Wrap for Food Shipping

Step by step sizing guide

Proper sizing ensures your shipment stays frozen while avoiding unnecessary expense. Follow this proven framework:

Determine transit time and conditions: Identify the expected shipping duration (T days) and ambient conditions (mild, warm or hot route). Use transit time thresholds: next day air (≤24 h), 2–3 days by air or ground, or longer haul ground shipments.

Select insulation quality: Use high R value EPS foam or vacuum insulation panels (VIP). Better insulation reduces heat ingress and can lower dry ice mass by 20–40 %. يقارن: dense EPS requires 5 lb of dry ice per 24 h for a 10 L void, while thin corrugate needs 8–10 lb. Upgrading insulation may be cheaper than shipping extra weight.

Estimate base dry ice weight: A practical rule is 5-10 رطل يوميا. Use the low end for tight EPS or VIP containers and the high end for thin corrugate or hot routes. Multiply by transit days and adjust for insulation and ambient factors:

Estimated Ice (رطل) = Base × T × Insulation Factor × Ambient Factor

مثال: 3 أيام, average corrugate (1.5), حار (1.2) → 8 رطل × 3 × 1.5 × 1.2 ≈ 43 رطل:contentReference[oaicite:23]{index=23}.

Account for carrier surcharges: Air carriers often add a dry ice fee of roughly $8 لكل حزمة. Avoid oversizing the package because dimensional weight will increase shipping cost.

Run a data logger trial: Validate your calculation by sending one test shipment with a temperature logger. Record actual hold time and adjust the formula for your lane.

Worked cost examples

Real numbers clarify budgeting. Consider three scenarios using the formulas above and retail dry ice pricing (≈$1.60–$3.00 per pound). These examples factor in materials ($3–$3.50 per box) and an $8 dry ice fee where applicable:

| سيناريو | Calculation | Estimated Cost | بصيرة |

| 2 day air (حاوية EPS) | 6 رطل × $1.80 = $10.80 الجليد + $8 fee + $3 مواد | ≈$22.80 | Good for online meal kits; modest weight and fee. |

| 4 day ground (corrugate) | 18 رطل × $1.60 = $28.80 الجليد + $0–8 fee + $3.50 مواد | ≈$32–$40 | Use better insulation or hybrid packs to lower cost. |

| 3 day air, الطريق الساخن | 29 رطل × $2.20 = $63.80 الجليد + $8 fee + $3.50 مواد | ≈$75.30 | For extreme heat waves, VIP panels may be cheaper than extra ice. |

These calculations show that insulation quality and route temperature heavily influence cost. Buying bulk reduces per pound pricing; combining orders with another shipper can drop the rate below $2/lb. Remember that local dry ice suppliers may offer volume discounts, and bigger orders lower the per pound cost.

Decision tool

Not sure whether a cheap dry ice wrap is right for your shipment? Answer these three questions:

Does your product require temperatures below −10 °C? If yes, use dry ice; if your goods must stay above freezing (0-8 درجة مئوية), gel packs or PCM may suffice.

What is the transit time and ambient heat? For less than 24 hours on a mild route, gel packs or water packs might be cheaper. For 48–72 hour frozen shipments, a dry ice wrap is usually necessary.

Is hazardous handling acceptable? If your team lacks training or cannot comply with UN1845 labeling, use gel or water packs to avoid hazmat regulations.

Use this tool to make a quick go/no go decision. When in doubt, hybrid packs combining a small amount of dry ice with gel packs provide a step down temperature profile and reduce handling risks.

Comparing Cheap Dry Ice Wraps with Gel Packs and PCMs

Cost and performance differences

عبوات الثلج, gel packs and phase change materials (بي سي إم) compete with dry ice wraps for cold chain shipments. Understanding their relative strengths helps you choose the most cost effective option.

Cost and reusability: Water or gel ice packs are generally the most affordable upfront. Gel packs can be refrozen multiple times and are non toxic, making them cost effective for frequent shippers. الجليد الجاف, على النقيض من ذلك, must be purchased for each shipment and may cost more initially. PCMs with specific melt points (على سبيل المثال, 2–8 °C or −20 °C) are reusable but often have higher unit costs.

نطاق درجة الحرارة: Gel packs maintain temperatures between 2 °C and 8 °C and are ideal for produce, dairy or pharmaceuticals that must not freeze. PCMs provide precise temperature bands and avoid overshoot but do not reach −70 °C; they are suitable for moderate cold shipments. Dry ice wraps maintain extremely low temperatures (−78 °C), making them essential for frozen meat, seafood or ice cream.

Regulatory and handling: Gel and water packs have no hazardous classification and are easier to dispose of. Dry ice requires UN1845 labeling, vented packaging and training. PCMs are generally safe but may require regulated disposal depending on their formulation. Handling dry ice requires insulated gloves and eye protection to avoid frostbite.

