تخيل لقاحًا دقيقًا أو صندوقًا من التوت يسافر مئات الأميال إلى باب منزلك. بدون التحكم المستمر في درجة الحرارة, كلاهما سوف يفسد قبل وقت طويل من وصولهما إليك. هذا نظام التبريد, المراقبة والتعامل الدقيق يسمى سلسلة البرد, وهو العمود الفقري لتوزيع الغذاء والدواء الحديث. في 2025 يشهد السوق العالمي للوجستيات سلسلة التبريد ازدهارًا - وتشير التقديرات إلى أنه سينمو من حوالي 293 مليار دولار أمريكي 2023 إلى أكثر من 862 مليار دولار أمريكي 2032- والمواكبة تعني فهم كيفية عملها. هذا الدليل, تم التحديث على 13 نوفمبر 2025, يزيل الغموض عن السلسلة الباردة, يشرح مكوناته, يستكشف الاتجاهات الناشئة ويوضح لك كيف يمكن أن يفيد عملك.

ما سلسلة البرد هو وكيف يعمل, بما في ذلك دورها في الغذاء, الأدوية والمنتجات الحساسة الأخرى.

المكونات الرئيسية للوجستيات سلسلة التبريد– أنظمة التبريد, تخزين, النقل والمراقبة.

الفوائد والتحديات للحفاظ على سلسلة التبريد, مع الأمثلة والحلول العملية.

كيفية تنفيذ أفضل ممارسات سلسلة التبريد, تغطية الامتثال, معايير درجة الحرارة وتدريب الموظفين.

2025 الاتجاهات والابتكارات مثل أجهزة استشعار إنترنت الأشياء, الذكاء الاصطناعي و blockchain اللذان يعيدان تشكيل الخدمات اللوجستية التي يتم التحكم في درجة حرارتها.

الأسئلة المتداولة وإجابات حول إدارة سلسلة التبريد.

ما هي السلسلة الباردة وكيف تعمل؟?

ال سلسلة البرد هي سلسلة توريد متخصصة مصممة للتعامل معها, تخزين ونقل البضائع الحساسة لدرجة الحرارة تحت ضوابط صارمة لدرجة الحرارة. بدلاً من السلسلة العادية حيث يمكن وضع البضائع في الظروف المحيطة, تستخدم الخدمات اللوجستية لسلسلة التبريد التبريد, التعبئة والتغليف المعزول والمراقبة في الوقت الحقيقي لحماية المنتجات من التلف. يعرّفها دليل الصناعة بإيجاز على أنها عملية التعامل, تخزين ونقل البضائع القابلة للتلف تحت ظروف يتم التحكم في درجة حرارتها. أ 2025 ويوضح التقرير أيضًا أن هذا التبريد المستمر - بدءًا من التصنيع ومرورًا بالتخزين والتوزيع - يحافظ على جودة المنتج من الإنتاج إلى الاستهلاك.

في الممارسة العملية, تجمع سلسلة التبريد بين العلم, التكنولوجيا والانضباط العملية. طعام, اللقاحات, البيولوجيا, المواد الكيميائية, قد تتطلب مستحضرات التجميل وحتى الآلات الموسيقية التبريد أو التحكم في الرطوبة لتبقى آمنة. على عكس سلسلة التوريد العادية, تعتمد السلسلة الباردة على التبريد والمراقبة المستمرة في كل مرحلة. يمكن للانحرافات الطفيفة في درجات الحرارة أن تؤدي إلى تدهور اللقاحات أو إفساد المأكولات البحرية. لمنع مثل هذه الخسائر, تم بناء سلسلة التبريد من عدة مكونات مترابطة: أنظمة التبريد, التخزين البارد, نقل يتم التحكم في درجة حرارته ومراقبة متطورة.

مكونات السلسلة الباردة: تبريد, التخزين والنقل

أنظمة التبريد. تعمل معدات التبريد على خفض درجات حرارة المنتج إلى نطاقات آمنة وتبقيها هناك. حاويات مبردة, تعتبر مجمدات الانفجار وأنظمة النيتروجين السائل شائعة; فهي تحافظ على درجات حرارة ثابتة أثناء النقل وتبريد المنتجات مسبقًا بسرعة. يمكن أن تصل المجمدات المبردة إلى درجات حرارة منخفضة للغاية أقل من -80 درجة مئوية للعلاجات البيولوجية والجينية. تمنع هذه التقنيات التلف وتحافظ على فعاليته.

