تخيل استثمار الملايين في مادة بيولوجية منقذة للحياة ثم تتحلل لأنها تركت الثلاجة لفترة طويلة جدًا. إدارة سلسلة التبريد الصيدلانية يحفظ اللقاحات, البيولوجيا والعلاجات الخلوية ضمن نطاقات درجات حرارة صارمة بحيث تظل فعالة عندما تصل إليك. في 2025 من المتوقع أن ينمو سوق سلاسل التبريد الصيدلانية بالدولار الأمريكي 6.4 مليار في 2024 إلى USD 6.6 مليار, مدفوعًا بتزايد الطلب على الطب الشخصي والتدقيق التنظيمي. يستخدم هذا الدليل لغة واضحة, بيانات محدثة وأمثلة من العالم الحقيقي لمساعدتك على الفهم, تقييم وتحسين سلسلة التبريد الصيدلانية الخاصة بك.

لماذا تعتبر إدارة سلسلة التبريد الصيدلانية ضرورية لسلامة المرضى? استكشاف حساسية درجة الحرارة, مخاطر التدهور والواجب الأخلاقي لحماية الأدوية.

ما هي المكونات التي تبني سلسلة تبريد دوائية فعالة؟? تعرف على التعبئة والتغليف, تخزين, أنظمة النقل والمراقبة.

كيف تشكل اللوائح ومتطلبات الامتثال سلسلة التبريد الخاصة بك? فهم الناتج المحلي الإجمالي, إرشادات إدارة الغذاء والدواء ومنظمة الصحة العالمية.

ما هي التقنيات التي تعمل على تحويل سلاسل التبريد الصيدلانية إلى 2025? اكتشف أجهزة استشعار إنترنت الأشياء, تحليلات الذكاء الاصطناعي, blockchain والمجمدات المبردة المحمولة.

ما هي التحديات المتبقية وكيف يمكنك التغلب عليها؟? تحديد العقبات مثل فشل المعدات, ارتفاع التكاليف وقضايا الميل الأخير, مع الحلول العملية.

ما هي أحدث الاتجاهات في مجال الخدمات اللوجستية لسلسلة التبريد? مراجعة نمو السوق, الاستدامة, الرؤية والمنتجات الناشئة.

لماذا تعتبر إدارة سلسلة التبريد الدوائية ضرورية لسلامة المرضى?

إجابة مباشرة

تعمل الإدارة الفعالة لسلسلة التبريد الصيدلانية على حماية سلامة المرضى لأن العديد من العلاجات تفقد فعاليتها أو تصبح غير آمنة عند تعرضها لدرجات حرارة خارج نطاقها المحدد. البيولوجيا, تحتوي اللقاحات والعلاجات الجينية على بروتينات وأحماض نووية حساسة تتحلل عندما تصبح دافئة جدًا أو باردة جدًا. رحلة درجة حرارة واحدة أثناء التصنيع, التخزين أو النقل يمكن أن يجعل الدفعة عديمة القيمة ويعرض المرضى للخطر. من خلال الحفاظ على نطاقات درجات الحرارة الصارمة وتوفير المراقبة في الوقت الحقيقي, عليك التأكد من أن كل جرعة تقوم بإدارتها تعمل على النحو المنشود وتفي بالمعايير التنظيمية.

شرح موسع

قد تتساءل عن سبب أهمية التحكم في درجة الحرارة. معظم الأدوية البيولوجية كبيرة الحجم, جزيئات معقدة تعتمد على هياكل دقيقة ثلاثية الأبعاد. الحرارة يمكن أن تفسد هذه البروتينات, في حين أن التجميد يمكن أن يسبب التجميع أو تلف بلورات الجليد. على سبيل المثال, تتطلب لقاحات mRNA تخزينًا شديد البرودة بين -80 درجة مئوية و-60 درجة مئوية, وتحتاج بعض العلاجات الجينية إلى درجات حرارة مبردة أقل من -150 درجة مئوية. حتى الأدوية الجزيئية الصغيرة يمكن أن تتحلل عند تعرضها للحرارة أو الرطوبة المفرطة. بدون إدارة سلسلة التبريد المناسبة, تفقد هذه المنتجات فعاليتها أو تصبح سامة, تقويض ثقة المرضى والصحة العامة. إن الاستثمار في التحكم في درجة الحرارة لا يحمي المرضى فحسب، بل يوفر المال أيضًا عن طريق منع عمليات السحب والهدر المكلفة.

ما هي نطاقات درجات الحرارة التي تتطلبها العلاجات المختلفة؟?

تختلف العلاجات بشكل كبير في احتياجاتها لدرجة الحرارة. يلخص الجدول أدناه النطاقات الشائعة وما تعنيه بالنسبة لعملياتك.

| نطاق درجة الحرارة | العلاجات سبيل المثال | أوضاع الشحن | الأهمية العملية |

| -150 درجة مئوية وأقل (المبردة) | العلاجات الجينية, بعض العلاجات المعتمدة على الخلايا | خزانات النتروجين السائل, الثلج الجاف | يتطلب حاويات متخصصة ونقل سريع لمنع ذوبان الجليد. التأكد من بروتوكولات التعامل وتدريب الموظفين لأن الأخطاء مكلفة. |

| -80 درجة مئوية إلى -60 درجة مئوية (بارد جدا) | لقاحات مرنا (على سبيل المثال, شركة فايزر بايونتيك) | ثلاجات فائقة البرودة, ناقلات الثلج الجاف | المراقبة في الوقت الحقيقي أمر ضروري; استخدام أجهزة استشعار إنترنت الأشياء للكشف عن الانحرافات. |

