Paquetes de hielo secos reutilizables: Qué comprar & Cómo enviar

Si estas buscando paquetes de hielo secos reutilizables, Aquí está la respuesta corta: El hielo seco real no es reutilizable., pero “bolsas de hielo seco” PCM reutilizables a −25 °C Se puede volver a congelar durante cientos de ciclos y enviar sin etiquetas de mercancías peligrosas.. Esta guía muestra qué comprar., cómo dimensionar durante 24 a 96 horas, y cómo cumplir con las normas 2025 reglas: compiladas a partir de nuestros tres borradores internos y manuales de juego de campo.

-

¿Qué significa “bolsas de hielo seco reutilizables”?? Términos claros y cuándo el PCM supera al hielo seco.

-

¿Cuántos paquetes necesitas?? Un método sencillo de dimensionamiento de 24 a 96 h con buffers.

-

¿Cuáles son los 2025 normas? IATA, PUNTO, y puntos de control de USPS que debes cumplir.

-

Cómo empacar bien? Un paso a paso que reduce roturas y reclamaciones.

-

¿Qué opción se adapta a tu carril?? Un selector rápido de comida., farmacéutico, y comercio electrónico.

¿Qué significa “bolsas de hielo seco reutilizables” en 2025?

Respuesta corta: Las "bolsas de hielo seco reutilizables" generalmente se refieren a materiales de cambio de fase de -21 °C a -26 °C. (PCM) placas o ladrillos, no hielo seco real. hielo seco (CO₂ sólido a -78,5°C) se sublima y no se puede volver a congelar; PCM mantiene un punto de ajuste de congelación estable y se recarga en un congelador. Para muchos alimentos congelados y diagnósticos., PCM mantiene ≤ −20°C sin trámites de DG, lo que simplifica la aceptación y reduce los costos.

Por qué te importa: Si su especificación es ≤ −50°C o necesitas un pulldown ultrafrío, usar hielo seco (a menudo con aislamiento VIP). Si su especificación es −25°C a −20°C, paquetes de hielo secos reutilizables (PCM) normalmente son más seguros de enviar, más fácil de manejar, y más barato a largo plazo porque se reutilizan los elementos.

Placas PCM de -25°C para envío de alimentos congelados

como funcionan: El PCM se comporta como una batería térmica: absorbe calor a su temperatura de cambio de fase para mantener la carga útil en un rango reducido. Encontrará placas rígidas y ladrillos flexibles acondicionados entre -25 °C y -26 °C para carriles congelados que no requieren hielo seco.. Resultado: temperatura estable, menos etiquetas, y repetir el uso.

| Opción de enfriamiento | Punto de ajuste | Reutilizable? | Significado para ti |

|---|---|---|---|

| hielo seco (Y 1845) | −78.5 ° C | No | Biológicos ultracongelados y postres ultracongelados; Se aplican las normas de la DG. |

| Paquetes PCM de −25 °C | −21°C a −26°C | Sí | Bolsas de hielo seco reutilizables alternativa para alimentos congelados/diagnóstico; sin etiquetas DG. |

| personaje + hielo seco | banda de −70°C | Sí (recipiente) | Tiempos de espera más prolongados con menos hielo seco; ideal para carriles ultrafríos de 3 a 6 días. |

Consejos prácticos que previenen los calentamientos

-

Condición completamente: Congelar PCM según las especificaciones; Los envases poco congelados tienen un rendimiento inferior.

-

Cobertura de seis lados: Rodee la carga útil para evitar puntos calientes.

-

Llenar los vacíos: El material de relleno apretado evita la convección y agrega horas.

Estuche de campo: Un cargador de kit reemplazó la espuma + Hielo seco con un sistema VIP reutilizable y reducción del hielo seco en aproximadamente un 75 %., lograr estabilidad de 144 a 240 h y menos eventos de formación de hielo durante los retrasos.

Cuántos paquetes de hielo secos reutilizables ¿Necesitas entre 24 y 72 h??

Idea central: Planificar por carga de calor, no conjeturas. El hielo seco comúnmente se sublima 5–10 lb por 24h en una hielera; para −21 °C a −25 °C PCM, calcular energía (ancho×alto), convertir a capacidad latente, y agregar un buffer. Empezar aquí, luego prueba de carril.