التخزين البارد. توفر المستودعات وغرف التبريد بيئات خاضعة للرقابة للتخزين على المدى الطويل. تستخدم المستودعات المبردة الكبيرة الألواح المعزولة, الضواغط, المكثفات وأنظمة التخزين والاسترجاع الآلية لمنع تسرب الهواء البارد وارتفاع درجات الحرارة. تحتوي غرف التبريد الأصغر حجمًا على منتجات محددة في درجات حرارة محددة. تحافظ المرافق على عدة نطاقات لدرجة الحرارة: المحيط (15-30 درجة مئوية), رائع (10-15 درجة مئوية), مبردة (0-10 درجة مئوية) وتجميد (-30 درجة مئوية إلى 0 درجة مئوية). تُستخدم النطاقات المنخفضة جدًا التي تقل عن -80 درجة مئوية في علاجات الخلايا والجينات.

النقل والتوزيع. المركبات المتخصصة – الشاحنات المبردة, السفن والطائرات - احتفظ بالبضائع ضمن درجة الحرارة المناسبة أثناء النقل. لشحنات المواد الغذائية اليومية, البضائع الطازجة تسافر في +2 درجة مئوية إلى +8 درجة مئوية بينما تتطلب الأطعمة المجمدة حوالي -20 درجة مئوية; بعض الأدوية تتطلب -60 درجة مئوية أو أقل. لا يقتصر النقل على الغذاء والدواء; قطع الزهور, مستحضرات التجميل, الورنيش, تحتاج الآلات الموسيقية وبعض الإلكترونيات أيضًا إلى درجات حرارة يمكن التحكم فيها. قد تحتاج الحاويات أيضًا إلى التحكم في الرطوبة أو الضغط, وأحيانًا التدفئة، على سبيل المثال, يمكن أن تتشوه الزيوت أو الأدوات الخشبية إذا أصبحت باردة جدًا.

المراقبة والتحكم. تقوم أجهزة الاستشعار ومسجلات البيانات بتسجيل درجة الحرارة والرطوبة بشكل مستمر, إرسال تنبيهات في حالة خروج القراءات عن النطاقات الآمنة. استخدام الأنظمة الحديثة مستشعرات إنترنت الأشياء, علامات GPS وRFID لتوفير رؤية في الوقت الحقيقي عبر سلسلة التوريد. في مرافق متطورة, تعمل أنظمة التحكم عن بعد وأنظمة التبريد في حالات الطوارئ على تصحيح الانحرافات أو تنبيه الموظفين تلقائيًا. تضمن المراقبة الكشف المبكر عن المشكلات وإثبات الامتثال.

نطاقات درجة حرارة سلسلة التبريد النموذجية

| نطاق درجة الحرارة | أمثلة على المنتجات | لماذا يهم |

| المحيط (15-30 درجة مئوية / 59-86 درجة فهرنهايت) | الأطعمة الجافة, بعض المستحضرات الصيدلانية | الحد الأدنى من التبريد اللازم; لا يزال يتطلب تهوية لتجنب تراكم الحرارة. |

| رائع (10-15 درجة مئوية / 50-59 درجة فهرنهايت) | جبن, المنتجات الطازجة | يحافظ على النكهة والملمس; يستخدم حاويات معزولة وأوقات نقل قصيرة. |

| مبردة (0-10 درجة مئوية / 32-50 درجة فهرنهايت) | اللقاحات, منتجات الألبان | يمنع نمو البكتيريا ويحافظ على نضارتها. |

| المجمدة (-30 درجة مئوية إلى 0 درجة مئوية / -22 درجة فهرنهايت إلى 32 ° f) | لحمة, المأكولات البحرية, الحلويات المجمدة | يوفر الحفاظ على المدى الطويل; يتطلب معدات التجميد العميق والطاقة الاحتياطية. |

| منخفض جدًا (أقل من -80 درجة مئوية / أقل من -112 درجة فهرنهايت) | البيولوجيا, لقاحات مرنا | يتطلب المجمدات المبردة والطاقة الزائدة عن الحاجة لتجنب الخسارة الكارثية. |

نصائح عملية وسيناريوهات المستخدم

للشركات الغذائية من المزرعة إلى المائدة: استخدم العبوات المعزولة وحزم الجل للشحنات أدناه 48 ساعات, واختيار الناقلات ذات الشاحنات المبردة. تأكد من بقاء درجة الحرارة بين +2 درجة مئوية و +8 درجة مئوية للمنتجات الطازجة. استخدم أجهزة استشعار إنترنت الأشياء لتنبيهك في حالة ارتفاع درجة الحرارة.

