إدارة سلسلة التبريد في الصيدلة: أ 2025 مرشد

Your pharmacy’s cold chain is more than just a refrigerator – it’s a complete, temperature controlled supply network that keeps sensitive medications safe from factory to patient. إدارة سلسلة التبريد في الصيدلة ensures biologics, اللقاحات, insulin and other specialty drugs stay within strict temperature ranges so they don’t lose potency or put patients at risk. في هذا 2025 guide you’ll learn why cold chain logistics matter, how to build a compliant process and which technologies are reshaping pharmacy operations.

Why cold chain management matters for pharmacies: Understand how temperature excursions damage biologics and why 43 % of specialty drugs require cold chain storage.

Key components of an effective pharmacy cold chain: Discover essential infrastructure, مستشعرات إنترنت الأشياء, packaging and validated processes.

Compliance and regulatory requirements: Learn how DSCSA tracing requirements, USP chapters <659>, <1079> و URAC 5.0 accreditation shape your cold chain.

Technologies transforming cold chain logistics: اكتشف إمكانية تتبع blockchain, التوجيه المدعوم بالذكاء الاصطناعي, low power data loggers and sustainable refrigerantsر.

2025 الاتجاهات والابتكارات: See how tariffs, sustainability goals and personalised medicine are reshaping pharmacy cold chains.

Why Is Cold Chain Management Crucial for Pharmacies?

Maintaining efficacy and safety: Pharmaceutical products such as biologics, vaccines and sterile injectables are highly sensitive to temperature fluctuations. Many biologics lose efficacy if kept outside their prescribed range; عن 43 % of the 292 specialty medicines approved between January 2018 ومارس 2023 required cold chain storage, و 6 % needed freezing or sub zero temperatures. بدون التحكم السليم في درجة الحرارة, these life saving therapies can degrade, rendering them ineffective or even harmful.

Financial and reputational risk: Distribution errors are eight times more likely with specialty medications than with conventional drugs. A single temperature excursion can lead to product replacement costs, delayed treatments and regulatory fines. For pharmacies operating in tight profit margins, avoiding spoilage is essential to protect revenue and trust.

Beyond the fridge: understanding the cold chain lifecycle

The pharmacy cold chain encompasses more than onsite refrigerators. It includes:

| منصة | Critical Elements | الآثار المترتبة على العالم الحقيقي |

| تصنيع & يطلق | Determining stability and critical temperature ranges; performing quality and stability testing | Manufacturers define the temperature profile of each drug and issue validated release specifications. |

| تخزين & إدارة المخزون | Warehouse and pharmacy storage units with backup power and alarmed temperature monitoringر | Ensures medications stay within specification across multiple locations and allows for continuous tracking. |

| مواصلات & تسليم الميل الأخير | شاحنات مبردة, المجمدات المبردة المحمولة ( 80 °C to 150 °C for cell therapies) والشاحنين المعزولين | Maintains conditions during distribution; last mile delivery is particularly vulnerable to delays and misrouting. |

| يراقب & excursion management | مسجلات بيانات إنترنت الأشياء, تتبع نظام تحديد المواقع, real time analytics and alarm notificationsر | Enables immediate intervention when temperatures drift outside safe ranges. |

| Patient hand off | Clear patient instructions, confirmation of receipt, documentation and follow up | Ensures that medications are delivered promptly and handled correctly to maintain efficacy. |

Practical advice for pharmacies

Map your end to end process: Track how products move from manufacturers to patients. Identify vulnerable points (مناطق التدريج, transit hand offs, patient delivery) and design controls for each.

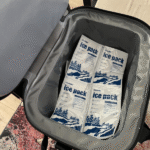

استخدم العبوة المعتمدة: Choose insulated shippers tested for your climate and route. Consider portable cryogenic freezers for ultra low temperature biologics.

تثقيف المرضى: Provide clear delivery windows and confirm that someone will receive shipments; delays or missed deliveries can lead to excursions.

دراسة حالة: أ 2025 case from a European pharmacy adopted IoT sensors that recorded temperature every five minutes in storage and delivery vehicles. When sensors detected fluctuations, staff received immediate push notifications and corrected the issue, ensuring all medications arrived within specifications and met new regulatory requirementsر. The system improved compliance and reduced waste.

Key Components of Effective Pharmacy Cold Chain Management

Pharmacy cold chains rely on multiple systems working seamlessly together. Effective management combines infrastructure, technology and procedures.

