[تحديث 11 Dec 2025]

When you handle fish or shellfish, temperature control is your most important tool. Cold chain standards and equipment for seafood products ensure that fresh fillets arrive at your restaurant or store as safe and flavourful as the day they were harvested. Keeping fish within the correct temperature window slows microbial growth and protects quality. This comprehensive guide explains which standards apply, how to comply with them and which devices you need to maintain the cold chain.

سيجيب هذا المقال:

What temperature requirements govern the seafood cold chain? Global standards require 0–5 °C for fresh fish and ≤ –18 °C for frozen products. We’ll translate them into practical guidelines for your operation.

Which regulations apply to fish suppliers and exporters? تحليل المخاطر ونقاط المراقبة الحرجة, ممارسات التصنيع الجيدة, FSMA and EU hygiene rules demand documented temperature control and traceability.

What equipment and packaging are essential? From insulated boxes and gel packs to IoT-enabled sensors, we detail the tools that keep seafood in the safe zone.

How can you keep fish fresh during storage and transport? Learn best practices for hygiene, humidity control and FIFO rotation.

ما هي الأحدث 2025 trends in cold chain logistics? Discover AI route optimisation, blockchain traceability and sustainable packaging innovations.

What temperature requirements govern the seafood cold chain in 2025?

الطازجة مقابل. frozen guidelines – Fresh fish deteriorates rapidly because natural enzymes and bacteria break down tissue. To slow spoilage, international standards require you to keep fresh fish between 0 درجة مئوية و 5 درجة مئوية and frozen fish at –18 °C or colder. الولايات المتحدة. FDA Food Code specifies that cold foods, بما في ذلك المأكولات البحرية, must be held at 41 ° f (5 درجة مئوية) أو أدناه. Exceeding these thresholds accelerates microbial growth and reduces shelf life.

Understanding maximum temperature limits for chilled fish

ال Agreement on the International Carriage of Perishable Foodstuffs (اعبي التنس المحترفين) sets maximum temperatures for transporting various foods. For fish, the maximum during transport and storage is 2 درجة مئوية. These maxima are good guidelines across all stages of production, distribution and retail display.

Keeping fish at 0 °C–5 °C maintains texture and slows bacterial growth. Melted ice in insulated containers naturally regulates temperatures around 0 °C and maintains humidity. Continuous monitoring with calibrated thermometers helps ensure products stay within safe limits.

Temperature requirements for frozen seafood

Frozen fish should remain at –18 °C or colder. The ATP permits a brief increase to -15 درجة مئوية during transport or local distribution, but retail display cabinets should still maintain -18 درجة مئوية and never be warmer than -12 درجة مئوية. Domestic freezers vary: three star freezers reach below –18 °C, two star freezers stay below –12 °C and one star freezers only reach –6 °C, limiting storage time to a few days.

Keeping frozen fish below –18 °C prevents microbial activity and extends shelf life, but remember that freezing is not a biocide; other physical and biochemical reactions can still occur. التجميد السريع, appropriate packaging and consistent temperatures maintain quality.

طاولة 1 – Key temperature ranges and what they mean for you

| نطاق درجة الحرارة | أمثلة على المنتجات & منصة | فائدة | ماذا يعني لك |

| 0 °C–5 °C | الأسماك الطازجة, chilled fillets | Maintains texture, slows bacterial growth | Use refrigerated rooms or ice; مراقبة بشكل مستمر |

| ≥ -18 درجة مئوية | أسماك مجمدة, fish blocks | Stops microbial activity and extends shelf life | Invest in validated freezers; never allow product to thaw during transport |

| 41 ° f (≈5 °C) | High risk foods such as seafood | Keeps foods out of the danger zone | Check storage and display units regularly to ensure they operate within 0–5 °C |

| 2 درجة مئوية (ATP max) | Transport of fish | International maximum for transport | Use calibrated thermometers during shipping; avoid temperature abuse |

نصائح عملية

Chill quickly: Perennia’s guide recommends chilling seafood to 0 °C immediately upon capture and keeping it there throughout the supply chain.

المراقبة بشكل مستمر: Use data loggers or IoT sensors to record temperature in real time. Alerts should notify you when readings drift outside safe ranges.

