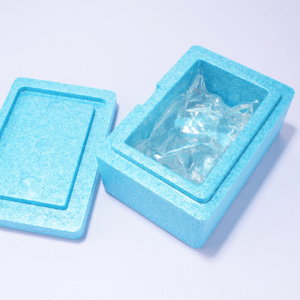

Cajas de envío de cadena de frío Son contenedores especializados diseñados para mantener seguros los productos sensibles a la temperatura durante el tránsito.. Dependen de elementos de aislamiento y refrigeración en lugar de refrigeración motorizada., haciéndolos esenciales para los productos farmacéuticos, biológicos, mariscos y comidas listas para comer. Según un 2025 guía de la industria, Las cajas frías suelen contener 5–25L de vacunas y se clasifican como de corto alcance. (vida mínima en frío de 48 horas a 43°C) o de largo alcance (mínimo 96 horas). con comercio electrónico, Aumentan las entregas de productos biológicos y kits de comida, Se prevé que el mercado mundial de envases de cadena de frío crezca de 33.670 millones de dólares en 2025 a 75.930 millones de dólares 2033. Esta guía explica cómo funcionan estas cajas., cómo elegir el tamaño y el material correctos, y por qué están evolucionando en 2025.

¿Qué define una caja de envío con cadena de frío?? Una explicación clara de pasivo vs.. sistemas activos, Componentes centrales y cómo mantienen la temperatura..

¿Cómo se debe seleccionar el tamaño de caja y el aislamiento correctos?? Una guía paso a paso para medir cargas útiles, elegir aislamiento (EPS, Puro, personaje), y planificación de elementos de refrigeración.

¿Qué materiales y tecnologías mejoran la confiabilidad?? Discusión sobre el aislamiento., refrigerantes, dispositivos de monitoreo, e innovaciones sostenibles.

¿Cómo se ven las tendencias del mercado en 2025? Datos actualizados sobre el crecimiento del mercado., liderazgo regional, y a los conductores les gustan los productos farmacéuticos, comercio electrónico y sostenibilidad.

¿Qué preguntas comunes hace la gente sobre las cajas de cadena de frío?? Respuestas rápidas a consultas de gran volumen sobre materiales, duración y cumplimiento.

¿Qué son las cajas de envío para cadena de frío y cómo funcionan??

Definición y funcionamiento del núcleo: Las cajas de envío de cadena de frío son contenedores aislados diseñados para mantener los productos dentro de un rango de temperatura específico sin refrigeración eléctrica.. Las directrices de adquisición de UNICEF establecen que las cajas frías son dispositivos pasivos revestidos con paquetes de refrigerante.; normalmente sostienen 5–25L y se clasifican como de corto alcance (vida fría ≥48 horas a 43°C) o de largo alcance (vida fría ≥96 horas). Los transportistas de vacunas son más pequeños (0.8–3.4L), siempre que 15–30 horas de la vida fría para los trabajadores sanitarios a pie. En lugar de compresores, Las cajas pasivas dependen del aislamiento. (como poliestireno expandido o paneles aislados al vacío) y paquetes de refrigerante preacondicionados para mantener la temperatura de la carga útil.

Componentes clave explicados: Una caja de cadena de frío consta de varias capas.. El capa aislante—hecho de poliestireno expandido (EPS), espuma de poliuretano o paneles aislados al vacío (VIP)—minimiza la transferencia de calor y maximiza el espacio de carga útil. Refrigerantes o materiales de cambio de fase. (PCM) como paquetes de gel, Las botellas de agua o hielo seco absorben o liberan calor para mantener rangos de temperatura específicos.. A recinto de embalaje elaborado a partir de polietileno de alta densidad, cartón corrugado o carcasas de metal Proporciona integridad estructural y protección.. Dispositivos de control de temperatura (registradores de datos digitales, Sensores IoT o etiquetas RFID) rastrear la temperatura y la humedad internas, enviar alertas en tiempo real cuando ocurren excursiones. Finalmente, mecanismos de cierre y juntas asegurar un sello hermético para evitar fugas térmicas.