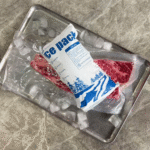

| -20 درجة مئوية (المجمدة) | اللقاحات الحديثة, بعض المواد البيولوجية | مجمدات, صناديق معزولة مع عبوات ثلج | هناك حاجة إلى التعبئة والتغليف التي تم التحقق منها والتحقق من درجة الحرارة الثابتة; يجب ألا يتسبب الثلج الجاف في إتلاف العبوة. |

| 2 درجة مئوية -8 درجة مئوية (مبردة) | معظم اللقاحات, الأجسام المضادة أحادية النسيلة, الأنسولين | شاحنات مبردة, الشاحنين السلبيين | هذا هو النطاق الأكثر شيوعا. يعد الحفاظ على درجة حرارة موحدة عبر التخزين والنقل أمرًا بالغ الأهمية. |

| 15 درجة مئوية – 25 درجة مئوية (درجة حرارة الغرفة التي تسيطر عليها) | تركيبات عن طريق الفم, بعض الحقن | كرتون معزول, الحاويات القياسية | لا يزال يتطلب المراقبة لتجنب التطرف, وخاصة في المناخات الدافئة. |

نصائح ونصيحة عملية

قم بتخطيط الملف الحراري لكل منتج: قم بتوثيق حدود درجة الحرارة المحددة بناءً على بيانات الاستقرار والمتطلبات الموضحة. تُعلم هذه الخطوة اختيار التغليف وتخطيط المسار.

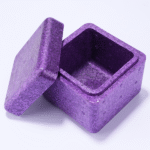

اختر حاويات تم التحقق من صحتها: استخدم عبوات مؤهلة مصممة للحفاظ على درجات الحرارة الداخلية على الرغم من الظروف المحيطة القاسية. تعمل الصناديق المعزولة القابلة لإعادة الاستخدام والمزودة بألواح معزولة بالتفريغ على تقليل النفايات والتكلفة.

خطة للطوارئ: تطوير إجراءات التشغيل القياسية التي تغطي التأخير, تغييرات المسار وانقطاع التيار الكهربائي. قم بتضمين تعليمات لإضافة الثلج الجاف أو نقل المنتجات إذا انحرفت درجات الحرارة.

حالة العالم الحقيقي: خلال طرح لقاح كوفيد 19 عالميًا, يجب أن تظل لقاحات mRNA عند -70 درجة مئوية. من خلال وضع مسجلات البيانات مع تنبيهات في الوقت الحقيقي داخل الحاويات, لاحظ الموظفون ارتفاعًا طفيفًا إلى -60 درجة مئوية وأضفوا الثلج الجاف لاستعادة درجة الحرارة المناسبة. وقد أنقذت الاستجابة السريعة الشحنة ومنعت خسارة باهظة الثمن.

ما هي مكونات سلسلة التبريد الصيدلانية الفعالة؟?

إجابة مباشرة

تدمج سلسلة التبريد الصيدلانية القوية بنية تحتية متخصصة, التعبئة والتغليف المعتمدة, المراقبة في الوقت الحقيقي والموظفين المدربين للحفاظ على سلامة درجة الحرارة طوال فترة التصنيع, التخزين والتوزيع. دون أن تعمل هذه المكونات معًا, فحتى أفضل مرافق التخزين ستفشل إذا تم تعبئة الشحنة بشكل غير صحيح أو إذا لم تتم مراقبة البيانات.

شرح موسع

سلسلة التبريد الصيدلانية هي أكثر من مجرد ثلاجة. يشمل جميع البنية التحتية, المعدات والعمليات اللازمة لحماية المنتجات الحساسة لدرجة الحرارة من المصنع إلى المريض. أنت بحاجة إلى أجنحة تصنيع يمكن التحكم بدرجة حرارتها, مستودعات تخزين باردة مزودة بأنظمة احتياطية ومختبرات لمراقبة الجودة للحفاظ على سلامة المنتج. وتشمل المعدات المتخصصة المجمدات المبردة, أنظمة تخزين النيتروجين السائل ورسم خرائط درجات الحرارة التي تضمن ظروفًا موحدة. نفس القدر من الأهمية هي العمليات: إجراءات التشغيل القياسية للتعامل, التغليف, النقل والمراقبة; برامج تدريبية للموظفين; والوثائق الخاصة بعمليات التدقيق. تستخدم المراقبة في الوقت الفعلي أجهزة استشعار إنترنت الأشياء ومسجلات البيانات لالتقاط درجة الحرارة, الرطوبة والموقع, تمكين التدخل الفوري عند حدوث الانحرافات.

ما هي حلول التغليف التي تناسب نطاقات درجات الحرارة المختلفة؟?

