Para la logística de alimentos perecederos, desviaciones de temperatura superiores a ±3°C puede desencadenar el crecimiento microbiano (FDA, 2021). Paquetes de hielo seco proporcionarprotección constante a -78,5 °C a través de la sublimación (transición de sólido a gas), eliminar el escurrimiento de líquidos que compromete la integridad del embalaje, lo que los hace indispensables para envíos congelados de alto valor.

Por qué Food Logistics elige bolsas de hielo seco

| Ventaja | Impacto de la industria alimentaria |

|---|---|

| Búfer térmico extendido | Mantiene ≤-18°C durante48-96 horas – excede las ventanas estándar de tránsito congelado |

| Exposición cero a la humedad | Evita que los envases se empapen, formación de cristales de hielo, y daños en la etiqueta |

| Eficiencia espacial | 1kg de hielo seco = 4Lvolumen de enfriamiento (vs hielo de agua de 8 litros) – 50% de ahorro de espacio |

| Cumplimiento normativo | Cumple con los requisitos de almacenamiento congelado de HACCP/FDA con control de temperatura auditable |

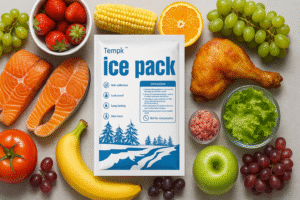

Aplicaciones específicas para alimentos

Perecederos de alto riesgo

→Mariscos: Mantiene -30°C para exportaciones premium de atún/salmón

→Carne/Aves: Evitan “abuso de temperatura” durante entregas en múltiples paradas

→Helado: Evita la separación de grasas & Daños en la textura por descongelación parcial.

Soluciones de última milla

• Frescura de los ingredientes del kit de comida

• Protección del chocolate gourmet

• Transporte de panadería congelada

Innovaciones en bolsas de hielo seco de grado alimenticio de Tempk

✓ Rendimiento de precisión: Mantenimiento <-20° C para96+ horas (validado según ISTA-7D)

✓ Integridad estructural: El laminado de triple capa resiste pinchazos durante el transporte paletizado

✓ Configuración personalizada:

Conclusión: Transformar los márgenes de seguridad alimentaria

Paquetes de hielo seco cortadosTasas de deterioro de los alimentos entre un 19% y un 34% (Datos de la cadena de frío de la IATA 2023) versus alternativas de gel. Combinando la confiabilidad del congelador con un funcionamiento sin humedad, Las soluciones de Tempk potencian:

•Exportadores para acceder a mercados premium

•comercio electrónicopara garantizar “fresco congelado” promesas de entrega

•Procesadores para pasar las auditorías de la FDA/USDA

Mejore la defensa de su cadena de frío con protección diseñada contra hielo seco, donde la integridad del producto se convierte en protección de ganancias.