Use the right refrigerant: Melting ice is effective for fresh fish; adequate quantities of ice and insulated containers maintain 0 درجة مئوية.

معايرة المعدات: Ensure thermometers and sensors are accurate. The FDA Food Code recommends checking temperatures at least every four hours.

مثال في العالم الحقيقي: A processor implemented QR codes and digital logs for each catch. When a temperature deviation occurred during transport, they traced it back to a specific batch and contacted distributors within minutes. This targeted recall saved them from pulling an entire shipment off shelves.

Which regulations govern seafood cold chain compliance?

The seafood cold chain is regulated by a patchwork of national and international rules. Ignoring them can lead to fines, shipment delays or product recalls.

تحليل المخاطر ونقاط المراقبة الحرجة, GMP and SSOP

The foundation of seafood safety is the تحليل المخاطر ونقطة التحكم الحرجة (تحليل المخاطر ونقاط المراقبة الحرجة) نظام. It requires processors to identify hazards, establish critical control points and implement monitoring procedures. ممارسات التصنيع الجيدة (ممارسات التصنيع الجيدة) and Sanitation Standard Operating Procedures (SSOP) complement HACCP by providing detailed hygiene rules for facilities, equipment and personnel. معاً, these frameworks reduce contamination risks and form the basis of most national standards.

FSMA rules in the United States

ال قانون تحديث سلامة الأغذية (FSMA) introduces several rules relevant to fish suppliers:

قواعد النقل الصحي: الشاحنين, loaders and carriers must use vehicles and equipment capable of maintaining safe temperatures and prevent cross contamination. They must also keep records of cleaning and training.

قاعدة تتبع الأغذية (FSMA 204): Finalised in 2022, this rule requires businesses to maintain records with Key Data Elements at Critical Tracking Events. Seafood products on the Food Traceability List must provide information to the FDA within 24 ساعات. The initial compliance date was January 20 2026 but may be extended to July 20 2028.

برنامج التحقق من الموردين الأجانب (FSVP): Importers must verify that their foreign suppliers comply with U.S. safety standards and maintain end to end visibility into seafood sourcing, handling and storage.

European Union hygiene and fisheries rules

تنظيم الاتحاد الأوروبي 852/2004 states that for food that cannot be stored safely at ambient temperature, maintaining the cold chain is essential. Food business operators must comply with temperature control requirements and maintain the cold chain. EU fisheries control regulations mandate vessel tracking, electronic catch reporting and phased digital traceability for both domestic and imported seafood.

Documentation and certification

Proper paperwork protects consumers and facilitates trade. Essential documents include a bill of sale, shipping note, certificate of origin, health certificates and HACCP or FSSC 22000 شهادة. Review regulations regularly, automate documentation via digital tools and consider third party certifications to demonstrate compliance.

قائمة المراجعة: are you compliant?

Do you know the متطلبات درجة الحرارة (0–5 °C for fresh, ≤ –18 °C for frozen)?

Have you implemented تحليل المخاطر ونقاط المراقبة الحرجة with defined critical control points and monitoring procedures?

Are you keeping temperature records و traceability logs for each batch?

Does your transport meet FSMA sanitary transportation متطلبات?

Have you accounted for FSMA 204 record keeping deadlines و EU digital traceability rules?

What equipment keeps seafood within the cold chain?

Maintaining the correct temperature is not just about refrigerated trucks. It requires a combination of packaging, المبردات, monitoring devices and trained personnel.

Insulated packaging and refrigerants

Packaging matters: Fresh or frozen fish must be protected from contamination, moisture loss and physical damage. Packaging should provide a barrier to oxygen and enable traceability. Isothermal boxes, vacuum packaging and moisture resistant materials prolong shelf life and preserve appearance.

ال Seafood Guide recommends foam boxes or foil/bubble liners for insulation, leak proof packaging such as wax boxes or plastic coolers, and using refrigerants to maintain temperature. The type and amount of packaging depend on species, كمية, distance and mode of transport. Eco friendly materials should be considered to reduce environmental impact.

