آخر تحديث: يناير 2026

If you’re picking an insulated box producer, ال “يمين” choice is the one that can prove performance, تناسق, and compliance at scale—not the one with the nicest brochure. في 2026, you should expect verified thermal data, stable supply, التخصيص, الاستدامة, and better traceability.

One practical benchmark: reusable solutions often target 20–100+ cycles, and lane-matching design choices can cut temperature drift dramatically over multi-day routes.

هذه المقالة سوف تساعدك:

Validate insulated box producer performance claims using measurable thermal metrics

Reduce total cost by comparing lifecycle value, ليس سعر الوحدة

Avoid risk with food and pharma insulated boxes using clear documentation

Choose materials for reusable insulated boxes and eco-friendly cold chain packaging

Use a simple decision tool to shortlist an insulated box producer fast

What Does an Insulated Box Producer Do for You?

An insulated box producer doesn’t just “make boxes.” They design, امتحان, manufacture, and scale thermal packaging so your product stays in range when time, طقس, and handling try to break your plan.

If they miss small details—like closure fit, استقرار الجدار, or repeatable molding—you pay for it through spoilage, complaints, وإعادة صياغة.

ماذا “جيد” looks like in plain terms

A strong insulated box producer helps you get three predictable outcomes:

Hold time you can trust for your real lanes

Repeatable quality across production batches

Clear documentation that reduces onboarding and audit friction

How Can an Insulated Box Producer Prove Thermal Performance?

A credible insulated box producer should show you test results that look like engineering, لا التسويق. Expect simulated lanes, multi-point probes, and repeatable protocols that match your shipping reality.

You want evidence of repeatability across batches, not a single “hero test.”

The thermal metrics you should request (ولماذا)

Ask your insulated box producer for a simple report that includes metrics like these:

| Performance focus | What to ask for | ماذا يعني لك |

|---|---|---|

| اكتساب الحرارة | °C/hour (قابل للتكرار) | Predictable delivery windows |

| عقد الوقت | Hours vs your lane target | رحلات أقل لدرجة الحرارة |

| Closure integrity | Leak check pass/fail | Lower spoilage risk |

| إعادة الاستخدام | Cycles achieved in real use | انخفاض التكلفة لكل شحنة |

These are the same practical indicators top producers use to translate design into outcomes.

نصائح عملية يمكنك التقديم اليوم

ممرات قصيرة (same/next day): Consider thinner walls with higher density to reduce bulk

ممرات طويلة (2-5 أيام): Add thickness or hybrid insulation to extend hold time

Return/reuse loops: Choose durable shells to protect ROI across cycles

مثال في العالم الحقيقي: One seafood shipper aligned wall thickness to route duration and cut heat gain nearly in half over 48 ساعات.

Which Materials Should Your Insulated Box Producer Recommend?

Material choice is where many projects quietly fail. The right insulated box producer recommends materials based on your lane, التعامل, and return model—not trends.

Common insulation options in 2026

| مادة | قوة | Thermal stability | فائدتك العملية |

|---|---|---|---|

| الرغوة EPS | خفيف الوزن | معتدل | منخفضة التكلفة, single-use lanes |

| إي بي بي | High impact | مستقر | قابلة لإعادة الاستخدام, tough handling |

| رغوة البولي يوريثان | High insulation efficiency | مستقر | Long holds with slimmer walls |

| هجين | قابل للضبط | الأمثل | Best balance for mixed lanes |

Plain-language takeaway: if handling is rough or you plan reuse, EPP usually wins. If you need long holds in a smaller footprint, PU or hybrid options are strong.

Tips that reduce cost without risking performance

Match density to abuse level (over-building burns money)

Ask for real reuse-cycle data, not assumptions

Confirm end-of-life options (recycling or take-back programs)

What Compliance and Quality Controls Should You Demand?

في 2026, “we comply” is not enough. Your insulated box producer should document material safety, قابلية التنظيف, مقاومة الرطوبة, and batch controls in a way that your QA team can approve quickly.

The buyer-friendly compliance checklist

Ask your insulated box producer to provide:

Food-contact and material safety declarations (as applicable to your markets)

Cleaning guidance and moisture behavior (عملي, not vague)

Documented quality controls (incoming material, in-process checks, final inspection)

Why this protects you: clear documentation reduces audits, speeds onboarding, and lowers risk when you scale.

حالة عملية: A pharma distributor shortened onboarding by choosing a producer with pre-validated documentation, saving weeks of back-and-forth.

How Does Customization Improve Cold Chain Outcomes?

Customization is not “nice to have.” It’s how an insulated box producer turns a generic container into a lane-specific solution that reduces excursions.

