Kits de comida de comercio electrónico en ascenso, Reglas estrictas de la logística farmacéutica, y los compradores preocupados por el clima han presionado Fabricantes de cajas más frescas de un grupo especializado de moldeadores de espuma a un motor global con un valor cercano a los EE.UU. $8.5 mil millones por 2025, creciente 8.5 % anualmente.

1 | ¿Quién es quién en la fila de la fábrica?

Nombres heredados: Sonoco ThermoSafe, Softbox, B Sistemas médicos, Nilkamal, y tecnologías de cadena fría: todavía el suministro de EPS y PUR más validados, mientras que las marcas orientadas al comercio minorista como Yeti e Igloo dominan los enfriadores duros. Mientras tanto, moldeadores regionales en la India, Vietnam, y México acortan los tiempos de entrega para plataformas de comestibles que no pueden esperar ocho semanas para un contenedor.

2 | Puntos de control de innovación

El que se mueve más rápido Fabricantes de cajas más frescas están cambiando las espumas fósiles por papel alveolar reciclable, pulpa moldeada, o reciclado postindustrial (Pir) paneles; El refrigerador All-Paper de DS Smith es un ejemplo de titular reciente. Tecnología de embalaje hoy Otros añaden sensores y refrigeración activa: el Cube autorefrigerado de Ember mantiene las vacunas en 2 - 8 ° C para 72 h mientras transmite GPS y temperatura a la nube.

3 | Elegir el socio adecuado

-

ciencia termal – Busque ISO 17025 laboratorios de pruebas, Perfiles ISTA 7D, e informes OQ/PQ específicos del carril.

-

Escalabilidad – Moldeo distribuido o flotas de alquiler que amortiguan los picos de vacaciones.

-

Circularidad – Programas de recuperación y diseños monomateriales que se deslizan hacia el reciclaje en la acera..

-

Datos & servicio - 24/7 análisis de carril, remodelación, y soporte para el kit.

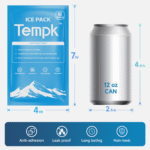

4 | Caja aislada Tempk™: un foco rápido

Parejas de cajas aisladas híbridas EPP/VIP reutilizables de Tempk <0.025 Conductividad W/m·K con ladrillos PCM encajables, entregando congelados, enfriado, o carriles ambientales sin cinta ni revestimientos. El caparazón resistente sobrevive 100+ viajes de ida y vuelta, Reducción de CO₂ y coste total por uso., mientras es suave, Toallitas para superficies de calidad alimentaria que se limpian en segundos: ideales para devoluciones farmacéuticas o kits de comida para el mismo día. Respaldado por un 1 400 m² R calibrado por CNAS¢ro D, Tempk puede cortar herramientas personalizadas en menos de cuatro semanas, Brindar a los transportistas un camino rápido desde el concepto hasta el transportista validado..