كيف ستتطور لوجستيات توريد سلسلة التبريد في 2025

عالم cold chain supply logistics is undergoing rapid change, مدفوعة بالتقنيات الجديدة, لوائح أكثر صرامة وتغيير توقعات المستهلكين. في هذا الدليل الشامل ستكتشف كيفية التشغيل الآلي, الذكاء الاصطناعي (منظمة العفو الدولية), تعمل التعبئة المستدامة وديناميكيات السوق الإقليمية على إعادة تشكيل طريقة تخزين المنتجات الحساسة لدرجة الحرارة, نقلها وتسليمها. تقدر قيمة سوق لوجستيات سلسلة التبريد العالمية بـ دولار أمريكي 436.30 مليار في 2025 ومن المتوقع أن يصل إلى حوالي دولار أمريكي 1,359.78 مليار من قبل 2034 مع 13.46 % CAGR. سيساعدك فهم هذه التحولات الآن على اتخاذ قرارات أكثر ذكاءً والحفاظ على سلعك آمنة ومربحة.

What cold chain supply logistics involves – from storage and transportation to handling and final delivery, بما في ذلك المكونات الأساسية وأنظمة التعبئة والتغليف.

How automation and AI transform operations – including robotics adoption, التحليلات التنبؤية والمراقبة في الوقت الحقيقي التي تقلل التكاليف والأخطاء.

Why sustainability and waste reduction matter – examining energy efficient solutions, التعبئة والتغليف القابلة للتحلل والفوائد الاقتصادية لخفض النفايات.

How sectors like pharmaceuticals and fresh foods drive growth – highlighting gene therapy temperature needs, market forecasts and emerging products.

What regional trends and challenges to expect in 2025 – exploring Asia–Pacific’s growth, Europe’s infrastructure investments and U.S. dominance.

الأسئلة المتداولة – clear answers on packaging choices, regulatory requirements and selecting suppliers.

What does cold chain supply logistics involve and why is it important?

Cold chain supply logistics refers to the interconnected processes of packaging, تخزين, handling and transporting temperature sensitive goods under controlled conditions. These processes keep products within a safe temperature range from production to consumption, ضمان السلامة والجودة. Without robust cold chain systems, الأطعمة القابلة للتلف, اللقاحات, biologics and chemicals would spoil or lose efficacy during transit. Demand for effective cold chain packaging is growing rapidly—the global cold chain packaging market was about US$20.08 billion in 2020 ومن المتوقع أن يصل US$36.65 billion by 2026; some analyses foresee it surpassing US$100 billion by the mid 2030s.

Understanding cold chain logistics is crucial across industries. Pharmaceuticals and biologics require strict temperature ranges (عادة 2-8 درجة مئوية) للحفاظ على الفاعلية; the World Health Organization estimates that over 25 % من اللقاحات تفقد فعاليتها بسبب فشل سلسلة التبريد. Fresh produce and meal kits comprise around 75 % سوق التغليف بسلسلة التبريد, where maintaining texture, flavour and nutritional value is essential. المواد الكيميائية, مستحضرات التجميل, agriculture and horticulture also rely on precise temperature control to protect product integrity. Effective cold chain logistics therefore safeguard public health, reduce waste and support global trade.

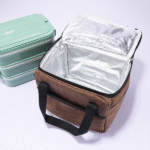

Core components of cold chain supply logistics packaging

Cold chain logistics integrates several elements working together to maintain temperature control throughout the shipment. Key components include insulation materials, temperature control mechanisms, tailored packaging design, coolants or phase change materials (PCMS), and sensors or data loggers. مواد العزل مثل البوليسترين الموسع (EPS), polyurethane foam and vacuum insulated panels (كبار الشخصيات) إنشاء حاجز حراري, reducing heat transfer and allowing longer transit times. آليات التحكم في درجة الحرارة can be active (using refrigeration units or dry ice) أو سلبي (relying on pre conditioned gel packs or PCMs); choosing the right system influences cost, التعقيد والأداء. Tailored packaging design ensures products fit snugly and minimises void space to maintain temperature uniformity.