Pasivo vs.. Sistemas Activos

Diferencias y casos de uso.: Las cajas pasivas utilizan aislamiento y refrigerantes sin alimentación externa., mientras sistemas activos incorporar compresores y ventiladores alimentados por electricidad o baterías. Los sistemas pasivos son más ligeros, Más económico e ideal para entregas de última milla o áreas sin energía confiable.. Cajas activas, aunque más pesado y costoso, Proporcionar un control preciso de la temperatura para envíos ultralargos o cuando hay disponible una fuente de energía constante.. La elección depende de la duración del envío., rango de temperatura y acceso a la electricidad.

| Componente | Materiales de ejemplo | Función | Lo que significa para ti |

| Aislamiento | EPS, espuma de poliuretano, VIP | Minimiza la transferencia de calor y maximiza el volumen de carga útil. | Un mejor aislamiento prolonga la vida útil del frío y reduce la necesidad de paquetes de refrigerante. |

| Refrigerantes/PCM | paquetes de gel, hielo seco, botellas de agua | Absorbe o libera calor para mantener la temperatura deseada. | Elegir el PCM adecuado garantiza la estabilidad de las vacunas (2–8 ° C) o productos congelados (–20°C a –80°C). |

| Caja de embalaje | Polietileno de alta densidad, cartón corrugado, conchas metálicas | Proporciona protección física y evita el aplastamiento o la contaminación. | Los gabinetes duraderos permiten la reutilización y protegen contenidos de alto valor.. |

| Monitoreo de temperatura | sensores de iot, Etiquetas RFID, registradores de datos | Realiza un seguimiento de las condiciones internas y la ubicación en tiempo real | El monitoreo lo ayuda a detectar desviaciones tempranamente y mantener el cumplimiento. |

| Cierre & Sello | Tapas con pestillo, juntas de silicona | Sella el contenedor para evitar fugas térmicas. | El sellado adecuado protege contra derrames y mantiene la temperatura interna. |

Consejos y sugerencias para los usuarios

Para entregas de corto alcance (p.ej., distribución regional de vacunas): Elija una caja pasiva liviana de 5 a 25 litros con aislamiento de EPS de alta calidad y paquetes de gel. Asegúrese de que los refrigerantes estén acondicionados a una temperatura de 2 a 8 °C durante al menos 24 horas antes de empacar..

Para envíos de largo alcance o ultrafríos: Considere cajas con aislamiento VIP y PCM adaptados a –20 °C o –80 °C. Si los envíos superan las 96 horas, explore soluciones híbridas que combinen PCM con hielo seco o elija una unidad activa.

Para entregas de última milla: Los transportadores de vacunas de menos de 3,5 litros son portátiles y mantienen entre 15 y 30 horas de vida fría, perfectos para los trabajadores de salud comunitarios..

Caso del mundo real: Una ONG médica en una zona rural de África utilizó cajas frías pasivas de largo alcance revestidas con paquetes VIP y PCM para transportar vacunas desde depósitos regionales a clínicas remotas.. Las cajas se mantuvieron entre 2 y 8 °C durante 96 horas sin electricidad., Permitir que los trabajadores de la salud completen las campañas de vacunación antes de regresar para su reacondicionamiento.. La ONG reportó cero desperdicio de vacunas durante esta campaña.

¿Cómo se selecciona el tamaño y el aislamiento adecuados de la caja de envío de la cadena de frío??

Seleccionar el tamaño de caja correcto implica equilibrar el costo, protección y control de temperatura. Las cajas de gran tamaño aumentan los costos de envío debido a los cargos por peso dimensional, mientras que las cajas de tamaño insuficiente corren el riesgo de dañar el producto y controlar mal la temperatura. A continuación se muestra una guía paso a paso basada en 2025 recomendaciones de la industria.

