موسع البولي بروبيلين (إي بي بي) تعمل الصناديق المبردة على تغيير طريقة حفظك للطعام, الأدوية والمواد القابلة للتلف الأخرى في درجة الحرارة المناسبة. مصنوعة من رغوة EPP عالية الأداء, توفر هذه الحاويات عزلًا رائعًا بينما تظل خفيفة الوزن وقوية. في 2025 يزدهر سوق الصناديق المبردة - ومن المتوقع أن ينمو من 4.6 مليار دولار أمريكي في عام 2018 2020 إلى 8.1 مليار دولار أمريكي 2025 بمعدل نمو سنوي مركب 12.1%, مدفوعًا بالطلب المتزايد على حلول سلسلة التبريد الموثوقة والمواد المستدامة. سيساعدك هذا الدليل على فهم ما صندوق التبريد EPP يكون, لماذا تتفوق على المواد التقليدية وكيفية اختيار المادة المناسبة لاحتياجاتك.

ما هو صندوق التبريد EPP? تعرف على كيفية قيام هذه الحاويات بالحفاظ على برودة العناصر باستخدام رغوة الخلايا المغلقة وسبب اختلافها عن المبردات التقليدية.

لماذا تختار EPP على المواد الأخرى؟? نحن نقارن EPP مع EPS وEPE حتى تتمكن من اتخاذ قرار مستنير باستخدام الكلمات الرئيسية الطويلة مثل "مزايا صندوق التبريد EPP" و"EPP vs EPS".

كيف يتم تصنيع مبردات EPP? فهم عملية تشكيل الصدر بالبخار بعبارات بسيطة.

أين يمكنك استخدام صندوق التبريد EPP؟? اكتشف تطبيقات العالم الحقيقي في توصيل الطعام, الخدمات اللوجستية الطبية والترفيه في الهواء الطلق.

2025 اتجاهات السوق ونصائح الاختيار. اكتشف أحدث بيانات السوق, اتجاهات الاستدامة وإرشادات حول اختيار صندوق التبريد EPP والعناية به.

ما هو صندوق التبريد EPP وكيف يعمل?

صندوق التبريد EPP عبارة عن حاوية معزولة للغاية مصنوعة من مادة البولي بروبيلين الممدد (إي بي بي) رغوة. يتكون EPP من حبات خلية مغلقة صغيرة مصبوبة في بنية متماسكة. على عكس البوليسترين الهش, يحبس هيكل الخلية المغلقة لـ EPP الهواء داخل كل خرزة, مما يمنحها عزلًا حراريًا فائقًا, خفة الوزن والقدرة على استعادة شكله بعد الصدمات. تتراوح درجات حرارة الخدمة النموذجية من -40 درجة مئوية إلى 120 درجة مئوية, مما يجعل EPP مناسبًا لكل من ظروف التجميد والبيئات الحارة دون تشويه.

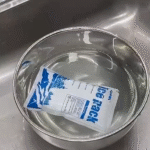

تعمل صناديق التبريد EPP عن طريق تقليل انتقال الحرارة. تقلل رغوة الخلية المغلقة من التوصيل الحراري, بينما تضمن مرونة المادة عدم تشقق الهيكل عند التحميل أو الاصطدام. عند وضع الطعام المبرد, اللقاحات أو عبوات الثلج بالداخل, تعمل جيوب الهواء المحاصرة على إبطاء معدل دخول الحرارة الخارجية إلى الصندوق. لأن EPP لا يمتص الماء ويقاوم الزيوت ومعظم المواد الكيميائية, فهو يحافظ على خصائصه العازلة حتى في الظروف الرطبة. هذا المزيج من العزل الحراري, تسمح مقاومة الصدمات والثبات الكيميائي لمبردات EPP بالحفاظ على المحتويات عند درجة حرارة ثابتة لفترة أطول من العديد من صناديق الرغوة التقليدية.

الخصائص الأساسية للبولي بروبيلين الموسع

تتميز رغوة البولي بروبيلين الموسعة بمجموعة من الخصائص التي تجعلها مثالية لصناديق التبريد. يمنح هيكل الخلية المغلقة EPP انتعاشًا مرنًا ممتازًا وامتصاصًا للصدمات; يمكنه الحفاظ على شكله بعد التأثيرات المتكررة. تتراوح كثافة EPP من 15 كجم/م3 إلى 100 كجم/م3, مما يعني أنه يمكن تصميم المنتجات لتحقيق التوازن بين القوة والوزن لتطبيقات محددة. يقاوم EPP درجات الحرارة المنخفضة والعالية (-40 درجة مئوية إلى +110 درجة مئوية) ولها مقاومة كيميائية متميزة. الرغوة قابلة لإعادة التدوير بنسبة 100%, مما يمنحها ميزة صديقة للبيئة على المواد البلاستيكية ذات الاستخدام الواحد.