Unit cost comparison:

| خيار | نطاق درجة الحرارة النموذجي | تكلفة الوحدة / إعادة الاستخدام | الأفضل ل |

| Cheap Dry Ice Wrap | −78 °C to −10 °C | $1.60–$3.00 per lb, single use | اللحوم المجمدة, المأكولات البحرية, بوظة, البيولوجيا |

| هلام / Water Pack | 2 درجة مئوية إلى 8 درجة مئوية | تكلفة منخفضة, قابل لإعادة الاستخدام | Meal kits, ينتج, ألبان |

| مواد تغيير المرحلة (بي سي إم) | −20 °C or 0–8 °C | $2–$5 per pack, قابل لإعادة الاستخدام | Temperature sensitive medicine, اللقاحات, long haul shipments where freezing is undesirable |

Choosing the right option

للأطعمة المجمدة: Use a cheap dry ice wrap when your product must stay below −10 °C. It delivers longer hold times and dryness but requires hazmat compliance and a higher cost per shipment.

For chilled or short trips: Use gel or water packs for goods that must not freeze or when transit time is less than 24 ساعات. Water packs offer the best ROI for chilled shipments because they cost very little and are easy to dispose of.

For high value pharmaceuticals: Consider PCMs when precise temperature control is required (على سبيل المثال, 2-8 درجة مئوية) and reuse is feasible. PCMs avoid the hazardous label and offer a consistent temperature band.

Practical combination strategies

الحزم الهجينة: Combine a small dry ice wrap with PCM or gel packs. The dry ice maintains frozen temperatures early in transit while PCMs buffer the load as the ice sublimates. This approach reduces total ice mass and mitigates the risk of overcooling sensitive items.

Route specific mixing: على سبيل المثال, a two day moderate temperature route can use 4 lb of dry ice plus two PCM packs to cover unexpected delays. This reduces weight and avoids regulatory surcharges while maintaining product integrity.

Return logistics: When customers can return packaging, reusable gel or PCM packs become more economical over multiple cycles. For one way shipments, single use dry ice wraps or water packs are often better.

السلامة والامتثال: Handling Cheap Dry Ice Wraps

Safety is non negotiable when shipping with dry ice. Solid CO₂ can cause frostbite, displace oxygen and build pressure if sealed improperly. Follow these guidelines to protect handlers and stay compliant with transportation regulations.

Hazards and safe practices

| خطر | Risk Description | Safe Practice |

| Direct contact | Dry ice sits at −78 °C. Touching it can cause immediate frostbite. | Wear insulated gloves and protective clothing; handle with tongs or scoop. |

| الاختناق | Sublimated CO₂ displaces oxygen in confined spaces. | Use in well ventilated areas; avoid enclosed vehicles; train staff to recognise signs of CO₂ buildup. |

| انفجار | Sealing dry ice in airtight containers causes gas pressure build up leading to rupture. | Always vent packages; اترك مساحة الرأس; never tape over vents. |

| Incorrect disposal | Improper disposal can damage pipes or harm the environment. | Let dry ice sublimate in a ventilated area; never dispose down drains. |

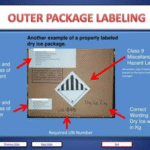

Labeling and regulatory compliance

UN1845 and Class 9 ملصق: Packages containing dry ice must be marked “Carbon Dioxide, solid” and display the UN1845 identifier along with net weight in kilograms. فصل 9 miscellaneous hazard label is required for air shipments.

التوثيق: For air freight, comply with IATA Packing Instruction 954. Many carriers impose a dry ice limit (على سبيل المثال, 5.5 lb for UPS air shipments) and require an International Special Commodities contract.

تمرين: Ensure anyone handling dry ice has been trained to recognise hazards and respond to emergencies.

Segregation: Do not place dry ice directly against food. Wrap the product in plastic or foil and use a divider.

Adhering to these rules prevents accidents, protects shipments and reduces the risk of carrier delays. Many shippers include a safety checklist in their SOP to ensure compliance.

2025 Trends Making Cheap Dry Ice Wraps More Affordable and Sustainable

نظرة عامة على الاتجاه

The dry ice market is evolving quickly in response to supply shortages, sustainability pressures and technological innovation. Dry ice consumption grows around 5 % كل سنة, but CO₂ supply grows only 0.5 %. This mismatch drives price volatility and motivates companies to optimize usage and explore alternatives. Here are notable developments in 2025:

Improved insulation materials: New vacuum insulation panels (VIP), fiber based wraps and recyclable liners reduce heat ingress and therefore the amount of dry ice required. Higher R values mean shippers can cut ice mass by up to 30 %.

Smart monitoring and IoT: Affordable data loggers and Bluetooth mini loggers track temperature in real time, enabling shippers to fine tune packouts and adjust for weather. Route aware kitting tools also help right size dry ice by factoring in seasonal variations.

Hybrid and staged cooling: Combining dry ice with PCMs or gel packs creates step down temperature profiles, preserving product quality while reducing total CO₂ mass. Automation systems now calculate the optimal mix based on lane length and product sensitivity.

Alternative CO₂ sources: To relieve supply pressure, manufacturers are investing in bioethanol derived CO₂ and carbon capture technologies. These renewable sources cut emissions and provide more stable supply. Localised production hubs further reduce transport losses.

Sustainability initiatives: Eco friendly wraps use biodegradable films and captured CO₂. Producers offer take back programs so wraps can be recycled or refilled. Regulatory bodies encourage life cycle assessments and carbon reporting.