Mida su producto con precisión: Determinar el producto longitud (l), ancho (W.) y altura (H) usando una cinta métrica; registre estas dimensiones en el orden L×W×H. Para formas irregulares, usar cuerda para medir curvas. dejar un pequeño amortiguador de aproximadamente 1⁄8 de pulgada en cada lado para amortiguar.

Cuenta de materiales de aislamiento y refrigeración.: Deje siempre espacio para elementos aislantes y refrigerantes.. Utilice paneles de poliestireno o de vacío según sus necesidades de temperatura.. Planifique elementos de enfriamiento como paquetes de gel o hielo seco para mantener la estabilidad.. Etiquete los paquetes claramente para un manejo seguro.

Materiales de aislamiento y rangos de temperatura

La investigación del Consorcio para el Embalaje de Distribución de la Universidad Estatal de Michigan proporciona directrices sobre los tipos de aislamiento, rangos de temperatura y duración. La siguiente tabla resume estos materiales y lo que significan para su envío..

| Material aislante | Rango de temperatura típico | Duración (aprox.) | Importancia para ti |

| Poliestireno expandido (EPS) | 35 °F a 46°F (1.7 °C a 7,8°C) | Hasta 24 horas | Asequible y ampliamente disponible; adecuado para envíos nocturnos de productos refrigerados. |

| Paneles de poliuretano (Puro) | –4°F a 46°F (–20 °C a 7,8 °C) | Hasta 48 horas | Mayor rendimiento de aislamiento; ideal para envíos de dos días que requieren congelación o refrigeración moderada. |

| Paneles aislados de vacío (VIP) | –60°F a 46°F (–51 °C a 7,8 °C) | Hasta 120 horas | Excepcional resistencia térmica con paredes delgadas, maximizar el espacio de carga útil; ideal para envíos de larga distancia o ultrafríos. |

Factores a considerar

Sensibilidad a la temperatura de los productos: Los productos altamente sensibles como vacunas o productos biológicos requieren rangos de temperatura estrictos. (2–8°C o –20°C). Seleccione el aislamiento y los PCM en consecuencia, y utilizar dispositivos de monitoreo para verificar el cumplimiento.

Duración del tránsito: Los tiempos de tránsito más largos aumentan el riesgo de variaciones de temperatura. Elija aislamiento y refrigerantes que mantengan la estabilidad durante toda la duración.. Para envíos que superan las 96 horas o que requieren –70°C, considere hielo seco combinado con VIP.

Condiciones estacionales: Los envíos de verano pueden necesitar un aislamiento más grueso o paquetes de refrigeración adicionales., mientras que los envíos de invierno pueden necesitar barreras térmicas adicionales para evitar la congelación.

Presupuesto de envío: Equilibrar el costo con el rendimiento es crucial. El aislamiento de alta calidad y los PCM requieren una mayor inversión inicial, pero pueden reducir el deterioro y las devoluciones..

Objetivos de sostenibilidad: Elija opciones ecológicas como aislamiento reciclable o biodegradable para reducir el impacto ambiental..

Consejos prácticos

Guión: Envío de insulina a clínicas rurales: Utilice una caja con revestimiento VIP con paquetes PCM configurados entre 2 y 8 °C; mida los viales de insulina con cuidado y deje espacio para un registrador de temperatura. Elija una caja lo suficientemente grande para acomodar los viales., PCM y amortiguación para evitar sobrecostes.

Guión: Entrega de kits de comida: Utilice aislamiento de EPS o PUR con paquetes de gel para envíos nocturnos. Para los meses de verano, duplique la cantidad de paquetes de gel o agregue un revestimiento de caja reflectante para minimizar la entrada de calor.

Guión: Exportación de mariscos congelados: Utilice una combinación de VIP y hielo seco para mantener de –20 °C a –30 °C. Asegúrese de que la caja permita la ventilación del CO₂ sublimado y siga las normas sobre materiales peligrosos..

Caso real: Una empresa de kits de comida cambió de cajas de cartón corrugado de gran tamaño a contenedores con aislamiento de PUR del tamaño adecuado y colocación optimizada de paquetes de gel.. Este cambio redujo las tarifas de peso dimensional en un 15 %., Disminución de los envíos estropeados en un 8%., y mayor satisfacción del cliente.