| ملكية | وصف | أهمية بالنسبة لك |

| بنية الخلية | رغوة خلية مغلقة مع الهواء المحاصر داخل كل خرزة | يمنع امتصاص الماء ويضمن بقاء المبرد عازلاً حتى عندما يكون مبللاً. |

| نطاق الكثافة | 15-100 كجم/م3 | يسمح للمصنعين بتخصيص القوة والوزن; تعتبر الكثافات المنخفضة أخف بالنسبة للمبردات المحمولة. |

| انتعاش مرن | امتصاص ممتاز للصدمات; يعود إلى الشكل الأصلي بعد عدة ضربات | ينجو مبردك من الصدمات والسقوط دون حدوث خدوش دائمة. |

| مرونة درجة الحرارة | يعمل من -40 درجة مئوية إلى 110 درجة مئوية ويذوب فوق 160 درجة مئوية | يحافظ على المحتويات آمنة في الظروف القاسية; لن تتشوه عند نقل الوجبات الساخنة. |

| المقاومة الكيميائية/الماء | يقاوم الزيوت, الشحوم والماء; يمتص < 0.3% من وزنه رطوبة | تنظيف أسهل وإعادة استخدام صحي; مثالية للتطبيقات الغذائية والطبية. |

| قابلية إعادة التدوير | 100 % قابلة لإعادة التدوير وإعادة الاستخدام | يدعم أهداف الاستدامة ويقلل من النفايات. |

نصائح عملية

استخدم EPP للرحلات المتكررة. لأن EPP يرتد مرة أخرى بعد التأثيرات, يمكنك إعادة استخدام نفس المبرد لمئات من عمليات التسليم أو النزهات.

لا تقلق بشأن الرطوبة. لا يمتص هيكل الخلية المغلقة أي ماء تقريبًا, لذا فإن التكثيف أو الانسكابات لن تؤدي إلى تدهور العزل.

توقع حياة طويلة. نقطة انصهار عالية لـ EPP (160-176 درجة مئوية) يعني أنه يتحمل ماء التنظيف الساخن; فقط تجنب النيران المباشرة.

مثال الحياة الحقيقية: تخيل أنك تحزم السندويشات, الفواكه والمشروبات المثلجة ليوم على الشاطئ. يحافظ مبرد EPP على برودة كل شيء بفضل عزله ويظل سليمًا حتى إذا جلس عليه أطفالك أو اصطدم به في صندوق السيارة. بعد الرحلة, المسح السريع يزيل الرمال والانسكابات لأن المادة تطرد الماء وتقاوم البقع.

لماذا تختار صندوق تبريد EPP بدلاً من المواد التقليدية?

عزل فائق ومتانة

العديد من المبردات مصنوعة من البوليسترين الموسع (EPS) أو البولي إيثيلين (إيبي), لكن توفر مبردات EPP أداءً حراريًا فائقًا. يوفر هيكل رغوة الخلية المغلقة لـ EPP امتصاصًا استثنائيًا للطاقة ويحافظ على عزل ممتاز حتى بعد التأثيرات المتكررة. في المقابل, يميل EPS إلى التصدع وفقدان القدرة العازلة بعد الضربات. نقطة انصهار EPP (حوالي 160-176 درجة مئوية) أعلى بكثير من EPS (90 -105 درجة مئوية), مما يسمح لك بنقل الوجبات الساخنة أو تعقيم المبرد دون تشويهه.

المتانة وقابلية إعادة الاستخدام هي مزايا إضافية. تم تصميم مبردات EPP بنسبة قوة عالية إلى الوزن, لذا فهي تمتص الصدمات دون ضرر ويمكن إعادة استخدامها مئات المرات. إن صلابة EPP تجعلها مثالية للأنظمة اللوجستية ذات الحلقة المغلقة, تقليل الحاجة إلى التغليف القابل للتصرف وتوفير المال بمرور الوقت.

EPP أيضًا غير سام وصحي. هيكلها الخامل يقاوم الماء, زيوت, المواد الكيميائية والميكروبات, مما يجعلها آمنة للأغذية والأدوية. لا يتطلب تصنيع EPP أي عوامل نفخ ضارة, والمواد خالية من المعادن الثقيلة والهيدروكربونات المهلجنة.