The following table summarises typical temperature ranges and packaging choices for common products:

| فئة المنتج | نطاق درجة الحرارة الآمنة | التعبئة والتغليف النموذجية | أهمية عملية |

| الأدوية | 35.6 درجة فهرنهايت – 46.4 درجة فهرنهايت (2-8 درجة مئوية) | Insulated containers with PCMs or gel packs; العبث الأختام الواضحة | يحافظ على فعالية الدواء ويقلل من نمو الميكروبات. |

| التمرد (ينتج, ألبان, لحمة) | ≤ 40 ° f (4.4 درجة مئوية) | صناديق EPS أو PUR مع عبوات هلامية; بطانات تنفس | Prevents spoilage and preserves texture or flavour. |

| الشوكولاتة | تليين في 85 ° f (29 درجة مئوية), ذوبان عند 93 ° f (34 درجة مئوية) | البريد الحراري مع العزل العاكس; التبريد المعتدل | يحافظ على المظهر ويمنع تكون الدهون. |

| الأطعمة المجمدة | -30 درجة مئوية إلى 0 درجة مئوية | حاويات من مادة البولي يوريثين تحتوي على ثلج جاف أو PCMs -20 درجة مئوية; شاحنات البليت القابلة لإعادة الاستخدام | يمنع ذوبان المأكولات البحرية والآيس كريم أثناء النقل الطويل. |

| بيولوجيا شديدة البرودة (لقاحات مرنا, العلاجات الجينية) | ≥ -80 درجة مئوية | VIPs combined with dry ice; حاويات جامدة قابلة لإعادة الاستخدام | Essential for ultra cold products; provides reliable –80 °C conditions. |

نصائح وإرشادات عملية

Map product requirements: Classify items into temperature zones (على سبيل المثال, cool 10–15 °C, refrigerated 0–10 °C, frozen –30–0 °C or ultra cold ≤ –80 °C) to select appropriate packaging.

مبردات الحالة المسبقة: Freeze or pre condition PCMs and gel packs to the correct temperature before packing to achieve optimal thermal performance.

تقليل المساحة الفارغة: Fill empty areas with cushioning to reduce heat transfer and prevent shifting during transit.

السيطرة على الرطوبة: Leafy greens may require up to 95 % الرطوبة النسبية; use absorbent liners or moisture regulating materials accordingly.

التسمية والوثيقة: ضع علامة على الحزم مع تعليمات التعامل (على سبيل المثال, "الحفاظ على المجمدة") and keep temperature records to meet regulatory requirements.

مثال في العالم الحقيقي: When COVID 19 vaccines were first distributed in the United States, مهندسين في شركة IPS للتغليف & Automation helped design cold chain shipping materials that maintained extremely low temperatures while meeting regulatory standards, ensuring vaccine integrity. This highlights the importance of well designed packaging in safeguarding public health.

How are automation and AI transforming cold chain supply logistics?

Automation and AI are emerging as core technologies that address labour shortages, optimise routes and improve decision making in cold chain supply logistics. Many warehouses remain unautomated—studies show that about 80 % من المستودعات تفتقر إلى الأتمتة—leaving significant room for efficiency gains. أنظمة التخزين والاسترجاع الآلية (AS/RS) and robotic handling reduce labour costs, operate continuously and minimise errors. By controlling temperature and humidity automatically, these systems also improve product quality.

AI and predictive analytics further enhance cold chain operations. Artificial intelligence can analyse historical data and real time sensor readings to forecast demand, تحسين الطرق والتنبؤ باحتياجات صيانة المعدات. According to Inbound Logistics’ 2025 استطلاع, 71 % of logistics technology vendors now offer AI solutions, a sharp rise from 50 % في 2024. AI enablement ranked among the top five challenges for shippers, مع 47 % of technology vendors indicating customers viewed AI adoption as critical. These statistics underscore that AI has moved from experimentation to mainstream adoption.

AI and predictive analytics in route optimisation

AI powered route optimisation uses real time traffic data, weather information and historical performance to chart the most efficient paths for shipments. This reduces transit times and prevents quality degradation by avoiding congestion or extreme environmental conditions. Predictive analytics also identify upcoming temperature excursions through continuous monitoring, triggering immediate alerts for corrective action. The integration of AI with IoT sensors—small devices attached to shipments that measure temperature, humidity and location—allows logistics providers to intervene proactively before spoilage occurs.

The benefits of AI extend beyond route planning. AI driven demand forecasting helps organisations allocate resources efficiently and maintain inventory levels, تقليل النفايات. Predictive maintenance algorithms monitor equipment health and schedule servicing before breakdowns occur, preventing costly product losses. In the inbound logistics survey, cost reduction remains the top customer challenge, yet vendors note that AI enablement now ranks highly, indicating broad recognition of AI’s value.