يعد اختيار العبوة المناسبة أمرًا بالغ الأهمية لأنه يؤثر بشكل مباشر على استقرار درجة الحرارة. هناك فئتان رئيسيتان:

| نوع التغليف | فوائد | اعتبارات | كيف يساعدك |

| الحاويات السلبية | خفيفة الوزن وفعالة من حيث التكلفة; مناسبة للنقل القصير إلى المتوسط. الخيارات القابلة لإعادة الاستخدام تقلل من النفايات. | مدة محدودة; يعتمد الأداء على الظروف المحيطة. يتطلب التكييف المسبق المناسب لعبوات الثلج والتعبئة الدقيقة. | مثالية للشحنات الروتينية خلال 24-72 ساعة. استخدمها عند شحن اللقاحات أو المواد البيولوجية عبر مسافات قصيرة. |

| الحاويات النشطة | توفير التبريد أو التدفئة المستمرة باستخدام الأنظمة الكهربائية أو الثلج الجاف; مناسبة للشحنات شديدة البرودة أو لمسافات طويلة. | أكثر تكلفة وأثقل; تتطلب مصادر الطاقة والصيانة. | اخترها للحصول على مواد بيولوجية ذات قيمة عالية, الرحلات الجوية لمسافات طويلة أو الشحنات عرضة للتأخير. |

| صناديق معزولة قابلة لإعادة الاستخدام مع مواد متغيرة الطور (PCMS) | اجمع بين الألواح المعزولة بالفراغ وPCMs للحفاظ على درجات حرارة ثابتة; تقليل التأثير البيئي. | تتطلب التنظيف والتحقق الدوري. التكلفة الأولية أعلى, لكن قيمة العمر أكبر. | استخدمه للشحن الصديق للبيئة عندما تحتاج إلى أداء واستدامة ثابتين. |

| المجمدات المبردة المحمولة | الحفاظ على درجات حرارة منخفضة للغاية (-80 درجة مئوية إلى -150 درجة مئوية) في البيئات الصعبة. | ضخمة وتتطلب طاقة أو ثلجًا جافًا; ارتفاع النفقات الرأسمالية. | ضروري للعلاجات الخلوية والجينية والطب الشخصي في المواقع النائية. |

مرافق التخزين وإدارة المخزون

يجب أن تحافظ مرافق تخزين سلسلة التبريد على نطاقات درجات الحرارة المعتمدة وأن تتضمن أنظمة احتياطية. تحتاج المستودعات إلى مناطق منفصلة لمتطلبات درجات الحرارة المختلفة وأنظمة إدارة المخزون المتقدمة لتتبع الموقع, تاريخ درجة الحرارة وتواريخ انتهاء الصلاحية. يمكن للأتمتة والروبوتات تحسين الدقة وتقليل الأخطاء البشرية. على سبيل المثال, قامت إحدى الشركات المصنعة للمواد البيولوجية بتنفيذ نظام تخزين بارد آلي مع استرجاع آلي; أدى هذا إلى تقليل وقت التعامل مع المنتج بنسبة 30 % وخفض الرحلات درجة الحرارة أثناء التدريج 40 %, توفير المال وتحسين الامتثال.

نصائح ونصيحة عملية

معايرة أجهزة المراقبة بانتظام: الحفاظ على شهادات المعايرة لتلبية عمليات التدقيق.

استخدام التسجيل المستمر لدرجة الحرارة: استخدم الإنذارات والإشعارات الآلية لاكتشاف الانحرافات. تضمن الطاقة الاحتياطية استمرار المعدات أثناء انقطاع التيار.

تدريب الموظفين: تعليم إجراءات التحميل والتفريغ المناسبة لتقليل التعرض لدرجات الحرارة المحيطة.

حالة العالم الحقيقي: قامت تعاونية ألبان متوسطة الحجم بتركيب أجهزة استشعار لإنترنت الأشياء في شاحنات التبريد. عندما اكتشفت أجهزة الاستشعار ارتفاعًا في درجة الحرارة أثناء موجة الحر, قام السائقون بتعديل التبريد وتجنبوا التلف, تقليل فقدان المنتج عن طريق 15 %. على الرغم من أن هذه الحالة تنطوي على الغذاء, تنطبق نفس المبادئ على المستحضرات الصيدلانية.

كيف تشكل اللوائح إدارة سلسلة التبريد الصيدلانية?

إجابة مباشرة

لوائح مثل ممارسات التوزيع الجيدة لمنظمة الصحة العالمية (الناتج المحلي الإجمالي), تضمن إرشادات إدارة الغذاء والدواء والمعايير الوطنية أن كل خطوة من سلسلة التبريد الصيدلانية تحافظ على جودة المنتج وسلامة المرضى. الامتثال يحمي المرضى, يمنع المنتجات المقلدة ويبقيك جاهزًا للتدقيق.

شرح موسع

تفرض الحكومات والمنظمات الدولية متطلبات صارمة لإدارة سلسلة التبريد لأن المخاطر كبيرة. تؤكد إرشادات الناتج المحلي الإجمالي لمنظمة الصحة العالمية على إدارة الجودة, المباني والمعدات المناسبة, التوثيق ومنع التزوير. يجب أن تكون المرافق مصممة لمنع التلوث والحفاظ على التحكم في درجة الحرارة; يجب أن تكون المركبات مناسبة للسلع الحساسة لدرجة الحرارة. المبادئ التوجيهية الوطنية, مثل تلك الصادرة عن وزارة الصحة اللبنانية, التوسع في هذه المبادئ, الإصرار على أن تكون حاويات الشحن مؤهلة لتحمل الظروف البيئية القاسية وأن يتم تصنيفها بشكل واضح, على سبيل المثال, "لا تجمد". ويطالب المنظمون أيضًا بتوثيق قوي وحفظ السجلات. على سبيل المثال, ادارة الاغذية والعقاقير 21 جزء CFR 11 وتتطلب قواعد الناتج المحلي الإجمالي سجلات إلكترونية ومراقبة في الوقت الحقيقي. يمكن أن يؤدي عدم الامتثال إلى رفض الشحنات, الاستدعاءات أو العقوبات القانونية.