Dosis de referencia (estadio de béisbol):

-

48 H, buen trazador de líneas, hielo seco: ~19 lb incluido el margen.

-

48 H, buen trazador de líneas, −21 ° C PCM: ~1,25–1,7 kg de PCM para una carga útil de 5 kg; Verificar con una prueba de carril.

Un mini selector para paquetes de hielo secos reutilizables

-

≤ objetivo de −50°C: Usar VIP + hielo seco; declarar kg netos y aplicar etiqueta Clase 9.

-

Objetivo de −25 °C a −20 °C: Usar paquetes de hielo secos reutilizables (−25°C PCM) en seis lados; agregar 25% buffer.

-

Kits mixtos: Híbrido (Lados PCM + adorno de hielo seco pequeño) y calificar el perfil.

Hielo seco vs. −25°C PCM: ¿Cuál es mejor para tu carril??

Final: Use hielo seco para descenso ultrafrío o rápido. Utilice PCM a −25 °C cuando tu especificación está congelada (≤ −20°C) y quieres activos reutilizables, cumplimiento más simple, y menor costo total por envío.

| Aspecto | Hielo seco (Co₂) | −25°C PCM (“bolsas de hielo seco reutilizables”) | Significado para ti |

|---|---|---|---|

| Temperatura | ~ −78.5 ° C | Punto de ajuste de −25 °C | Adaptarse a las necesidades del producto; Evite congelar demasiado los alimentos con PCM.. |

| Reutilizabilidad | De uso único | De uso múltiple | La reutilización reduce costes y residuos. |

| Cumplimiento | Y 1845, Clase9 | Normalmente no pertenecientes a la Dirección General | PCM evita etiquetas/documentos de materiales peligrosos. |

| tiempo de espera (con caja derecha) | 24–72h típico | 24–96h típico | VIP mejora cualquiera de los dos enfoques. |

¿Puedes enviar? paquetes de hielo secos reutilizables y cumplir en 2025?

Sí, si sigues las reglas actuales.. Para Envíos aéreos con hielo seco., utilizar IATA PI954: envasado ventilado, Diamante clase 9 ≥100 mm, “UN1845” y masa neta de hielo seco (kilos) en el cartón exterior. A NOSOTROS. 49 CFR§173.217 espejos ventilando/marcando, y Aire de USPS limita los paquetes a ≤5lb hielo seco. Pasajeros puede llevar ≤2.5 kg con aprobación de la aerolínea en un paquete ventilado. Usando paquetes de hielo secos reutilizables (PCM) evita la mayoría de los pasos DG para rangos congelados.

Lista de verificación a prueba de fallos: Patio de ventilación abierto; Etiqueta de clase9 (sin escritura dentro del diamante); “Dióxido de hielo seco/carbono, Sólido," Y 1845, kg netos en la caja; variaciones de aceptación aclaradas con el transportista.

Cómo empacar paquetes de hielo secos reutilizables envío (paso)

Meta: Mantenga la temperatura dentro del rango mientras minimiza las reclamaciones.

-

Condición previa

-

Ruta del hielo seco: producto de etapa ≤ −20°C; revestimiento preenfriado.

-

ruta PCM: congelar paquetes según las especificaciones; confirmar la temperatura central; limpiar la escarcha.

-

-

construir la base

-

hielo seco: pellets/losas con una almohadilla de malla para el flujo de gas.

-

PCM: paneles en seis caras para una isoterma uniforme.

-

-

Cargar la carga útil

-

Artículos de bolsa; añadir material de estiba; Coloque el registrador en el núcleo..

-

-

Rematar & cerca

-

hielo seco: agregar capa superior; cinta en las costuras pero mantenga un camino de ventilación.

-

PCM: cerrar bien; Evite los sellos herméticos.

-

-

Etiqueta & manos libres

-

hielo seco: Etiqueta de clase9, Y 1845, Kg neto; agregar notas de AWB.

-

solo PCM: documentos estándar; sin etiqueta de DG.

-

Consejos prácticos para sus escenarios

-

kits de comida congelada (48 H, verano): Utilice PCM a −25 °C en seis lados, buen EPS, y un espaciador kraft encima del producto; agregar 25% buffer de tiempo.

-

Biológicos (−70°C, 3–5 días): Cargador VIP + hielo seco; declarar kg netos; Variaciones del portador de precarga.

