ورقة حزمة الثلج الجاف والرطب: كيفية الاختيار والاستخدام في 2025?

مقدمة

When transporting temperature sensitive goods, اختيار المبردات المناسبة مهم. Should you use a wet and dry dry ice pack sheet or stick with gel or traditional ice? This comprehensive guide answers that question. You’ll learn what these products are, why dry ice can reach temperatures around –78.5 °C and why some products need the moisture free cold that dry ice provides. بحلول النهاية, you’ll be ready to select the best solution for your 2025 cold chain challenges.

What is a wet and dry dry ice pack sheet and how does it work? — includes the science of sublimation and how gel layers slow down dry ice evaporation.

When should you choose a dry ice pack sheet instead of a wet gel pack? — learn why dry ice stays at –78.5 °C and leaves no moisture, while gel packs maintain 2 - 8 درجة مئوية.

How to safely use and hydrate dry ice pack sheets? — covers step by step activation, التهوية ومعدات الحماية.

2025 اتجاهات سلسلة التبريد والابتكارات — automation, AI driven logistics and sustainable packaging.

FAQs and expert recommendations — answers to common questions and actionable tips.

What Are Wet and Dry Dry Ice Pack Sheets?

إجابة مباشرة

أ wet and dry dry ice pack sheet refers to two types of refrigerant packs used in cold chain logistics: عبوات هلامية ذات أساس مائي (the “wet” type) and sheets containing dry ice particles (the “dry” type). Dry ice pack sheets keep products frozen because dry ice sublimates directly from solid carbon dioxide to gas at about –78.5 °C, لا يترك أي رطوبة وراء. حزم هلام, على النقيض من ذلك, freeze water and maintain temperatures near 0 درجة مئوية إلى 8 درجة مئوية. By combining these materials into a flexible sheet, shippers can select a cooling method that meets their product’s temperature range.

التفسير الموسع

Dry ice pack sheets are made by encasing dry ice pellets or flakes within a sealed, flexible polymer. كما يسامي الثلج الجاف (يتحول من الصلبة إلى الغاز), it absorbs heat and maintains a consistent low temperature. Because there is no melting, there is no moisture; this protects sensitive cargo such as electronics, pharmaceuticals or dry goods from water damage. حزم هلام, لكن, contain water based phase change material (بي سي إم) that freezes at 0 درجة مئوية. They are ideal for keeping goods cool (2 - 8 درجة مئوية) without freezing them.

Recent market analysis explains that dry ice is odorless, slightly acidic and non flammable. Production involves compressing gaseous CO₂ into liquid and then pressing it into pellets or blocks. Because dry ice has a lower temperature than water based ice and leaves no residue, demand for dry ice has grown; the global dry ice market is projected to rise from USD 1.66 مليار في 2025 إلى USD 2.73 مليار من قبل 2032. These trends underscore why dry ice pack sheets are gaining popularity.

Benefits of Dry Ice vs Traditional Ice

| طريقة التبريد | نطاق درجة الحرارة | مدة (تقريبا.) | رُطُوبَة | فائدة عملية |

| Mini dry ice pack sheet | -78.5 درجة مئوية إلى -18 درجة مئوية | 24 - 48 ح | لا أحد (subledlimates) | Maintains ultra low temperatures for vaccines and biologics |

| حزمة الثلج التقليدية (على أساس الماء) | 0 درجة مئوية | 12 - 24 ح | يترك الماء | Suitable for chilled products like produce but not for freezing requirements |

| حزمة هلام | 2 - 8 درجة مئوية | يختلف (عادة 24 ح) | Minimal moisture when melted | Keeps goods above freezing; ideal for pharmaceuticals that must not freeze |

How Do Wet and Dry Dry Ice Pack Sheets Work?

معلومات مفصلة

تسامي is the key to dry ice’s effectiveness. When solid CO₂ is exposed to room temperatures, it absorbs heat and converts directly to gas, maintaining cold temperatures without melting. Gel sheet dry ice packs combine this property with a flexible gel layer that slows down sublimation and distributes cold evenly. The typical structure includes:

| عنصر | وصف | دلالة |

| طبقة ورقة جل | Flexible material that surrounds dry ice pellets | Prolongs cooling effect and ensures uniform temperature distribution |

| قلب الثلج الجاف | Source of ultra cold temperatures via sublimation | Maintains low temperatures and prevents spoilage of sensitive cargo |

| غلاف خارجي واقي | متينة, lightweight polymer film | Provides safe handling and protects contents from physical damage |

Because the gel layer moderates sublimation, gel sheet dry ice packs offer extended cooling durations and reduce the risk of “hot spots.” In contrast, disposable dry ice sheets use pure dry ice and can maintain temperatures for 24 - 72 hours depending on the thickness and insulation.

