Elementos interactivos: Proporcionar un Herramienta de selección de embalaje que pregunta a los usuarios sobre el tipo de producto, rango de temperatura deseado, Duración del tránsito y objetivos de sostenibilidad para recomendar el embalaje adecuado. (p.ej., reutilizable versus desechable, PCM versus hielo seco). Incluir un Prueba de autoevaluación sobre la preparación de envases sostenibles y un claro Llamado a la acción (CTA) solicitar a los usuarios que soliciten una consulta gratuita sobre embalaje.

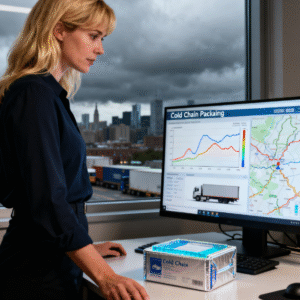

Soluciones de embalaje para cadena de frío Son contenedores y materiales especializados que protegen los productos sensibles a la temperatura, desde vacunas hasta mariscos, durante el envío y el almacenamiento.. A partir de 2024 el mercado global estaba valorado en aproximadamente Dólar estadounidense 34.28 mil millones y se prevé que crezca hasta Dólar estadounidense 89.84 mil millones por 2034, que ilustra la creciente demanda de envases resistentes. Necesita un embalaje que no solo mantenga las temperaturas adecuadas sino que también se alinee con los objetivos de sostenibilidad y las regulaciones emergentes.. Esta guía explica los impulsores del mercado., explora materiales como el poliestireno expandido (EPS), paneles aislados al vacío (VIP) y materiales de cambio de fase (PCM), y muestra cómo la innovación y las expectativas de los consumidores están cambiando la forma en que se envían productos perecederos..

¿Qué es el embalaje de cadena de frío y por qué lo necesita?? Comprender los conceptos básicos, incluyendo rangos de temperatura y materiales.

¿Qué tan grande es el mercado y dónde está creciendo más rápidamente?? Obtener números actualizados, Perspectivas regionales y segmentos clave..

¿Qué materiales y tecnologías debería considerar?? Explora EPS, Puro, VIP, PCM, paquetes de gel y etiquetas inteligentes.

¿Cómo pueden los envases sostenibles beneficiar a su negocio?? Conozca las preferencias de los consumidores, Regulaciones y soluciones reutilizables..

¿Qué innovaciones están dando forma al embalaje en 2025 y más allá? Descubra la IA, sensores de iot, cadena de bloques, y aislamiento avanzado.

¿Qué es el embalaje de cadena de frío y por qué lo necesita??

Una definición clara

El embalaje de cadena de frío se refiere a contenedores y materiales aislados especializados diseñados para mantener temperaturas seguras para productos perecederos durante el transporte y almacenamiento.. Incluye cajas isotérmicas, transportistas de paletas, paquetes de gel, Ladrillos de espuma y materiales de cambio de fase.. Estos paquetes protegen artículos como alimentos., vacunas, productos farmacéuticos y biológicos por calor o congelación, garantizando calidad y seguridad. Una solución de embalaje adecuada es esencial porque incluso una ligera variación de temperatura puede comprometer la integridad del producto..

Por qué te importa

Sin embalaje adecuado, Tus mariscos congelados podrían descongelarse o tus vacunas perder potencia.. Los envases de cadena de frío mantienen rangos específicos: congelados (–20 °C a –80 °C), refrigerado (2 °C a 8 °C) o temperatura ambiente controlada (15 °C a 25 °C). Materiales como espuma de poliestireno., espuma de poliuretano, Los paneles aislados al vacío y los bioplásticos a base de algas minimizan la transferencia de calor.. Los paquetes de gel o PCM absorben y liberan calor para estabilizar la temperatura. Eligiendo la solución adecuada, proteges la calidad del producto, cumplir con las regulaciones y reducir el desperdicio.