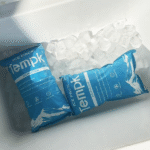

المبردات: حزم هلام (مواد تغيير المرحلة) are common for perishables because they thaw without producing excess water. Wet ice works for short distances but requires drainage to collect meltwater. الجليد الجاف (ثاني أكسيد الكربون الصلب) is often used for frozen products; لكن, it can be hazardous and many shippers have strict regulations on its use.

Monitoring and traceability equipment

أجهزة استشعار إنترنت الأشياء ومسجلات البيانات – Real-time monitoring across the entire cold chain is increasingly necessary. Leading operators deploy a network of IoT sensors in warehouses, trucks and last mile vehicles to track temperature, الرطوبة والموقع. عندما يحدث انحراف, alerts enable corrective actions before spoilage happens.

منصات متكاملة – Linking Warehouse Management Systems (WMS), نظم إدارة النقل (TMS), Enterprise Resource Planning (تخطيط موارد المؤسسات) and IoT dashboards provides end to end visibility. Such integration allows managers to track every pallet in real time, detect bottlenecks and simplify regulatory audits.

Advanced thermal packaging – Even with sensors, poor packaging can ruin shipments. Advanced cold chain companies use insulated containers, phase change materials and optimized pallet layering to maintain temperatures during multimodal transport. They test packaging under worst-case scenarios like high ambient heat or extended transit times to reduce risk.

تخطيط الطريق التنبؤي – AI-driven route planning anticipates traffic, weather and cold storage availability. Refrigerated trucks can be rerouted if sensors detect rising temperatures, preventing excursions.

Training and SOP enforcement – Technology alone cannot prevent errors if personnel aren’t trained. التدريب على السيناريو, digital standard operating procedures and certification programs help staff handle temperature-sensitive products correctly.

طاولة 2 – Equipment and packaging options

| Equipment/packaging | وصف | Example benefit |

| Foam boxes / isothermal containers | Insulated boxes that minimise heat transfer; often combined with gel packs | يحافظ على 0 °C–5 °C for fresh fish during overnight transport |

| حزم هلام (مواد تغيير المرحلة) | Reusable packs that solidify at a specific temperature and release cold as they melt | Control temperature without excess water; safe for air freight |

| الجليد الرطب | الجليد التقليدي, suitable for short trips when drainage is available | Provides rapid cooling; ideal for local deliveries |

| الجليد الجاف | Solid CO₂ used to keep frozen products below –18 °C | Maintains ultra-cold conditions for long-distance shipments |

| Data loggers/IoT sensors | Devices that record temperature, الرطوبة والموقع بشكل مستمر | Provide real-time alerts and traceability for regulatory audits |

| Cold rooms and freezers | Refrigerated rooms for 0 °C–5 °C and frozen storage facilities at –18 °C or lower | Inhibit microbial growth and extend shelf life |

| تغليف فراغ & modified atmosphere | Packages with reduced oxygen; extend shelf life and prevent freezer burn | Improve appearance, reduce oxidation and allow longer transport |

Practical tips for equipment selection

تقييم احتياجاتك: Consider species, كمية, transit time and destination. High-value products justify investment in IoT sensors and advanced packaging.

التحقق من صحة المعدات: Calibrate thermometers and sensors regularly and keep service logs for audits.

Combine solutions: Use a combination of insulation, refrigerants and real-time monitoring. على سبيل المثال, gel packs with IoT sensors can maintain temperature and provide alerts.

فكر في الاستدامة: Choose reusable packaging and eco-friendly materials to reduce waste. Solar-powered refrigeration units are emerging options for regions with limited electricity.

حالة عملية: An exporter used melting ice in insulated containers to maintain fish at 0 °C while employing IoT sensors for real-time tracking. Alerts allowed the team to adjust routing and avoid temperature deviations, reducing spoilage and increasing customer satisfaction.

How can you keep fish fresh during storage and transport?

Keeping seafood safe requires more than equipment; it demands disciplined processes.

Hygiene and sanitisation

Maintaining the hygiene of storage areas prevents cross-contamination. Cold rooms and equipment must undergo rigorous cleaning with approved products; الأرضيات, الجدران, shelves and utensils should be sanitised frequently. Operators must wear personal protective equipment and dispose of waste properly.