للصيدليات والعيادات: تخزين اللقاحات بين +2 درجة مئوية و +8 درجة مئوية وتجنب تعريضها لدرجات حرارة التجمد. استخدم الثلاجات الطبية وأجهزة تسجيل البيانات الرقمية لمراقبة الظروف.

لمحلات الزهور أو معالجات الفن: الحفاظ على برودة, بيئة رطبة قليلاً عند شحن الزهور المقطوفة أو الأعمال الفنية; درجات الحرارة شديدة البرودة يمكن أن تلحق الضرر بها. قم بتعبئة العناصر بمواد ماصة للرطوبة وراقب الرطوبة إلى جانب درجة الحرارة.

دراسة حالة: أثناء توزيع لقاحات mRNA لكوفيد 19, كان على مقدمي الخدمات اللوجستية الحفاظ على درجات حرارة -60 درجة مئوية إلى -70 درجة مئوية أثناء النقل. استخدام الحاويات المبردة المتخصصة والمراقبة المستمرة, لقد احتفظوا باللقاحات ضمن النطاق, ضمان بقاء الجرعات فعالة عند تناولها.

فوائد وتحديات الخدمات اللوجستية لسلسلة التبريد

يؤدي تنفيذ سلسلة تبريد قوية إلى تحقيق فوائد كبيرة. من خلال الحفاظ على المنتجات ضمن نطاقات درجة الحرارة الآمنة, الشركات تقليل التلف وزيادة الإيرادات لكل شحنة. يحصل العملاء على سلع ذات جودة أفضل, مما يؤدي إلى زيادة الرضا والولاء. تتيح سلسلة التبريد أيضًا إمكانية الوصول إلى أسواق جديدة - المنتجات الطازجة من قارة أخرى أو الأدوية التي يتم تسليمها إلى المجتمعات النائية - بينما تساعد الشركات على الامتثال للوائح الصارمة مثل تلك التي تفرضها إدارة الغذاء والدواء ومنظمة الصحة العالمية.

لكن, تشكل لوجستيات سلسلة التبريد أيضًا تحديات. يمكن أن تحدث تقلبات في درجات الحرارة أثناء التحميل, انقطاع التيار الكهربائي أو أوقات العبور الطويلة. قد يؤدي التغليف غير المناسب إلى تسخين المنتجات أو تجميدها بشكل غير متوقع. وتزداد مخاطر التلوث عندما تتقاسم البضائع المساحة مع مواد غير متوافقة. بالإضافة إلى, الحاجة إلى المعدات المتخصصة, يزيد الموظفون المدربون والتوثيق من التعقيد التشغيلي والتكلفة.

التحديات والحلول المشتركة

| تحدي | خطر على منتجك | كيفية التخفيف |

| تعطل التحكم في درجة الحرارة | وحتى التعرض لفترة وجيزة خارج النطاق الآمن يمكن أن يجعل اللقاحات أو الأغذية غير صالحة للاستعمال. | استخدم أنظمة تبريد قابلة للتطوير وطاقة زائدة عن الحاجة; تجهيز المركبات بالتبريد الاحتياطي ومراقبة درجات الحرارة بشكل مستمر. |

| التعبئة والتغليف غير كافية | التغليف التالف يعرض البضائع للحرارة أو الرطوبة; وصول الشحنات مدلل. | اختر العزل الذي يتوافق مع احتياجات المنتج (حزم هلام, لوحات فراغ); تطبيق تتبع RFID للكشف عن الحوادث والتصرف بسرعة. |

| التلوث والاتصال المتبادل | التعرض للمواد الكيميائية أو البكتيريا الأخرى يمكن أن يضر بالمنتجات. | مناطق التخزين منفصلة, اتبع بروتوكولات الصرف الصحي وتدريب الموظفين على إجراءات التعامل. |

| عدم الامتثال التنظيمي | يمكن أن يؤدي الفشل في تلبية ممارسات التوزيع الجيدة إلى عمليات الاسترجاع, الغرامات والإضرار بالسمعة. | الاحتفاظ بسجلات دقيقة, استخدام المعدات المعتمدة ومعايرة الأجهزة بانتظام. |

تحمل انتهاكات سلسلة التبريد عواقب وخيمة: تدهور المنتج, مخاطر الصحة العامة, الخسائر المالية, الإجراء التنظيمي, الإضرار بالسمعة وانقطاع الإمدادات. على سبيل المثال, ذكرت إحدى الدراسات ذلك حتى 35 % من اللقاحات معرضة للخطر بسبب سوء التعامل مع درجة الحرارة- إهدار مكلف وتهديد للصحة العامة. إن التعرف على المخاطر يساعد المنظمات على تنفيذ التدابير الوقائية.