Tipos de embalaje y zonas de temperatura.

| Tipo de embalaje | Rango de temperatura típico | Los mejores casos de uso | Lo que esto significa para ti |

| Envases de espuma EPS o PUR | 2 °C-8 °C | Productos frescos, lácteos, vacunas | Ligero, bajo costo y ampliamente disponible; bueno para envíos cortos. |

| Paneles aislados al vacío (VIP) | –20 °C a –80 °C | Carne congelada, biológicos | Proporcionar un aislamiento superior con paredes delgadas; ideal para viajes largos pero más costoso. |

| Paquetes de gel y ladrillos de espuma. | Mantener las condiciones ambientales o refrigeradas. | Kits de comida, productos farmaceuticos | Proporcionar refrigeración flexible; Puede ser reutilizable y combinado con aislamiento.. |

| Material de cambio de fase (PCM) paquete | 2 °C–8 °C o –20 °C a –25 °C | Vacunas, biológicos, reactivos | Packs reutilizables que absorben y liberan calor en puntos específicos; no peligroso. |

| Envasado de hielo seco | Por debajo de –70 °C | Productos biológicos congelados, células congeladas | Embalaje de un solo uso que proporciona temperaturas ultrafrías pero está sujeto a regulaciones sobre materiales peligrosos.. |

Consejos y consejos prácticos

Haga coincidir el rango de temperatura de su producto con el embalaje adecuado: Utilice paquetes PCM para productos biológicos que requieran entre 2 y 8 °C o –20 °C, y hielo seco para envíos ultrafríos como materiales CRISPR.

Considere la duración del envío: Los paquetes de gel y PCM funcionan bien para envíos bajo 72 horas. Para viajes más allá 96 horas en congelación, Es posible que se necesiten hielo seco o sistemas híbridos..

Plan de reutilización: Elija paquetes de PCM duraderos o contenedores aislados para reducir los residuos y reducir los costos a largo plazo.

Ejemplo de caso: Una empresa de biotecnología que envía vacunas a clínicas rurales adoptó paquetes de PCM dentro de contenedores VIP. La solución se mantuvo entre 2 y 8 °C durante 72 horas sin refrigeración activa, Reducir el uso de hielo seco y la manipulación peligrosa.. Como resultado, las pérdidas de producto disminuyeron 20%, y los costos de envío disminuyeron debido a los paquetes reutilizables.

¿Qué tamaño tiene el mercado de envases de cadena de frío y dónde está creciendo??

Tamaño y crecimiento del mercado

El mercado del embalaje de cadena de frío está en auge. Towardspackaging informa que la industria estaba valorado en USD 34.28 mil millones en 2024 y se espera que llegar a USD 89.84 mil millones por 2034, creciendo en un CAGR de 11.3 %. El informe indica que América del Norte dominó el mercado en 2024, mientras que Asia Pacífico está preparada para un crecimiento significativo. Poliestireno expandido (EPS) lideró el segmento de materiales, contenedores isotérmicos liderados por tipo de producto, y pez, La carne y el marisco dominaron el segmento de uso final..

En los Estados Unidos, el tamaño del mercado era Dólar estadounidense 7.97 mil millones en 2024, y se prevé que crezca a un 15.6 % CAGR de 2025 a 2030. Contenedores y cajas isotérmicos mantenidos 55.2 % de participación en los ingresos en 2024 debido a la creciente demanda de productos sensibles a la temperatura. Materiales aislantes representados. 58.1 % de participación en los ingresos. Se espera que las compresas frías crezcan a 17.6 % Tocón impulsado por la entrega de kits de comida y la compra de comestibles en línea.

Impulsores y dinámica regional

La expansión del mercado está impulsada por la creciente demanda de alimentos congelados, productos farmaceuticos, y entregas de comestibles de comercio electrónico. El dominio de América del Norte se debe a fuertes envíos farmacéuticos y redes de distribución avanzadas., Considerando que el crecimiento de Asia Pacífico está impulsado por el aumento de los ingresos y las exportaciones biofarmacéuticas. Europa está invirtiendo en envases neutros en carbono para cumplir los objetivos de sostenibilidad de la UE. Mientras tanto, América Latina y Medio Oriente & África está intensificando la logística de la cadena de frío para respaldar las exportaciones de alimentos y productos farmacéuticos de alto valor. En muchas economías emergentes, brechas de infraestructura, Los altos costos de energía y el cumplimiento regulatorio siguen siendo desafíos..

Tendencias por segmento

Los EE. UU.. El mercado revela interesantes tendencias en subsegmentos.:

Tipos de producto: Los contenedores y cajas isotérmicos ocupan la mayor parte (55.2 %). Las compresas frías y los bloques de gel están ganando popularidad debido a las entregas de kits de comida y envíos de comestibles a domicilio..

tipos de materiales: Materiales aislantes como espuma de poliuretano y captura VIP. 58.1 % de ingresos gracias al alto rendimiento térmico. Los refrigerantes reutilizables, como los PCM y los paquetes de gel, se están convirtiendo en alternativas sostenibles.