الصداقة البيئية وكفاءة التكلفة

الاستدامة هي مصدر قلق رئيسي في 2025. الرغوة epp هي 100 % قابلة لإعادة التدوير وإعادة الاستخدام, المواءمة مع أهداف الاقتصاد الدائري. يستهلك الإنتاج طاقة منخفضة نسبيًا ولا يعتمد على عوامل النفخ الكيميائية الضارة, مما يمنح EPP الحد الأدنى من البصمة البيئية. لأنه يمكن إعادة طحن مبردات EPP وتشكيلها في منتجات جديدة دون خسارة كبيرة في الأداء, أنت تستثمر في منتج يدعم تقليل النفايات.

بالمقارنة مع EPS أو صناديق الرغوة ذات الاستخدام الواحد, تتمتع مبردات EPP بتكلفة أولية أعلى ولكن أ انخفاض التكلفة الإجمالية للملكية. طول عمرها يعني أنك تشتري بدائل أقل, والوزن المنخفض يخفض تكاليف النقل. في سلاسل التوريد, توفر القدرة على إعادة استخدام المبرد مئات المرات مع الحفاظ على العزل عائدًا قويًا على الاستثمار.

مقارنة EPP, مبردات EPS وEPE

يقارن الجدول التالي الخصائص الرئيسية للمواد الرغوية الشائعة المستخدمة في المبردات. يساعدك فهم هذه الاختلافات على اختيار الحل الصحيح.

| ملكية | إي بي بي (موسع البولي بروبيلين) | EPS (موسع البوليسترين) | إيبي (البولي ايثيلين الموسع) | ماذا يعني لك |

| بنية الخلية | رغوة الخلية المغلقة | رغوة الخلية المغلقة | رغوة الخلية المغلقة | جميع المواد الثلاث تحبس الهواء, لكن حبات EPP الموحدة توفر مرونة أفضل. |

| انتعاش مرن | ممتاز | فقير | معتدل | يتحمل EPP التأثيرات المتكررة دون أن يتشقق, لذلك يستمر مبردك لفترة أطول. |

| كثافة (كجم/م3) | 15-100 | 10-50 | 20-80 | الكثافة المنخفضة تعني مبردات أخف; يوفر EPP التوازن بين القوة والوزن. |

| امتصاص الطاقة | عالي | معتدل | قليل | تحمي EPP المحتويات الهشة بشكل أفضل أثناء النقل. |

| نطاق درجة الحرارة | -40 درجة مئوية إلى 110 درجة مئوية (نقطة الانصهار ~ 160-176 درجة مئوية) | -30 درجة مئوية إلى 80 درجة مئوية (ذوبان ≈ 90-105 درجة مئوية) | -60 درجة مئوية إلى 80 درجة مئوية | يتحمل EPP مياه التنظيف الساخنة والبرودة الشديدة دون تزييفها. |

| قابلية إعادة التدوير | ممتاز | معتدل | جيد | يدعم EPP جهود الاستدامة وبرامج الحلقة المغلقة. |

| يكلف | ارتفاع التكلفة الأولية; انخفاض تكلفة دورة الحياة | تكلفة أولية منخفضة; معدل استبدال أعلى | معتدل | الاستثمار في خطة الدفع الميسرة يحقق وفورات طويلة الأجل. |

نصائح لاختيار المواد

يختار إي بي بي عندما المتانة, تعتبر قابلية إعادة الاستخدام والأداء الحراري من الأولويات, خاصة بالنسبة للوجستيات سلسلة التبريد أو الرحلات الطويلة.

يختار EPS للشحنات لمرة واحدة حيث تكون التكلفة حرجة ويتوقع الحد الأدنى من المعالجة.

يختار إيبي عندما تحتاج إلى توسيد خفيف الوزن ولكن يمكنك تحمل عزل أقل.

مثال الحالة: تحولت خدمة توصيل الطعام من صناديق EPS ذات الاستخدام الواحد إلى مبردات EPP قابلة لإعادة الاستخدام. تتحمل مبرداتها الآن التحميل والتفريغ المتكرر دون تقطيع, والعزل المحسن يحافظ على الوجبات ساخنة أو باردة حتى يتم تسليمها. أكثر من عام, أعلنت الشركة عن انخفاض تكاليف التعبئة والتغليف بنسبة 40٪ بسبب القدرة على إعادة استخدام كل مبرد مئات المرات.

كيف يتم تصنيع صناديق التبريد EPP?

يعد إنشاء صندوق تبريد EPP عملية متعددة المراحل تعمل على تحويل راتينج البولي بروبيلين الخام إلى حاوية رغوية متينة. إنه ليس مشروع DIY; مطلوب معدات صب الصدر البخارية المتخصصة. الخطوات الأساسية هي:

ما قبل التوسع: يتم وضع حبات البولي بروبيلين الصلبة في وعاء موسع مسبقًا حيث تتسبب الحرارة والبخار في تليينها وتمددها مثل الفشار. عامل النفخ المدمج في الخرز يخلق خلايا مغلقة صغيرة, التحكم في الكثافة النهائية وحجم الخلية.