Market expansion: The global dry ice market, قيمتها $1.54 مليار في 2024, is projected to reach $2.73 مليار من قبل 2032. في أثناء, the cold chain packaging refrigerants market (حزم هلام, foam bricks) is expected to grow from $1.57 مليار في 2024 ل $2.92 مليار من قبل 2032. This growth fuels competition and innovation.

Sector specific efficiency: Meat processors are using thinner slices and pellets of dry ice for rapid cooling on processing lines, while better insulated boxes extend hold time during transport. Pharmaceutical shippers are adopting barrier technologies that slow CO₂ gas release and reusable PCM containers.

آخر تقدم في لمحة

IoT enabled lane validation: Affordable sensors help calibrate packouts and reduce excess ice, trimming costs and preventing overcooling.

مواد مستدامة: Recyclable liners and biodegradable polymer films reduce plastic waste while maintaining insulation performance.

Local production & renewable CO₂: Bioethanol capture and on site generation secure supply and lower carbon footprints.

Market insights

Dry ice price volatility is here to stay, so diversifying refrigeration methods is crucial. Gel and PCM markets are growing rapidly, projected to more than double by 2029. The reusable icepack market for therapy and food shipping is expected to reach $2.5 مليار من قبل 2032. By keeping multiple packout options validated, shippers can shift between refrigerants when price spikes or supply shortages arise.

الأسئلة المتداولة

How much dry ice do I need for shipping frozen meat?

خطة على 5–10 pounds of dry ice per day depending on insulation quality and ambient temperature. Dense EPS containers may require 5 lb/day, while thin corrugate boxes in summer heat can need 8–10 lb/day. Always run a trial with a temperature logger to validate hold time.

Can I ship fruit or vegetables with a cheap dry ice wrap?

Use caution. Dry ice maintains sub zero temperatures that can freeze and damage produce. للفواكه, vegetables and dairy, gel packs or PCMs that hold 2–8 °C are safer and more cost effective.

Is a dry ice wrap safe for air travel?

نعم, but strict rules apply. Packages must be vented, labeled “Carbon Dioxide, solid” with UN1845 and net weight, and may have a dry ice limit (غالباً 5.5 lb for air shipments). Check carrier and IATA regulations before shipping.

What are the main advantages over gel packs?

Dry ice wraps deliver much colder temperatures (down to −78 °C) and longer hold times than gel packs. They also avoid water residue, remain flexible when frozen and are space saving. لكن, they are more expensive and require hazmat handling.

How can I reduce the cost of using dry ice wraps?

Buy in bulk to reduce per pound price, optimise insulation to lower the required ice mass, and consider hybrid packouts with PCMs or gel packs. Pre freeze goods and fill void spaces to minimise sublimation. Negotiate lower dry ice surcharges and maintain relationships with multiple suppliers to avoid regional shortages.

ملخص وتوصيات

Cheap dry ice wraps for food provide an affordable way to keep shipments frozen without leaks or mess. By combining reflective insulation with solid CO₂, they maintain ultra cold temperatures for up to 72 hours and protect product quality. The key to affordability is right sizing the ice mass (5-10 رطل يوميا), investing in good insulation and buying ice in bulk. Dry ice wraps excel for frozen meat, seafood and ice cream, while gel packs or PCMs suit chilled goods. Always follow safety rules: ارتداء القفازات, vent packages and label shipments. في 2025, advances in insulation, IoT monitoring and bio derived CO₂ will further cut costs and improve sustainability.

الخطوات التالية القابلة للتنفيذ

Assess your product’s temperature needs and transit time. Use the decision tool above to decide whether a dry ice wrap or gel pack is appropriate.

Calculate your dry ice requirement using the sizing formula provided and run a data logger trial. Adjust ice mass based on results.

ترقية العزل إذا كان ذلك ممكنا; investing in high R value liners may reduce ice weight and shipping fees.

Consider hybrid packouts for mixed temperature loads or to manage heat spikes. Combining dry ice with PCMs can reduce cost and risk.

Stay updated on 2025 الاتجاهات by subscribing to industry newsletters. Innovations in bio based CO₂ and smart packaging can improve both sustainability and your bottom line.

Develop a handling SOP that includes training, labeling and disposal guidelines. Standardised processes reduce accidents and regulatory fines.

حول Tempk

Tempk هي شركة رائدة في مجال الخدمات اللوجستية لسلسلة التبريد, offering comprehensive solutions for food, شحنات الأدوية والتكنولوجيا الحيوية. We specialise in dry ice wraps, حزم هلام, phase change materials and high performance insulation. لدينا ص&D team continuously tests new materials to improve R values and reduce environmental impact. We also integrate IoT sensors for real time monitoring and provide regulatory guidance to ensure your shipments remain compliant. عن طريق اختيار Tempk, you gain access to expertise that balances product safety, cost efficiency and sustainability.

Ready to optimise your cold chain? Contact us for a personalised consultation on the best combination of dry ice wraps, gel packs and insulation for your product. Our experts can help you design a cost effective packout and navigate the evolving regulatory landscape.