Cold chain infrastructure and equipment

Modern pharmacies need tailored equipment to suit different temperature zones. A typical facility includes:

Ultra low temperature freezers للبيولوجيا والعلاجات الخلوية ( 80 °C to 150 °C).

ثلاجات الحفاظ 2 درجة مئوية – 8 درجة مئوية للقاحات والأنسولين.

Controlled ambient areas for drugs requiring 20 درجة مئوية – 25 درجة مئوية (درجة حرارة الغرفة).

Backup generators and uninterruptible power supplies to prevent temperature excursions during power outages.

Monitoring technologies and data loggers

Real time monitoring is critical. تقوم أجهزة استشعار إنترنت الأشياء بتسجيل درجة الحرارة, humidity and position throughout the supply chain. Low power data loggers like those offered by ThingsLog transmit readings via 4G/2G networks, allowing pharmacies to measure conditions every 15 minutes or even every secondر. These sensors integrate with platforms that convert raw data into actionable insights, triggering alarms when temperatures drift outside safe rangesر.

فوائد:

Immediate alerts reduce excursion response time and minimize product loss.

Historical data supports audits and demonstrates compliance.

Predictive analytics identify patterns and allow proactive maintenance and route optimisation.

Packaging and sustainable refrigerants

Packaging protects products during transit. Traditional gel packs and dry ice are being replaced by مواد تغيير المرحلة (PCMS) and reusable insulated shippers that maintain specific temperatures without external power. Sustainable refrigerants like hydrofluoroolefins (مركبات الوقود الثقيل) و CO₂ based cooling systems have low global warming potential and comply with evolving environmental regulations. Eco friendly refrigerants and reusable packaging reduce waste and operational costs while maintaining product integrity.

Validated processes and staff training

Validated procedures ensure repeatability and compliance. Pharmacies must:

Define temperature ranges and excursion criteria for each medication.

Perform route specific validation tests that simulate worst case scenarios, considering seasonal temperature differences and delays.

Train staff in packaging, conditioning ice packs and handling shipments consistently.

توثيق كل خطوة; “if it isn’t documented, it didn’t happen”.

How Do Pharmacies Ensure Continuity, Sustainability and Compliance?

Continuity means an unbroken cold chain. Sustainable practices reduce environmental impact, and compliance safeguards patient safety and accreditation.

Ensuring continuity: end to end protection

Continuity requires integrated systems:

Optimised thermal packaging and monitoring – Combining the right packaging with sensors extends the time medications remain within the desired temperature range. If a package is delivered to the wrong address, monitoring technology allows quick recovery before the medication degrades.

Last mile logistics planning – Specialty medications are particularly vulnerable during last mile delivery, so pharmacies should use route optimisation tools, designate “critical shipments” and arrange contingency plans for delays.

Rescue protocols – Develop procedures to correct misdeliveries and temperature excursions, including package retrieval and repackaging.

الاستدامة: تقليل التأثير البيئي

السلسلة الباردة كثيفة الاستهلاك للطاقة. Sustainable strategies include:

قابلة لإعادة الاستخدام, recyclable and biodegradable packaging: وفقا لتقنيات السلسلة الباردة, sustainable packaging uses recycled plastics, biodegradable mailers and plant based materials like polylactic acid (جيش التحرير الشعبى الصينى).

المبردات المستدامة: HFOs and phase change materials maintain temperatures with minimal environmental impact. Gel ice packs and reusable insulated shippers reduce waste.

الطاقة المتجددة: Solar powered refrigeration units are emerging, enabling cold storage in regions with unreliable electricity and lowering energy costs.

امتثال: meeting accreditation and regulatory standards

Regulatory bodies impose strict requirements for pharmacy cold chains:

URAC 5.0 الاعتماد requires specialty pharmacies to define evidence based temperature ranges, determine suitable packaging and perform qualification testing for each medication.

USP general chapters <659>, <1079> و <1079.2> outline standards for packaging, storing and transporting temperature sensitive products.

ممارسة توزيع جيدة (الناتج المحلي الإجمالي) guidelines from regulators such as the FDA and EMA ensure that distributors of medicines maintain product viability and safety.

قانون أمن سلسلة توريد المخدرات (DSCSA): The DSCSA requires an interoperable electronic system to trace certain prescription drugs at the package level, preventing counterfeit or harmful products from entering the supply chain. يجب أن يلتزم المصنعون والقائمون بإعادة التغليف بحلول شهر مايو 2025, تجار الجملة بحلول أغسطس 2025 وموزعات كبيرة بحلول نوفمبر 2025. Pharmacies must prepare for electronic product tracing and data sharing.