تكييف: يتم تعتيق الخرزات الموسعة لعدة ساعات إلى أيام في الصوامع لمعادلة الضغط الداخلي وتثبيت حجمها. يضمن التكييف المناسب القالب المتسق واستقرار الأبعاد.

صب (عملية الصدر بالبخار): يتم حقن الخرز المكيف في قالب على شكل المبرد النهائي. يقوم البخار ذو الضغط العالي بدمج الخرزات معًا, تشكيل قوي, هيكل رغوة متماسكة.

التبريد والقولبة: يتم تبريد الجزء المصبوب عن طريق تدوير الماء عبر قنوات القالب, مما يمنع الانكماش. بمجرد تبريده, تقوم القاذفات الميكانيكية بتحرير المبرد من القالب.

معالجة ما بعد: يتم قطع المواد الزائدة, ويتم إضافة ميزات اختيارية مثل المفصلات أو المزالج. يمكن أيضًا تشكيل العلامات التجارية أو الملصقات المخصصة مباشرة على السطح.

تضمن هذه العملية أن تتمتع مبردات EPP بكثافة موحدة وضيقة, هيكل الخلية المغلقة, توفير عزل وقوة متسقة.

فهم عملية صندوق البخار

تعد عملية صندوق البخار أمرًا أساسيًا لأداء EPP. على عكس الرغاوي المبثوقة, قالب الصدر بالبخار يدمج الخرز بدون مواد كيميائية. تعمل هذه الطريقة على إنشاء مفاصل قوية وإزالة الفجوات الهوائية, وهذا هو السبب في أن مبردات EPP لا تتخلص من الخرز مثل EPS. بعد صب, يتم تبريد الأجزاء "لضبط" الشكل; التبريد غير السليم يمكن أن يسبب تزييفها أو ضعف المفاصل.

| خطوة التصنيع | ماذا يحدث | أهمية |

| ما قبل التوسع | تتوسع الخرزات بالبخار; تتشكل الخلايا | يتحكم في الكثافة وجودة العزل. |

| تكييف | الخرز يستقر في الصوامع | يضمن دقة الأبعاد ويقلل من العيوب. |

| صب | البخار ذو الضغط العالي يدمج الخرز في القالب | يُنتج شكل المبرد وقوته. |

| التبريد/ديمولدينغ | الماء يبرد القالب; تم إخراج الجزء | يمنع الانكماش والتزييف. |

| معالجة ما بعد | التشذيب, إضافة الأجهزة | التخصيص والتشطيب للمبرد الخاص بك. |

نصائح المستخدم

عند تقييم مبردات EPP, اسأل الموردين عن عملية التشكيل الخاصة بهم; ينتج التبريد الذي يتم التحكم فيه جيدًا الصناديق الأكثر استقرارًا من حيث الأبعاد.

ابحث عن الخيارات التي يمكن من خلالها تشكيل شعارك في الصندوق للتعرف على العلامة التجارية - تسمح عملية التصنيع الخاصة بـ EPP بهذا التخصيص.

إذا كنت تحتاج إلى أداء محدد, طلب درجات كثافة مختلفة; الكثافات المنخفضة تعني مبردات أخف للتخييم, بينما توفر الكثافات الأعلى صلابة أكبر للاستخدام الصناعي.

أين يمكنك استخدام صندوق التبريد EPP؟?

الغذاء والمشروبات

تستخدم مبردات EPP على نطاق واسع في توصيل الطعام, خدمات تقديم الطعام والبقالة. عزلها الفائق يحافظ على الطعام الساخن ساخنًا والطعام البارد باردًا أثناء النقل. تعتمد شركات أدوات الوجبات على صناديق EPP للحفاظ على نضارة المكونات القابلة للتلف وتقليل هدر الطعام. للاستخدام اليومي, تستخدم العائلات مبردات EPP للنزهات, رحلات التخييم والنزهات الشاطئية.

الطبية والصيدلانية

ال تعتمد الصناعات الطبية والصيدلانية على مبردات EPP لنقل اللقاحات, عينات الدم, الأدوية والعينات المخبرية. تعد قدرة EPP على الحفاظ على نطاق درجة حرارة ثابت وخصائصه الصحية أمرًا بالغ الأهمية للحفاظ على المنتجات الحساسة. تضمن طبيعة المادة غير السامة والمقاومة للمواد الكيميائية عدم وجود تفاعلات ضارة مع الحمولات الصيدلانية.

