Envío de hielo seco Soluciones: Garantía de temperatura de precisión para cadenas de suministro globales

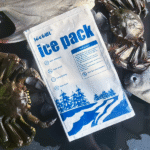

Mantener la integridad del producto durante el transporte no es negociable para los productos farmacéuticos., alimentos perecederos, y materiales de diagnóstico. Paquetes de hielo seco (Co₂ sólido) Diseñados específicamente para contenedores de envío, brindan una protección criogénica incomparable donde falla la refrigeración convencional..

Ventajas críticas de rendimiento de envío

1. Retención criogénica extendida

-

Mantiene -78,5°C durante 72+ horas en embalaje de tránsito estándar

-

Garantiza la conservación del estado congelado durante:

-

Vacunas & biológicos

-

Mariscos de alto valor

-

Materiales de ensayos clínicos

-

2. Cambio de fase sin humedad

-

Sublimación (sólido→gas) previene:

-

Contaminación del producto

-

Necesidades de contención secundaria

-

Compromiso de integridad del embalaje

-

3. Optimización de densidad

-

35% mayor capacidad de carga útil vs.. alternativas de gel

-

Permite configuraciones estables en paletas

-

Reduce los costos de flete a través de la eficiencia volumétrica

Aplicaciones de envío específicas del sector

| Industria | Envíos críticos | Resultado de cumplimiento |

|---|---|---|

| Farmacéutico | Vacunas de ARNm, terapias celulares | 2-8°C/-20°C cumplimiento de la cadena |

| Logística de alimentos | Mariscos de calidad sushi, comidas congeladas | Preservación de la vida útil |

| Diagnóstico | Muestras de laboratorio, reactivos | Integridad del análisis sin compromisos |

Soluciones de envío diseñadas por Tempk

✓ rendimiento térmico validado

-

Protección térmica de 96 horas verificada por terceros

-

Mantenimiento constante a -70 °C en entornos extremos

✓ Diseño adaptable al envío

-

Configuraciones modulares para:

-

Envíos de paquetes (1-5kilos)

-

Cargas paletizadas LTL

-

Contenedores de carga aérea

-

✓ Listo para el cumplimiento normativo

-

Sistemas de ventilación que cumplen con IATA

-

Soporte de documentación para 21 Parte CFR 11

✓ Cadena de frío sostenible

-

Fabricación con compensación de carbono

-

Programa de reciclaje de circuito cerrado

Optimización del protocolo de envío

-

Preacondicionamiento

-

Siempre atempere el embalaje antes de cargarlo.

-

-

Colocación estratégica

-

Colocar las mochilas contra los puntos térmicos débiles

-

-

Cumplimiento de ventilación

-

Mantenga ≥2% del área de ventilación del contenedor para la liberación de gases de CO₂.

-

Por qué Tempk ofrece retorno de la inversión

Ejemplo de caso: El distribuidor mundial de vacunas redujo las variaciones de temperatura en 92% mientras aumenta la densidad de carga útil en 28% a través del sistema de matriz de hielo seco configurable de Tempk.

Conclusión

Las bolsas de hielo seco diseñadas para la logística de envíos resuelven desafíos críticos de control de temperatura a través de un rendimiento criogénico garantizado, operación sin humedad, y optimización del transporte. Las soluciones de Tempk ofrecen protección térmica validada, adaptabilidad del modo de envío, y pleno cumplimiento normativo para productos farmacéuticos., alimento, y envíos de diagnóstico. Para especialistas de la cadena de suministro que requieren garantía de temperatura lista para auditoría desde el origen hasta el destino, La tecnología de hielo seco de Tempk proporciona retornos mensurables a través de una reducción de la pérdida de producto y una economía de transporte optimizada..