نصائح عملية للامتثال:

Align your processes with USP guidelines and GDP frameworks; ensure your validation data reflect your specific routes and climate.

Develop vendor qualification programs to assess suppliers’ cold chain capabilities.

Invest in electronic traceability systems to meet DSCSA requirements by 2025.

Regulatory and Compliance Requirements: What Pharmacies Need to Know

Pharmacies must navigate a complex regulatory landscape. Beyond URAC and USP, local legislation may introduce additional rules.

Good Distribution Practice and GxP

GDP and Good Manufacturing/Clinical Practice (جي اكس بي) regulations establish minimum standards for facilities, المعدات والعمليات. They require participants to protect product integrity and document every step. The research review by Filipova and Grigorov (2024) يلاحظ ذلك no specific cold chain regulations for pharmacies currently exist in many regions; بدلاً من, pharmacies adopt GDP principles and adapt them to their operations.

USP <659>, <1079> و <1079.2>

دستور الأدوية الأمريكي (USP) provides guidance on:

<659> Packaging and storage requirements: defines controlled room, الظروف المبردة والمجمدة.

<1079> Good storage and shipping practices: emphasises proper packaging, labelling and recordkeeping.

<1079.2> متوسط درجة الحرارة الحركية (MKT) calculations: helps determine the effect of temperature excursions over time.

Pharmacies should incorporate these guidelines into SOPs and staff training.

URAC 5.0 اعتماد الصيدلة المتخصصة

The latest URAC standards emphasise defined temperature ranges, packaging and qualification testing. They give pharmacies flexibility to tailor cold chain strategies, considering medication-specific requirements and geographic factors.

DSCSA (نحن. Traceability Law)

Under DSCSA, all stakeholders must exchange transaction information, التاريخ والتصريحات (ل, TH and TS) electronically. This includes product identifiers (رقم الكثير, تاريخ انتهاء الصلاحية, رقم سري). بواسطة 2025, pharmacies must be able to receive and store DSCSA transaction data and share it upon request. This shift from paper to digital traceability enhances security and enables rapid recalls.

Innovations and Technologies Transforming Cold Chain Logistics

Technological innovation is making the pharmacy cold chain smarter, أكثر اخضرارا وأكثر مرونة.

Blockchain للتتبع

Blockchain creates a tamper proof, transparent ledger for tracking temperature sensitive medicines. Each transaction is immutably recorded, reducing the risk of falsification or theft. بواسطة 2025, blockchain systems are being integrated with IoT sensors to automatically record environmental conditions and custody changes. This ensures that DSCSA data are secure, verifiable and easily auditable.

أجهزة استشعار إنترنت الأشياء والتحليلات التنبؤية

Networks of IoT sensors provide real time temperature, الرطوبة وبيانات الموقع. Advanced analytics identify patterns, predict potential excursions and recommend preventive actions. على سبيل المثال, an AI powered route optimisation tool can adjust delivery plans to avoid traffic delays and extreme weather, minimising the risk of temperature excursions. Predictive models also forecast equipment maintenance needs, تقليل وقت التوقف عن العمل والتلف.

Portable cryogenic technology and ultra cold shipping

Portable cryogenic freezers maintain temperatures from -80 درجة مئوية إلى -150 درجة مئوية and are essential for transporting cell and gene therapies. These devices often include integrated sensors and satellite communication to provide continuous tracking and alerts. As more cell therapies enter the market, demand for portable ultra cold solutions is increasing.

Solar powered refrigeration and energy efficiency

Solar powered cold storage units enable التبريد خارج الشبكة, particularly in regions with unreliable electricity or high energy costs. They harness solar energy to maintain stable temperatures, reducing dependence on fossil fuels and lowering long term costs.

Sustainable refrigerants and eco friendly packaging

Environmental responsibility drives innovation in refrigerants. Hydrofluoroolefins (مركبات الوقود الثقيل) و مواد تغيير المرحلة provide efficient cooling with low global warming potential, complying with tightening regulations. Reusable shippers and envelope mailers containing sustainable refrigerants reduce waste and shipping weight. CO₂ based transport refrigeration systems further cut greenhouse gas emissions.

Selecting the Right Temperature Zones and Storage Solutions

Pharmacies store diverse products requiring different temperature zones. The right environment preserves efficacy and meets regulatory standards.