الخدمات اللوجستية وسلسلة التبريد

في الخدمات اللوجستية لسلسلة التبريد, تستخدم الشركات حاويات EPP لشحن البضائع القابلة للتلف مثل المأكولات البحرية, الفواكه ومنتجات الألبان, ضمان وصول المنتجات ضمن نطاق درجة الحرارة المطلوبة. يقلل هيكل EPP خفيف الوزن من تكاليف النقل, ومرونته تسمح بالاستخدام المتكرر عبر العديد من دورات الشحن, مما يجعلها مناسبة لشبكات التوزيع ذات الحلقة المغلقة.

الترفيه في الهواء الطلق واستخدامات المستهلك

لأن مبردات EPP خفيفة وقوية, إنها خيار شائع لعشاق الهواء الطلق. المعسكر, يقدر الصيادون ورواد الشاطئ المبرد الذي يمكنه إبقاء المشروبات باردة لساعات دون إضافة وزن غير ضروري. بالإضافة إلى ذلك, سطح EPP المقاوم للماء يجعل من السهل تنظيفه بعد المغامرات الخارجية, تعزيز النظافة وسهولة الاستخدام.

التطبيقات الصناعية

أبعد من استخدام المستهلك, يتم تكييف مبردات EPP للصناعات المتخصصة. على سبيل المثال, في قطاع الفاكهة والزراعة, تعمل مبردات EPP المخصصة على حماية المنتجات الحساسة أثناء الحصاد والنقل. في الهندسة, إن مزيج EPP من العزل وامتصاص الصدمات يجعله مناسبًا لتغليف الإلكترونيات وشحن الأدوات الدقيقة الذي يتم التحكم في درجة حرارته.

| قطاع | العناصر النموذجية التي تم شحنها | فوائد صندوق التبريد EPP |

| توصيل الطعام & تقديم الطعام | وجبات طازجة, محلات البقالة, مجموعات الوجبات | يحافظ على جودة الطعام ودرجة حرارته; قابلة لإعادة الاستخدام لتقليل النفايات. |

| طبي & الأدوية | اللقاحات, البيولوجيا, عينات الدم | صحية, نطاق درجة حرارة مستقر وحماية من الصدمات. |

| الخدمات اللوجستية & سلسلة البرد | المأكولات البحرية, ألبان, ينتج | الوزن الخفيف يخفض تكاليف الشحن; متينة للشحن بحلقة مغلقة. |

| الترفيه في الهواء الطلق | مشروبات, وجبات خفيفة, الطعم | محمولة وسهلة التنظيف; يقاوم الصدمات والخدوش. |

| التغليف الصناعي | الإلكترونيات, أدوات المختبر | يوفر العزل الحراري والحماية من الصدمات للمعدات الحساسة. |

نصائح قابلة للتنفيذ

اختر الحجم المناسب. للنزهات العائلية, عادةً ما يكون مبرد سعة 20-30 لترًا كافيًا, في حين أن الشحنات الطبية قد تتطلب حاويات صغيرة متخصصة تدمج عبوات هلامية أو مواد متغيرة الطور.

استخدميه مع عبوات الجل. قم بدمج مبردات EPP مع عبوات الثلج الهلامية أو مواد تغيير الطور للتحكم في درجة الحرارة بشكل ممتد, باتباع تعليمات الشركة المصنعة.

التحقق من متطلبات الصناعة. قطاعات معينة (على سبيل المثال, الأدوية) لديها معايير تنظيمية للتحكم في درجة الحرارة ووضع العلامات; تأكد من أن مبرد EPP الخاص بك يلبي هذه الإرشادات.

مثال الحياة الحقيقية: تستخدم العيادة مبردات EPP لشحن اللقاحات عبر المنطقة. تحافظ رغوة الخلية المغلقة على الحمولة عند درجة حرارة 2-8 درجات مئوية لساعات, في حين أن صلابة الصندوق تمنع تلفه إذا أسقطه الساعي. لأنه يتم إعادة استخدام المبردات بعد التعقيم, تعمل العيادة على تقليل نفايات التغليف وتوفير التكاليف اللوجستية.

2025 تطورات السوق واتجاهاته

نمو السوق والإحصائيات

يتوسع سوق الصناديق المبردة بسرعة. وفقا لتقرير ماركيتس آند ماركتس, من المتوقع أن ينمو سوق صناديق التبريد العالمية من 4.6 مليار دولار أمريكي في عام 2018 2020 إلى 8.1 مليار دولار أمريكي 2025, يمثل معدل نمو سنوي مركب قدره 12.1 %. وتشمل محركات النمو زيادة شحنات الأدوية, حملات اللقاحات والطلب على توصيل الأغذية الطازجة. ومن المتوقع أن تكون منطقة آسيا والمحيط الهادئ السوق الأسرع نموا بسبب العمالة بأسعار معقولة والمواد الخام الوفيرة.