Industrias de uso final: Pez, carne & Los mariscos dominan debido a los estrictos requisitos de control de temperatura.. Los productos farmacéuticos y biológicos representan una gran proporción en Europa y América del Norte..

Lo que significa para ti

Las cifras demuestran que el embalaje ya no es una idea de último momento; es una inversión estratégica. Con la expansión del comercio mundial de alimentos y productos farmacéuticos, Las empresas necesitan envases que puedan escalar en todas las regiones y cumplir con las regulaciones locales.. Comprender qué segmentos están creciendo más rápido le ayuda a asignar recursos de forma eficaz. Por ejemplo, si sirves el mercado de kits de comida, invertir en compresas frías livianas; si envía productos biológicos, considere VIP y PCM.

Qué materiales y tecnologías impulsan las soluciones de embalaje de la cadena de frío?

Materiales tradicionales: EPS, PUR y VIP

Poliestireno expandido (EPS) y espuma rígida de poliuretano (Puro) son los caballos de batalla del embalaje de la cadena de frío. Proporcionan ligereza, aislamiento rentable y dominó la participación del material en 2024. El EPS se utiliza a menudo en envíos de pescado y marisco debido a su bajo coste y aislamiento eficaz.. La espuma PUR ofrece beneficios similares pero puede ser más duradera. Paneles aislados al vacío (VIP) Ofrecer un aislamiento superior con paredes delgadas., haciéndolos ideales para productos farmacéuticos y biológicos de alto valor. Sin embargo, Los VIP son más caros y requieren un manejo cuidadoso..

Materiales de cambio de fase (PCM) vs hielo seco

Los PCM absorben y liberan calor a temperaturas específicas, manteniendo rangos estables (como 2–8 °C o –20 °C). Son reutilizables, no peligroso y simplifica el cumplimiento. hielo seco, dióxido de carbono sólido, se sublima a –78,5 °C para proporcionar condiciones ultrafrías para productos biológicos congelados. El hielo seco es económico por envío, pero debe reponerse y manipularse de acuerdo con las regulaciones sobre materiales peligrosos.. Los sistemas PCM requieren una mayor inversión inicial pero ofrecen múltiples ciclos de reutilización, Reducir el desperdicio y los costos a largo plazo..

Embalaje inteligente e integración de IoT

Tecnologías como indicadores de temperatura del tiempo, Etiquetas RFID y sensores IoT están cada vez más integrados en los envases para monitorear las condiciones en tiempo real. El embalaje inteligente le permite a usted y a sus clientes verificar el historial de temperatura mediante códigos QR, garantiza el cumplimiento de las directrices de la FDA y la OMS, y activa alertas si un paquete se desvía de su rango objetivo. Análisis predictivo Puede pronosticar fallas en los equipos y sugerir rutas alternativas.. Visión por computadora impulsada por IA inspecciona el embalaje en busca de fugas o daños, y los drones evalúan las condiciones del almacén. El embalaje inteligente no sólo mejora la seguridad sino que también reduce los controles manuales y acelera la toma de decisiones.

Materiales emergentes y opciones sostenibles

La sostenibilidad está provocando un cambio de los plásticos derivados de combustibles fósiles a alternativas biodegradables y reciclables. Materiales como los bioplásticos a base de algas, La espuma de almidón de maíz y la fibra de madera proporcionan aislamiento y reducen el impacto ambiental.. Los envases derivados de algas marinas están ganando terreno porque forman películas que son comestibles o se disuelven en agua., sin dejar microplásticos. Se utilizan cartón y papel reciclado para las cajas exteriores y proporcionan soporte estructural.. Algunas empresas están experimentando con soluciones híbridas Combinando PET reciclado con VIP para mejorar el rendimiento térmico y la reciclabilidad.. Los geles refrigerantes seguros para el drenaje evitan productos químicos nocivos y se pueden desechar de forma segura.

