Cold Chain Artisanal Chocolate Supply Chain Management?

Cold chain artisanal chocolate supply chain management is how you keep premium bars and bonbons glossy, snappy, and “gift-perfect” when they travel. Your goal is not “as cold as possible.” Your goal is stable and dry, because temperature swings and condensation are what trigger bloom and texture drift. Many chocolate storage guides recommend a cool range (a menudo alrededor 12–18ºC) and warn that condensation can cause sugar bloom if you warm products too fast after chilling.

This article will help you answer:

-

How does cold chain artisanal chocolate supply chain management stop bloom and melt complaints?

-

Qué temperature and humidity targets work for artisanal chocolate shipping?

-

Where do “hidden handoffs” break your chocolate cold chain?

-

Cual pack-out recipe fits your lane time, clima, y presupuesto?

-

How do monitoring, validation tests, and traceability reduce disputes and returns?

What does cold chain artisanal chocolate supply chain management actually mean?

Cold chain artisanal chocolate supply chain management means controlling time, temperatura, and moisture from your finishing room to the customer’s hands. It’s a system, not a single box or a single truck. If you only “add ice packs” but ignore handoffs, you still lose.

cold chain artisanal chocolate …

Think of chocolate like a polished car finish. One rough car wash can ruin the shine. In cold chain artisanal chocolate supply chain management, one uncontrolled handoff can ruin the surface you worked so hard to perfect.

What changes when you run it like a system?

You stop chasing “average temperature,” and you start preventing spikes y condensación. That shift alone reduces the most common customer complaints: melted edges, bloom haze, and gritty mouthfeel.

| What you control | Typical failure | Simple system fix | Practical benefit for you |

|---|---|---|---|

| Estabilidad de temperatura | Heat spike + re-cool cycle | Aislamiento + buffer coolant | Better gloss and snap |

| Moisture exposure | Condensation → sugar bloom | Sealed liner + warm-up rule | Fewer “looks old” claims |

| Dwell time at handoffs | Boxes sit in warm air | Dock timer + earlier pickup | Fewer surprise excursions |

Why do bloom and “melted” claims happen so fast?

Because chocolate fails from short spikes and repeated swings—not only from full melting. A single hot van, a locker delay, or a sunny doorstep can shift appearance and texture. Research continues to show temperature cycling is a major driver of fat bloom and texture changes. 科学直通车

Here’s the key mindset for cold chain artisanal chocolate supply chain management: design for the worst 45 minutos, not the best 23 horas.

cold chain artisanal chocolate …

The two bloom triggers you can actually control

-

Temperature cycling: Warm exposure followed by re-cooling can accelerate fat bloom formation. 科学直通车

-

Condensación: If chocolate is cold and meets humid air, moisture can form and later crystallize sugar on the surface. Callebaut+1

Practical tips you can apply this week

-

Stop “fridge-to-door” habits: cold product + warm humid air = condensation risk. Callebaut

-

Add a customer warm-up card: “Keep sealed for 1–2 hours before opening in humid weather.”

cold chain artisanal chocolate …

-

Track peak internal temperature: peaks explain complaints better than averages.

cold chain artisanal chocolate …

Caso del mundo real (typical pattern): Brands often discover that the “damage” happened during a delay at the last mile, not during line-haul transit.

cold chain artisanal chocolate …

What temperature and humidity targets should you set in 2025?

Start with a realistic cool-and-dry target you can actually hold. For pure chocolate, many storage guides point to 12–18ºC and emphasize avoiding condensation during warm-up. Callebaut

In cold chain artisanal chocolate supply chain management, your “best” target is the one your packaging + operations can consistently deliver—especially through handoffs.

A simple target-setting approach

-

Pick a “comfort zone” for your finished goods (often near 12–18°C for pure chocolate storage). Callebaut

-

Add a “no-condensation rule” (sealed warm-up before opening). Callebaut+1

-

Use a backup band for mild climates where “cool stability” matters more than deep chilling.

| Target style | Temperature goal | Moisture rule | Lo que significa para ti |

|---|---|---|---|

| “Comfort zone” | 12–18ºC | Prevent condensation | Best for premium finish protection Callebaut |

| “Cool stability” | 16–20°C | Keep dry, sellado | Practical when ambient risk is moderate |

| “Heat-risk lane” | Stay below softening risk | Extra sealing + buffers | Packaging and planning matter most |

Consejos prácticos para tu equipo

-

Pre-condition product before packing: don’t pack warm chocolate into “cold” packaging.

cold chain artisanal chocolate …

-

Treat humidity like a KPI: most sugar-bloom complaints are “moisture stories,” not “temperature stories.” Callebaut

Where do “hidden handoffs” break your cold chain most often?

Most failures happen where you don’t have direct control. The highest-risk points are waiting time at pickup, sorting hubs, and last-mile delivery cycles.

cold chain artisanal chocolate …

Cold chain artisanal chocolate supply chain management improves fastest when you map these handoffs like a journey, not a straight line.