الأطر التنظيمية الرئيسية ومتطلباتها

| نطاق / معيار | المتطلبات الرئيسية | كيف يؤثر ذلك على الخدمات اللوجستية الخاصة بك |

| منظمة الصحة العالمية ممارسات التوزيع الجيدة (الناتج المحلي الإجمالي) | نظام إدارة الجودة; المباني والمعدات المؤهلة; الوثائق; منع التزييف | يتطلب تسجيل درجة الحرارة المستمر, معايرة المعدات والتدريب الشامل. يجب الحفاظ على سلسلة الحراسة وتوثيق كل خطوة. |

| إرشادات إدارة الغذاء والدواء لسلسلة التبريد (21 جزء CFR 11) | يضمن بقاء درجة الحرارة ضمن النطاقات المحددة; يتطلب حفظ السجلات الإلكترونية وأنظمة المراقبة الموثوقة | يمكن أن يؤدي عدم الامتثال إلى رفض الشحنات أو سحب المنتج. استخدم أجهزة الاستشعار المعتمدة والتنبيهات الآلية لتلبية هذه المتطلبات. |

| وكالة الأدوية الأوروبية (ema) | على غرار لوائح إدارة الغذاء والدواء (FDA) التي تتضمن مواصفات صارمة لدرجة الحرارة للنقل داخل الاتحاد الأوروبي | يتطلب وثائق عبر الحدود, التحقق من صحة التعبئة والتغليف والامتثال للنقل المحلي. |

| ممارسات التصنيع الجيدة (ممارسات التصنيع الجيدة) | يغطي عمليات التصنيع, بما في ذلك التخزين المبرد وتصميم الغرفة الباردة | يفرض العمليات التي تم التحقق من صحتها عبر خطوات التصنيع. يجب عليك الحفاظ على الاتساق من استلام المواد الخام لملء النهاية. |

| قانون تحديث سلامة الأغذية (FSMA) قاعدة 204 | يتطلب إمكانية تتبع الأطعمة عالية المخاطر داخلها 24 ساعات; ذات صلة لأن العديد من مقدمي الخدمات يتعاملون مع الأغذية والأدوية | يتطلب أنظمة قابلة للتشغيل البيني لإدارة المتطلبات الغذائية والصيدلانية. |

نصائح ونصيحة عملية

إجراء تدريب منتظم: تأكد من أن جميع الموظفين يفهمون متطلبات الناتج المحلي الإجمالي وعواقب عدم الامتثال.

التحقق من صحة طرق التعبئة والتغليف والنقل: أداء تأهيل الأداء في ظل أسوأ الظروف المحيطة.

الحفاظ على الوثائق: احتفظ بالسجلات التي تدعم ادعاءات الاستقرار وتبرر قبول الرحلات البسيطة لدرجات الحرارة.

حالة العالم الحقيقي: قام برنامج وطني للصحة العامة برقمنة الوثائق عبر شبكة توزيع اللقاحات. السجلات في الوقت الحقيقي لدرجة الحرارة والتعامل مع تحسين الامتثال وتقليل فقدان المنتج بنسبة 25 %.

ما هي التقنيات التي تعمل على تحويل إدارة سلسلة التبريد الصيدلانية في 2025?

إجابة مباشرة

في 2025 يتم إحداث ثورة في سلسلة التبريد الصيدلانية بواسطة أجهزة استشعار إنترنت الأشياء, التحليلات التنبؤية, blockchain, الأتمتة والتعبئة المستدامة. توفر هذه التقنيات رؤية في الوقت الحقيقي, اتخاذ قرارات استباقية وزيادة إمكانية التتبع, مساعدتك على منع الرحلات, تحسين الطرق وتعزيز الاستدامة.

شرح موسع

يعد الابتكار التكنولوجي الجانب الأكثر إثارة في سلاسل التبريد الصيدلانية الحديثة. تحل مراقبة إنترنت الأشياء في الوقت الفعلي محل أدوات تسجيل البيانات التفاعلية. أجهزة الاستشعار تتبع درجة الحرارة, الرطوبة والموقع وإرسال التنبيهات عند انحراف الظروف. تستخدم التحليلات التنبؤية والذكاء الاصطناعي البيانات التاريخية والحية للتنبؤ بالمخاطر, مثل التأخير, أعطال المعدات واضطرابات الطقس. تقوم تقنية Blockchain بإنشاء سجلات ثابتة لبيانات درجة الحرارة وسلسلة أحداث الحضانة, توفير إمكانية التتبع من النهاية إلى النهاية. تعمل الأتمتة والروبوتات على تحسين التخزين البارد والتوزيع, بينما تتيح الطائرات بدون طيار إمكانية توصيل الميل الأخير إلى المناطق النائية. أخيراً, تتيح المجمدات المبردة المحمولة والتعبئة المستدامة النقل الآمن للعلاجات الخلوية والحلول الصديقة للبيئة.