Understanding temperature zones

المجمدة (0 درجة فهرنهايت أو أقل) – Required for long term storage of certain vaccines, gene therapies and some biological samples. Portable cryogenic freezers handle extremely low temperatures.

مبردة (35-40 درجة فهرنهايت / 2-8 درجة مئوية) – Standard range for most vaccines, insulin and biologics.

المحيطة التي تسيطر عليها (55-70 درجة فهرنهايت / 20-25 درجة مئوية) – For tablets and liquids that require protection from extreme heat or cold.

Selecting equipment that can maintain these zones simultaneously reduces risk and improves efficiency. Many modern cold storage facilities offer مناطق درجة حرارة متعددة والمراقبة المستمرة.

Matching products to zones

Pharmacies should assign each medication to its appropriate zone and avoid short term exposure to incorrect temperatures. Storing a refrigerated medication in an ambient zone, ولو لفترة وجيزة, can lead to spoilage and regulatory issues.

Facility design considerations

Multiple loading bays and cross docking areas reduce dwell time and exposure to ambient conditions.

Integrated warehouse management systems (WMS) provide real time inventory visibility at the SKU level and sync with monitoring devices for compliance reporting.

موقع يهم: proximity to transportation hubs and climate conditions influences energy consumption and risk of excursions.

Ensuring Quality Through Real Time Monitoring and Data Analytics

The role of low power data loggers

Low power data loggers monitor temperature and humidity across storage units, trucks and containers. Systems like ThingsLog can measure conditions every 15 دقائق on battery power and transmit real time data via mobile networksر. These loggers are configurable, enabling pharmacies to monitor multiple parameters and receive alerts when pre set thresholds are crossedر.

Data aggregation and AI

Collected data feed into cloud platforms that analyse trends and generate actionable insights. Predictive algorithms forecast equipment failure, identify high risk routes and suggest rerouting before excursions occur. AI also helps prioritise shipments based on temperature sensitivity and delivery windows.

Remote monitoring case study

في أ 2025 قضية, a leading pharmacy chain implemented a remote monitoring system with temperature and humidity sensors in both storage areas and delivery vehicles. The system sent push notifications to owners when deviations occurred, allowing immediate intervention and preventing spoilageر. نتيجة ل, the pharmacy met new government regulations and maintained the integrity of its medications while improving operational efficiency.

2025 Latest Developments and Trends in Pharmacy Cold Chain Management

نظرة عامة على الاتجاه

يتطور مشهد سلسلة التبريد بسرعة. في 2025, several factors converge:

Personalised medicine and advanced therapies: نمو البيولوجية, gene and cell therapies requires ultra cold storage and precise handling. The cell and gene therapy market is projected to reach US$74 billion by 2034, growing from US$6.31 billion in 2024 بمعدل نمو سنوي مركب قدره 27.92 %.

نمو السوق: The global cold chain pharma market has grown from 8.85 مليار دولار أمريكي 2024 إلى 10.04 مليار دولار أمريكي 2025 ومن المتوقع أن يصل 18.20 مليار دولار أمريكي 2030. This expansion is driven by increasing demand for biologics, vaccines and speciality drugs.

الاستدامة والمبادرات الخضراء: Regulatory pressure and consumer expectations are driving adoption of eco friendly packaging and refrigerants. Solar powered storage units and reusable shippers reduce carbon footprints.

إمكانية التتبع الرقمي: DSCSA implementation in the U.S. (with deadlines in 2025) is pushing pharmacies toward electronic product identifiers and blockchain enabled tracking. European regulations emphasise similar standards under the Falsified Medicines Directive (مرض الحمى القلاعية).

Tariffs and supply chain resilience: الولايات المتحدة الجديدة. tariffs on imported packaging and refrigeration equipment introduced in 2025 زادت التكاليف, prompting companies to adopt local manufacturing, modular packaging designs and diversified sourcing.

Collaboration and integration: مقدمي الخدمات اللوجستية, packaging manufacturers and technology companies are forming partnerships to offer integrated cold chain solutions.

آخر تقدم في لمحة

Integration of blockchain with IoT sensors creates a unified source of truth for product provenance and environmental data, تعزيز الشفافية والامتثال.

تحسين المسار القائم على الذكاء الاصطناعي والصيانة التنبؤية reduce excursions and operational costs by forecasting delays and equipment failures before they happen.