¿Qué materiales y tecnologías mejoran la confiabilidad de la cadena de frío??

Aislamiento, Refrigerantes y embalaje exterior

Un embalaje eficaz para la cadena de frío requiere los materiales adecuados. Aislamiento es crucial: revestimientos de transporte aislados y bolsas térmicas Crear barreras que minimicen la transferencia de calor.. Bolsas térmicas son ideales para el almacenamiento de alimentos a corto plazo, mientras sobres aislados proteger pequeñas muestras farmacéuticas durante la entrega de comercio electrónico. Refrigerantes trabajar junto con el aislamiento; Los materiales de cambio de fase se congelan y funden a temperaturas específicas., mantener un ambiente estable, mientras paquetes de gel y hielo seco Proporcionar refrigeración para envíos refrigerados o congelados.. Cajas de cartón corrugado Actúa como embalaje exterior resistente y protege los productos de daños físicos durante la manipulación..

Dispositivos de monitoreo y registro de datos

El control de la temperatura es vital. Registradores de datos digitales, Etiquetas RFID y sensores de iot rastrear la temperatura interna, humedad y ubicación en tiempo real. Las directrices de envío de vacunas de la OMS recomiendan incluir un dispositivo electrónico de temperatura en cada caja de envío para documentar las variaciones de temperatura y proporcionar un registro de cumplimiento.. Estos dispositivos deben medir temperaturas de –20°C a +55°C, con precisión de ±0,5°C, e incluyen funciones de inicio/parada y configuraciones de alarma. Los datos en tiempo real permiten a los equipos de logística actuar rápidamente si las temperaturas se desvían del rango requerido.

Innovaciones sostenibles

La presión ambiental y la responsabilidad corporativa están impulsando las innovaciones en el envasado de la cadena de frío. Las opciones sostenibles incluyen:

Embalajes reciclables y reutilizables: Straits Research señala que los fabricantes están adoptando plásticos y cartón reciclables para reducir los residuos de un solo uso. Empresas como Softbox han introducido el Tempcel ECO, a remitente de paquetes sin plástico Hecho de cartón corrugado que es 100% reciclable..

Materiales biodegradables: Neveras biodegradables hechas de maíz, almidón, La fibra de madera y el algodón se descomponen naturalmente..

Materiales de aislamiento innovadores: Las fibras de cartón postindustriales recicladas pueden ofrecer un fuerte rendimiento térmico y al mismo tiempo ser reciclables.. Se combinan paneles aislados al vacío y materiales de cambio de fase para prolongar la vida útil del frío y reducir el consumo de energía..

Embalaje inteligente e IoT: Los sensores integrados en cajas proporcionan la temperatura en tiempo real, datos de humedad y ubicación. Los dispositivos IoT ayudan a optimizar las rutas, Reduzca el uso de energía y automatice los informes de calidad..

Comparación de PCM y hielo seco

En 2025, los desarrolladores de envases deben elegir entre materiales de cambio de fase (PCM) y hielo seco. Los PCM absorben y liberan calor a temperaturas predefinidas (p.ej., 2–8°C o –20°C) y normalmente son reutilizables. El hielo seco proporciona temperaturas ultrafrías (< –70°C) Adecuado para productos biológicos congelados pero requiere etiquetado de materiales peligrosos..

| Tipo de embalaje | Rango de temperatura típico | Los mejores casos de uso | Notas |

| Materiales de cambio de fase | +2 °C a –20°C | Vacunas, biológicos, reactivos, kits de ensayos clínicos | Reutilizable y no peligroso; múltiples ciclos de reutilización compensan el mayor costo inicial. |

| Hielo seco | < –70°C | Biológicos ultrafríos, CRISPR, células congeladas, muestras de plasma | Efectivo pero de un solo uso; requiere etiquetado peligroso y contenedores ventilados. |

Consejos para el usuario y asesoramiento basado en escenarios

Para empresas preocupadas por la sostenibilidad: Seleccione aislamientos reciclables o biodegradables y reutilice cajas y paquetes de gel.. Comunicar esta elección a los clientes para mejorar la lealtad a la marca..