Your “Four Hot Minutes” checklist

-

Packing table exposure

-

Dock staging with doors open

-

Carrier network hubs and parked vans

-

Doorstep, lobby, locker, or re-delivery loops

cold chain artisanal chocolate …

Consejos prácticos que puedes aplicar ahora

-

Move pickup earlier in the day during hot seasons.

cold chain artisanal chocolate …

-

Label “time out of controlled space” on cartons to change behavior fast.

cold chain artisanal chocolate …

-

Add a “no weekend idle” rule for heat-risk months.

cold chain artisanal chocolate …

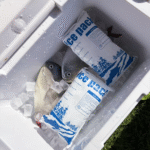

How do you choose packaging that prevents spikes, not just melts?

Packaging is your most reliable temperature defense in cold chain artisanal chocolate supply chain management. It should slow temperature change, reduce moisture exposure, and protect the presentation.

Your packaging system is usually five parts:

-

Remitente

-

refrigerante (gel, PCM, or hybrid buffer)

-

Placement strategy (top/bottom/sides)

-

Barrera de humedad + sellos

-

Void fill and corner protection

cold chain artisanal chocolate …

PCM vs gel: which one is better for chocolate?

PCM can be tuned to a target band and often reduces fast swings. Gel is simpler but can increase condensation risk if it over-cools.

cold chain artisanal chocolate …

| Cooling approach | Fortaleza | Weak spot | Lo que significa para ti |

|---|---|---|---|

| paquetes de gel | Simple, costo más bajo | Can over-cool → condensation | Best for short, mild lanes |

| Tuned PCM | Smoother temperature control | Mayor costo unitario | Best for premium finish protection |

| Híbrido | Flexible for mixed climates | More pack-out steps | Best when lanes vary week to week |

Practical pack-out tips (high impact)

-

Match coolant to lane time: don’t overbuild a 24-hour lane with a 72-hour pack-out.

cold chain artisanal chocolate …

-

Add a moisture barrier for humid regions and include a warm-up instruction card.

cold chain artisanal chocolate …

-

Protect corners and movement: presentation damage can look like “quality damage.”

cold chain artisanal chocolate …

Herramienta de decisión interactiva: pick your shipping setup in 2 minutos

Answer these and follow the recommendation:

-

Is transit time usually under 24 horas?

-

Yes → go to Q2

-

No → go to Q3

cold chain artisanal chocolate …

-

-

Do you ship to humid regions often?

-

Yes → Insulated shipper + moisture barrier + warm-up card

-

No → Insulated shipper + light buffer, focus on anti-spike design

cold chain artisanal chocolate …

-

-

Do parcels face >30°C outdoor exposure risk?

-

Yes → Higher-performance insulation + tuned buffer coolant + validación de carril

-

No → Moderate insulation + validated pack-out + spot-check monitoring

cold chain artisanal chocolate …

-

How can you validate lanes before peak heat and holidays?

Validation turns cold chain artisanal chocolate supply chain management from guessing into repeatable control. You define pass/fail limits, instrument real shipments, and test “delay scenarios.”

cold chain artisanal chocolate …

If you ship parcels with intermediate transfers, ISO has a dedicated standard for indirect temperature-controlled refrigerated parcel delivery services (ISO 23412:2020), and ISO confirms it remains current after a 2025 revisar. 国际标准化组织

The standards you’ll hear most often

-

ISTA 7D / Ista 7e are commonly referenced for thermal transport packaging development and evaluation. 国际安全运输协会+1

-

Norma ASTM D3103 is a test method used to evaluate thermal insulation performance of insulated packaging systems. ASTM International | ASTM

A simple lane validation plan you can run

-

Pick worst-case lanes (hottest, más largo, most handoffs).

-

Define pass/fail (internal product-zone temperature stays in your target band).

-

Use real pack-outs (same tape, relleno de vacíos, and coolant).

-

Place sensors near the product core and near the wall.

-

Run multiple trials to capture variability.

cold chain artisanal chocolate …

| Validation scenario | What to measure | Pass/fail idea | Practical benefit for you |

|---|---|---|---|

| Summer profile | Peak internal temperature | Stay in target band | Fewer “melted” claims |

| Winter profile | Condensation risk | No wetness events | Fewer sugar-bloom disputes |

| Delay scenario (+24h) | Survival time | Still acceptable | Fewer refunds during disruptions |

Practical reality: Your “delay test” often reveals more than your “normal test.”

cold chain artisanal chocolate …

What should you monitor to reduce disputes and chargebacks?

Monitor enough to learn and to prove what happened—without drowning in dashboards. Cold chain artisanal chocolate supply chain management improves fastest when you connect temperature events to lanes, pack-out versions, and carriers.

cold chain artisanal chocolate …

For traceability design, GS1 publishes a Global Traceability Standard to help organizations structure identifiers and traceability processes across supply chains. GS1+1

Minimum viable monitoring (start here)

-

Lot/batch ID

-

Pack-out recipe version

-

Handoff timestamps

-

Internal temperature history (exceptions matter most)

cold chain artisanal chocolate …

| Data point | Por que importa | How you use it | Lo que significa para ti |

|---|---|---|---|

| Temperature log | Confirms excursions | Claim decisions | Less “he said / she said” |

| Handoff timestamps | Finds delay points | Carrier scorecards | Better negotiations |

| Lot-level link | Speeds investigations | QA actions | Faster containment |

Practical tips for monitoring

-

Start with your arriba 3 complaint lanes, then expand.

cold chain artisanal chocolate …

-

Usar exception alerts instead of reading every chart.

cold chain artisanal chocolate …

How do you plan dispatch so chocolate never waits in the wrong place?