مراقبة إنترنت الأشياء في الوقت الحقيقي

تمنحك مستشعرات إنترنت الأشياء رؤية مستمرة. تقوم أجهزة الاستشعار بنقل البيانات عبر شبكات منخفضة الطاقة مثل الشبكات الخلوية, LoRaWAN أو LTE M للمنصات السحابيةأنا. إذا انحرفت درجات الحرارة عن الحدود الآمنة, تتيح لك التنبيهات التدخل بسرعةأنا. تعمل المراقبة في الوقت الفعلي على تبسيط عملية الامتثال عن طريق تسجيل البيانات تلقائيًا وإنشاء تقارير جاهزة للتدقيقأنا. تضمن مراقبة الميل الأخير بقاء الأدوية ضمن المواصفات حتى التسليمأنا.

فوائد أجهزة استشعار إنترنت الأشياء في الوقت الحقيقي

| فائدة | مثال | ماذا يعني لعملك |

| الوقاية من التلف | تنبيهات في الوقت الحقيقي تؤدي إلى اتخاذ إجراءات تصحيحية (إضافة الثلج الجاف, إعادة توجيه الشحنات) قبل أن تتلف المنتجات. | تجنب فقدان المنتج وحماية سلامة المرضى. |

| الامتثال التنظيمي | تسجيل البيانات الآلي يتوافق مع إدارة الغذاء والدواء 21 جزء CFR 11 ومتطلبات الناتج المحلي الإجمالي. | يقلل من العبء الإداري وضغوط التدقيق. |

| أمن الميل الأخير | تقوم أجهزة الاستشعار بمراقبة الظروف حتى لحظة التسليمأنا. | يزيل النقاط العمياء في سلسلة التوريد ويحسن المساءلة. |

| الصيانة التنبؤية & تحسين الطريق | تكتشف خوارزميات الذكاء الاصطناعي الأنماط غير الطبيعية وتوصي بالطرق المثلى. | يقلل من وقت التوقف عن العمل ويضمن عمليات تسليم أسرع. |

| مقاييس الاستدامة | تحليلات متكاملة تتبع استخدام الطاقة وانبعاثات الكربون. | يساعدك على تحقيق الأهداف البيئية وإبلاغ التقدم إلى أصحاب المصلحة. |

التحليلات التنبؤية والذكاء الاصطناعي

يستفيد الذكاء الاصطناعي من البيانات التاريخية وفي الوقت الفعلي للتنبؤ بالاضطرابات المحتملة, مثل تأخير حركة المرور, ارتفاع درجات الحرارة وتعطل المعدات. يمكن أن يقترح الطرق المثلى, جدولة صيانة وحدات التبريد وحتى ضبط استراتيجيات التعبئة والتغليف. في حالة واحدة من العالم الحقيقي, استخدم أحد موزعي الأدوية في جنوب شرق آسيا تحسين المسار بمساعدة الذكاء الاصطناعي. من خلال الجمع بين بيانات GPS والتنبؤات الجوية, قامت الشركة بتقصير طرق التسليم عن طريق 12 % وتقليل استهلاك الوقود.

Blockchain للتتبع

توفر Blockchain شيئًا غير قابل للتغيير, سجل لامركزي لبيانات درجة الحرارة وسلسلة أحداث الحضانة. يمكن للعقود الذكية أتمتة عمليات التحقق من الامتثال وشروط الإصدار; على سبيل المثال, يمكنهم التأكد من قبول الشحنة فقط إذا ظلت درجة الحرارة ضمن النطاق. تعتبر تقنية Blockchain مفيدة بشكل خاص للمنتجات ذات القيمة العالية والشحنات عبر الحدود لأنها تبني الثقة بين العديد من أصحاب المصلحة.

الأتمتة, الروبوتات والطائرات بدون طيار

تعمل الأتمتة على إحداث تحول في التخزين البارد والتوزيع. تعمل الملتقطات الآلية والمركبات الموجهة المستقلة على تقليل تعرض الإنسان للبيئات الباردة وتسريع المعالجة. يتم تجريب طائرات بدون طيار مجهزة بحمولات يمكن التحكم في درجة حرارتها لتوصيلها إلى الميل الأخير إلى المواقع النائية. تعمل هذه الابتكارات على تحسين الوصول إلى الأدوية في المناطق الريفية مع تقليل أوقات التسليم.

المجمدات المبردة المحمولة والتعبئة المستدامة

تحافظ المجمدات المبردة المحمولة على درجات حرارة منخفضة تصل إلى -80 درجة مئوية إلى -150 درجة مئوية, حتى في البيئات الصعبة. أنها توفر تتبع درجة الحرارة في الوقت الحقيقي وإخطارات التحذير, حماية المنتجات شديدة البرودة مثل العلاجات الخلوية. التغليف المستدام - مثل الحاويات المعزولة القابلة لإعادة التدوير والأغلفة الحرارية القابلة للتحلل - يقلل من التأثير البيئي مع حماية المنتجات.

نصائح ونصيحة عملية

ابدأ بمنصات قابلة للتطوير: اختر أنظمة إنترنت الأشياء التي تدعم أنواعًا متعددة من أجهزة الاستشعار ويمكن أن تنمو مع عملياتك.

استثمر في أمن البيانات: تأكد من أن البائعين يستخدمون التشفير, تحديثات البرامج الثابتة العادية وعناصر التحكم في الوصول.

استخدم الذكاء الاصطناعي لدعم القرار: انشر التحليلات التنبؤية للتنبؤ برحلات درجات الحرارة وتحسين جداول الصيانة.