Robotics and end to end visibility

Robotic systems are increasingly deployed to handle pallets, sort packages and manage inventory. These machines can operate 24/7, accelerating throughput and reducing manual errors. على سبيل المثال, robotic forklifts navigate warehouses using sensors and machine vision, minimising product damage and improving safety. في أثناء, تتبع في الوقت الحقيقي with IoT devices provides end to end visibility; في 2022 عقد قطاع الأجهزة زيادة 76.4 % سوق تتبع ومراقبة سلسلة التبريد. This visibility enables logistics companies to optimise routes, ensure regulatory compliance and enhance customer satisfaction.

Why are sustainability and waste reduction key priorities?

Environmental sustainability is no longer optional for cold chain operations. The food cold chain is responsible for roughly 2 % من انبعاثات ثاني أكسيد الكربون العالمية, و more than one billion tonnes of food are wasted every year—equivalent to 8-10 % من انبعاثات الغازات الدفيئة العالمية. Sustainable practices can help reduce this footprint while preserving product integrity. Regulatory pressures and consumer expectations are pushing companies to adopt energy efficient refrigeration systems, renewable energy sources and biodegradable or recyclable packaging.

Sustainable materials and eco friendly innovations

Green logistics focuses on reducing emissions and resource consumption throughout the supply chain. في التعبئة والتغليف, there is growing interest in paper and paperboard materials, which are biodegradable and account for 42 % of the cold chain packaging materials market in 2025. Insulated containers dominate by providing 40.4 % الحصة السوقية because of their durability and ability to protect goods from physical damage. في أثناء, companies are innovating in refrigerants: Cryopak introduced Eco Gel, a biodegradable gel pack that maintains consistent temperatures and can withstand repeated use, offering a sustainable alternative to traditional gels.

Another eco friendly innovation is وحدات التخزين البارد التي تعمل بالطاقة الشمسية. These units provide reliable cooling in regions with inconsistent electricity grids and reduce energy costs. Commercial solar rates vary between 3.2 و 15.5 سنتا لكل كيلوواط ساعة, offering significant savings compared with the average commercial utility cost of 13.10 سنتا لكل كيلوواط ساعة في 2024. Solar installations thus bridge gaps in rural healthcare and food distribution across Southeast Asia.

Sustainability also extends to مواد تغيير المرحلة (PCMS) و حاويات جامدة قابلة لإعادة الاستخدام. The PCM segment was valued at 3.6 مليار دولار أمريكي 2024, indicating growing adoption. Reusable rigid containers and pallet shippers are expected to grow from 4.97 مليار دولار أمريكي 2025 إلى 9.13 مليار دولار أمريكي 2034. Despite higher upfront costs, these systems lower total cost of ownership and reduce waste over time.

Economic benefits of waste reduction

Reducing spoilage saves money and lessens environmental impact. يمكن أن يفقد الطعام القابل للتلف المهدر ما يصل إلى 50 % of its value دون التحكم المناسب في درجة الحرارة. Effective cold chain logistics minimise returns, protect brand reputation and maximise each shipment’s value. بالإضافة إلى ذلك, sustainable practices help companies comply with environmental regulations and avoid penalties. As energy prices become more volatile, investments in efficient refrigeration and renewable energy can provide a competitive advantage.

How do pharmaceuticals and fresh food drive cold chain supply logistics growth?

The pharmaceutical sector is a major driver of cold chain expansion. خلال جائحة كوفيد 19, the need for ultra cold storage to distribute vaccines highlighted gaps in infrastructure and accelerated investment. تقريبًا 20 % من الأدوية الجديدة قيد التطوير هي العلاجات الجينية والخلوية, التي تتطلب درجات حرارة شديدة البرودة and precise handling. ومن المتوقع أن يصل سوق سلسلة التبريد الصيدلانية العالمية 1,454 مليار دولار أمريكي 2029 مع 4.71 % CAGR من 2024 ل 2029, underscoring long term demand for robust logistics.