-

Aperitivos congelados D2C: Bolsas de hielo seco reutilizables + Programa de devolución QR; elimine los recargos por materiales peligrosos y simplifique los scripts CS.

ejemplo real: Una marca de productos del mar cambió de hielo seco de 12 a 15 libras a PCM de -21 °C + personaje. Los reembolsos cayeron y los defectos de la DG desaparecieron; 72 h celebró las pruebas de verano con un 25% margen.

2025 tendencias que dan forma paquetes de hielo secos reutilizables decisiones

Instantánea de tendencia (2025): Las aerolíneas reiteran la aceptación del hielo seco (100 mm etiqueta Clase 9, masa neta declarada), mientras cargadores VIP reutilizables y PCM bajo cero más potentes expandir, Reducir la formación de hielo y la complejidad de DG en muchos carriles.. El mercado de hielo seco sigue creciendo (previsión ~USD1.66B en 2025 a ~USD 2,73 mil millones por 2032), pero los sistemas reutilizables ganan participación en la alimentación y la atención sanitaria.

Último progreso de un vistazo

-

Menos hielo seco, más reutilización: Los paquetes VIP reducen la masa de hielo seco en aproximadamente un 75 % y se mantienen entre 120 y 240 h..

-

PCM de −25 °C convencionales: No Director General “paquetes de hielo secos reutilizables“habilitar carriles congelados con transferencias más simples.

-

Validación estandarizada: Los perfiles ISTA7E ayudan a los compradores a comparar manzanas con manzanas entre proveedores.

Insight del mercado: Espere un conjunto de herramientas híbrido: hielo seco para ultrafrío; paquetes de hielo secos reutilizables (PCM) para −25°C a −20°C donde la reutilización reduce el costo y el riesgo.

Preguntas frecuentes

Q1: ¿Las “bolsas de hielo seco son reutilizables” en realidad hielo seco??

No. El hielo seco se sublima y no se puede reutilizar. Los productos reutilizables son Paquetes PCM de −25 °C se vuelve a congelar para uso repetido.

Q2: ¿Cuánto durará el hielo seco??

Plan 5–10 lb por 24h Dependiendo del aislamiento y el calor ambiental; validar en tu ruta.

Q3: ¿Los paquetes de PCM requieren etiquetas de materiales peligrosos??

Típicamente No. Esa es una ventaja principal de paquetes de hielo secos reutilizables para carriles congelados.

Q4: ¿Pueden los pasajeros volar con hielo seco??

Sí-≤2.5 kg (5.5 lb) por pasajero con aprobación de la aerolínea, contenedor ventilado, y etiquetas.

Q5: ¿Cuál es la forma más rápida de dimensionar un paquete PCM de 48 h??

Calcular la fuga de calor (W.) × horas, dividir por PCM Wh/kg, agregar 25–50% buffer, luego prueba de cámara a ISTA7E.

Resumen & recomendaciones

Puntos clave: Bolsas de hielo seco reutilizables normalmente significa −25°C PCM puedes volver a congelar; tamaño por carga de calor; y seguir 2025 IATA/DOT/USPS reglas siempre que uses hielo seco real. Usar VIP + hielo seco para ultrafrío; Utilice PCM para la mayoría de los alimentos congelados y diagnósticos para simplificar y reutilizar los activos..

Siguientes pasos:

-

Elige tu objetivo de carril (≤ −70°C frente a. −25°C a −20°C).

-

Ejecute una prueba de empaquetamiento en el peor de los casos durante 24 a 72 horas con un registrador.

-

Documentar etiquetas/SOP y crear un plan de rotación de PCM.

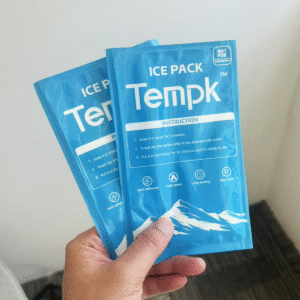

CTA: Quiere un pack-out específico para el carril? Reserve una consulta de 20 minutos con Tempk.

Acerca de Tempk

Somos un equipo de soluciones de cadena de frío centrado en prácticas, paquetes respaldados por pruebas. Diseñamos, calificar, y suministro placas PCM reutilizables y Cargadores VIP que corta masa de hielo seco, reducir el flete, y simplificar el cumplimiento. Dos ventajas que gustan a los clientes: kits validados por carril con SOP claros y plantillas de etiquetas, y menor costo total por envío, sin sorpresas en los centros.