موزع صناديق الثلج الصناعية: كيفية الاختيار في 2026?

Choosing an industrial ice box distributor is not just purchasing. It is a risk decision that protects product quality, امتثال, and customer trust. For sensitive lanes like 2-8 درجة مئوية pharma or 24–72 hour توصيل الطعام, many failures start before the truck moves, during staging and packing. If you pick the wrong industrial ice box distributor, you may pay twice: once for boxes, and again for claims, يعيد شحنه, and lost accounts.

هذه المقالة سوف تجيب لك:

What an industrial ice box distributor really provides beyond supply

كيف cold chain ice box distribution affects reliability and speed

Which specs and documents you should request for food and pharma lanes

How to validate packouts with a simple testing plan, لا تسويق المطالبات

A scoring method to compare distributors before you scale in 2026

What Does an Industrial Ice Box Distributor Actually Do?

An industrial ice box distributor keeps insulated packaging available, usable, and repeatable at scale. They do more than ship boxes. They forecast demand, position inventory, and support packout steps your team can execute every day.

If you ship daily, “good enough” supply becomes a bottleneck fast. قوي industrial ice box distributor prevents stockouts during peaks and reduces damage in transit. They also help you standardize a small set of SKUs, so training stays simple.

Industrial Ice Box Distributor vs. Seller: ما هو الفرق?

A basic seller focuses on price and availability. A true industrial ice box distributor partner focuses on fit and failure modes. They ask about your lane duration, ambient exposure, and staging time.

| What you need | Basic vendor | Industrial ice box distributor partner | ماذا يعني لك |

| Lane understanding | الحد الأدنى | Maps lanes and risks | Fewer surprises in peak season |

| Packout guidance | Generic | Lane-specific SOPs | تدريب أسرع, أخطاء أقل |

| Validation support | خياري | Testing plan + السجلات | Easier customer approvals |

| Service model | Ship-and-forget | Stocking + reorder system | Fewer stockouts and rush freight |

Industrial Ice Box Distributor Tips You Can Use Today

Ask for a lane profile worksheet: مدة, ambient range, staging time, وحساسية المنتج.

Demand a one-page packout SOP: صور, quantities, pass/fail checks.

Confirm inventory visibility: you should see stock status and lead time in writing.

حالة حقيقية: A frozen meal shipper reduced late deliveries after switching to a distributor with regional stock and fixed reorder triggers.

Why Does Your Industrial Ice Box Distributor Matter in 2026?

Your industrial ice box distributor controls availability, response time, and day-to-day continuity. Even the best box design fails if it arrives late, damaged, or in the wrong quantity. في 2026, demand spikes and climate volatility make “backup plans” a baseline requirement.

موثوق industrial ice box distributor also helps you reduce temperature excursions by preventing common process failures. These failures include warm staging, inconsistent refrigerant conditioning, and packout shortcuts. Small process fixes often beat expensive upgrades.

Industrial Ice Box Distributor Capability Checklist

| القدرة | ما الذي تبحث عنه | لماذا يهمك |

| Inventory planning | Forecast-based stock | Prevents shortages |

| Regional warehousing | Multiple locations | تجديد أسرع |

| Damage prevention | Palletized handling | Fewer cracked boxes |

| Packout support | إجراءات التشغيل القياسية البسيطة | Consistent results |

| Issue resolution | Clear escalation path | Faster recovery |

نصائح عملية ل 2026

Ask for “peak season” proof: how they allocate stock when demand spikes.

Request lead times for emergencies: not just standard shipping.

Track damage rates: ask for replacement policy and typical defect rates.

حالة حقيقية: A distributor activated buffer stock during a seasonal surge and kept a seafood program shipping without missed windows.

Which Specs Should You Request From an Industrial Ice Box Distributor?

Request specs that match your lane, not generic “72-hour” claims. A box is not “good” or “bad” in isolation. It is good for a duration, ملف تعريف المحيط, and payload geometry. لك industrial ice box distributor should explain performance in plain language, with test context.

Start with five spec questions. Then ask for matching evidence, ليست الصفات. This approach prevents overspending and reduces spoilage risk.

Industrial Ice Box Distributor Spec Questions That Matter

What temperature band must you hold? مبردة, المجمدة, or controlled room temperature

How long is door-to-door time? include delays and weekend holds

What is payload geometry? air gaps and headspace change results

How rough is handling? تكديس, قطرات, اهتزاز, ضغط

Single-use or reusable? return strategy changes total cost

Industrial Ice Box Distributor Decision Tool: Pick Your Setup in 90 ثواني

Use this with your industrial ice box distributor before you request quotes.