في سوق التغليف بسلسلة التبريد الأوسع, الإيرادات تنمو من 31.69 مليار دولار أمريكي 2024 إلى 35.49 مليار دولار أمريكي 2025 بمعدل نمو سنوي مركب قدره 12.0 %. ومن المتوقع أن يصل السوق 61.45 مليار دولار أمريكي 2029 مع معدل نمو سنوي مركب قدره 14.7 %. إن التحضر السريع وزيادة الطلب على الأطعمة الحساسة لدرجة الحرارة والمواد البيولوجية هي التي تدفع هذا النمو. وتشمل الاتجاهات اعتماد مواد التعبئة والتغليف الصديقة للبيئة ودمج أجهزة استشعار إنترنت الأشياء لمراقبة درجة الحرارة.

الابتكارات الناشئة في صناديق التبريد EPP

تمكين مراقبة إنترنت الأشياء: تأتي مبردات EPP المتقدمة الآن مزودة بأجهزة استشعار مدمجة لدرجة الحرارة والموقع. تسمح هذه الأجهزة لشركات الشحن بتتبع الظروف في الوقت الفعلي وضمان الامتثال للوائح. إن الجمع بين عزل EPP وأجهزة الاستشعار الذكية يقلل من التلف ويضمن الجودة.

ألواح معزولة بالفراغ (VIP) ومواد تغيير المرحلة (بي سي إم): تقوم بعض الشركات المصنعة بدمج VIPs أو PCMs في صناديق EPP للحصول على أداء حراري أطول. توفر VIPs الموصلية الحرارية المنخفضة للغاية, بينما تحافظ أجهزة PCM على درجة حرارة ثابتة أثناء تغير الطور. يعمل هذا التآزر على توسيع نافذة الشحن الآمن للمستحضرات الصيدلانية والبيولوجية.

المضافات القابلة للتحلل وبرامج إعادة التدوير: على الرغم من أن EPP قابل لإعادة التدوير بالفعل, تقوم الشركات بتجربة المجلدات الحيوية وتستعيد البرامج لتقليل النفايات بشكل أكبر. يؤدي استخدام كريات EPP المعاد تدويرها لإنتاج حاويات جديدة إلى تقليل استهلاك المواد الخام.

التخصيص والعلامات التجارية: تتيح عملية تشكيل الصناديق بالبخار للشركات إنتاج أشكال مخصصة, الألوان والشعارات مصبوب. تساعد هذه القدرة العلامات التجارية على تمييز عبواتها وتعزيز تجربة العملاء.

رؤى السوق

يشير النمو القوي في السوق إلى أن الاستثمار في مبردات EPP القابلة لإعادة الاستخدام من المرجح أن يؤتي ثماره. مع توسع التجارة الإلكترونية وتسليم الميل الأخير, خفيف الوزن, تعمل المبردات المتينة على تقليل تكاليف الشحن والأثر البيئي. إن التركيز على الاستدامة يعني أن المستهلكين والشركات يفضلون المواد ذات العمر الطويل وقابلة لإعادة التدوير. يمكن للشركات التي تعتمد مبردات EPP أيضًا أن تتماشى مع أهداف المسؤولية الاجتماعية للشركات وتلبية اللوائح البيئية الأكثر صرامة.

اختيار صندوق التبريد EPP المناسب لاحتياجاتك

يتضمن اختيار مبرد EPP تقييم حالة الاستخدام الخاصة بك, متطلبات القدرات وتفضيلات التصميم. استخدم دليل القرار البسيط هذا لتضييق خياراتك:

تحديد التطبيق الخاص بك. هل تخطط لرحلة تخييم في عطلة نهاية الأسبوع؟, توصيل وجبات طازجة أو نقل اللقاحات? كل سيناريو له متطلبات مختلفة لدرجة الحرارة والسعة.

تحديد الحجم ووقت العزل. قم بتقدير حجم العناصر التي تحتاج إلى تخزينها (لتر أو عدد الحاويات القياسية) ومدة التبريد المطلوبة. تحتوي الصناديق الأكبر حجمًا على كمية أكبر ولكنها قد تكون أثقل.

التحقق من درجة الكثافة. توفر EPP ذات الكثافة العالية صلابة ومتانة أكبر للاستخدام الصناعي, بينما تعمل الكثافات المنخفضة على تقليل وزن المبردات المحمولة.

النظر في ميزات إضافية. ابحث عن خيارات مثل الأغطية المفصلية, الأختام المضادة للتسرب, مقابض أو عجلات. تدمج بعض المبردات مقصورات عبوات الهلام أو مراقبة درجة الحرارة.