مثال عملي

Consider a pharmaceutical company shipping mRNA vaccines that must remain at –70 °C. A mini dry ice pack sheet can maintain –78.5 °C for more than 48 ساعات, enabling the vaccines to arrive intact even during long international flights. عبوات الجل التقليدية, التي تحافظ على 2 - 8 درجة مئوية, would be insufficient for such ultra low temperatures and would allow the vaccine to degrade.

User tips and advice

Pre chill packaging: Pre cool the shipping container before adding dry ice sheets to maximize cooling duration.

استخدام عزل عالي الجودة: Combine dry ice sheets with insulated containers or VIP panels to slow heat transfer.

مراقبة درجة الحرارة: Employ smart sensors or data loggers to track internal temperatures, وخاصة بالنسبة للمستحضرات الصيدلانية.

Combine with gel packs when necessary: For shipments that include both frozen and chilled items, use gel packs to buffer temperature gradients and slow dry ice sublimation.

دراسة حالة: A biotech lab used gel sheet dry ice packs to transport genetic samples requiring −20 °C. By placing the gel sheet around samples and packing additional dry ice on top, they maintained the necessary temperature for 48 hours and reduced sample spoilage.

When Should You Choose a Dry Ice Pack Sheet Over a Wet Gel Pack?

إجابة مباشرة

Choose a dry ice pack sheet when your cargo must remain frozen or near ultra low temperatures. Dry ice maintains about –109.3 °F (-78.5 درجة مئوية), making it ideal for frozen foods, بوظة, and pharmaceuticals that require sub zero conditions. Gel packs and other wet packs are better suited for goods needing refrigeration rather than freezing.

التفسير الموسع

The decision hinges on the temperature range and sensitivity of your products. اللحوم المجمدة, seafood and vaccines benefit from dry ice sheets because they remain well below freezing and prevent microbial growth. Dry ice also avoids the mess of melting water and reduces the risk of texture changes in frozen foods. حزم هلام, في المقابل, preserve goods like chocolate, cosmetics and medicines that must not freeze. For products requiring controlled refrigeration (2 - 8 درجة مئوية), gel packs keep temperatures stable without exposing items to extreme cold.

The general packing guideline is to use equal weight of dry ice and product for 48 hour frozen shipments and 1.5 times the product weight for 72 شحنات ساعة. لحزم هلام, about one third of the product weight provides up to 48 hours of refrigeration.

Benefits and scenarios

| سيناريو | الحزمة الموصى بها | سبب |

| Shipping vaccines requiring –70 °C | Mini dry ice pack sheet | Provides ultra low temperature and moisture free cooling |

| Shipping fresh seafood above freezing | Hydrate dry ice pack (قابل لإعادة الاستخدام)** or gel pack | Keeps seafood at 0 درجة مئوية – 5 °C without freezing |

| تسليم عدة وجبات (frozen meals at –18 °C) | حزمة من رقائق الثلج الجاف | Maintains –20 °C for 24 ساعات |

| Chocolates and delicate cosmetics | عبوة جل قياسية | Maintains chilled temperatures without freezing |

نصائح واقتراحات عملية

Assess your product’s temperature threshold: If freezing would damage the product (على سبيل المثال, زهور, المنتجات الطازجة), opt for gel packs.

Factor in transit duration: Longer transit times may require larger or multiple dry ice sheets; for short deliveries, قد تكون عبوات الجل كافية.

Consider regulatory limits: الشحنات غير الطبية التي تحتوي على أكثر من 5.5 جنيه (2.5 كجم) of dry ice must comply with IATA and U.S. أنظمة.

القضية الفعلية: A meal delivery company shipping pre cooked frozen meals replaced bulky gel bricks with gel sheet dry ice packs. The new packs kept meals at –20 °C for 24 ساعات, reduced packaging weight and improved customer satisfaction.

الاستخدام الآمن, ترطيب, and Activation of Dry Ice Pack Sheets

معلومات مفصلة

Dry ice packs must be handled with care. Skin contact with dry ice can cause severe frostbite; always use insulated gloves or tongs when handling. على عكس حزم الهلام, dry ice sheets release carbon dioxide gas as they sublimate; proper ventilation is critical.

Disposable dry ice pack sheets require activation:

هيدرات الورقة by immersing it in warm water until the polymer cells expand.

تجميد على الأقل 24 ساعات to reach the lowest possible temperature.

Pack with the fabric side facing the product and ensure the package is vented to allow CO₂ gas to escape.

للحصول على أفضل النتائج, pre chill your products, use larger sheets for longer durations and choose high quality insulation. Dry ice sheets last 24 - 72 hours depending on thickness and insulation. They can be reused until the textile surface becomes unhygienic.

Safety practices and regulations

تهوية: Use vented packaging to prevent pressure build up.

الحماية الشخصية: ارتداء القفازات العازلة والنظارات الواقية.

