If you’re choosing an ice gel pack vaccine supplier, you’re buying temperature confidence, not just cooling packs. Most refrigerated vaccine lanes aim for a 2–8°C band, and many packaging setups target 24–120 hours of hold time.

The risk is simple: one wrong supplier choice can create leaks, freeze damage, or inconsistent batches. This updated January 2026 guide shows you how to qualify the right partner with practical tools and clear pass/fail rules.

This Article Will Help You Answer:

- How to build a lane profile before selecting an ice gel pack vaccine supplier

- How to define “الأداء المعتمد” for your 2–8°C vaccine shipping lanes

- How to reduce freeze risk with conditioning and controlled-temperature options

- How to request audit-ready documentation and batch traceability

- How to run a sample test plan that saves weeks and avoids false results

- How to lock supplier specs and avoid silent material changes

مورد لقاحات حزمة الآيس جل: Start With Your Lane Profile

إجابة مباشرة: Your ice gel pack vaccine supplier can’t succeed without a lane profile that reflects time, حرارة, التعامل, and shipper type. If you skip this step, you’ll receive generic recommendations that fail during real delays. A good lane profile turns “we ship vaccines” into measurable requirements. It also prevents you from comparing suppliers using mismatched assumptions.

التفسير الموسع: Think of your lane profile like a route forecast. Short city delivery is a quick grocery trip. Cross-border transport is a road trip with unexpected stops. When your lane changes, your risk changes, so your ice gel pack vaccine supplier must match cooling behavior to your lane realities. Lane profiles typically include transit duration, التعرض المحيطي, التعامل مع الأحداث, and shipper insulation type.

Lane Profile Builder (5-minute worksheet)

Fill this out once per lane group (حار / طبيعي / رائع):

| عامل الحارة | What you record | Example range | ما يتغير بالنسبة لك |

|---|---|---|---|

| مدة العبور | Door-to-door hours | 24-96 | Required hold time |

| التعرض المحيطي | Peak outside temperature | 15–40°C | Heat load risk |

| Handling events | Handoffs and waiting | قليل / واسطة / عالي | Leak and shift risk |

| نوع الشاحن | EPS / VIP / إي بي بي | single choice | Pack-to-volume ratio |

نصائح عملية يمكنك استخدامها على الفور

- الممرات الساخنة: define your worst month and test that lane first.

- Multi-box programs: keep one lane profile per box size.

- Clinic delivery: treat freeze risk as a top-level requirement.

Real-world pattern: Teams that define lanes early avoid endless sample loops and inconsistent packing outcomes.

مورد لقاحات حزمة الآيس جل: ماذا “Validated” Should Mean

إجابة مباشرة: أ “التحقق من صحة” ice gel pack vaccine supplier shows repeatable temperature control, not a single best-case graph. You should see stable performance near your target band, plus clear conditioning and packing rules. “Validated” also means results are repeatable across production lots. Without batch consistency, validation is just marketing.

التفسير الموسع: Vaccine shipping needs stability more than extreme cold. Ice gel packs should provide a controlled thermal buffer, not a sudden cold spike. Your ice gel pack vaccine supplier should be able to explain the temperature curve in simple terms, like a steady drip rather than a broken pipe. In many programs, the target range is 2–8°C, and hold duration goals can sit around 24–120 hours depending on the lane.

The performance signals you should look for

| Performance signal | ماذا “جيد” يبدو | ماذا “bad” يبدو | ماذا يعني لك |

|---|---|---|---|

| Target band control | stays near 2–8°C | swings widely | fewer quarantines |

| Hold time clarity | lane-based guidance | vague claims | predictable shipping |

| التكرار | stable across lots | changes per lot | مفاجآت أقل |

| Re-freeze durability | consistent over cycles | degrades fast | تكلفة أقل لكل استخدام |

نصائح واقتراحات عملية

- Ask for lane-based guidance by hours, لا “بين عشية وضحاها” language.

- Require repeat testing after any material or process change.

- Confirm re-freeze behavior if you reuse gel packs across cycles.

مثال عملي: Buyers often discover “great” packs fail because the instructions are unclear and hard to repeat.

مورد لقاحات حزمة الآيس جل: Freeze-Risk Controls That Actually Work

إجابة مباشرة: Freeze risk is reduced by controlling coolant state, تباعد, and contact surfaces—not by adding more ice. Many failures happen when frozen packs touch cartons directly. Your ice gel pack vaccine supplier should offer conditioning guidance and safer configuration options. They should also explain tradeoffs in plain language, not technical jargon.

التفسير الموسع: “أكثر برودة” is not always safer for refrigerated vaccines. A fully frozen pack can act like a cold hammer when contact is direct. Conditioning is a simple idea: you moderate the pack surface before packing, so cooling becomes stable. Some lanes also use controlled-temperature options, such as 4–5°C PCM-style coolants, when freeze risk is your biggest pain.