Fresh foods also fuel growth. ومن المتوقع أن يصل سوق الخدمات اللوجستية لسلسلة التبريد الغذائي في أمريكا الشمالية 86.67 مليار دولار أمريكي 2025. Rising demand for plant based and organic certified foods creates new supply chain requirements. بحسب ميرسك, يمكن أن تكون الأطعمة النباتية مسؤولة عن ذلك 7.7 % سوق البروتين العالمي من خلال 2030, يستحق أكثر $162 مليار, and these products require specialised refrigerated transportation. Online ordering has increased direct to consumer sales, pushing warehouses and retailers to rethink last mile delivery strategies. Investments in fresh food logistics and last mile delivery infrastructure will continue to grow to satisfy consumer expectations.

Pharmaceutical logistics and ultra cold requirements

اللقاحات, insulin and gene therapies must stay within strict temperature ranges. For mRNA vaccines and certain biologics, درجات الحرارة as low as –80 °C مطلوبة; VIPs combined with dry ice or reusable rigid containers provide the necessary conditions. ال dry ice segment held 55.16 % of the technology market share in 2024, illustrating its importance in ultra cold transportation. Pre cooling facilities—used to remove field heat from produce and pharmaceuticals before storage—were valued at US$204.4 billion in 2024, reflecting the infrastructure needed to maintain product quality across the supply chain.

طعام طازج, meal kits and last mile delivery

المنتجات الطازجة, ألبان, meat and meal kits represent about 75 % سوق التغليف بسلسلة التبريد. Temperature thresholds vary across products—perishables should stay at or below 40 ° f (4.4 درجة مئوية), while chocolates soften at 85 ° f (29 درجة مئوية). Meal kit delivery benefits from multi zone shippers that can combine cool (10-15 درجة مئوية) والمبردة (0-10 درجة مئوية) compartments to improve load utilisation by حتى 30 %. Last mile delivery strategies emphasise automation, route optimisation and consumer visibility; according to Trackonomy, companies are investing in real time tracking devices and software to provide up to date information and enhance customer satisfaction.

What regional trends and challenges will shape cold chain supply logistics in 2025?

Regional dynamics influence both opportunities and challenges. In the cold chain logistics market, Asia–Pacific is expected to grow at a 14.3 % معدل نمو سنوي مركب من 2025 ل 2034, driven by rising demand for fresh foods, pharmaceuticals and improved infrastructure. Asia also leads in adopting innovations such as blockchain for traceability, solar powered cold storage and IoT sensors, particularly in Southeast Asia. Europe holds over 30 % of the cold chain packaging materials revenue in 2025, boosted by strong pharmaceutical production and strict regulatory compliance. Germany accounts for 17.87 % of Europe’s cold chain packaging market, reflecting its large dairy industry. في أمريكا الشمالية, advanced logistics infrastructure and high perishable demand give the region the largest revenue share of 33.10 % في 2025.

Regional growth and infrastructure investments

Investments in infrastructure will continue. في المملكة المتحدة, cold storage provider Magnavale announced a £130 million (US$161.3 million) استثمار to build a 101,000 pallet cold store. Such projects expand capacity and modernise aging facilities. Regulatory pressures also drive change; تلاحظ ميرسك ذلك ageing cold storage infrastructure (40– 50 سنة) and the phase out of environmentally harmful refrigerants like HCFCs and HFCs require modernisation and compliance with sustainability goals. الاضطرابات الجيوسياسية, like restrictions on the Panama Canal or black swan events, underscore the need for resilient and diversified supply routes.

Economic partnerships and trade policies will influence supply chains. The United States introduced new tariffs in 2025 that increased costs for critical components in temperature controlled packaging. Companies are responding by exploring near shoring and diversifying vendor strategies to mitigate cost pressures. في أثناء, manufacturers are expanding into emerging markets; على سبيل المثال, يعمل وول مارت أكثر من 10,526 منافذ عبر 24 بلدان, illustrating how global retail expansion drives demand for cold chain logistics.