الامتثال التنظيمي: Follow IATA and domestic regulations for shipping more than 5.5 رطل من الجليد الجاف.

تخزين: Store dry ice in a well ventilated area and never in airtight containers.

تصرف: Allow unused dry ice to sublimate in open, well ventilated spaces. Do not pour down sinks or drains, as the extreme cold can damage fixtures.

نصيحة الخبراء: Always include clear instructions for the end user on handling remaining dry ice to prevent accidents.

Choosing the Right Pack Sheet for Different Industries

الصيدلانية والتكنولوجيا الحيوية

The pharmaceutical industry requires precise temperature control. Vaccines and biologics often need temperatures between –70 °C and –20 °C. Gel sheet dry ice packs with a controlled sublimation rate maintain ultra low temperatures and reduce handling complexity. في 2025, predictive analytics and IoT sensors enable real time monitoring of pharmaceutical shipments. The North American pharmaceutical cold chain market is expected to reach USD 1,454 مليار من قبل 2029 مع معدل نمو سنوي مركب قدره 4.71 %.

Food and meal delivery

الأطعمة المجمدة, seafood and meal kits require consistent freezing at –18 °C. Dry ice sheets can maintain –20 °C for 24 ساعات, ensuring meat and seafood remain safe. Gel packs protect perishable produce (0 - 5 درجة مئوية) دون تجميد. مع نمو التجارة الإلكترونية, the North American food cold chain market is projected to reach USD 86.67 مليار في 2025. Investing in dry ice sheet solutions helps reduce food waste and improve customer satisfaction.

التجارة الإلكترونية ومجموعات الوجبات

The rise of direct to consumer food and health products demands affordable and sustainable packaging. Disposable dry ice sheets are lightweight and reduce dimensional weight, cutting shipping costs. They also allow flexible sizing by cutting the sheet into smaller cells. Using smart technology, shipping systems can adjust the number of sheets per shipment based on predictive analytics.

Biotech and laboratory samples

Biotech samples require reliable cooling to maintain sample integrity. Gel sheet dry ice packs maintain low temperatures while providing cushioning to protect vials and tubes. Real time tracking can verify temperature compliance and provide audit trails.

Hydrate packs for daily use

Hydrate dry ice packs — reusable sheets that absorb water before freezing — are versatile for everyday cooling. Users soak the sheet, freeze it overnight and place it in coolers. These packs are reusable and suitable for picnics, camping trips or transporting seafood and fresh produce. They offer long lasting cooling and can even help maintain refrigerator temperatures during power outages.

2025 اتجاهات وابتكارات سلسلة التبريد

صناعة سلسلة التبريد تتطور بسرعة. Understanding these trends helps you select the right cooling solutions.

الأتمتة والروبوتات

The industry faces labor shortages, prompting adoption of automated storage and retrieval systems (AS/RS) and robotic handlers. Automation reduces labor costs, minimizes errors and maintains consistent temperature control. تظهر الدراسات حول 80 % من المستودعات لا تزال غير آلية, تسليط الضوء على إمكانات النمو الكبيرة.

الاستدامة كقيمة أساسية

Environmental regulations and consumer demand push companies to adopt sustainable practices. Sustainable cold chain solutions help reduce carbon footprints and food waste. The global food cold chain infrastructure accounts for roughly 2 % من انبعاثات ثاني أكسيد الكربون. Manufacturers are developing eco friendly gel packs, compostable packaging and recyclable dry ice sheets. Programs like Cryopak’s R3 Service offer reuse and recycling, saving clients millions of dollars and reusing hundreds of thousands of tons of materials.

نهاية إلى نهاية الرؤية والتتبع في الوقت الحقيقي

IoT enabled sensors provide continuous temperature, بيانات الموقع والرطوبة, allowing businesses to optimize routes and reduce waste. Real time visibility enhances customer satisfaction and ensures regulatory compliance.

تحديث البنية التحتية

Aging cold storage facilities require upgrades for energy efficiency and compliance. Investments in better insulation, data collection and on site renewable energy are essential.

الذكاء الاصطناعي والتحليلات التنبؤية

الذكاء الاصطناعي يحسن التوجيه, يتنبأ بفشل المعدات ويتنبأ بالطلب. AI reduces costs and improves reliability by analyzing historical and real time data.

النمو في سلسلة التبريد الصيدلانية

The pharmaceutical sector drives demand for ultra cold storage. عن 20 % of new drugs are gene or cell based therapies requiring strict temperature control. The COVID 19 pandemic accelerated investment in cold chain capacity and highlighted the need for reliable dry ice solutions.

Last mile and fresh food logistics

يتوقع المستهلكون أن تكون طازجة, high quality produce delivered quickly. The North American food cold chain market is projected to reach USD 86.67 مليار في 2025. Online ordering and meal kits require efficient last mile delivery, prompting innovation in packaging and refrigeration.