Compliance with health norms

Health standards establish requirements for installations, operational procedures and traceability. Companies that follow these rules demonstrate commitment to quality and consumer health. Keeping temperature and sanitisation records is especially important for exporters facing diverse international regulations.

Proper packaging and humidity control

Packaging must protect fish from contamination, humidity loss and physical damage. Use materials resistant to moisture and low temperatures; vacuum packaging and isothermal boxes can extend shelf life. Controlling humidity prevents drying or ice formation and preserves texture.

Monitoring and technology

Connected sensors and IoT systems enable real-time monitoring of temperature and humidity. Automatic warnings allow immediate corrective actions when conditions deviate. Such automation reduces human error, improves traceability and decreases waste.

Transport management

Refrigerated or frozen food vehicles must be validated periodically and maintain stable temperatures during the entire journey. Intelligent routing, thermal packaging and agile loading/unloading processes avoid thermal oscillations. A FIFO (First In, أول خروج) strategy ensures that older stock is used first, reducing waste and managing expiry dates.

تدريب الموظفين وإجراءات التشغيل الموحدة

Untrained staff can introduce critical errors. Provide scenario based training on reading temperature logs, responding to alerts and handling high-value inventory. Digital SOPs and gamified dashboards improve compliance and reduce human error.

مثال في العالم الحقيقي: A seafood exporter obtained FSSC 22000 certification after implementing continuous temperature and humidity monitoring with breach alerts that triggered immediate action. The system reduced waste and improved audit readiness.

2025 trends shaping seafood cold chain logistics

تتطور الخدمات اللوجستية لسلسلة التبريد بسرعة. New technologies and sustainability initiatives are changing how seafood is transported and stored.

AI-driven route optimisation and predictive analytics

Artificial intelligence enables real-time route adjustments based on traffic, نوافذ الطقس والتسليم. This improves efficiency, reduces fuel consumption and enhances delivery reliability. Predictive analytics forecast demand, anticipate equipment maintenance and detect high-risk shipments. AI-driven demand forecasting is especially valuable for seafood suppliers facing volatile catch volumes and changing consumer preferences.

Blockchain and end-to-end traceability

Blockchain is being integrated into cold chain operations to create immutable records of product journeys. This enhances transparency, ensures compliance with food safety regulations and builds consumer trust. جنبا إلى جنب مع أجهزة استشعار إنترنت الأشياء, blockchain can record temperature, location and handling conditions at each stage, providing verifiable proof for audits and claims.

Sustainable and lightweight packaging

مواد صديقة للبيئة, such as biodegradable or recyclable insulation, are gaining traction to reduce waste. خفيف الوزن, حاويات الشحن المعزولة المجهزة بأجهزة استشعار لإنترنت الأشياء تراقب درجة الحرارة, الرطوبة والموقع في الوقت الحقيقي. Solar-powered refrigeration solutions are being deployed in regions with limited electricity access, reducing the environmental footprint while improving food security.

Real-time monitoring and end-to-end visibility

Continuous monitoring and real-time tracking are becoming standard. Advanced IoT devices provide real-time data on temperature, الرطوبة والموقع. Integrated platforms enable end-to-end visibility and allow immediate corrective actions. Real-time visibility enhances customer satisfaction by providing up-to-date information about their orders.

الأتمتة والروبوتات

Cold chain facilities are adopting automated storage and retrieval systems (AS/RS) and robotic handling to address labour shortages and improve efficiency. تعمل الأنظمة الآلية بشكل مستمر, reduce errors in inventory tracking and provide precise temperature control. تشير الدراسات إلى أن حوالي 80 % من المستودعات ليست مؤتمتة بعد, highlighting significant potential for growth.

الاستدامة كقيمة أساسية

تعمل المخاوف البيئية واللوائح الأكثر صرامة على دفع الاستدامة إلى مقدمة الخدمات اللوجستية لسلسلة التبريد. التبريد الموفرة للطاقة, renewable energy sources and sustainable packaging reduce the carbon footprint and minimise waste. Sustainable practices also help companies comply with environmental regulations and avoid penalties.