مراجعة الشهادات. لنقل الأدوية, تأكد من أن المبرد يلبي المعايير ذات الصلة مثل WHO PQS, إرشادات ISTA أو الناتج المحلي الإجمالي.

مصفوفة القرار

| استخدام الحالة | الحجم المقترح | الحد الأدنى من وقت العزل | الميزات الموصى بها |

| نزهة/نزهة عائلية | 20-30 لتر | 4-8 ساعات | بناء خفيف الوزن; سطح سهل التنظيف; مقابض للحمل وحجم صغير. |

| أطقم تقديم الطعام/الوجبات | 40-60 لتر | 12-24 ساعة | EPP متوسط الكثافة; إدراجات VIP/PCM اختيارية; غطاء ذو علامة تجارية. |

| شحنات الأدوية | 5-20 لتر | 24-72 ساعة | EPP عالي الكثافة; فتحات حزمة هلام متكاملة; تسجيل درجة الحرارة. |

| سلسلة التبريد الصناعية | 60-100 لتر+ | 24-48 ساعة | EPP عالي الكثافة; المزالج القوية; التوافق مع أنظمة البليت. |

نصائح للأداء الأمثل

قم بتهيئة المبرد مسبقًا: قم بتجميد أو تبريد عبوات الجل مسبقًا وقم بتبريد الصندوق مسبقًا قبل التحميل لتمديد فترة التبريد.

تقليل مساحة الهواء: املأ المبرد بالكامل قدر الإمكان; الفضاء الفارغ يسرع ارتفاع درجة الحرارة.

طبقة العناصر بشكل صحيح: ضع الكمادات الباردة فوق العناصر (مغسلة الهواء البارد) وتجنب الفتح المتكرر. استخدم الفواصل لفصل الحمولات المختلفة.

فحص بانتظام: التحقق من حالة المبرد بعد كل استخدام. استبدل الأختام البالية أو الأجزاء التالفة للحفاظ على العزل.

العناية والصيانة لصناديق التبريد EPP

تعتبر مبردات EPP منخفضة الصيانة بفضل مقاومتها للماء والمواد الكيميائية, لكن الرعاية المناسبة تطيل عمرهم.

تنظيف: بعد الاستخدام, امسح الجزء الداخلي والخارجي بصابون خفيف وماء. تجنب الفرش الكاشطة; قطعة قماش ناعمة تحافظ على السطح. لأن EPP لا يمتص الماء, فهو يجف بسرعة ويقاوم نمو العفن.

التعقيم: للتطبيقات الطبية أو الغذائية, قم بتطهير المبرد بالمبيض المخفف أو المطهرات. يتحمل EPP درجات حرارة التنظيف العالية دون تزييفها.

تخزين: قم بتخزين المبرد في مكان جاف بعيدًا عن أشعة الشمس المباشرة لمنع تدهور الأشعة فوق البنفسجية. أبقِ الغطاء مفتوحًا قليلاً للسماح بتدفق الهواء وتجنب الروائح.

تجنب الأحمال الثقيلة: على الرغم من أن EPP قوي, الضغط لفترة طويلة قد يسبب تشوه. لا تكدس العناصر الثقيلة في الأعلى عند تخزين المبرد.

إعادة التدوير بمسؤولية: عندما يصل المبرد إلى نهاية عمره الإفتراضي, قم بإعادتها إلى جهة إعادة التدوير أو الشركة المصنعة التي تقبل رغوة EPP. يمكن تحويل EPP المعاد تدويره إلى منتجات جديدة.

سيناريوهات عملية

التعقيم بعد نقل اللقاحات: امسح الجزء الداخلي بمطهر كحولي, ثم اشطفه وجففه; المادة لن تمتص الرطوبة أو المواد الكيميائية.

تنظيف بعد الاستخدام في الهواء الطلق: قم بإزالة الرمل أو الأوساخ بقطعة قماش مبللة. لأن EPP يصد الماء, لن يصبح المبرد منديًا, والروائح لن تستمر.

إصلاح الأضرار الطفيفة: عادة ما تعود الخدوش الصغيرة مرة أخرى. في حالة حدوث خدش سطحي, قم بالرمل بخفة أو املأها بمجموعة إصلاح متوافقة. تجنب المواد اللاصقة التي تحتوي على مذيبات يمكن أن تؤدي إلى تحلل مادة البولي بروبيلين.

الأسئلة المتداولة

س 1: ما هو نطاق درجة الحرارة الذي يمكن لصندوق التبريد EPP التعامل معه?