Elegir la solución adecuada

| Material o tecnología | Características clave | Casos de uso adecuados | Ventajas |

| EPS/PUR | Paneles de espuma rígida; bajo costo; aislamiento moderado | Envíos de alimentos a corta distancia, kits de comida | Asequible, ampliamente disponible, fácil de reciclar (con infraestructura). |

| VIP | Paneles de vacío con aislamiento fino. | Productos farmacéuticos, biológicos, bienes de alto valor | Excelente rendimiento térmico, reduce el tamaño y el peso. |

| Paquetes de PCM | Paquetes reutilizables que se derriten/solidifican a temperaturas establecidas | Vacunas, kits de ensayos clínicos | Mantener rangos específicos; no peligroso; múltiples ciclos de reutilización. |

| hielo seco | Co₂ sólido; se sublima a –78,5 °C | Terapias genéticas, células congeladas | Proporciona un ambiente ultra frío.; ampliamente disponible. |

| Espuma a base de algas | Biodegradable, compostable | Kits de comida ecológicos, mariscos | Reduce el uso de plástico; se disuelve en agua; atractivo amigable para el consumidor. |

| Sensores inteligentes & etiquetas | RFID, indicadores de temperatura del tiempo, códigos QR | Todos los envíos de alto valor | Monitoreo en tiempo real, integración de cadena de bloques, análisis predictivo. |

Mejores prácticas y recomendaciones

Equilibrar rendimiento y costo: Utilice espuma o cartón corrugado para envíos de bajo riesgo.; invertir en VIP y PCM para productos farmacéuticos de alto valor y tiempos de tránsito extendidos.

Integrar monitoreo: Agregue sensores o etiquetas inteligentes a cualquier paquete de cadena de frío. Los datos en tiempo real garantizan la detección temprana de variaciones de temperatura y el cumplimiento normativo..

Adoptar envases reutilizables: Los contenedores duraderos y los paquetes de PCM reducen los costos a largo plazo y ayudan a cumplir los objetivos de sostenibilidad.

Evaluar la infraestructura de reciclaje local: Seleccione materiales que realmente puedan reciclarse en la región de su destinatario.; considerar la posibilidad de recuperar programas si falta infraestructura.

Ejemplo de caso: Una empresa de kits de comida cambió del EPS al papel reciclable y a los envases de espuma a base de almidón.. La nueva solución mantuvo las temperaturas refrigeradas durante 24 horas y volumen de embalaje reducido en 30 %. La satisfacción del cliente mejoró, y la empresa ahorró en tarifas de eliminación de residuos y al mismo tiempo se alineó con sus compromisos de sostenibilidad..

¿Cómo pueden los envases sostenibles beneficiar a su empresa??

Preferencias de los consumidores y presiones regulatorias

Tener envases sostenibles para la cadena de frío ya no es algo agradable: es imprescindible. Según tecnologías de la cadena de frío, 79 % de los consumidores cambian sus preferencias de compra en función del impacto social o ambiental; 67 % dicen que serán más cautelosos ante la escasez de recursos debido a la crisis del COVID 19. Los gobiernos también están elevando el listón: Los estados miembros de la UE deben pagar 0,80 € por kilogramo de envases de plástico no reciclados, y el Reino Unido impone un impuesto a los envases con menos de 30 % contenido reciclado. La Directiva europea sobre envases y residuos de envases exige que 65 % de todos los residuos de envases sean reciclados por 2025, con objetivos más altos por 2030. En los EE.UU., responsabilidad extendida del productor (EPR) Las leyes en estados como California y Maine exigen que las empresas financien programas de reciclaje., Impulsar la adopción de soluciones reciclables y reutilizables..

Tipos de embalajes sostenibles y sus beneficios

Las soluciones sostenibles para la cadena de frío se dividen en varias categorías:

Materiales reciclables: Cartulina, El polietileno y el papel se utilizan cada vez más para revestimientos aislantes y cajas exteriores.. Estos materiales se pueden procesar y reutilizar., reducir los residuos de vertederos.

Embalaje reutilizable: Paquetes de gel duraderos, Los contenedores aislados y los transportadores de paletas se pueden reutilizar varias veces., Reducción del costo por envío y del desperdicio.. Se prevé que el mercado de envases reutilizables para la cadena de frío crezca de Dólar estadounidense 4.97 mil millones en 2025 a USD 9.13 mil millones por 2034.

Materiales biodegradables: Espuma de almidón de maíz, fibra de madera, Los bioplásticos de algas y el aislamiento de algodón se descomponen naturalmente y reducen el impacto ambiental..

Refrigerantes ecológicos: Los paquetes de gel aptos para drenaje y los geles biodegradables reemplazan los refrigerantes dañinos y se pueden desechar de manera segura.

Materiales aislantes innovadores: El reciclaje de fibras de cartón postindustriales para convertirlas en aislamientos de alto rendimiento reduce el desperdicio y ofrece un excelente rendimiento térmico..