Para envíos con requisitos regulatorios estrictos: Utilice sistemas PCM validados con registradores de datos y garantice el cumplimiento de las buenas prácticas de distribución (PIB) y regulaciones de la FDA. Los PCM evitan el etiquetado peligroso y simplifican el despacho de aduanas transfronterizo.

Para temperaturas extremadamente bajas: Utilice hielo seco en recipientes ventilados.. Capacite al personal sobre el manejo de materiales peligrosos e incluya documentación y etiquetas apropiadas.. Considere sistemas híbridos que combinen PCM y hielo seco para mantener la estabilidad durante períodos prolongados..

Caso práctico: Una empresa de biotecnología pasó de los paquetes de gel a los contenedores de PCM para cargas útiles de 2 a 8 °C y logró 40 % de reducción de costos después de diez envíos, con excursiones de temperatura cero. Otra empresa de terapia génica adoptó transportistas de hielo seco para cargas útiles ultrafrías y logró un despacho de aduana sin problemas siguiendo el etiquetado de peligros y protocolos validados..

¿Cuáles son las últimas tendencias del mercado y los impulsores de crecimiento de Cajas de envío de cadena de frío en 2025?

El mercado de embalajes para cadena de frío, en particular cajas de envío aisladas, se está expandiendo rápidamente debido a la creciente demanda de productos farmacéuticos., biológicos, kits de comida y comestibles en línea. Los analistas predicen múltiples tendencias de crecimiento:

Crecimiento y tamaño del mercado

Mercado de envases de cadena de frío: Straits Research valora el mercado mundial de envases de cadena de frío en 30.410 millones de dólares en 2024, proyectándolo para crecer desde 33.670 millones de dólares en 2025 a 75.930 millones de dólares 2033, a CAGR del 10,70%. Otro informe pronostica 89.840 millones de dólares por 2034 (11.3 % CAGR).

Mercado de envases aislados: IMARC Group estima el mercado mundial de envases aislados en 15.170 millones de dólares en 2024, con un proyectado 23.840 millones de dólares por 2033 y un CAGR del 4,89% (2025–2033). Las cajas y contenedores representan 45.7 % de este mercado, mientras que Asia Pacífico lidera con más del 35,8% de cuota de mercado.

Perspectivas regionales: América del Norte dominó el mercado de embalaje de cadena de frío en 2024 debido a redes logísticas maduras y estrictas regulaciones de la FDA. Se espera que Asia Pacífico crezca significativamente gracias al aumento de las exportaciones de productos del mar y productos farmacéuticos..

Factores de crecimiento: El crecimiento del mercado está impulsado por la distribución de vacunas, biológicos, terapias genéticas y entrega de medicamentos a domicilio; el pez, segmento de carnes y mariscos dominado en 2024; y el comercio electrónico y los kits de comida requieren cajas aisladas robustas.

Impulsores y tendencias

Farmacéutica y Biotecnología: La creciente cartera de productos biológicos y terapias genéticas exige un estricto control de la temperatura. Las empresas farmacéuticas están invirtiendo en cajas aisladas avanzadas que integran VIP, PCM y enfriamiento activo para envíos de medicamentos GLP 1, Vacunas de ARNm y terapias génicas..

Alimentos y Bebidas: El comercio mundial de alimentos perecederos y la explosión de los servicios de kits de comida requieren cajas de envío confiables. Pez, Los envíos de carne y marisco dominan el mercado., mientras que los kits de comida dependen de envíos de paquetes más pequeños con aislamiento de alto rendimiento..

Comercio electrónico & Directo al consumidor: Las compras de comestibles en línea y las entregas en farmacias están creciendo; los consumidores exigen rapidez, envíos con temperatura controlada. Los EE. UU.. Los sectores farmacéutico y de kits de comida directos al consumidor se están expandiendo., Impulsando la adopción de embalajes aislados..