تعمل مبردات EPP بفعالية من حوالي -40 درجة مئوية إلى 110 درجة مئوية ولها نقطة انصهار تتراوح بين 160 درجة مئوية و176 درجة مئوية. يتيح لهم هذا النطاق الواسع نقل البضائع المجمدة أو الوجبات الساخنة دون تزييفها.

Q2: ما مدى صداقة البيئة مع مبرد EPP?

إن EPP قابل لإعادة التدوير بنسبة 100% ويمكن إعادة معالجته إلى منتجات جديدة. لا تستخدم عملية التصنيع أي عوامل نفخ ضارة, والمواد خالية من المعادن الثقيلة والهيدروكربونات المهلجنة.

س 3: هل يمكن استخدام مبردات EPP لشحنات الثلج الجاف?

نعم. تحمل EPP لدرجات الحرارة المنخفضة (وصولا إلى -40 درجة مئوية) والمقاومة الكيميائية تسمح لها بالعمل مع الثلج الجاف, على الرغم من أن التهوية المناسبة مطلوبة لتجنب تراكم الضغط. اتبع دائمًا إرشادات السلامة للتعامل مع الثلج الجاف.

س 4: ما المدة التي تدوم فيها مبردات EPP؟?

مع الرعاية المناسبة, يمكن إعادة استخدام مبرد EPP مئات المرات. إن مقاومتها للصدمات ونقطة الانصهار العالية تعني أنها تدوم أكثر من العديد من المبردات البلاستيكية أو EPS.

س 5: هل تمتص مبردات EPP الروائح؟?

لا. يمنع هيكل الخلية المغلقة لـ EPP امتصاص الماء, الروائح والميكروبات. لكن, يوصى بالتنظيف بعد كل استخدام للحفاظ على برودة المبرد.

ملخص وتوصيات

الوجبات الرئيسية: تجمع صناديق التبريد EPP بين العزل الحراري الفائق, المتانة والصداقة للبيئة. هيكلها الخلوي المغلق يحبس الهواء للعزل, يقاوم المواد الكيميائية والماء, ويوفر امتصاصًا ممتازًا للصدمات. تعمل EPP عبر نطاق واسع من درجات الحرارة ويمكن إعادة استخدامها مئات المرات. بالمقارنة مع EPS وEPE, يوفر EPP متانة أفضل, إمكانية إعادة التدوير وفوائد التكلفة على المدى الطويل. ينمو السوق العالمي لصناديق التبريد بسرعة, مع الطلب الذي تغذيه شحنات الأدوية, التجارة الإلكترونية وأهداف الاستدامة. يؤدي الاستثمار في مبردات EPP إلى مواءمة عملياتك مع أفضل الممارسات البيئية وإعدادك للابتكارات المستقبلية مثل مراقبة إنترنت الأشياء وتكامل VIP/PCM.

توجيه العمل: حدد حالة الاستخدام واحتياجات السعة الخاصة بك, اختر درجة الكثافة والميزات المناسبة, وقم بإقران المبرد الخاص بك بحزم الجل المناسبة. قم بتبريد الصندوق مسبقًا وتعبئته بإحكام للحصول على أفضل النتائج. قم بتنظيف وتخزين المبرد الخاص بك بشكل صحيح لإطالة عمره وإعادة تدويره بطريقة مسؤولة عند التقاعد. إذا كنت مشتركًا في الخدمات اللوجستية لسلسلة التبريد أو توصيل الطعام, فكر في التحول إلى مبردات EPP لتقليل نفايات التغليف, خفض تكاليف النقل والوفاء بالتزامات الاستدامة.

حول Tempk

نحن تيمبك, مورد محترف لحلول التعبئة والتغليف للتحكم في درجة الحرارة. ملكنا صناديق برودة EPP يتم تصنيعها باستخدام رغوة البولي بروبيلين الموسعة عالية الأداء, توفير عزل ممتاز مع الحفاظ على الوزن الخفيف والمتانة. على عكس صناديق الرغوة التقليدية, فهي لن تتخلص من الجزيئات أو تمتص الرطوبة, الحفاظ على نظافة منتجاتك وبيئتك. نحن نجمع بين التصنيع القوي, مراقبة الجودة والتصميمات القابلة للتخصيص لتوفير مبردات موثوقة للأغذية, المستحضرات الصيدلانية والاستخدام الصناعي.

دعوة إلى العمل

للعثور على صندوق التبريد EPP المناسب لاحتياجاتك, تواصل مع فريق Tempk. نحن نقدم استشارات شخصية لمساعدتك في اختيار الحجم المثالي, الكثافة والميزات. اتصل بنا اليوم لمعرفة كيفية إعادة استخدام منتجاتنا, يمكن للمبردات الصديقة للبيئة أن تعزز عمليات سلسلة التبريد الخاصة بك وتحمي منتجاتك.