Datos que respaldan la sostenibilidad

El blog de Taylor informa que 43 % de los consumidores consideran el impacto ambiental del embalaje al tomar decisiones de compra. Creció el mercado de envases reutilizables para productos de belleza y cuidado personal 65 % de 2020 a 2021. 74 % de americanos están interesados en comprar productos en envases recargables, mostrando la aceptación generalizada de los modelos de reutilización. Crece la oferta de PET reciclado acerca de 4 % anualmente durante la última década, reflejando una mayor demanda de materiales reciclados.

Desafíos y cómo superarlos

A pesar de estos beneficios, La adopción de envases sostenibles enfrenta obstáculos:

Costo: Diseño, Obtener y producir envases sostenibles puede ser más caro que el EPS convencional.. Sin embargo, compra al por mayor, Las asociaciones con proveedores y el análisis de costos del ciclo de vida a menudo revelan ahorros a largo plazo..

Gestión del cambio: Cambiar de materiales requiere un compromiso de toda la organización y ajustes en los procesos. Los proyectos piloto y la formación de los empleados pueden facilitar la transición.

Confianza: Las partes interesadas pueden dudar de que los nuevos materiales ofrezcan una protección adecuada. Validar soluciones mediante pruebas térmicas, certificaciones y estudios de casos.

Infraestructura: Puede que falte infraestructura de reciclaje o compostaje. Considere esquemas de recuperación, programas de embalaje reutilizables o asociaciones locales para garantizar la recuperación al final de su vida útil.

Disponibilidad: Los materiales sostenibles pueden ser escasos, causando problemas en la cadena de suministro. Diversificar proveedores y mantener stock de reserva para reducir el riesgo..

Ejemplo de caso: Un distribuidor farmacéutico reemplazó las cajas de EPS de un solo uso con un conjunto de envíos VIP reutilizables y paquetes de PCM. Aunque los costos iniciales fueron mayores, la empresa redujo el desperdicio de envases en 70 %, ahorró dinero durante tres años y cumplió con los nuevos requisitos de EPR. Los clientes apreciaron el esfuerzo de sustentabilidad, impulsar la reputación de la marca.

¿Qué innovaciones están dando forma al embalaje de la cadena de frío? 2025 y más allá?

AI, IoT y análisis de datos

La inteligencia artificial y los sensores de IoT están transformando los envases. Las etiquetas inteligentes registran el historial de temperatura y escanean a través de aplicaciones de teléfonos inteligentes. Las plataformas impulsadas por IA detectan patrones en los datos de los sensores y predicen cuándo podría fallar una unidad de almacenamiento. La integración con blockchain proporciona registros de temperatura inmutables y automatiza el pago cuando los envíos cumplen condiciones específicas. Empresas como Flexport y Shipwell utilizan IA para analizar el clima, Tráfico y disponibilidad de instalaciones para optimizar rutas y reducir el consumo de combustible..

Sistemas reutilizables y modulares

Los envases reutilizables están ganando terreno. Towards Packaging predice que el mercado de envases reutilizables para la cadena de frío crecerá hasta Dólar estadounidense 9.13 mil millones por 2034. Los sistemas modulares con componentes apilables permiten a los transportistas ajustar la capacidad y reducir el espacio vacío. Los programas de reutilización a menudo incluyen seguimiento digital para garantizar la devolución y el saneamiento.. Las empresas están explorando programas de depósito en los que los clientes pagan una tarifa reembolsada al devolver el embalaje..

Aislamiento avanzado y materiales sostenibles

Los nuevos materiales aislantes incluyen bioplásticos a base de algas y espuma reciclada que ofrecen un rendimiento térmico comparable al del EPS y al mismo tiempo reducen el impacto ambiental. Los paneles aislados al vacío son cada vez más delgados y asequibles, hacerlos accesibles a los transportistas más pequeños. Materiales de cambio de fase están siendo diseñados con puntos de fusión precisos y mayor capacidad de calor latente para extender el control de temperatura sin aumentar el peso.. El embalaje híbrido que combina hielo seco y PCM ofrece compartimentos con múltiples temperaturas para envíos mixtos.

Refrigerantes sostenibles y geles ecológicos

Los geles seguros para drenaje y los refrigerantes biodegradables están reemplazando a los paquetes de gel convencionales, Reducción del impacto ambiental. Algunas empresas utilizan refrigerantes basados en PCM derivados de aceites vegetales o extractos de plantas.. Se están realizando investigaciones sobre disolventes eutécticos naturales que pueden ajustarse a temperaturas específicas y reutilizarse muchas veces..