الشراكات الاستراتيجية والتكامل

التعاون بين مصنعي المواد الغذائية, packaging suppliers and technology providers enhances efficiency and resilience. بواسطة 2025, عن 74 % ومن المتوقع أن يتم توحيد البيانات اللوجستية, enabling better integration across supply chains.

Green and sustainable materials

Sustainable materials such as compostable gel packs and recycled cardboard packouts reduce waste and carbon footprints. Innovations like NexBlu™ GPS use 20 % less material, أَدْخَل 30 % recycled graphite beads and increase payload capacity by 25 - 30 %.

تكامل التكنولوجيا الذكية

Dry ice and gel sheet packs now include sensors that monitor temperature and send alerts when deviations occur. Disposable dry ice sheets incorporate biodegradable materials and IoT monitoring, while AI recommends the optimal number of sheets per shipment.

Include an illustrative diagram

الأسئلة الشائعة

س 1: كم من الوقت تدوم صفائح الثلج الجاف? Dry ice pack sheets typically maintain sub zero temperatures for 24 - 72 ساعات, depending on thickness and insulation. Test your configuration under real conditions to confirm performance.

Q2: هل يمكن إعادة استخدام صفائح الثلج الجاف؟? نعم. They can be reused until the textile surface becomes unhygienic. Always ensure that the sheet is fully rehydrated and frozen before each use.

س 3: هل صفائح الثلج الجاف آمنة للشحن الجوي؟? نعم, dry ice sheets are permitted for air shipments when properly packaged and labeled. Keep shipments below 5.5 pounds of dry ice to minimize regulatory requirements.

س 4: What is the difference between gel sheet dry ice packs and regular gel packs? Gel sheet dry ice packs use dry ice to achieve ultra low temperatures, while regular gel packs rely on water based PCM and maintain 2 - 8 درجة مئوية. Gel sheet dry ice packs are therefore ideal for frozen shipments, whereas gel packs suit refrigerated goods.

س 5: How can I maximize the efficiency of mini dry ice pack sheets? قم بتبريد الحاوية مسبقًا, use high quality insulation, and monitor temperature with sensors. Adjust the number of sheets based on ambient temperature and transit duration.

ملخص وتوصيات

To deliver temperature sensitive products safely, you need the right refrigerant. Dry ice pack sheets provide ultra low temperatures (-78.5 درجة مئوية) ولا تترك أي رطوبة, مما يجعلها مثالية للأطعمة المجمدة, اللقاحات والبيولوجية. Gel packs maintain chilled temperatures (2 - 8 درجة مئوية) without freezing and are perfect for products like chocolate or cosmetics. Combining these technologies in flexible sheets allows you to tailor cooling to your specific needs. Follow safety practices (قفازات, تهوية) and comply with regulations when shipping dry ice.

في 2025, cold chain logistics are being transformed by automation, الاستدامة, real time tracking and AI. Choosing eco friendly gel sheet dry ice packs and leveraging smart sensors can enhance your operations and meet rising customer expectations. Adopt modern solutions, evaluate your product temperature needs and collaborate with trusted suppliers to keep your shipments safe and efficient.

نصيحة قابلة للتنفيذ

تقييم الشحنات الخاصة بك: Identify the temperature requirements and transit duration for each product.

حدد المبرد المناسب: Use dry ice pack sheets for frozen or ultra cold shipments and gel packs for chilled goods.

تنفيذ المراقبة الذكية: Invest in IoT sensors and data loggers to ensure end to end temperature visibility.

اتبع إرشادات السلامة والتنظيمية: ارتداء معدات الحماية, ضمان التهوية, and comply with weight restrictions on dry ice.

إعطاء الأولوية للاستدامة: Choose recyclable or biodegradable pack sheets and participate in reuse programs like Cryopak’s R3 Service.

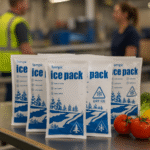

حول Tempk

في Tempk, نحن متخصصون في high performance temperature control solutions including mini dry ice pack sheets, gel sheet packs, hydration packs and insulated packaging. لدينا ص&D center and quality control laboratory ensure that every product meets rigorous standards. With innovative solutions like EcoGel™ gel packs and recyclable EcoPak™ packaging, we are committed to sustainability and efficiency. سواء كنت تقوم بشحن اللقاحات, مجموعات المأكولات البحرية أو الوجبات, we provide custom solutions to keep your goods safe. Contact us today for expert advice on optimizing your cold chain logistics.

دعوة إلى العمل

على استعداد لتعزيز عمليات سلسلة التبريد الخاصة بك? اتصل بخبراء Tempk for a custom consultation and discover how wet and dry dry ice pack sheets can protect your temperature sensitive products.