نصائح المستخدم للتغلب على التحديات

إجراء رسم خرائط منتظمة لدرجة الحرارة: قم باختبار مناطق التخزين بشكل دوري لتحديد النقاط الساخنة والباردة, إجراء عمليات محاكاة انقطاع التيار الكهربائي وضبط الإجراءات وفقًا لذلك.

اتبع الأول في, أول خروج (يصرف أولاً) طريقة: قم ببيع أو توزيع المخزون القديم أولاً لتقليل الهدر وضمان الامتثال.

تسمية وتنظيم المخزون: ضع علامة واضحة على تواريخ انتهاء الصلاحية وشروط التخزين; ترتيب الرفوف للسماح بتدفق الهواء المناسب.

تدريب فريقك: يجب على كل شخص يتعامل مع سلع سلسلة التبريد أن يفهم متطلبات درجة الحرارة, إجراءات الطوارئ وحفظ السجلات.

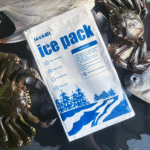

التخطيط لحالات الطوارئ: إعداد خطط الطوارئ لانقطاع التيار الكهربائي, فشل المعدات وتأخير النقل; مخزون مولدات الطوارئ وحزم الثلج الاحتياطية.

مثال العالم الحقيقي: قامت تعاونية ألبان إقليمية بقطع التلف عن طريق 25 % بعد تطبيق أجهزة استشعار درجة حرارة إنترنت الأشياء والتحول إلى علب كرتونية معزولة أكثر سمكًا. مكّنت التنبيهات في الوقت الفعلي السائقين من تصحيح المشكلات قبل تسخين المنتجات, والاستثمار مدفوع عن نفسه خلال موسم واحد.

الامتثال لسلسلة التبريد وأفضل الممارسات: دليلك خطوة بخطوة

يعد الامتثال للمعايير الوطنية والدولية أمرًا ضروريًا. الهيئات التنظيمية مثل FDA, ال وكالة الأدوية الأوروبية (ema) و منظمة الصحة العالمية فرض ممارسات التوزيع الجيدة (الناتج المحلي الإجمالي) التي تغطي التحكم في درجة الحرارة, أنظمة التحقق من صحتها, التتبع والموظفين المدربين. يتضمن الامتثال أيضًا معايير المعايرة مثل نيست أو UKAS, المبادئ التوجيهية لسلامة البيانات الإلكترونية (ملحق برنامج الرصد العالمي للاتحاد الأوروبي 11) والقواعد الخاصة بكل بلد.

متطلبات سلسلة التبريد الأساسية

يتطلب الوفاء بمعايير الامتثال الاهتمام بعدة عناصر:

صيانة دقيقة لدرجة الحرارة: احتفظ بالمنتجات ضمن نطاقات خاضعة لرقابة مشددة — عادةً 2 درجة مئوية إلى 8 درجة مئوية للسلع المبردة, -20 درجة مئوية للتجميد القياسي و أقل من -70 درجة مئوية للتخزين المنخفض للغاية.

24/7 يراقب: استخدم مسجلات البيانات الآلية وأنظمة الوقت الحقيقي لتتبع درجات الحرارة بشكل مستمر. اختر الأجهزة المزودة بأجهزة إنذار للرحلات.

البنية التحتية المعتمدة: الاستثمار في وحدات التبريد المعتمدة, حاويات النقل وأدوات المراقبة التي تعمل باستمرار.

بيئات تخزين آمنة: تقييد الوصول والحفاظ على مناطق منفصلة للمنتجات المختلفة.

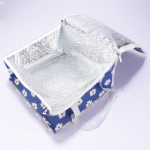

التعبئة والتغليف المتخصصة: استخدم التغليف الحراري مثل الشاحنين المعزولين, مواد متغيرة الطور وحزم هلامية للحفاظ على درجات الحرارة أثناء النقل.

حفظ السجلات التفصيلية: سجل بيانات درجة الحرارة, شهادات المعايرة, سجلات التدريب وأي انحرافات.

خطط الطوارئ: إعداد بروتوكولات لانقطاع التيار الكهربائي, أعطال المعدات ورحلات درجة الحرارة.

الموظفين المدربين: التأكد من تدريب الموظفين على التعامل, الرصد والاستجابة لحالات الطوارئ.

