الدور الأساسي ل مصانع عبوات الثلج في الحفاظ على سلسلة التبريد باردة

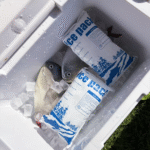

حفظ الأشياء مثل الأطعمة الطازجة, الأدوية المنقذة للحياة, والمواد الكيميائية الحساسة الباردة أثناء النقل أمر حيوي. هذا “سلسلة البرد” يعتمد على المعدات المتخصصة, وتشكل عبوات الثلج جزءًا أساسيًا من هذا النظام. مصانع عبوات الثلج هم الأبطال المجهولون, تصنيع حلول التبريد الموثوقة التي تحمي هذه السلع الحساسة لدرجة الحرارة من المصنع إلى الثلاجة.

مصانع عبوات الثلج: محرك موثوقية التبريد

إن صنع عبوات ثلج فعالة ليس بالأمر السهل. تجمع المصانع بين مواد هلامية أو مواد تبريد خاصة (PCMS) مع التعبئة والتغليف صعبة. بينما تصبح عبوات الجل الأساسية باردة, تم تصميم أجهزة PCM الحديثة لتذوب عند درجات حرارة محددة, عقد البرد لفترة أطول وأكثر ثباتا.

الجودة غير قابلة للتفاوض. تستخدم المصانع الجيدة مواد عالية الجودة تفي بقواعد صارمة (مثل FDA للاستخدام الطبي) واتباع معايير الصناعة الصارمة لسلامة التغليف أثناء الشحن. يضمن الاختبار الصارم أن كل عبوة تعمل كما هو متوقع.

حزم أكثر ذكاءً, مصانع أكثر ذكاءً

تستمر مصانع عبوات الثلج في الابتكار. تجاوز المواد الهلامية الأساسية, إنهم ينتجون الآن أجهزة PCM متقدمة للتحكم الفائق في البرد. تساعد الأتمتة في جعل الحزم أسرع وأكثر اتساقًا.

تمتلك المصانع الرائدة فرقًا من الخبراء تصمم عبوات ثلج مخصصة لتلبية الاحتياجات الفريدة - سواء كانت فترة حياة باردة أطول للقاحات أو أشكال محددة لمجموعات الوجبات. إنهم حتى يستكشفون التكنولوجيا الذكية, مثل أجهزة تتبع درجة الحرارة الصغيرة المدمجة في العبوة, لمراقبة الشحنات في الوقت الحقيقي.

الذهاب إلى اللون الأخضر: إنتاج عبوات الثلج المستدامة

تتطلب صناعة سلسلة التبريد حلولاً صديقة للبيئة, ومصانع عبوات الثلج تستجيب. هذا يعنى:

-

التعبئة والتغليف القابلة لإعادة التدوير: استخدام مواد مثل بلاستيك HDPE الذي يمكن إعادة تدويره.

-

نفايات أقل: تحسين الإنتاج لتقليل الخردة.

-

تصاميم قابلة لإعادة الاستخدام: تم استخدام إنشاء عبوات متينة مئات المرات, خفض التكاليف والنفايات.

-

المواد الهلامية الحيوية (الناشئة): يقوم البعض بتطوير تركيبات هلامية تتحلل بشكل طبيعي.

Tempk: تقديم الأداء & الاستدامة

يجسد مصنع عبوات الثلج في Tempk هذا النهج الحديث. باستخدام تقنية PCM عالية الأداء, تقدم حزم Tempk موثوقة, برودة طويلة الأمد للطعام, فارما, وما وراءها.

المزايا الرئيسية لـ Tempk:

-

عمر طويل: مصممة لمئات من عمليات إعادة الاستخدام, توفير المال.

-

قوي & التغليف الأخضر: تستخدم الأغلفة الخارجية HDPE القابل لإعادة التدوير.

-

جودة صارمة: يتم اختبار كل حزمة بدقة للتأكد من الأداء المتسق الذي يلبي المعايير الدولية.

المستقبل بارد (وفعالة)

مع نمو التجارة العالمية في السلع القابلة للتلف, الطلب على الجودة العالية, ارتفاع حزم الجليد المستدامة. وستكون مصانع عبوات الثلج أساسية لتلبية هذا الطلب. من خلال الاستثمار في الابتكار والممارسات الصديقة للبيئة, تساعد المصانع مثل Tempk الشركات على البناء بكفاءة, موثوق, وسلاسل تبريد صديقة للبيئة للمستقبل.