Market size comparisons and growth outlook

Below is a comparison of regional market sizes and growth rates drawn from industry analyses:

| منطقة | الإحصائيات الرئيسية | Implications for your business |

| لوجستيات سلسلة التبريد العالمية | Market size US$436.30 billion in 2025, projected to reach US$1,359.78 billion by 2034 مع معدل نمو سنوي مركب قدره 13.46 %. | Rapid global expansion suggests robust demand; investing now positions you ahead of competitors. |

| آسيا والمحيط الهادئ | Highest CAGR at about 14.3 % من 2025 إلى 2034; fastest growing packaging materials region with a 7.2 % CAGR. | Opportunities in logistics infrastructure, e commerce groceries and pharmaceutical distribution. |

| أوروبا | Holds >30 % of packaging materials revenue share; major investments in modern cold stores like Magnavale’s £130 million facility. | High regulation and sustainability standards require compliance; partnerships with European providers can facilitate market entry. |

| أمريكا الشمالية | Largest revenue share (33.10 %) of cold chain packaging market; significant seafood harvests (US$6.3 billion dockside value) driving demand for chilled logistics. | Mature infrastructure and strong pharma industry make this a stable market for growth. |

| أمريكا اللاتينية & الأسواق الناشئة | Growing demand due to expansions in retail chains like Walmart and increasing e commerce. | Businesses should consider localized partnerships and regulatory compliance to serve new consumers. |

What challenges and opportunities define the future of cold chain supply logistics?

Several challenges confront the industry. High costs of advanced packaging solutions—such as VIPs, PCMs and reusable systems—can be prohibitive for small and medium sized companies. Rising raw material prices further squeeze margins. شيخوخة البنية التحتية remains a critical issue; many cold storage facilities are 40–50 years old and rely on refrigerants that are being phased out. نقص العمالة persist, pushing operators to embrace automation and robotics. التعقيد التنظيمي-على سبيل المثال, نحن. قانون تحديث سلامة الأغذية (FSMA) قاعدة 204, قانون أمن سلسلة توريد المخدرات (DSCSA) serialization requirements and EU sustainability directives—add compliance burdens.

ورغم هذه التحديات, الفرص كثيرة. تغليف صديق للبيئة is a major growth area as consumers and regulators demand sustainable options. التكامل التكنولوجي—from AI and IoT to blockchain and solar energy—enables proactive management, reduces waste and enhances transparency. الشراكات الاستراتيجية among food manufacturers, packaging suppliers and tech providers can streamline supply chains and broaden market reach. There is also room for consolidation and collaboration; بواسطة 2025, 74 % ومن المتوقع أن يتم توحيد البيانات اللوجستية, تسهيل التكامل السلس عبر سلاسل التوريد.

2025 latest cold chain supply logistics developments and trends

نظرة عامة على الاتجاه

مشهد السلسلة الباردة في 2025 continues to evolve with technological, environmental and market driven changes. وتشمل التطورات الرئيسية:

Advanced IoT sensors and real time tracking: IoT devices with GPS and temperature monitoring capabilities provide continuous visibility, enabling immediate corrective actions and reducing spoilage. يمثل قطاع الأجهزة زيادة 76.4 % سوق تتبع ومراقبة سلسلة التبريد في 2022.

Blockchain لإمكانية التتبع من النهاية إلى النهاية: Distributed ledgers make shipment records transparent and tamper proof; companies can share real time temperature, humidity and transit data with stakeholders to ensure compliance and build trust.

Solar powered cold storage and renewable energy integration: Solar units provide reliable cooling in remote locations and reduce energy costs, aligning with corporate sustainability goals and supporting rural healthcare.

تحسين المسار المدعوم بالذكاء الاصطناعي والصيانة التنبؤية: AI analyses real time and historical data to forecast demand, plan efficient routes and schedule maintenance before breakdowns. This improves reliability and reduces operating costs.

المجمدات المبردة المحمولة: Emerging devices maintain temperatures as low as –80 °C to –150 °C, critical for biologics and cell therapies.

Sustainable refrigerants and packaging materials: Innovations like Eco Gel and biodegradable PCMs offer alternatives to traditional gel packs, while paper and paperboard solutions reduce environmental impact.

Tariff driven supply chain adjustments: الولايات المتحدة الجديدة. التعريفات المقدمة في 2025 زيادة تكاليف مكونات التعبئة والتغليف التي يتم التحكم في درجة حرارتها, حث الشركات على استكشاف القرب من المساندة وتنويع الموردين.

رؤى السوق

Industry surveys reveal that 91 % of logistics technology vendors serve supply chain and transportation companies, و manufacturing usage of logistics IT increased to 81 % في 2025. AI adoption skyrocketed: 71 % of vendors offer AI solutions, and AI enablement emerged as a top customer challenge. Despite strong interest in technology, underutilisation remains—many logistics operations still rely on manual processes, indicating a large opportunity for digital transformation.

