The Strategic Advantage of حزم الثلج الجاف في لوجستيات سلسلة التبريد

Maintaining precise temperature control is non-negotiable for pharmaceuticals, الأطعمة القابلة للتلف, والمواد الكيميائية المتخصصة. As global supply chains expand, حزم الثلج الجاف (CO₂ الصلبة) have emerged as a game-changing solution for ultra-cold transport. Let’s examine why they’re transforming temperature assurance strategies.

Core Operational Benefits

1. أداء حراري متفوق

Dry ice packs maintain cryogenic temperatures (-78.5درجة مئوية), outperforming gel packs that typically stay near 0°C. This deep-freeze capability ensures:

-

Vaccine integrity during intercontinental transit

-

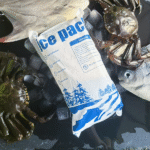

Frozen state preservation for seafood/meat

-

Stability for temperature-sensitive reagents

2. Zero-Liquid Phase Change

عملية التسامي (الصلبة → الغاز) eliminates:

-

Water damage risks to packaging

-

Moisture-triggered product degradation

-

Post-transit cleanup requirements

3. تحسين المساحة

Compact blocks replace bulky refrigeration units, increasing payload capacity by 15-30% in standard shipping containers.

Cross-Industry Implementation

| قطاع | التطبيقات الحرجة | Key Outcomes |

|---|---|---|

| فارما | توزيع اللقاحات, biologics transport | Compliance with 2-8°C/-20°C requirements |

| طعام | Premium seafood, وجبات مجمدة, بوظة | Extended shelf-life preservation |

| التكنولوجيا الحيوية | مواد التجارب السريرية, عينات المختبر | Uncompromised sample viability |

Tempk’s Engineering Edge

Tempk’s dry ice solutions deliver measurable supply chain improvements:

✓ Extended Duration Performance

يحافظ العزل الحاصل على براءة اختراع على درجات الحرارة المستهدفة 40% longer than industry standards, even in extreme ambient conditions.

✓ Configurable Formats

Modular designs accommodate:

-

Small parcel shipments (السعاة الطبية)

-

Full-pallet configurations (bulk perishables)

-

Custom geometries for specialty containers

✓ سلسلة باردة مستدامة

100% recyclable high-density shells with carbon-neutral production support ESG compliance goals.

خاتمة

Dry ice packs resolve critical cold chain vulnerabilities through unmatched temperature control, كفاءة الفضاء, and moisture-free operation. Tempk elevates these advantages with engineered solutions offering extended thermal protection, shipment-specific configurability, والمسؤولية البيئية. For logistics managers requiring guaranteed temperature integrity from origin to destination, Tempk’s dry ice technology delivers quantifiable ROI across healthcare, طعام, and industrial sectors.