قائمة مرجعية لأفضل الممارسات

استخدام المعدات الطبية: تتقلب الثلاجات المنزلية كثيرًا بالنسبة للقاحات الحساسة; اختر المعدات المصممة للاستخدام الصيدلي.

مراقبة درجات الحرارة في الوقت الحقيقي: توفر أجهزة تسجيل البيانات الرقمية وأنظمة التنبيه اللاسلكية تحديثات وإنذارات مباشرة.

معايرة وصيانة المعدات: معايرة موازين الحرارة والمجمدات مرتين في السنة على الأقل وصيانة المستندات.

اعتماد إدارة المخزون FIFO: تدوير المخزون لتجنب البضائع منتهية الصلاحية.

التسمية بوضوح: قم بتضمين تواريخ انتهاء الصلاحية والاستلام على جميع الطرود.

تدرب بانتظام: عقد قصيرة, دورات تدريبية مركزة كل بضعة أشهر لإبقاء الموظفين على دراية بالإجراءات الصحيحة.

التخطيط لحالات الطوارئ: احتفظ بمصادر الطاقة الاحتياطية وإجراءات التشغيل القياسية (SOP) لانقطاع التيار الكهربائي أو تأخير النقل.

توثيق كل شيء: الاحتفاظ بسجلات رقمية لدرجات الحرارة, الصيانة وحوادث عمليات التدقيق.

قائمة التحقق من جاهزية سلسلة التبريد

استخدم هذا التقييم الذاتي لمعرفة مدى استعداد مؤسستك. لكل سؤال, إجابة نعم أو لا:

هل تعرف نطاق درجة الحرارة الدقيق الذي تتطلبه منتجاتك؟?

هل جميع وحدات التخزين الخاصة بك مزودة بمقاييس حرارة معايرة وأجهزة تسجيل البيانات؟?

هل تقوم بمراقبة درجات الحرارة بشكل مستمر وتلقي تنبيهات للرحلات?

هل تم تصنيف مواد التعبئة والتغليف الخاصة بك لظروف النقل التي تتوقعها؟?

هل يتلقى فريقك تدريبًا مستمرًا على التعامل مع سلسلة التبريد وإجراءات الطوارئ؟?

هل لديك خطط طوارئ موثقة لانقطاع التيار الكهربائي وتأخير النقل?

هل تقوم بإجراء خرائط منتظمة لدرجة الحرارة وصيانة المعدات؟?

هل تحتفظ بسجلات مفصلة لدرجات الحرارة؟, المعايرة والإجراءات التصحيحية?

إذا أجبت لا إلى أي سؤال, تلك المنطقة تستحق الاهتمام. معالجة الثغرات الآن ستحمي جودة المنتج وتساعدك على الالتزام باللوائح.

نصيحة: فكر في الشراكة مع مزود سلسلة تبريد ذو خبرة إذا كانت صيانة البنية التحتية الخاصة بك غير عملية. يمكن للمتخصصين تقديم المعدات المعتمدة, موظفين مدربين وخدمات مراقبة في الوقت الفعلي مصممة خصيصًا لتلبية احتياجاتك.

2025 اتجاهات سلسلة التبريد والابتكارات

يتطور مشهد سلسلة التبريد بسرعة. أفاد محللو السوق أن السوق العالمية للوجستيات سلسلة التبريد تم تقييمها دولار أمريكي 293.58 مليار في 2023 ومن المتوقع أن تصل إلى دولار أمريكي 862.33 مليار من قبل 2032. دراسة أخرى تقدر السوق في 436.30 مليار دولار أمريكي 2025, متوقعا أن يتجاوز 1.3 تريليون دولار أمريكي 2034. وتعكس هذه الأرقام ارتفاع الطلب على الأغذية الطازجة, البيولوجيا, اللقاحات وغيرها من المنتجات الحساسة لدرجة الحرارة في جميع أنحاء العالم.

الاتجاهات الناشئة التي تشكل سلسلة التبريد

المرونة الجيوسياسية وتخطيط القدرات. الاضطرابات مثل الاضطرابات الجيوسياسية, أثرت التعريفات التجارية وأحداث البجعة السوداء على أوقات العبور والقدرة. يستثمر مشغلو سلسلة التبريد في القدرة المرنة والطرق المتنوعة للحفاظ على الخدمة, ويشير الخبراء إلى أن السوق جاهز للتعامل مع الاضطرابات المستقبلية.