Freeze-Risk Quick Selector

| حالتك | Safer approach | لماذا يساعد | What to ask your supplier |

|---|---|---|---|

| Clinics report “بارد جدا” | conditioned coolant + طبقة عازلة | يقلل من المسامير الباردة | conditioning SOP + diagram |

| Hot lanes with long dwell | optimized pack ratio | avoids late-stage warming | hot-lane test evidence |

| Mixed staff skill levels | fewer SKUs + تسميات واضحة | reduces mistakes | وضع العلامات + ورقة التدريب |

| المنتجات الحساسة | 4–5°C controlled coolant option | يمنع التجميد | recommended configuration |

نصائح واقتراحات عملية

- Use a buffer layer between coolant and cartons.

- Avoid direct contact between frozen packs and product.

- Standardize orientation so packers do it the same way every shift.

Actual case style: A distributor reduced “too-cold” incidents after moving to conditioning and better spacing rules.

مورد لقاحات حزمة الآيس جل: Quality Evidence You Should Demand

إجابة مباشرة: A qualified ice gel pack vaccine supplier provides proof in three buckets: أداء, robustness, and lot consistency. You should receive a structured evidence pack, not scattered emails. That evidence must survive staff turnover and peak-season pressure. It should also be easy to understand in your warehouse.

التفسير الموسع: When something goes wrong, your supplier’s proof becomes your defense. That is why documentation matters as much as cooling power. The evidence pack should include performance summaries, drop-and-leak checks, seal integrity controls, and change-control policies.

The Evidence Pack (request list)

- Performance summary: الفرقة المستهدفة, expected hold time, lane assumptions

- Robustness proof: drop resistance and leakage checks

- Batch controls: fill tolerance and seal integrity checks

- Work instructions: تكييف, التعبئة, and handling guidance

- Change control: what happens if film, هلام, or process changes

| Evidence item | ما يجب أن تراه | العلم الأحمر | معنى عملي بالنسبة لك |

|---|---|---|---|

| Lot traceability | batch ID on docs and cartons | “we can’t share” | faster root cause |

| Leak checks | defined method + frequency | only visual claims | fewer mess events |

| Change control | written notice timeline | silent changes | stable performance |

| Packing SOP | step-by-step diagram | vague steps | fewer packing errors |

نصائح واقتراحات عملية

- Request one-page instructions for packers and receivers.

- Ask for a “no-change window” during your peak shipping months.

- Define rejection criteria before you place the first large order.

Real-world lesson: Many failures begin after unannounced film or seal changes, not route changes.

مورد لقاحات حزمة الآيس جل: Sample Testing Without Wasting Weeks

إجابة مباشرة: Compare ice gel pack vaccine supplier samples using the same shipper, نفس الحمولة, and the same conditioning method you will use in production. If you change variables, your comparison becomes noise. A gel pack is “جيد” only inside your packaging system. That system includes insulation, payload ratio, and placement rules.

التفسير الموسع: Sample tests fail when teams run a “perfect lab” سيناريو. Real shipping includes tape patterns, fill levels, والتأخير. Your test should copy your normal packing process, then add one controlled stress event. That gives you a result you can trust. It also reduces endless back-and-forth with each ice gel pack vaccine supplier.

A repeatable test plan (3 يدير, high confidence)

- Baseline run: normal ambient, normal packing, measure internal points.

- Hot-lane run: higher ambient exposure for your worst month.

- Handling run: a controlled drop sequence, then continue the test.

| Test element | الخيار أ | الخيار ب | ما يتغير بالنسبة لك |

|---|---|---|---|

| تكييف | الصلبة المجمدة | controlled pre-cool | freeze risk vs stability |

| الموضع | all-around | balanced top/bottom | uniformity inside box |

| Payload fill | low fill | high fill | sensitivity to empty space |

| مدة | 24 ساعات | 72 ساعات | confidence for longer lanes |

نصائح واقتراحات عملية

- Avoid over-freezing if your SOP will not do it every day.

- Track temperature at multiple points inside the shipper.

- Keep closure method consistent, including your tape pattern.

Actual case style: A clinic program reduced “بارد جدا” events after switching from fully frozen packs to controlled conditioning.

مورد لقاحات حزمة الآيس جل: Product Options You Should Expect

إجابة مباشرة: A capable ice gel pack vaccine supplier offers multiple formats and clear guidance, because you are buying temperature behavior. Packs should match your box footprint and your lane duration. They should also be robust enough for handling and storage conditions. If your supplier sells only one size, you end up forcing the wrong pack into the right lane.

التفسير الموسع: Standardization is growing in 2026 لوجستيات اللقاح. Teams want fewer configurations, not more. That pushes suppliers to offer a small, smart product range with simple rules. Typical options include brick packs, flat panels, thicker films for rough handling, and reusable designs for closed-loop programs.