حالة العالم الحقيقي: استخدمت إحدى شركات التكنولوجيا الحيوية التي تقوم بشحن العلاجات الخلوية أجهزة استشعار إنترنت الأشياء والذكاء الاصطناعي لمراقبة الشحنات. أثناء تأخير حركة المرور, قام النظام بتنبيه الفريق, الذي نقل الشحنة إلى شاحنة يتم التحكم بدرجة حرارتها وأنقذ دفعة تبلغ قيمتها الملايين.

ما هي التحديات والحلول الموجودة للحفاظ على سلامة درجة الحرارة؟?

إجابة مباشرة

تواجه سلاسل التبريد الصيدلانية تحديات مثل تعطل المعدات, فجوات البنية التحتية, ارتفاع تكاليف الطاقة, تسليم الميل الأخير المعقد والأعباء التنظيمية; يتطلب كل منها حلولاً مستهدفة مثل مراقبة إنترنت الأشياء, مراكز الوفاء الصغيرة والتدريب.

شرح موسع

إن الحفاظ على الأدوية ضمن نطاقات درجات الحرارة المطلوبة أمر أسهل من الفعل. غالبًا ما تحدث رحلات درجة الحرارة أثناء التحميل والتفريغ, خاصة عند استخدام التسجيل اليدوي أو عندما تكون البنية التحتية للميل الأخير غير كافية. أعطال المعدات, مثل انقطاع التيار الكهربائي أو تعطل المجمدات, هي خطر كبير آخر. تكاليف الطاقة المرتفعة وإمدادات الكهرباء غير الموثوقة يمكن أن تجعل تخزين درجات الحرارة المنخفضة للغاية باهظ التكلفة. بالإضافة إلى ذلك, يمثل النقل عبر الحدود تعقيدًا من خلال اللوائح المختلفة والتأخير الجمركي. للتغلب على هذه التحديات, تستثمر الشركات في التكنولوجيا المبردة المحمولة, مراكز الوفاء الصغيرة, تحسين المسار وبرامج التدريب.

التحديات المشتركة والحلول العملية

| نطاق درجة الحرارة & منتج | التحديات الأولية | حلول عملية & فوائد |

| 2 درجة مئوية -8 درجة مئوية (اللقاحات, البيولوجيا) | خطر الرحلات أثناء التحميل / التفريغ; التسجيل اليدوي; عدم كفاية البنية التحتية للميل الأخير | استخدم الحاويات المعزولة وحزم الجل; تنفيذ تتبع في الوقت الحقيقي; الاستفادة من مراكز التنفيذ الصغيرة لتوصيل الميل الأخير; تدريب الموظفين على إجراءات التعامل. |

| -20 درجة مئوية إلى -80 درجة مئوية (اللقاحات المجمدة) | فشل المعدات وارتفاع تكاليف الطاقة; تعقيد العبور عبر الحدود | نشر الشاحنات المبردة المزودة بأجهزة استشعار لإنترنت الأشياء; تحسين الطرق لتقليل وقت العبور; الاستثمار في وحدات التبريد الموفرة للطاقة. |

| -80 درجة مئوية إلى -150 درجة مئوية (خلية & العلاجات الجينية) | تتطلب درجات الحرارة المنخفضة للغاية حاويات متخصصة; البنية التحتية باهظة الثمن | استخدم المجمدات المبردة المحمولة المزودة بأجهزة استشعار مدمجة; اختر Dewars مع التتبع الرقمي; تخطيط الشحنات لتقليل المناولة. |

استراتيجيات لتخفيف مخاطر درجة الحرارة

نشر التكنولوجيا المبردة المحمولة: تضمن المجمدات المبردة المحمولة النقل الآمن للعلاجات الخلوية والجينية, الحفاظ على درجات حرارة منخفضة للغاية حتى في المناطق النائية.

تحسين المسارات باستخدام الذكاء الاصطناعي: تحسين المسار يقلل من وقت السفر, استهلاك الطاقة ومخاطر الرحلات.

دمج مراكز الوفاء الصغيرة: قم بتقصير مسافات الميل الأخير عن طريق تنظيم الشحنات في مراكز التنفيذ المحلية الصغيرة, تقليل التعرض للظروف المحيطة.

تدريب فريقك: العديد من الرحلات ناتجة عن خطأ بشري; التدريب المنتظم يمكّن الموظفين من الاستجابة بسرعة عندما تنطلق الإنذارات.

حالة العالم الحقيقي: خلال الوباء, يتطلب توزيع لقاحات mRNA درجات حرارة منخفضة للغاية. قامت الشركات بنشر المجمدات والمنصات السحابية التي تدعم إنترنت الأشياء. عندما تشير أجهزة الاستشعار إلى الانحرافات, قامت الفرق بإعادة توجيه الشاحنات أو تجديد الثلج الجاف للحفاظ على فعاليتها. أدت هذه التجربة إلى تسريع الاستثمار في التحليلات التنبؤية والبنية التحتية الرقمية عبر سلسلة التبريد الصيدلانية.

2025 الاتجاهات ورؤى السوق في إدارة سلسلة التبريد الدوائية

نظرة عامة على الاتجاه

الطلب على اللقاحات, تعمل البيولوجيا والطب الشخصي على دفع النمو السريع في سلاسل التبريد الصيدلانية. ومن المتوقع أن ينمو السوق من الدولار الأمريكي 6.4 مليار في 2024 إلى USD 6.6 مليار في 2025 والدولار الأمريكي 9.6 مليار من قبل 2035. ومن المتوقع أن يرتفع قطاع الخدمات اللوجستية لسلسلة التبريد الأوسع نطاقًا - بما في ذلك الأغذية والأدوية - مقارنة بالدولار الأمريكي 293.58 مليار في 2023 إلى USD 862.33 مليار من قبل 2032. في أثناء, أصبحت أنظمة المراقبة في الوقت الفعلي وتحليلات الذكاء الاصطناعي معيارًا قياسيًا, والاستدامة هي أولوية متزايدة. تقوم الشركات بتكوين شراكات استراتيجية لتوسيع الشبكات وتحسين المرونة.