Sostenibilidad: La sostenibilidad es un factor fundamental. Una encuesta de McKinsey encontró que 43 % de consumidores consideran el impacto ambiental y 74 % de estadounidenses están interesados en envases recargables. Por lo tanto, los productores están invirtiendo en materiales reciclables., cajas biodegradables y reutilizables.

Innovaciones Tecnológicas: sensores de iot, Las etiquetas RFID y los embalajes inteligentes proporcionan visibilidad y análisis de datos en tiempo real, permitiendo la optimización de rutas y la gestión proactiva de riesgos.

Presión regulatoria: Normas como la Ley de Modernización de la Seguridad Alimentaria (FSMA) en los EE.UU.. y las directrices del PIB de la UE exigen embalaje y trazabilidad validados. FSMA 204 mandatos 24trazabilidad horaria para alimentos de alto riesgo, empujando a las empresas a invertir en registradores de datos y embalajes estandarizados.

Desafíos y oportunidades

Sostenibilidad vs.. Actuación: Equilibrar el rendimiento térmico con materiales ecológicos sigue siendo un desafío. Los VIP y PCM proporcionan un aislamiento superior, pero tienen un costo mayor y es posible que no sean fácilmente reciclables.. Se están realizando investigaciones para desarrollar VIP de fibras recicladas y espumas biodegradables..

Expectativas del consumidor: Los clientes esperan cada vez más que los envases sean sostenibles y fáciles de reciclar. Las empresas que adoptan cajas reutilizables o reciclables en la acera pueden generar lealtad a la marca.

Infraestructura en regiones en desarrollo: Los países en desarrollo están invirtiendo en corredores de cadena de frío en lugar de construir redes enteras, Centrándose en exportaciones clave como productos del mar o vacunas.. La aprobación por parte de la India de 27 nuevos proyectos de cadena de frío muestra cómo las inversiones específicas pueden impulsar las exportaciones agroalimentarias.

Preguntas frecuentes (Preguntas frecuentes)

- ¿De qué están hechas las cajas de envío de cadena de frío??

Las cajas de cadena de frío suelen estar hechas de materiales aislantescomo poliestireno expandido (EPS), espuma de poliuretano o paneles aislados al vacío. Incluyen un recinto rígido(cartón corrugado, polietileno de alta densidad o metal) y paquetes de refrigerante como paquetes de gel o materiales de cambio de fase para mantener temperaturas estables. - ¿Cuánto tiempo puede mantener la temperatura una caja de cadena de frío??

Las cajas frías se clasifican por vida fría.. Cajas de corto alcancemantener la temperatura durante un mínimo de 48 horasa 43°C ambiente, mientras cajas de largo alcance mantenerlo durante 96 horas. Los portadores de vacunas proporcionan 15–30 horas de la vida fría. - ¿Cuál es la diferencia entre cajas de envío activas y pasivas??

Cajas pasivasUtilice paquetes de aislamiento y refrigerante sin alimentación externa.. Son ligeros e ideales para envíos de última milla o de corta duración.. Cajas activascontienen unidades de refrigeración motorizadas (compresores y ventiladores) y se utilizan para envíos de larga distancia o ultrafríos que requieren un control preciso. - ¿Qué material aislante debo elegir??

EPS es asequible y adecuado para envíos de hasta 24 horas; Los paneles de poliuretano ofrecen un rendimiento de rango medio de hasta 48 horas.; Los VIP proporcionan el mejor aislamiento para envíos de hasta 120 horas. La elección depende de la duración., rango de temperatura y presupuesto. - ¿Las cajas de envío de la cadena de frío son reciclables??

Muchas cajas modernas utilizan Plásticos reciclables y cartón ondulado.. Las empresas están desarrollando transportistas sin plástico como Tempcell ECO de Softbox, hecho enteramente de cartón corrugado. La reutilización y el reciclaje reducen los residuos y se alinean con los objetivos de sostenibilidad. - ¿Necesito un registrador de temperatura??