Waiting is often more dangerous than driving. Cold chain artisanal chocolate supply chain management fails when cartons sit on warm docks or idle over weekends.

cold chain artisanal chocolate …

A simple dispatch rule-set that protects quality

-

Ship early in the week during heat-risk seasons

-

Avoid pre-holiday backlogs when networks clog

-

Align cutoffs with real pickup behavior

-

Pre-stage pack-out materials at the right temperature

cold chain artisanal chocolate …

Consejos prácticos que puedes aplicar ahora

-

Create lane “recipes” (destination group → tested pack-out).

cold chain artisanal chocolate …

-

Add a weather trigger to switch pack-outs during heat waves.

cold chain artisanal chocolate …

What should you demand from carriers and 3PLs?

You don’t need a perfect carrier—you need a measurable one. Cold chain artisanal chocolate supply chain management improves when your carrier follows defined handling, dwell limits, and escalation processes.

cold chain artisanal chocolate …

ISO 23412:2020 focuses on requirements for indirect, temperature-controlled refrigerated delivery services for parcels with intermediate transfer, reinforcing that “service control” matters, not just packaging. 国际标准化组织

Carrier/3PL checklist (keep it practical)

-

Maximum dock dwell time

-

Defined handoff rules (sombra, puesta en escena, scanning discipline)

-

Exception escalation path

-

Seasonal plan for peak heat and peak volume

cold chain artisanal chocolate …

¿Qué hay de nuevo en 2025 for cold chain artisanal chocolate supply chain management?

2025 is about fewer surprises, more proof, and tighter economics. Standards and validation practices are more visible, and buyers expect better documentation across handoffs. 国际标准化组织+1

Al mismo tiempo, cocoa market pressure remains real. In late 2025, ICCO reported global grindings estimates of 4.81 million tonnes (2023/24) y 4.60 million tonnes (2024/25), highlighting demand and margin stress that makes every damaged shipment hurt more. International Cocoa Organization

Latest developments you should care about

-

More lane validation: thermal testing standards are mainstream in cold-chain packaging programs. Smithers+1

-

More focus on waste reduction: FAO has long highlighted that roughly one-third of food produced for consumption is lost or wasted globally—temperature stability reduces avoidable disposal. FAOHome

-

More science on cycling: 2025 research continues to analyze how temperature cycling drives fat bloom formation and microstructure change. 科学直通车

Preguntas frecuentes

Q1: Is bloomed chocolate unsafe to eat?

Generalmente no. Bloom is mainly a quality and appearance issue, but customers treat it like failure.

Q2: Should you always ship artisanal chocolate with ice packs?

No. Over-cooling can increase condensation risk during warm-up, which can create sugar bloom. Callebaut

Q3: What is the single best temperature rule to follow?

Pick a stable cool target (often around 12–18°C for storage) and prevent condensation during warm-up. Callebaut

Q4: What’s the fastest way to reduce summer complaints?

Stop spikes: mejor aislamiento, better handoff discipline, and a no-weekend-idle rule during heat-risk months.

cold chain artisanal chocolate …

Q5: Do small brands really need traceability?

You don’t need enterprise complexity. Basic lot IDs and consistent capture rules can deliver most benefits. GS1

Resumen y recomendaciones

Cold chain artisanal chocolate supply chain management works when you control spikes, swings, and moisture, not just average temperature. Start by setting a realistic cool target, adding a no-condensation warm-up rule, and mapping your hidden handoffs. Then build lane-specific pack-out recipes, validate worst-case lanes with instrumented tests, and monitor exceptions so you can improve fast.

Tus próximos pasos (simple 30-day plan)

-

Define your target band + no-condensation rule.

-

Construir two pack-out recipes (mild vs hot/humid).

cold chain artisanal chocolate …

-

Validate your worst lane with a delay scenario.

cold chain artisanal chocolate …

-

Track complaints by lane and carrier, then optimize.

Acerca de Tempk

Y tempk, we help you turn cold chain artisanal chocolate supply chain management into a repeatable system, not a guess. We focus on practical packaging design (aislamiento, moisture barriers, and temperature buffers), plus monitoring workflows that help you learn which lanes fail and why. If you want fewer bloom complaints and fewer “melted” tickets, we can help you map lane risks, build seasonal pack-out recipes, and set up a validation plan.

CTA: Share your top 3 carriles (tiempo de tránsito, destination climate, tipo de producto). We’ll outline a lane-specific pack-out and monitoring plan you can validate before your next peak season.