أحدث التطورات في لمحة

تغيرات السوق: وقد أدت الاضطرابات الجيوسياسية وأحداث البجعة السوداء إلى إجهاد القدرة اللوجستية, لكن قطاع سلسلة التبريد أظهر مرونة من خلال بناء القدرات والتنويع عبر وسائل النقل.

رؤية أكبر: توفر الاستثمارات في البرمجيات والمنصات الرقمية رؤية شاملة, تمكين تدفق البيانات دون انقطاع ومراقبة درجة الحرارة.

ترقيات الاستدامة: ويتم استبدال البنية التحتية القديمة لتخزين التبريد بمرافق موفرة للطاقة. تعمل اللوائح على التخلص التدريجي من المبردات ذات القدرة العالية على الاحتباس الحراري, دفع الشركات إلى اعتماد تقنيات صديقة للبيئة.

المنتجات الناشئة: ظهور العلاجات الخلوية والجينية, تتطلب اللقاحات والمستحضرات البيولوجية النباتية حلول سلسلة تبريد مصممة خصيصًا لنطاقات التبريد الفائقة والبرودة الشديدة.

المجمدات المبردة المحمولة: تحافظ المجمدات المبردة المحمولة على المواد البيولوجية والعلاجات الخلوية عند -80 درجة مئوية إلى -150 درجة مئوية, تمكين النقل الآمن إلى المناطق النائية.

التخزين البارد بالطاقة الشمسية: تعمل وحدات التخزين البارد التي تعمل بالطاقة الشمسية على تقليل تكاليف الطاقة وتوفر تحكمًا مستدامًا في درجة الحرارة في المناطق التي لا يمكن الاعتماد عليها في إمدادات الكهرباء.

تحسين المسار المدعوم بالذكاء الاصطناعي: تقوم خوارزميات الذكاء الاصطناعي بضبط المسارات في الوقت الفعلي بناءً على حركة المرور والطقس, تقليل وقت العبور وتحسين الموثوقية.

التتبع blockchain: تضمن أنظمة Blockchain الشفافية وسجلات مقاومة للتلاعب, تعزيز الامتثال والثقة.

رؤى السوق

ومن المتوقع أن تصل إيرادات قطاع الأدوية إلى الدولار الأمريكي 1.454 تريليون بواسطة 2029, مع معدل نمو سنوي مركب قدره 4.71 %. يؤدي الطلب المتزايد على المواد البيولوجية المعقدة والطب الشخصي إلى دفع الاستثمارات القابلة للتطوير, حلول سلسلة التبريد المتوافقة. تظل مرونة سلسلة التوريد أولوية بعد الاضطرابات المرتبطة بالوباء; ويساعد تنويع الاستراتيجيات اللوجستية وتعزيز الشراكات الشركات على تحمل الصدمات المستقبلية.

نصائح وتوصيات عملية للبقاء في المقدمة

إجراء تحليل الفجوة: قم بتقييم عمليات سلسلة التبريد الحالية لديك لتحديد نقاط الضعف في التغليف, تخزين, النقل والتوثيق.

التحقق من صحة التعبئة والتغليف في ظل أسوأ الظروف: تأكد من أداء الحاويات وشركات الشحن أثناء درجات الحرارة القصوى والتأخير.

تنفيذ المراقبة في الوقت الحقيقي: توفر مستشعرات إنترنت الأشياء والأنظمة الأساسية السحابية رؤية شاملة وتحكمًا استباقيًا.

استثمر في الاستدامة: اعتماد التعبئة والتغليف القابلة لإعادة الاستخدام, التبريد الموفر للطاقة والمبردات ذات القدرة المنخفضة على إحداث الاحترار العالمي لتلبية المتطلبات التنظيمية والبيئية.

التعاون مع الشركاء ذوي الخبرة: غالبًا ما يمتلك المتخصصون الخارجيون في سلسلة التبريد معدات معتمدة ومدى انتشار عالمي, ضمان الامتثال والحد من المخاطر.

الأسئلة المتداولة (التعليمات)

س 1: ما هي رحلة درجة الحرارة في إدارة سلسلة التبريد الصيدلانية?

تحدث رحلة درجة الحرارة عندما يتعرض المنتج الصيدلاني لدرجات حرارة خارج النطاق الموصوف له. قد تكون الرحلات الصغيرة مقبولة إذا كانت مدعومة ببيانات الاستقرار, لكن الانحرافات الكبيرة تؤثر على جودة المنتج. قم دائمًا بتقييم الرحلات مع فريق الجودة الخاص بك وتوثيق النتائج.

Q2: كيف أختار بين التغليف السلبي والنشط?

التغليف السلبي خفيف الوزن وفعال من حيث التكلفة, مثالية للشحنات التي تصل إلى 72 ساعات. توفر العبوة النشطة تبريدًا أو تسخينًا مستمرًا ولكنها أثقل وأكثر تكلفة. اعتمد اختيارك على مدة الشحن, حساسية المنتج والظروف المحيطة.