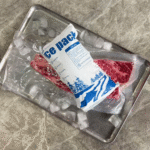

المنتجات المبردة (لا تجمد)

≤24 ساعة: عزل معتدل + gel packs often works

24-72 ساعة: higher insulation + tighter SOPs usually needed

المنتجات المجمدة

≤36 hours: العزل + frozen gel may work in mild weather

>36 hours or hot lanes: higher-performance system is likely required

High-value or regulated payloads

Add monitoring options and validation files from day one

| الملف الشخصي لين | Typical setup direction | What to ask your distributor | ماذا يعني لك |

| قصير, محلي | Moderate insulation | Fast replenishment | Lower labor and cost |

| لمسافات طويلة, حار | Higher insulation | “Bad day” validation | Fewer summer failures |

| المأكولات البحرية المجمدة | مراقبة الرطوبة | ختم + leak controls | Fewer meltwater complaints |

| Pharma 2–8°C | Freeze-risk control | Refrigerant separation SOP | Less potency risk |

Industrial Ice Box Distributor Spec Tips and Recommendations

الحجم الصحيح أولاً: paying for air is the fastest way to inflate cost.

Standardize SKUs: fewer sizes means faster training and fewer mistakes.

Require a written spec sheet: مقدار, مادة, إنهاء, and reuse cycle.

حالة حقيقية: A dessert brand reduced claims by moving to a smaller shipper and standardizing gel placement.

How Do You Vet an Industrial Ice Box Distributor for Food Shipments?

A food-grade industrial ice box distributor should help you run an audit-ready process, not just sell materials. Food lanes fail when staging is warm, lids stay open too long, or wet ice leaks. Your distributor should design steps that real teams can follow under time pressure.

Focus on “repeatability” more than “perfection.” You want a simple SOP that reduces human error. You also want clear guidance on hygiene, التحكم في التسرب, and pre-cooling steps where needed. In many markets, food transport expectations focus on sanitary handling and verified temperature control, not vague “best effort.”

Industrial Ice Box Distributor Food: What “Audit-Ready” Looks Like

| Risk area | What your distributor should provide | ماذا يعني لك |

| Warm staging | Simple staging rules | Fewer summer spoilage claims |

| Wet ice leaks | Secondary containment | Cleaner handling and fewer returns |

| Packout errors | Photo SOP + pass/fail checks | Faster training for new staff |

| وحدات SKU مختلطة | Thermal grouping rules | More consistent product temps |

Industrial Ice Box Distributor Food Lane Tips and Recommendations

If your dock is warm: pre-chill product and packaging, not just gel packs.

If you use wet ice: require leak controls and drainage planning.

If turnover is high: use one-page SOPs with pictures and checks.

حالة حقيقية: A meal-kit program cut late-summer complaints after adding shaded staging rules and a “lid-close within 60 seconds” check.

How Do You Vet an Industrial Ice Box Distributor for Pharma and GDP?

A GDP-ready industrial ice box distributor must protect both temperature and documentation. في فارما, “proof” matters as much as performance. You need a clear validation approach, a deviation workflow, and monitoring options for higher-risk lanes. GDP-style programs expect documented controls and evidence you can show during audits.

For 2–8°C products, freezing can be as damaging as overheating. Many health authorities treat freeze protection as a first-class risk, especially for vaccines and biologics. لك industrial ice box distributor should help you prevent direct contact between frozen refrigerants and product. Winter lanes need a freeze-risk plan, not just extra coolant.

Industrial Ice Box Distributor Pharma: GDP-Ready Document Pack

| وثيقة | What it should include | لماذا يهمك |

| Validation summary | ملفات تعريف, حمولة, pass criteria | Supports audits and approvals |

| حزمة SOP | خطوات, صور, quantities | Reduces operator variation |

| Change control rules | what triggers retesting | Prevents “silent” performance drift |

| Deviation workflow | actions and escalation | Faster response to excursions |

| خيارات المراقبة | device choices and placement | Better evidence for high value |

Industrial Ice Box Distributor Pharma Tips and Recommendations

Separate refrigerants from product: use spacers or barriers where needed.

Plan for winter: add freeze protection for 2–8°C payloads.

Standardize handoff checks: simple receiving checklist reduces disputes.

حالة حقيقية: A clinic network reduced vaccine waste after switching to a packout that separated refrigerants and added a receiving checklist.