تعزيز الرؤية من خلال البرمجيات. تعمل منصات البيانات في الوقت الفعلي على تحسين التتبع ومراقبة درجة الحرارة, إعطاء أصحاب المصلحة الرؤى اللازمة للتصرف بسرعة. تعد الرؤية أمرًا بالغ الأهمية عند التعامل مع البضائع الحساسة لدرجة الحرارة; تتيح البيانات المستمرة استجابات فورية للانحرافات وتخطيط أفضل للمخزون.

منتجات جديدة وتحولات غذائية. ظهور البروتينات النباتية, الأطعمة العضوية والخالية من الغلوتين تعيد تشكيل وسائل النقل المبردة. يمكن أن تشكل الأطعمة النباتية 7.7 % سوق البروتين العالمي من خلال 2030, جلب معهم متطلبات درجة الحرارة الجديدة وتعقيدات سلسلة التوريد.

تحديث مرافق التخزين البارد. ويجري استبدال المستودعات القديمة - التي تم بناء بعضها منذ 40 إلى 50 عامًا - أو تحديثها لتحسين كفاءة استخدام الطاقة, الأتمتة والتكامل. الضغط التنظيمي للتخلص التدريجي من المبردات الضارة بالبيئة (مركبات الكربون الهيدروكلورية فلورية ومركبات الكربون الهيدروفلورية) يسرع هذه الترقيات.

إنترنت الأشياء وتكنولوجيا الاستشعار. توفر أجهزة إنترنت الأشياء مراقبة في الوقت الحقيقي لدرجة الحرارة, الرطوبة والموقع, السماح للشركات باكتشاف المشكلات ومعالجتها على الفور. تعمل هذه المستشعرات على تقليل النفايات وضمان جودة المنتج.

Blockchain من أجل الشفافية. Blockchain يخلق غير قابل للتغيير, دفتر حسابات شفاف للمعاملات. فهو يحسن إمكانية التتبع ويساعد على ضمان بقاء المنتجات ضمن نطاقات درجات الحرارة الآمنة. في سلاسل التبريد الصيدلانية, تعمل تقنية blockchain على تقليل معالجة البيانات وتعزيز الامتثال.

الذكاء الاصطناعي والتحليلات التنبؤية. يعمل الذكاء الاصطناعي على تحسين الطرق, يتنبأ بالطلب ويحدد الاضطرابات المحتملة قبل حدوثها. يتيح الجمع بين الذكاء الاصطناعي وبيانات درجة الحرارة التاريخية للمشغلين منع الرحلات الاستكشافية وجدولة الصيانة بشكل استباقي.

غرفة تبريد تعمل بالطاقة الشمسية. تتبنى المناطق النائية ذات إمدادات الكهرباء غير المستقرة غرف تبريد تعمل بالطاقة الشمسية لحماية اللقاحات والسلع القابلة للتلف. تعمل هذه الوحدات على خفض تكاليف الطاقة وتوفير تبريد موثوق.

المجمدات المبردة المحمولة. بالنسبة للمستحضرات البيولوجية والعلاجات الخلوية التي تتطلب درجات حرارة منخفضة مثل -150 درجة مئوية, توفر المجمدات المبردة المحمولة إمكانية الحركة والظروف شديدة البرودة المستمرة.

التغليف المستدام ودرجات الحرارة المنخفضة. تتحول الشركات إلى العزل القابل للتحلل, حاويات قابلة لإعادة الاستخدام وتصاميم موفرة للطاقة. يهدف بعض مشغلي غرف التبريد إلى تغيير معايير التخزين المجمد من -18 درجة مئوية إلى -15 درجة مئوية لتقليل استهلاك الطاقة.

تصور نمو السوق

لتوضيح التوسع السريع في الخدمات اللوجستية لسلسلة التبريد, الرسم البياني أدناه يرسم حجم السوق المتوقع من 2021 ل 2034. ويظهر الاتجاه نموا هائلا, مما يعكس زيادة الطلب عبر الصناعات.

الابتكارات وتأثيرها

| ابتكار | فائدة عملية | حالة الاستخدام النموذجي |

| أجهزة استشعار إنترنت الأشياء وتتبع نظام تحديد المواقع العالمي (GPS). | درجة الحرارة في الوقت الحقيقي وبيانات الموقع; تنبيهات فورية تمنع التلف. | مراقبة شحنات اللقاحات, الأطعمة القابلة للتلف والمنتجات الزهرية. |

| إمكانية تتبع البلوكشين | سجل غير قابل للتغيير لكل معاملة; تحسين المساءلة والثقة. | تتبع الأدوية من الشركة المصنعة إلى المريض; ضمان صحة الأغذية العضوية. |