High-impact customization options (that actually matter)

| Custom feature | What it changes | ينفع لك |

|---|---|---|

| Insert geometry | Airflow paths | More even temperatures |

| تصميم الغطاء | جودة الختم | Fewer leaks |

| Branding/labels | تعريف | Faster sorting |

| Tracking slots | Data capture | Proof of compliance |

These are practical upgrades that improve consistency without over-complicating operations.

Do this before you customize

Start with payload mapping: size to product, not vice versa

الطيار قبل القياس: validate with a small run

Lock specs: prevent drift between batches

How Do You Compare Cost Across Insulated Box Producer Quotes?

If you compare only unit price, you will choose wrong. A better method is cost per protected shipment, which includes losses, replacements, and admin effort.

A cost comparison you can trust

| سائق التكلفة | Low-price box | Optimized box | النتيجة الخاصة بك |

|---|---|---|---|

| سعر الوحدة | قليل | معتدل | Misleading alone |

| معدل الخسارة | أعلى | أدنى | Margin protection |

| دورات إعادة الاستخدام | Few | كثير | Lower lifetime cost |

| Admin effort | عالي | قليل | Time saved |

خلاصة القول: pick the insulated box producer that reduces total cost, not the invoice line.

أداة القرار التفاعلية: Insulated Box Producer Fit Score (2 دقائق)

Score each item 0–2 points (0 = no proof, 1 = partial, 2 = clear proof). Add them up.

The insulated box producer provides lane-matched thermal reports (time/temperature curves).

Results are repeatable across batches (not one-off).

The producer can explain failures and fixes (not just successes).

Materials match your lane and handling model (single-use vs return).

Clear documentation supports your QA/compliance checks.

QC plan covers batch consistency and traceability.

Custom inserts/lids are available and piloted before scale.

Lead times are realistic and communicated in writing.

Sustainability plan is practical (إعادة الاستخدام, repair, or end-of-life).

The producer can support scale without spec drift.

How to interpret your score

16-20: Strong fit—move to pilot lanes

11-15: Conditional—pilot only with clear improvement plan

0-10: High risk—keep searching for another insulated box producer

2026 الاتجاهات: What Insulated Box Producers Are Changing Now

في 2026, the best insulated box producer is becoming more “data-ready” and more lifecycle-focused. Buyers increasingly expect packaging that supports measurement, يقلل من النفايات, ويحسن التكرار.

أحدث لقطة التقدم

Data-ready designs: built-in space for sensors and labels

الكفاءة المادية: less foam for the same hold time

برامج دائرية: repair/refurbish options to reduce waste

نظرة السوق: buyers now prefer producers who offer lifecycle plans, not just products.

الأسئلة المتداولة

س 1: How do I verify an insulated box producer’s performance claims? Ask for lane-specific test reports with time-temperature curves, and check repeatability across batches—not a single test.

Q2: Are reusable insulated boxes worth it for small volumes? في كثير من الأحيان نعم, if routes are predictable. Even a few reuse cycles can offset higher upfront cost.

س 3: What lead time should I expect from an insulated box producer in 2026? Standard designs ship faster than custom builds. Strong producers communicate timelines clearly and early.

س 4: How do I reduce box size without losing performance? Use more efficient insulation choices and optimize inserts to reduce dead air and stabilize internal temperatures.

س 5: What’s the quickest way to shortlist an insulated box producer? Use the Fit Score tool above, then pilot the top two on your most common lane before scaling.

س6: What should I ask for in a first RFQ email? Ask for lane assumptions, thermal test summary, material options, QC plan, مهلة, and reuse/circular program details.

ملخص وتوصيات

A great insulated box producer proves performance with data, matches materials to your lane reality, and helps you win on lifecycle cost—not just price.

Your next step is simple: define your top lanes, set hold-time targets, request test data, and run a small pilot before scaling.

Your 3-step action plan

ممرات الخريطة (مدة, المخاطر المحيطة, درجة الحرارة المستهدفة, حمولة)

Shortlist using the Fit Score (هدف ل 16+)

Pilot with real packaging builds, then lock specs for scale

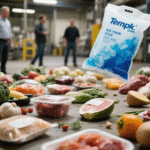

حول Tempk

و Tempk, we design and manufacture insulated boxes for food and pharmaceutical cold chains, focusing on measurable performance, مواد متينة, وتوثيق واضح. We emphasize practical customization and repeatable quality that supports your daily operations as you grow.

CTA: If you want a faster, lower-risk selection process, talk with our team to review your lanes and recommend an insulated box configuration that matches your 2026 متطلبات.