The cold chain packaging materials market stands at 9.5 مليار دولار أمريكي 2025 ومن المتوقع أن تصل US$15.7 billion by 2032 مع 7.6 % CAGR. ورق & paperboard products lead the segment, المحاسبة ل 42 % الإيرادات, while insulated containers hold 40.4 % يشارك. The food sector accounts for 65 % of end user demand, and the pharmaceutical sector shows high growth due to personalised medicine and biologics.

الأسئلة المتداولة

س 1: How do I choose the right packaging for cold chain supply logistics in 2025?

Select packaging based on your product’s temperature requirements, مدة الشحن والالتزامات التنظيمية. على سبيل المثال, EPS foam boxes with gel packs work for perishable foods needing temperatures around 0–10 °C, while VIPs and dry ice are necessary for ultra cold biologics at –80 °C. Evaluate insulation performance, الوزن والاستدامة; consider reusable containers to reduce long term costs.

Q2: What regulations affect cold chain supply logistics?

Major regulations include the U.S. قانون تحديث سلامة الأغذية (FSMA) قاعدة 204, requiring traceability records; قانون أمن سلسلة توريد الأدوية (DSCSA) التسلسل للأدوية; and EU sustainability directives focusing on eco friendly materials. Compliance demands accurate temperature monitoring and record keeping.

س 3: How can automation reduce costs in my cold chain operation?

Automation reduces labour costs and minimises human error. Robotic handling and automated storage systems operate continuously, زيادة الإنتاجية وتقليل أوقات الدورة. AI based predictive maintenance prevents equipment failures, while route optimisation algorithms cut fuel costs and improve delivery reliability.

س 4: لماذا تعتبر الاستدامة مهمة في لوجستيات سلسلة التبريد?

Sustainability reduces environmental impact and improves profitability. تساهم سلسلة التبريد الغذائي في 2 % من انبعاثات ثاني أكسيد الكربون العالمية; adopting renewable energy and biodegradable packaging lowers this footprint. Reducing food waste (more than one billion tonnes globally) can cut greenhouse gas emissions by up to 8–10 % and improve margins.

س 5: ما الذي يجب أن أبحث عنه عند اختيار شريك لوجستي لسلسلة التبريد؟?

Assess potential partners for regulatory compliance (الناتج المحلي الإجمالي, FSMA, DSCSA), التكامل التكنولوجي (تتبع في الوقت الحقيقي, منظمة العفو الدولية, blockchain), sustainable practices and geographic reach. Check whether they offer end to end visibility and customised solutions for your specific product requirements.

اقتراح

لتزدهر في 2025, businesses must embrace the transformation sweeping cold chain supply logistics. Automation and AI enhance efficiency, predictive analytics optimize routes and prevent breakdowns, and real time tracking provides end to end visibility. Sustainable packaging and renewable energy reduce environmental impact and compliance risks, while robust infrastructure and regional investments support global growth. The pharmaceutical and fresh food sectors drive demand for ultra cold storage and precise delivery, making innovation essential.

الخطوات التالية القابلة للتنفيذ:

تدقيق سلسلة التبريد الخاصة بك: Map product temperature requirements, packaging systems and transport routes to identify gaps and upgrade opportunities.

استثمر في التكنولوجيا: تنفيذ أجهزة استشعار إنترنت الأشياء, AI driven analytics and automated handling systems to improve visibility, reduce errors and cut costs.

اعتماد الحلول المستدامة: Transition to eco friendly packaging materials and explore renewable energy sources such as solar powered storage units.

تعزيز الشراكات: التعاون مع الموردين, logistics providers and customers to standardize data, share resources and increase resilience.

Monitor regulations and markets: Stay updated on global trends, tariffs and regional investments to adapt strategies and seize new opportunities.

من خلال اتخاذ هذه الخطوات, you’ll position your organisation to deliver temperature sensitive products safely, sustainably and profitably in the coming years.

عن Tempk

Tempk هي شركة رائدة في مجال توفير حلول التعبئة والتغليف واللوجستيات لسلسلة التبريد. We specialize in reusable and recyclable insulated containers, phase change materials and IoT enabled monitoring systems designed to keep your products within their target temperature ranges. With our research and development centre and decades of industry experience, we deliver solutions tailored to pharmaceuticals, الأطعمة, المواد الكيميائية وأكثر من ذلك. Our commitment to innovation and sustainability helps clients reduce waste and operational costs while meeting regulatory standards.