| تحسين المسار القائم على الذكاء الاصطناعي | تقليل وقت العبور والتحديد التنبؤي لرحلات درجة الحرارة. | تخطيط طرق التسليم للعيادات النائية أو المناطق الحضرية المزدحمة. |

| غرفة تبريد تعمل بالطاقة الشمسية | موثوق, التبريد خارج الشبكة; انخفاض تكاليف الطاقة والانبعاثات. | تخزين اللقاحات في المجتمعات الريفية التي لا تتوفر فيها كهرباء مستقرة. |

| المجمدات المبردة المحمولة | الحفاظ على درجات حرارة منخفضة للغاية (وصولا إلى -150 درجة مئوية) للبيولوجيا والعلاجات الخلوية. | نقل العلاجات الجينية أو لقاحات mRNA إلى المستشفيات النائية. |

| التغليف المستدام & انخفاض معايير درجة الحرارة | يخفض النفايات والبصمة الكربونية; معايير جديدة مثل -15 درجة مئوية تقلل من استخدام الطاقة. | شحن الأطعمة المجمدة, الأدوية والمنتجات المتخصصة. |

نتطلع إلى الأمام

مع نضوج التكنولوجيا وتطور المعايير التنظيمية, سلسلة التبريد مهيأة لمزيد من النمو. الشركات التي تتبنى إنترنت الأشياء, الذكاء الاصطناعي والممارسات المستدامة سيعززان الشفافية, تقليل النفايات وتلبية توقعات المستهلكين فيما يتعلق بالجودة والمسؤولية البيئية. وستكون الشركات التي تعمل على تحديث بنيتها التحتية وتستثمر في التدريب والامتثال في وضع أفضل لخدمة السوق المتوسعة للسلع الحساسة لدرجة الحرارة.

الأسئلة المتداولة

- في أي درجة حرارة يجب تخزين اللقاحات؟?يجب الاحتفاظ بمعظم اللقاحات بين +2 درجة مئوية و +8 درجة مئوية; تتطلب اللقاحات المجمدة مثل الحماق -50 درجة مئوية إلى -15 درجة مئوية, واللقاحات شديدة البرودة مثل معززات mRNA التي تحتاجها -80 درجة مئوية إلى -60 درجة مئويةللتخزين على المدى الطويل. بمجرد إذابته, يمكن الاحتفاظ بالعديد من اللقاحات +2 درجة مئوية إلى +8 درجة مئوية لفترة محدودة. استشر دائمًا إرشادات الشركة المصنعة واستخدم مسجلات البيانات الرقمية لمراقبة درجات الحرارة.

- كيف تختلف سلسلة التبريد عن سلسلة التوريد العادية؟?تقوم سلسلة التوريد التقليدية بنقل البضائع دون التحكم الصارم في درجة الحرارة. على النقيض من ذلك, تستخدم سلسلة التبريد معدات تبريد متخصصة, التعبئة والتغليف المعزول والمراقبة المستمرة ل الحفاظ على المنتجات ضمن نطاقات درجات الحرارة الدقيقة. كما يتطلب وثائق مفصلة, البنية التحتية المعتمدة والامتثال للمعايير التنظيمية.

- ما هي الصناعات التي تعتمد على سلسلة التبريد؟?تستخدم شركات الأغذية والمشروبات لوجستيات سلسلة التبريد للحفاظ على المنتجات, ألبان, اللحوم والمأكولات البحرية الطازجة من المزرعة إلى المائدة. وتعتمد عليه صناعة الأدوية للحفاظ على فعالية اللقاح وفعالية الدواء. ومن بين المستخدمين الآخرين شركات التكنولوجيا الحيوية, مصنعي المواد الكيميائية, باعة الزهور, المتاحف ومنتجي الإلكترونيات.

- ماذا يحدث عندما يتم اختراق سلسلة التبريد؟?يحدث الاختراق - أو الانحراف في درجة الحرارة - عندما تبتعد المنتجات عن نطاقها المحدد. وتشمل العواقب تدهور المنتج, مخاطر الصحة العامة, الخسائر المالية, الإجراءات التنظيمية والإضرار بالسمعة. للقاحات, حتى التعرض القصير أعلاه +8 درجة مئوية يمكن أن تتحلل حتى 20 % من الفاعلية. منع الانتهاكات مع الأنظمة الزائدة عن الحاجة, المراقبة والتدريب المستمر.