س 3: لماذا تعتبر المراقبة في الوقت الفعلي أفضل من أجهزة تسجيل البيانات التقليدية؟?

لا توفر أجهزة تسجيل البيانات التقليدية المعلومات إلا بعد النقل, مما يجعل الوقت متأخرًا جدًا للعمل. تقوم أجهزة استشعار إنترنت الأشياء في الوقت الفعلي بنقل البيانات بشكل مستمر, إطلاق التنبيهات عند حدوث انحرافات وتسهيل التدخل الفوري, الحد من التلف وضمان الامتثال.

س 4: كيف يمكن أن تصبح عمليات سلسلة التبريد أكثر استدامة?

تتضمن الاستدامة استخدام مواد التعبئة والتغليف القابلة لإعادة الاستخدام, التبريد الموفر للطاقة والمبردات البديلة ذات القدرة المنخفضة على الاحتباس الحراري. المجمدات المبردة المحمولة, يساعد التخزين الذي يعمل بالطاقة الشمسية والعزل القابل للتحلل على تقليل التأثير البيئي.

س 5: ما هي المستندات التنظيمية الشائعة التي أحتاج إلى الاحتفاظ بها؟?

يتطلب المنظمون سجلات لدرجة الحرارة, المناولة والتوزيع لضمان التتبع. التوثيق الإلكتروني تحت إدارة الغذاء والدواء 21 جزء CFR 11 وتوفر المبادئ التوجيهية للناتج المحلي الإجمالي دليلاً على الامتثال وتسهل عمليات التدقيقأنا.

ملخص وتوصيات

في 2025 إدارة سلسلة التبريد الصيدلانية يبقى حارس جودة الدواء وسلامة المرضى. من خلال التحكم في درجات الحرارة من التصنيع إلى تسليم الميل الأخير, أنت تحمي المواد البيولوجية الحساسة, اللقاحات والعلاجات الجينية من التدهور. تتطلب سلسلة التبريد القوية بنية تحتية متكاملة, التعبئة والتغليف المعتمدة, المراقبة في الوقت الحقيقي والامتثال التنظيمي. التقنيات الناشئة مثل أجهزة استشعار إنترنت الأشياء, منظمة العفو الدولية, توفر تقنية blockchain والمجمدات المبردة المحمولة رؤية غير مسبوقة وقوة تنبؤية. التحديات مثل فشل المعدات, يمكن التغلب على التكاليف المرتفعة والخدمات اللوجستية المعقدة في الميل الأخير من خلال تحسين المسار, مراكز الوفاء الصغيرة وتدريب الموظفين. تشير اتجاهات السوق إلى النمو السريع, قدر أكبر من الاستدامة وزيادة الرؤية.

الخطوات التالية القابلة للتنفيذ

قم بتقييم سلسلة التبريد الحالية لديك: إجراء تدقيق شامل لضوابط درجة الحرارة, الوثائق, التدريب والمعدات. تحديد الفجوات وتحديد أولويات التحسينات.

تنفيذ المراقبة في الوقت الحقيقي: انشر مستشعرات إنترنت الأشياء ولوحات المعلومات السحابية للحصول على رؤية مستمرة وتنبيهات تلقائيةأنا.

التحقق من صحة العبوة وترقيتها: حدد حلول التغليف بناءً على حساسية المنتج ومدة الشحن, والتأكد من أنهم مؤهلون في أسوأ الظروف.

تدريب فريقك: توفير التعليم المستمر حول إجراءات المناولة, المتطلبات التنظيمية والاستجابات لحالات الطوارئ.

استثمر في الاستدامة: اختر حاويات قابلة لإعادة الاستخدام, التبريد الموفر للطاقة والمبردات ذات القدرة المنخفضة على إحداث الاحترار العالمي. فكر في التخزين الذي يعمل بالطاقة الشمسية والعزل القابل للتحلل.

التعاون مع الخبراء: كن شريكًا مع موفري سلسلة التبريد ذوي الخبرة واستفد من تقنيات الذكاء الاصطناعي وتقنية blockchain لتحسين المسارات وإمكانية التتبع.

حول Tempk

Tempk هي شركة رائدة في حلول سلسلة التبريد, متخصصة في التعبئة والتغليف التي تسيطر عليها درجة الحرارة, المراقبة في الوقت الحقيقي والاستشارات اللوجستية. نقوم بتصميم صناديق معزولة بألواح معزولة بالفراغ ومواد تغيير الطور, تطوير منصات مراقبة إنترنت الأشياء والشراكة مع شركات النقل لضمان الامتثال للوائح الناتج المحلي الإجمالي وإدارة الغذاء والدواء. تساعدك حلولنا على حماية سلامة المنتج, تقليل النفايات وتبسيط العمليات. سواء كنت بحاجة إلى أجهزة شحن سلبية للقاحات الروتينية أو مجمدات محمولة مبردة للعلاجات الجينية, لدينا الخبرة والتكنولوجيا لدعم سلسلة التبريد الصيدلانية الخاصة بك.

دعوة إلى العمل: على استعداد لتعزيز استراتيجية سلسلة التبريد الخاصة بك? اتصل بخبراء Tempk للحصول على تقييم مخصص واكتشف كيف يمكن لحلولنا المبتكرة تحسين الخدمات اللوجستية الصيدلانية الخاصة بك.