Sí. Las directrices de la OMS recomiendan incluir un dispositivo electrónico de temperaturaen cada envío internacional de vacunas para registrar las temperaturas y verificar que no se excedan los límites. Los registradores de datos proporcionan un registro continuo y ayudan a garantizar el cumplimiento de GDP y FSMA 204 regulaciones. - ¿En qué se diferencian los PCM del hielo seco??

Los PCM absorben y liberan calor en puntos de ajuste específicos (p.ej., 2–8°C o –20°C), Son reutilizables y normalmente no son peligrosos.. El hielo seco se sublima a –78,5°C y se utiliza para envíos ultracongelados (< –70°C) pero requiere etiquetas de materiales peligrosos. - ¿Qué normativa afecta a las cajas de cadena de frío en 2025?

En los EE.UU., el Ley de modernización de la seguridad alimentaria (FSMA), Análisis de riesgos y puntos de control críticos (HACCP)y Ley de seguridad de la cadena de suministro de medicamentos (DSCSA)requieren trazabilidad, control de temperatura adecuado y documentación. Las especificaciones PQS y las directrices de buenas prácticas de distribución de la Organización Mundial de la Salud establecen estándares para el transporte de vacunas..

Resumen y recomendaciones

Control de llave: Las cajas de envío de cadena de frío son contenedores con aislamiento pasivo o activo que mantienen rangos de temperatura específicos mediante aislamiento., paquetes de refrigerante y dispositivos de monitoreo. Elegir el tamaño de caja correcto requiere mediciones precisas, espacio para aislamiento y la combinación correcta de EPS, Materiales PUR o VIP, junto con paquetes de gel o hielo seco. Los datos del mercado muestran que los envases de cadena de frío crecerán significativamente, impulsado por productos farmacéuticos, biológicos, Comercio electrónico y embalaje sostenible.. Los consumidores esperan opciones respetuosas con el medio ambiente, y las regulaciones exigen trazabilidad y control de temperatura confiables.

Plan de acción:

Evalúe las necesidades de su producto: Identificar el rango de temperatura, duración y sensibilidad del tránsito. Utilice esta información para seleccionar materiales de aislamiento y refrigerante adecuados..

Tamaño correcto de tu caja: Mida las dimensiones de la carga útil y deje espacio para aislamiento y refrigeración.. Evite cajas de gran tamaño para reducir los costos de envío.

Invertir en seguimiento: Incluya un registrador de datos digital o un sensor de IoT en cada envío para garantizar el cumplimiento y proporcionar trazabilidad..

Elija opciones sostenibles: Opte por materiales reciclables o biodegradables para alinearse con las expectativas del cliente y los objetivos de sostenibilidad corporativa..

Manténgase actualizado sobre las regulaciones: Supervisar las actualizaciones de FSMA, Directrices de DSCSA y OMS para garantizar que su embalaje cumpla con los requisitos legales y evite sanciones.

Acerca de Tempk

TEMPK es un proveedor líder de soluciones de cadena de frío, especializada en cajas isotérmicas, paquetes de gel, Materiales de cambio de fase y dispositivos de control de temperatura.. Nuestro centro de investigación y desarrollo explora continuamente materiales ecológicos y tecnologías de aislamiento avanzadas para ofrecer Productos de cadena de frío reutilizables y reciclables.. Ofrecemos diseños de embalaje personalizados adaptado a la comida, industrias farmacéuticas y biotecnológicas, Garantizar la integridad del producto desde el origen hasta el destino.. Asóciese con Tempk para optimizar sus operaciones de cadena de frío.

Llamado a la acción: Listo para mejorar su cadena de frío? Contáctanos para una consulta y descubre cómo nuestras innovadoras cajas, Los PCM y las soluciones de monitoreo pueden proteger sus productos, reduzca el desperdicio y ayude a su negocio a cumplir 2025 normas de cumplimiento.