طاولة 3 – Emerging trends and their practical significance

| اتجاه | وصف | ماذا يعني لك |

| منظمة العفو الدولية & تحسين الطريق | AI adjusts routes in real time based on traffic, weather and schedules | Reduce transit time, fuel costs and temperature deviations |

| إمكانية تتبع البلوكشين | Immutable records of temperature, الموقع والتعامل | Build consumer trust, simplify audits and respond quickly to recalls |

| التغليف المستدام & التبريد الشمسي | Eco-friendly materials and solar-powered units | Meet sustainability goals and reduce energy costs |

| IoT-enabled containers | Lightweight containers with sensors for temperature, الرطوبة والموقع | Continuous monitoring and improved shelf life |

| الأتمتة & الروبوتات | التخزين الآلي, retrieval and handling systems | Lower labour costs, reduce errors and maintain consistent temperatures |

| Integrated visibility & التحليلات التنبؤية | End-to-end IoT and AI platforms | Proactive management of risks, improved compliance and better demand forecasting |

رؤى السوق

International trade and retail expansion drive cold chain growth. According to MarketsandMarkets, the cold chain market is projected to reach دولار أمريكي 372 مليار من قبل 2029, من دولار أمريكي 228.3 مليار في 2024. Influencer-driven food trends and social media are also increasing demand for diverse seafood products. The Asia–Pacific region, especially India, is poised for strong growth due to high dairy consumption and the expansion of quick service restaurants.

الأسئلة المتداولة

What temperature should fresh and frozen fish be stored at? Fresh fish should be kept between 0 درجة مئوية و 5 درجة مئوية, while frozen fish must remain at –18 °C or colder. Maintaining these temperatures preserves flavour and prevents spoilage.

Why is continuous monitoring necessary in the seafood cold chain? Continuous monitoring using data loggers or IoT sensors provides real-time alerts when temperature or humidity deviates. It enables immediate corrective actions and supports traceability.

What are the best packaging options for shipping seafood? Use insulated boxes with gel packs for fresh fish and dry ice for frozen products. Packaging should be moisture-resistant and provide a barrier to oxygen.

Do I need to follow HACCP if I only transport seafood? نعم. HACCP principles apply to all stages of the seafood supply chain, including storage and transport. HACCP helps identify hazards, establish critical control points and ensure food safety.

How does blockchain improve seafood traceability? Blockchain creates tamper-proof records of each step, from harvest to delivery. إلى جانب أجهزة استشعار إنترنت الأشياء, it can document temperature and location, making audits easier and building consumer confidence.

ملخص وتوصيات

الوجبات الرئيسية: Maintaining the seafood cold chain requires precise temperature control (0–5 °C for fresh, ≤ –18 °C for frozen), adherence to regulations like HACCP, FSMA and EU hygiene rules, proper packaging and refrigerants, continuous monitoring and robust traceability systems. Emerging trends such as AI driven route optimisation, blockchain and sustainable packaging are transforming the industry. صحة, staff training and record keeping remain essential.

خطة العمل:

Define your critical control points using HACCP and set up real-time monitoring at each stage.

Invest in the right equipment: اختر التغليف المعزول, عبوات هلامية أو ثلج جاف, and IoT sensors for continuous monitoring. Calibrate devices regularly.

Implement integrated platforms to link your WMS, TMS and ERP, ensuring end-to-end visibility and simplified compliance.

ابق متوافقًا: Review FSMA and EU requirements, maintain temperature logs and seek third party certification.

احتضان الابتكار: Pilot AI route optimisation, blockchain traceability and sustainable packaging solutions to reduce waste and improve efficiency.

حول Tempk

ملف الشركة: و Tempk, we specialise in sustainable cold chain solutions. Our insulated containers and phase change gel packs are engineered to keep seafood at 0 °C–5 °C for over 48 ساعات, while our dry ice alternatives maintain –18 °C for frozen products. We design reusable packaging made from recyclable materials, helping you cut costs and reduce environmental impact. With an R&D centre focused on innovative refrigerants, we continuously improve performance and safety.

لماذا تختارنا؟? We offer a full suite of temperature-sensitive packaging, IoT-enabled monitoring devices and compliance services. Our experts help you implement HACCP, FSMA and EU requirements, and we provide training to ensure your team handles seafood safely. We also offer custom solutions for mixed-temperature shipments and long-distance exports. To learn how our products can protect your seafood and elevate your cold chain, contact our team for a consultation.