Blockchain y contratos inteligentes

La tecnología Blockchain garantiza la integridad y el soporte de los datos. contratos inteligentes para cumplimiento y pagos automatizados. Cuando se integra con sensores de IoT, blockchain registra cada lectura de temperatura en un libro de contabilidad a prueba de manipulaciones. Esta transparencia genera confianza entre los transportistas., transportistas y reguladores. Los contratos inteligentes liberan pagos o cobertura de seguro solo si el envío se mantiene dentro de rangos de temperatura específicos, Reducir las disputas y los gastos administrativos..

El papel de la regulación y la estandarización

Los gobiernos y los grupos industriales están desarrollando estándares para envases reutilizables., Calibración de sensores e intercambio de datos.. Por 2025, 74 % Se espera que los datos logísticos estén estandarizados.. Esta estandarización permitirá un intercambio fluido de información entre socios y apoyará iniciativas de economía circular.. Organismos reguladores como la FDA, La EMA y la OMS actualizan las directrices para el envío de productos biológicos, que requieren embalaje validado y monitoreo digital.

Ejemplo de caso: Una nueva empresa europea de biotecnología adoptó bolsas aisladas a base de algas con etiquetas RFID integradas. El embalaje se mantuvo entre 2 y 8 °C durante 48 horas y era compostable después de su uso.. Con integración blockchain, la empresa proporcionó a los reguladores registros de temperatura verificables, acelerar el despacho transfronterizo y fortalecer sus credenciales de sostenibilidad.

¿Cuáles son los desafíos y las mejores prácticas para implementar soluciones de embalaje de cadena de frío??

Desafíos clave

Presiones de costos: El aislamiento avanzado y los sistemas reutilizables tienen costos iniciales más altos. Determinar el costo total de propiedad considerando los ciclos de reutilización., eliminación de residuos y multas por cumplimiento.

Complejidad y formación: Nuevos materiales y tecnologías requieren formación para el embalaje, seguimiento y devolución de contenedores. Sin procedimientos adecuados, Los empleados pueden hacer mal uso de los componentes o ignorar las alertas..

Cumplimiento regulatorio: Los estándares varían según el país y la categoría de producto.. El embalaje debe cumplir con normas como la FDA. 21 Parte CFR 11 para registros electrónicos, Regulaciones de mercancías peligrosas de la IATA para hielo seco y leyes locales de reciclaje.

Logística inversa: Gestionar la devolución y el saneamiento de envases reutilizables requiere infraestructura y colaboración con transportistas y clientes.. La pérdida o el robo de contenedores reutilizables puede erosionar el ahorro de costos.

Seguridad e integración de datos: Compartir datos de sensores entre socios exige sistemas y acuerdos seguros. Los silos de datos pueden obstaculizar la visibilidad y la respuesta.

Mejores prácticas

| Desafío | Práctica recomendada | como ayuda |

| Costo | Realizar un análisis de costos del ciclo de vida y negociar contratos de varios años con proveedores de embalaje. | Ayuda a cuantificar el ahorro procedente de la reutilización, reducción de residuos y reducción del deterioro. |

| Complejidad | Proporcionar capacitación práctica y manuales digitales.; comenzar con proyectos piloto | Genera confianza en los empleados e identifica problemas antes de la implementación completa. |

| Cumplimiento regulatorio | Manténgase actualizado sobre las regulaciones globales y locales; asociarse con proveedores de embalaje que proporcionen sistemas validados | Reduce el riesgo de multas y pérdida de producto.; garantiza que la documentación cumpla con los requisitos de auditoría. |

| Logística inversa | Configure puntos de recogida y realice un seguimiento de los contenedores con códigos QR; diseñar envases fáciles de limpiar | Mejora las tasas de retorno y garantiza el saneamiento., preservar la vida útil del embalaje. |

| Seguridad de datos | Utilice transmisión de datos cifrada y blockchain; establecer acuerdos claros para compartir datos | Protege la información confidencial y genera confianza entre los socios. |

Consejo práctico

Empezar poco a poco: Poner a prueba una solución de embalaje sostenible en una única línea o ruta de producto antes de ampliarla. Recopilar datos sobre el rendimiento de la temperatura., Comentarios de los clientes y logística de devolución..