- كيف يمكن للشركات الصغيرة البدء في استخدام لوجستيات سلسلة التبريد?ابدأ بتحديد متطلبات درجة حرارة منتجاتك. استخدم العبوات المعزولة وحزم الجل للشحنات القصيرة واشترك مع شركات النقل التي تقدم النقل المبرد. استثمر في أجهزة تسجيل البيانات ذات الأسعار المعقولة والمراقبة السحابية. تدريب الموظفين على التعامل مع الإجراءات والحفاظ على نظام حفظ السجلات لإثبات الامتثال.

ملخص وتوصيات قابلة للتنفيذ

استكشف هذا الدليل أساسيات سلسلة التبريد, موضحًا كيف يحافظ التحكم المستمر في درجة الحرارة على اللقاحات, طعام, المواد الكيميائية وأكثر من ذلك. قمنا بفحص المكونات الرئيسية – أنظمة التبريد, التخزين البارد, النقل والمراقبة - وسلط الضوء على درجات الحرارة النموذجية التي تتراوح من درجة الحرارة المحيطة إلى درجة الحرارة المنخفضة جدًا. تشمل فوائد لوجستيات سلسلة التبريد تقليل التلف, زيادة رضا العملاء والوصول إلى أسواق جديدة, بينما تنطوي التحديات على اضطرابات في درجات الحرارة, التعبئة والتغليف غير الكافية والتعقيد التنظيمي. يتطلب الامتثال صيانة دقيقة لدرجة الحرارة, البنية التحتية المعتمدة, يراقب, الوثائق, التخطيط للطوارئ والموظفين المدربين.

خطة العمل:

تقييم احتياجات المنتج الخاص بك. تحديد متطلبات درجة الحرارة الدقيقة لكل منتج.

استثمر في البنية التحتية المناسبة. استخدم معدات التبريد المعتمدة, التعبئة والتغليف المعزولة والمركبات المعتمدة.

تنفيذ المراقبة في الوقت الحقيقي. نشر أجهزة استشعار إنترنت الأشياء وأجهزة تسجيل البيانات لتتبع درجة الحرارة, الرطوبة والموقع بشكل مستمر.

تدريب فريقك. تثقيف الموظفين بانتظام حول إجراءات المناولة, الاستجابة لحالات الطوارئ ومتطلبات الامتثال.

اعتماد الممارسات المستدامة. اكتشف التغليف الصديق للبيئة, أنظمة كفاءة في استخدام الطاقة ومعايير درجات الحرارة المنخفضة حيثما كان ذلك مناسبا.

احتضان الابتكار. تقييم التقنيات الجديدة مثل تحسين المسار القائم على الذكاء الاصطناعي, blockchain والتخزين بالطاقة الشمسية.

إنشاء خطط الطوارئ. الاستعداد لانقطاع التيار الكهربائي, فشل المعدات وتأخير النقل; الحفاظ على أنظمة النسخ الاحتياطي وبروتوكولات الطوارئ.

من خلال اتباع هذه الخطوات, يمكنك بناء سلسلة تبريد مرنة تحمي جودة المنتج, يلبي المعايير التنظيمية ويرضي العملاء.

حول Tempk

شركة تيمبك المتخصصة في حلول التعبئة والتغليف والخدمات اللوجستية المبتكرة لسلسلة التبريد. نقوم بتصميم وتصنيع مجموعة واسعة من الصناديق المعزولة, حزم هلام, عبوات الثلج وأكياس التبريد الكهربائية لتوصيل الطعام, تطبيقات المستحضرات الصيدلانية والتكنولوجيا الحيوية. تستخدم منتجاتنا مواد عالية الأداء مثل ألواح العزل الفراغي ووسائط تغيير الطور للحفاظ على درجات حرارة مستقرة لفترات طويلة. نحن نعطي الأولوية للاستدامة من خلال تقديم خيارات قابلة لإعادة الاستخدام وإعادة التدوير ونستثمر باستمرار في البحث والتطوير لتقليل آثار الكربون.. مع رقابة صارمة على الجودة وشهادة Sedex, نحن نساعد العملاء على التنقل بين المتطلبات التنظيمية والتأكد من وصول البضائع الحساسة لدرجة الحرارة بأمان وفي الوقت المحدد.

دعوة إلى العمل: سواء كنت تقوم بشحن الجبن الحرفي أو اللقاحات المنقذة للحياة, يمكن لخبرائنا مساعدتك في تصميم حل للتحكم في درجة الحرارة يناسب احتياجاتك. اتصل بنا اليوم لمناقشة تحديات سلسلة التبريد الخاصة بك واستكشاف مجموعتنا من حلول التعبئة والتغليف والمراقبة.