How Should an Industrial Ice Box Distributor Handle Testing and Thermal Validation?

Thermal validation is only useful when it matches your real lane risks. A trustworthy industrial ice box distributor explains test conditions in plain language. They describe the ambient profile, payload start temperature, and sensor placement. They do not hide behind a single number.

You do not need perfect testing. You need repeatable testing that de-risks your top lanes. Use a temperature-exposure test logic similar to common transit simulation approaches, so results reflect real handling and ambient swings. Start with “normal day” and “bad day” scenarios, ثم قم بقفل إجراء التشغيل المعياري (SOP)..

Industrial Ice Box Distributor Validation Plan You Can Run

Pick your قمة 3 الممرات by revenue or complaint risk.

Test one normal day profile and one bad day profile.

Run at least two packers و two different days.

Lock the SOP and set change control triggers.

| Validation element | What to define | ماذا يعني لك |

| ملف تعريف المحيط | صيف, شتاء, peak temps | Predicts seasonal failures |

| Payload rules | كتلة, geometry, start temp | Improves repeatability |

| Packout diagram | coolant location and qty | Reduces “tribal knowledge” |

| الأجهزة | sensor spots and interval | Stronger evidence in disputes |

| تمرير المعايير | time in range | Clear go/no-go decisions |

Industrial Ice Box Distributor Validation Tips and Recommendations

Test the delay scenario: include staging and missed pickup conditions.

Revalidate after changes: new materials or sizes can shift results.

Make it packer-proof: fewer decisions at packout means fewer errors.

حالة حقيقية: A biologics shipper cut excursions after adding a delay-ready packout validated for an extra hold window.

How Can an Industrial Ice Box Distributor Lower Your Total Landed Cost?

Lower unit price does not equal lower cost. A capable industrial ice box distributor reduces hidden expenses like spoilage, يعيد شحنه, expedited freight, and labor time. The best savings often come from right-sizing, simplification, and fewer mistakes.

Think in total landed cost per shipment. Then compare options on claims rate, labor minutes, and damage risk. This is how you protect margin in 2026.

Industrial Ice Box Distributor TCO Mini Calculator

Ask your industrial ice box distributor to estimate these in one sheet:

Packaging cost per shipment

Typical claims or spoilage rate

Reship rate and expedited shipping cost

Labor minutes per packout

Disposal cost or return handling cost

| Cost lever | What a good distributor optimizes | Result for you |

| Dimensional efficiency | right-size box and fill range | Lower freight and material spend |

| Labor time | simpler SOP and fewer SKUs | Faster packing and fewer errors |

| معدل الضرر | pallet handling and protection | Fewer replacements and refunds |

| Inventory strategy | reorder triggers and buffer stock | Fewer emergencies |

| Reverse logistics | reuse loop design | Lower long-term packaging spend |

Cost Tips and Recommendations

Daily shipping: prioritize labor simplicity over “maximum insulation.”

Weekly shipping: prioritize hold time and inventory resilience.

Premium goods: prioritize validation and monitoring to protect margin.

حالة حقيقية: A frozen brand cut total cost after standardizing two box sizes and one packout diagram.

Industrial Ice Box Distributor Service Models: Which One Fits You?

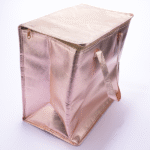

The right service model depends on your volume pattern and return reality. حديث industrial ice box distributor may offer stock-and-ship, make-to-order, a managed program, or pooled reusable assets. Each model has a clear best use case.

If you want reuse, treat it like a program. تصميم للعودة, تنظيف, and accountability from day one. خلاف ذلك, reuse becomes a theory that fails in operations.

Industrial Ice Box Distributor Service Models: When Each Fits Best

| نموذج | الأفضل ل | Key risk | What to ask your distributor |

| Stock-and-ship | fast scaling | limited customization | real lead times and backup SKUs |

| Make-to-order | unique sizes | delays and MOQs | QC process and change control |

| Program model | high volume | forecast errors | safety stock rules and SLAs |

| إعادة الاستخدام / pooling | closed-loop routes | return loss | تتبع, تنظيف, deposits |

Service Model Tips and Recommendations

Spiky demand: require a peak buffer plan and reorder triggers.

B2B pallets: ask for consistent labeling and pallet quantities.

DTC parcels: demand unboxing clarity and simple disposal instructions.