Format choice guide

| خيار | When it works best | ماذا تشاهد | ينفع لك |

|---|---|---|---|

| Small bricks | ممرات قصيرة, tight boxes | placement mistakes | easy control |

| Flat panels | you need uniform cooling | corner gaps | عدد أقل من النقاط الساخنة |

| Thicker film | rough handling lanes | cost increase | lower leak risk |

| Multi-cycle packs | closed-loop networks | cleaning SOP | lower cost per trip |

نصائح واقتراحات عملية

- If receivers struggle with SOPs: choose formats that are easy to place.

- If parcels get dropped: prioritize stronger seals and thicker films.

- If you ship mixed products: request a sensitivity-based configuration guide.

Actual case style: A warehouse reduced packing time after standardizing one pack format across several SKUs.

مورد لقاحات حزمة الآيس جل: مهلة, سعة, and Seasonality

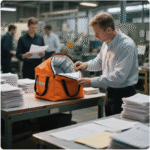

إجابة مباشرة: A dependable ice gel pack vaccine supplier should scale like a utility: steady output and stable quality. العديد من الإخفاقات قيد التشغيل, not thermal. Late production and rushed packing create the same risk as a weak gel formula. Capacity planning protects your program when demand spikes.

التفسير الموسع: Vaccine programs often run in waves. If your supplier cannot handle peaks, your team starts substituting packs. That is where mistakes multiply. You need predictable lead times, stable packaging, and a buffer stock strategy. Practical planning also includes staging space for conditioning and re-freezing cycles.

Peak-season readiness checklist

- Forecast demand by lane group (حار / طبيعي / رائع)

- Hold buffer stock for top pack sizes

- Confirm storage space for staged conditioning

- Confirm palletization prevents punctures

- Set reorder points based on lead time, لا أمل

| Planning item | What to confirm | علامة جيدة | معنى بالنسبة لك |

|---|---|---|---|

| مهلة | standard vs peak | stable ranges | fewer urgent air shipments |

| التغليف | carton strength | puncture prevention | تسربات أقل |

| تخزين | staging area | controlled workflow | repeatable packing |

| Buffer stock | safety inventory | supplier supports it | fewer stockouts |

نصائح واقتراحات عملية

- Avoid too many SKUs unless labeling and training are excellent.

- Use simple color coding for pack types to prevent mix-ups.

- Train receivers on re-freezing and storage expectations.

Operational win: Simple inventory rules often reduce temperature incidents more than expensive upgrades.

مورد لقاحات حزمة الآيس جل: Contract Terms That Protect You

إجابة مباشرة: A safe contract locks specifications, defines acceptance rules, and forces change transparency from your ice gel pack vaccine supplier. Price matters, but clarity prevents losses. If a supplier changes film or gel behavior without notice, your validation becomes invalid. Strong suppliers accept these terms because they already run controlled processes.

التفسير الموسع: Contracts are not just legal documents. They are your protection against silent changes, missed deliveries, and quality drift. A good contract includes spec locks, change notice windows, and clear rejection criteria. It also defines what happens when something goes wrong.

Contract essentials checklist

- Spec lock: نوع هلام, نوع الفيلم, ملء الوزن, seal method

- تغيير الإشعار: minimum days before any material or process change

- Rejection criteria: what triggers a return or credit

- Audit rights: ability to visit or request production records

- Liability limits: who pays for temperature failures

| Contract term | ما يجب تضمينه | العلم الأحمر | معنى عملي بالنسبة لك |

|---|---|---|---|

| Spec lock | detailed material list | “subject to change” | stable performance |

| تغيير الإشعار | 90-day minimum | no notice clause | time to revalidate |

| Rejection criteria | clear pass/fail rules | vague language | عدد أقل من النزاعات |

| Audit rights | annual visit option | “غير مسموح به” | الشفافية |

نصائح واقتراحات عملية

- Lock specs before placing large orders.

- Require written notice for any material or process change.

- Define rejection criteria in advance to avoid disputes.

Real-world lesson: Many failures begin after unannounced film or seal changes, not route changes.

مورد لقاحات حزمة الآيس جل: Final Checklist for 2026

إجابة مباشرة: Use this checklist to qualify any ice gel pack vaccine supplier before committing to a large order. It covers lane fit, تصديق, freeze risk, الوثائق, testing, product options, سعة, and contract terms. If a supplier cannot answer these questions clearly, they are not ready for your program.

Final qualification checklist

- صالح المسار: Does the supplier understand your lane profile?

- تصديق: Can they show repeatable temperature control?

- خطر التجميد: Do they offer conditioning guidance and safer options?

- التوثيق: Is the evidence pack complete and audit-ready?

- الاختبار: Can you run a fair sample test with their support?

- Product options: Do they offer formats that match your needs?

- سعة: Can they scale for your peak season?

- عقد: Will they accept spec locks and change notice terms?

خاتمة: Choosing an ice gel pack vaccine supplier is not just about price or cooling power. It is about finding a partner who understands your lanes, provides clear documentation, and commits to stable performance. Use this guide to qualify suppliers with confidence and protect your vaccine program in 2026.