Involucrar a los proveedores temprano: Trabaje con fabricantes de envases para personalizar soluciones para sus productos y red de distribución.. Solicite datos de rendimiento térmico y certificaciones de sostenibilidad..

Monitorear y ajustar: Utilice sensores de IoT para recopilar datos en tiempo real sobre el rendimiento del embalaje y ajuste sus protocolos en consecuencia. Con el tiempo, Puedes reducir los materiales y el peso del amortiguador..

Ejemplo de caso: Una empresa de comercio electrónico de productos del mar puso a prueba un programa de cajas aislantes retornables. Proporcionaron a los clientes etiquetas de devolución prepagas y ofrecieron puntos de fidelidad por las cajas devueltas.. El piloto logró un 60 % tasa de retorno, Reducción del desperdicio de envases a la mitad y mejora de la retención de clientes..

2025 Últimos desarrollos y tendencias en embalaje de cadena de frío

Descripción general de la tendencia

El panorama mundial del envasado en cadena de frío en 2025 está moldeado por la sostenibilidad, Tecnología inteligente y regulaciones en evolución.. Las empresas deben adaptarse a objetivos de reciclaje más estrictos, Demanda de los consumidores de opciones ecológicas y reglas de control de temperatura más estrictas.. Al mismo tiempo, Innovaciones como el embalaje habilitado para IA., Los refrigerantes híbridos y blockchain están elevando el nivel de confiabilidad y eficiencia..

Último progreso de un vistazo

Expansión del mercado reutilizable: Se prevé que el mercado de envases reutilizables para la cadena de frío crezca de Dólar estadounidense 4.97 mil millones en 2025 a USD 9.13 mil millones por 2034. Empresas de los sectores alimentario y farmacéutico están invirtiendo en transportistas duraderos y sistemas de depósito..

Monitoreo impulsado por IA: Los sensores inteligentes y el análisis predictivo se están convirtiendo en estándar. Las soluciones de embalaje ahora incluyen registradores de datos integrados, Etiquetas RFID y códigos QR para proporcionar visibilidad en tiempo real y respaldar el mantenimiento predictivo.

Aumento del aislamiento biodegradable: Materiales derivados de algas, Se comercializan almidón de maíz y fibras de madera., Ofrecer un rendimiento térmico comparable y al mismo tiempo satisfacer las expectativas de los consumidores en cuanto a envases sin plástico..

Refrigerantes híbridos: Las empresas están combinando PCM con hielo seco en paquetes modulares para soportar rangos de temperatura mixtos dentro de un solo envío.. Las soluciones híbridas reducen los envíos peligrosos y aumentan la flexibilidad.

Armonización regulatoria: Organizaciones internacionales como la Asociación Internacional de Transporte Aéreo (IATA), Organización Marítima Internacional (OMI) y la Organización Mundial de la Salud (OMS) están alineando los estándares de control de temperatura y documentación, simplificando el cumplimiento transfronterizo.

Ideas del mercado

La consolidación del mercado está aumentando. Actores importantes como Cold Chain Technologies, Sonoco Thermosafe y CSafe están invirtiendo en envases inteligentes y materiales sostenibles. Las asociaciones entre proveedores de logística y empresas de embalaje son comunes a medida que las empresas buscan integrar soluciones de seguimiento y embalaje.. La financiación de capital de riesgo está fluyendo hacia las nuevas empresas de envases sostenibles, particularmente aquellos que producen aislamiento biodegradable y etiquetas inteligentes.

Preguntas frecuentes

¿Qué son los materiales de cambio de fase?, y en qué se diferencian de las bolsas de gel o hielo seco?

Materiales de cambio de fase (PCM) Son compuestos que almacenan y liberan calor a temperaturas específicas., mantener condiciones estables dentro de un paquete. A diferencia de los paquetes de gel, que simplemente retienen el frío o el calor, Los PCM experimentan una transición de fase (sólido a líquido o viceversa), Absorber o liberar calor latente para mantener la temperatura deseada.. El hielo seco proporciona condiciones ultrafrías (< –70°C) sublimando, pero es de un solo uso y está regulado como material peligroso.. Los PCM son reutilizables y más fáciles de manejar, haciéndolos ideales para vacunas y productos biológicos que requieren rangos de 2 a 8 °C o –20 °C.

¿Cómo puedo decidir entre envases reutilizables y de un solo uso??