حالة حقيقية: A regional distributor reduced stockouts by moving a customer to a managed program with weekly forecasts.

2026 Latest Developments and Trends for Industrial Ice Box Distribution

في 2026, the best industrial ice box distributor behaves more like a logistics partner than a catalog. Three forces shape buyer expectations: reuse pressure, rising monitoring culture, and faster replenishment needs. Climate volatility also pushes more teams to build seasonal packouts.

Industrial Ice Box Distributor Trends: أحدث التطورات في لمحة

Regional hub networks: shorter lead times and fewer emergency shipments

Distributor-led packout training: fewer mistakes at fulfillment centers

برامج قابلة لإعادة الاستخدام: lower waste when return rates are real

Validation files as default: more customers demand proof, not promises

Monitoring add-ons: more lanes benefit from simple data loggers

Market Insight You Can Use

Buyers increasingly reward distributors who reduce operational noise. That means fewer surprises, clearer documentation, and faster recovery when things go wrong. If a distributor cannot explain your packout in plain language, they will not protect your brand.

أدوات تفاعلية: Make the decision in one meeting

1) Self-assessment: Is your industrial ice box distributor scale-ready?

إجابة نعم أو لا:

Can they guarantee supply during peak demand?

Do they operate regional warehouses near your lanes?

Can they provide a lane-based packout SOP with photos?

Can they explain validation conditions in plain language?

Do they have a defined escalation process for issues?

إذا أجبت لا to two or more, your distributor may limit growth.

Industrial Ice Box Distributor Scorecard (0–20 points)

Score each item 0-2:

Inventory visibility and availability clarity

Lead-time reliability in normal weeks

Lead-time reliability in peak weeks

Packout SOP quality and simplicity

Thermal validation evidence quality

Damage prevention and pallet handling

Documentation speed (same day vs “later”)

Issue resolution process and ownership

Cost optimization guidance (التكلفة الإجمالية للملكية, not price)

Communication responsiveness

تفسير:

16-20: strong partner

11-15: usable with safeguards

0-10: high operational risk

الأسئلة المتداولة

س 1: What makes a food-grade industrial ice box distributor reliable?

They provide clean handling guidance, leak controls, and a repeatable packout SOP your team can follow every shift.

Q2: Do I need an industrial ice box distributor with thermal validation?

If your lanes are long, حار, منظم, or high-value, validation reduces risk and speeds customer approvals.

س 3: How do I choose an industrial ice box distributor for frozen seafood?

Prioritize seal integrity, التحكم في الرطوبة, and damage prevention. Then validate with a “hot day + delay” scenario.

س 4: What should a GDP-ready industrial ice box distributor for pharma provide?

Expect validation summaries, change control rules, deviation workflows, and monitoring options for higher-risk lanes.

س 5: Is one industrial ice box distributor enough, or should I dual-source?

One distributor simplifies operations. Two distributors reduce risk. Many teams qualify a backup once volume grows.

س6: Are reusable industrial coolers always cheaper?

Only when return rates are high and cleaning is controlled. If returns are uncertain, start with a pilot lane.

س7: How often should I review distributor performance?

Quarterly reviews work well. Track delays, damages, temperature complaints, and labor time per packout.

Q8: What is the biggest mistake buyers make in 2026?

Buying by unit price instead of lane risk. The wrong packout can fail even a “premium” box.

Summary and practical recommendations

قوي industrial ice box distributor keeps your cold chain stable through inventory planning, lane-fit specs, and repeatable packout guidance. Start by defining your lanes and risks, then request evidence that matches real conditions. Validate your top lanes with “normal day” and “bad day” tests. أخيراً, choose a service model that fits your volume and return reality.

Next Step to Qualify an Industrial Ice Box Distributor

تشغيل أ 30-day improvement sprint with your industrial ice box distributor:

Map your top lane risks: حرارة, التأخير, التدريج, winter freeze.

Standardize one packout SOP and train two packers.

Validate a bad-day scenario and lock change control rules.

Track complaints, يعيد شحنه, and labor minutes every week.

Decide whether to scale single-use or pilot reuse.

حول Tempk

في Tempk, we build cold-chain packaging systems designed for real operations, not lab-only claims. We support durable insulation options, practical packout methods, and documentation that helps teams ship with confidence. We work with distributors and shippers to standardize lane-based SOPs and reduce avoidable failures.

دعوة إلى العمل: Share your temperature range, target duration, and top lanes. We will outline a lane-based packaging plan you can use to qualify an industrial ice box distributor.