أنظمة التبريد الموفرة للطاقة use variable speed compressors and renewable energy sources to lower energy consumption, aligning with climate goals.

المواءمة التنظيمية: Agencies worldwide are moving towards unified cold chain standards, simplifying international distribution while increasing the compliance burden.

رؤى السوق

Pharmaceutical cold chain logistics is experiencing robust growth across regions. في 2024, Europe dominated the market due to stringent regulations and advanced infrastructure. Asia Pacific is expected to grow at the fastest CAGR through 2030, driven by increased healthcare expenditure, manufacturing expansion and investments in cold chain technology. North America remains a key market, with DSCSA driving digital transformation and heightened adoption of AI and blockchain. المبادرات الحكومية, e commerce and home delivery models further fuel growth.

الأسئلة المتداولة

What temperature range is required for most vaccines and biologics? Vaccines and many biologics must be kept between 2 درجة مئوية و 8 درجة مئوية (35 درجة فهرنهايت – 46 ° f) throughout storage and transport. Some advanced therapies require ultra cold conditions ( 60 °C to 150 °C).

How can pharmacies reduce the environmental impact of their cold chain? Use reusable, التعبئة والتغليف القابلة لإعادة التدوير أو القابلة للتحلل; adopt sustainable refrigerants such as HFOs or CO₂ based systems; employ solar powered refrigeration units; and plan routes to minimize energy use.

What are common causes of cold chain failures in pharmacies? Failures often stem from limited understanding of third party data, inadequate validation of packaging and routes, poor staff training and not verifying manufacturer requirements. Inconsistent materials or processes and lack of documentation are also major factors.

Does my pharmacy need a third party vendor for cold chain validation? ليس بالضرورة. Accreditation standards do not mandate third party validation. Third party vendors can help, but pharmacies must still conduct internal tests tailored to their products, routes and climates.

Why is blockchain important for pharmacy cold chains? Blockchain provides an immutable record of product handling and environmental conditions, reducing the risk of counterfeiting and data tampering. Combined with DSCSA requirements, blockchain ensures traceability and improves recall efficiency.

ملخص وتوصيات

الوجبات الرئيسية:

Cold chain management protects patient safety and pharmacy revenue. Nearly half of new specialty medications require temperature control, and distribution errors are eight times more likely without a robust cold chain.

Effective cold chains combine infrastructure, monitoring and procedures. مجمدات منخفضة للغاية, مستشعرات إنترنت الأشياء, sustainable packaging and validated processes create a resilient system.

Compliance is non negotiable. URAC accreditation, USP guidelines and DSCSA traceability mandates require pharmacies to document procedures, validate pack outs and implement electronic tracking.

Technology is transforming cold chain logistics. بلوكتشين, منظمة العفو الدولية, IoT and sustainable refrigerants are making systems more transparent, predictive and environmentally friendly.

2025 trends emphasize sustainability, digitalisation and collaboration. نمو السوق, personalised medicine, tariff impacts and regulatory harmonisation demand continuous innovation and cross industry partnerships.

خطة العمل:

قم بمراجعة سلسلة التبريد الحالية لديك: Identify weaknesses in temperature control, الرصد والتوثيق. Use this article’s checklist to address gaps.

استثمر في المراقبة في الوقت الحقيقي: Deploy IoT sensors and integrate them with your inventory management system to anticipate and prevent excursions.

Update your SOPs and training: Align procedures with USP chapters, URAC and GDP guidelines; ensure staff understand validation data and pack out requirements.

اعتماد الحلول المستدامة: Evaluate eco friendly packaging, refrigerants and renewable energy sources to reduce environmental impact and meet regulatory expectations.

الاستعداد لDSCSA: Implement electronic traceability systems and educate your staff on new data exchange requirements ahead of the 2025 المواعيد النهائية.

حول Tempk

Tempk is a leader in temperature controlled logistics for life sciences. We specialise in smart cold chain solutions هذا الجمع precise refrigeration equipment, real time IoT monitoring and validated packaging. Our team of engineers and pharmacists understands the regulatory landscape and the unique challenges of specialty medications. من خلال الشراكة مع Tempk, you gain access to sustainable technologies, compliance expertise and scalable services that keep your products safe and your operations efficient. Whether you need ultra low temperature storage, DSCSA ready tracking or customised packaging design, نحن هنا للمساعدة.

Get in touch today to discover how Tempk can optimise your pharmacy’s cold chain and support your compliance journey.