Considere la frecuencia de envío, distancia, Valor del producto y objetivos de sostenibilidad.. Los envases reutilizables tienen costos iniciales más altos, pero ofrecen ahorros a largo plazo a través de múltiples ciclos.. Es ideal para envíos frecuentes y logística de devolución establecida.. Los envases de un solo uso pueden ser más prácticos para envíos únicos o destinos que carecen de infraestructura de retorno..

¿Son los materiales biodegradables lo suficientemente robustos para aplicaciones de cadena de frío??

Sí, cuando se diseña correctamente. Las espumas biodegradables y los plásticos a base de algas marinas están diseñados para proporcionar un aislamiento comparable al del EPS y, al mismo tiempo, se descomponen naturalmente después de su uso.. Sin embargo, debe validar su rendimiento con pruebas térmicas y asegurarse de que se ajusten a los requisitos de peso y tamaño de su producto..

¿Las etiquetas inteligentes y los sensores de IoT aumentan significativamente los costos de embalaje??

Mientras que las etiquetas inteligentes añaden costes, Reducen la pérdida de productos y los problemas de cumplimiento al proporcionar visibilidad en tiempo real.. Muchos transportistas descubren que los ahorros al evitar el deterioro y los retrasos superan el gasto adicional.. Comience con envíos críticos y escale gradualmente.

¿En qué se diferencian las regulaciones para los envíos de hielo seco y de PCM??

El hielo seco está clasificado como material peligroso y debe cumplir con IATA., Regulaciones DOT y ONU. Los envíos requieren un etiquetado especial, ventilación y entrenamiento. Los envíos de PCM generalmente no son peligrosos, pero aun así deben cumplir con los requisitos de validación y registro de temperatura., como la FDA 21 Parte CFR 11.

Resumen & Recomendaciones

El mercado de envases de cadena de frío está experimentando un rápido crecimiento, se prevé que aumente desde Dólar estadounidense 34.28 mil millones en 2024 a USD 89.84 mil millones por 2034. Contenedores aislados, Los paquetes de gel y los materiales avanzados como VIP y PCM son componentes clave de esta expansión.. La dinámica del mercado varía según la región: América del Norte lidera debido a la fuerte demanda farmacéutica, mientras Asia Pacífico se está poniendo al día rápidamente. Las presiones de sostenibilidad están remodelando los envases, con consumidores y reguladores exigiendo materiales reciclables, soluciones reutilizables y biodegradables. Innovaciones como la monitorización habilitada por IA, Los sistemas de embalaje reutilizables y los refrigerantes híbridos dominarán 2025 y más allá.

Pasos de acción:

Evalúe los requisitos de su producto y ruta Elegir materiales de embalaje y refrigerantes adecuados.. Utilice herramientas de decisión para hacer coincidir el rango de temperatura y el tiempo de tránsito.

Invierta en envases inteligentes con sensores y registro de datos para envíos de alto valor para evitar daños y demostrar el cumplimiento.

Transición al embalaje sostenible integrando soluciones reciclables o reutilizables. Evalúe el costo del ciclo de vida y asóciese con proveedores que ofrezcan opciones ecológicas..

Innovaciones piloto como paquetes de PCM y espuma biodegradable en carriles seleccionados antes de ampliarlos; recopilar datos sobre el rendimiento y los comentarios de los clientes.

Manténgase informado sobre las regulaciones con respecto a los impuestos sobre el embalaje y los objetivos de reciclaje para evitar sanciones y satisfacer las expectativas de los clientes..

Acerca de Tempk

En Templ, Diseñamos y fabricamos embalajes inteligentes para la cadena de frío que mantienen sus productos seguros y sus objetivos de sostenibilidad encaminados.. Nuestro portafolio incluye contenedores VIP reutilizables, Packs PCM y cajas isotérmicas ecológicas fabricadas con materiales reciclados. Integramos sensores de IoT y análisis de la nube para brindar visibilidad en tiempo real e informes de cumplimiento.. Con una red global de socios, Entregamos soluciones personalizadas para alimentos., industrias farmacéuticas y biotecnológicas. Estamos comprometidos a reducir los residuos y la huella de carbono a través de un diseño innovador y prácticas de economía circular..

Listo para transformar tu embalaje? Póngase en contacto con Tempk hoy para una consulta gratuita sobre cómo adaptar soluciones de embalaje de cadena de frío sostenibles y confiables a sus necesidades.. Mantengamos sus productos seguros, Tus clientes contentos y nuestro planeta sano..