Pellets de hielo seco y Hojas de paquete de hielo seco están en el corazón del transporte marítimo congelado moderno. Estos agentes ultrafríos aseguran las vacunas, carnes, y las muestras biológicas viajan de forma segura desde la fábrica hasta el destino. En 2025 El mercado del hielo seco enfrenta presiones de oferta y demandas de sostenibilidad, pero continúa creciendo rápidamente.; El consumo mundial está aumentando alrededor 5 % al año, mientras que el suministro de CO₂ aumenta sólo 0.5 %, provocando aumentos periódicos de precios. Esta guía explica cómo funcionan los gránulos y las hojas de hielo seco., cómo elegir el formato adecuado para sus necesidades, y cómo manipularlos y almacenarlos de forma segura. Aprenderás las mejores prácticas, Consideraciones de costos, y tecnologías emergentes como los sistemas híbridos, sensores inteligentes, y producción de hielo seco capturado con carbono, todo utilizando un lenguaje claro y ejemplos prácticos..

¿Qué diferencia a los gránulos de hielo seco y a las láminas de hielo seco?? Conozca la ciencia detrás de los pellets y las láminas y cómo cada formato afecta la velocidad de enfriamiento, duración y manejo.

¿Cuándo debería elegir pellets frente a láminas empaquetadas?? Descubra directrices basadas en escenarios para productos farmacéuticos, carne, transporte de biotecnología y alimentos.

¿Cuánto hielo seco debes usar?? Utilice fórmulas y tablas prácticas para calcular el peso de los pellets o el recuento de hojas en función del tiempo de tránsito y el volumen del contenedor..

¿Qué normas reglamentarias y de seguridad se aplican en 2025? Comprender las etiquetas de peligro, Y 1845 calificación, Requisitos de ventilación y límites IATA..

¿Qué innovaciones están dando forma a la industria del hielo seco?? Explorar 2025 tendencias como la captura de CO₂, peletizadores automatizados, hojas reutilizables, Sistemas PCM híbridos y sensores inteligentes..

¿Cómo se pueden optimizar los costes y la sostenibilidad?? Aprende estrategias para estirar cada kilogramo de hielo seco, reducir los residuos y adoptar alternativas más ecológicas.

Comprensión de los gránulos de hielo seco y las hojas de embalaje

El hielo seco es dióxido de carbono sólido (Co₂). A –78,5 °C (–109 ° F) hace más frio que el agua helada, y se sublima (pasa directamente de sólido a gas) sin dejar líquido. Dos formatos principales dominan la logística de la cadena de frío: pellets y hojas de embalaje.

¿Qué son los gránulos de hielo seco??

Los gránulos de hielo seco son pequeños trozos cilíndricos de CO₂ sólido. Cada gránulo suele tener entre 3 y 16 mm de diámetro y una superficie elevada en relación con su masa.. Esta geometría permite una rápida absorción del calor y un enfriamiento intenso.. Cuando se coloca dentro de cajas aisladas, Los pellets crean una rápida caída de temperatura a –78,5 °C., congelar la carga útil y evitar la descongelación. Los pellets se utilizan a menudo en el envío de productos farmacéuticos., Transporte de muestras biotecnológicas y limpieza industrial gracias a su rápido enfriamiento y control preciso de la temperatura.. La siguiente tabla contrasta los pellets con otros métodos de enfriamiento.:

| Método de enfriamiento | Rango de temperatura | Duración | Aplicación ideal | Beneficio práctico |

| Pellets de hielo seco | –78,5 ºC | 24–48 horas | Envío ultra frío | Sin residuos líquidos; enfriamiento rápido |

| Paquetes de hielo seco | –40 °C a –60 °C | 36–72 horas | Envíos a media temperatura | Reutilizable, sublimación más lenta |

| Paquetes de gel | 0 °C a –20 °C | 12–24 horas | Transporte de alimentos perecederos | Económico; reutilizable |

| Materiales de cambio de fase (PCM) | Personalizable | 24–96 horas | Kits biofarmacéuticos o de diagnóstico | Bandas de temperatura estables |

Los pellets son de un solo uso y requieren equipo de protección personal. (PPE) como guantes y gafas aislantes porque el contacto directo puede provocar congelación. Su rápida sublimación también significa que necesita una ventilación adecuada para evitar la acumulación de CO₂.. En tránsito, suelen durar entre 24 y 48 horas, según la calidad del aislamiento y la temperatura externa..

¿Qué son las láminas de hielo seco??

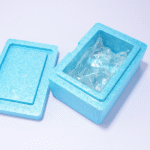

Hojas de hielo seco (También llamadas capas de hielo seco.) Son paneles flexibles llenos de bolitas de hielo seco o nieve de CO₂ recubiertas de plástico duradero o tela tejida.. Están diseñados para proporcionar estabilidad, enfriamiento extendido hasta 72 horas. A diferencia de los pellets sueltos, Las láminas minimizan la liberación de vapor y se pueden reutilizar varias veces., Reducir los residuos y los riesgos de manipulación.. Las hojas de carga a menudo incorporan bolsillos o celdas que albergan pellets.; Cuando se congele, Forman un panel rígido que encaja perfectamente alrededor o encima de su producto., evitando el movimiento y asegurando una temperatura uniforme.

Las ventajas clave de las hojas de paquete incluyen:

Duración de enfriamiento extendida – Muchas hojas de embalaje mantienen una temperatura estable hasta 72 horas.

Sin riesgo de contacto directo – Los pellets están sellados en el interior., reducir la exposición al CO₂ y el riesgo de congelación.

Diseño reutilizable – Las hojas de alta calidad se pueden volver a congelar y reutilizar., Reducción de residuos y costes de embalaje..

Tamaños personalizables – Las hojas están disponibles en varios recuentos de celdas. (p.ej., 24celúla, 48celúla) y se puede cortar para adaptarse a diferentes contenedores.

Porque las hojas empaquetadas se enfrían gradualmente, Son muy adecuados para envíos a temperatura media, como carne congelada., mariscos, y muestras biotecnológicas que requieren condiciones de –20 °C a –60 °C. Las empresas suelen combinar láminas de embalaje con pellets para lograr un enfriamiento rápido y sostenido..

Elegir entre pellets y hojas de embalaje

La elección entre gránulos de hielo seco y hojas de embalaje depende de la sensibilidad a la temperatura de su producto., duración del envío, y requisitos de manejo. Utilice las siguientes pautas:

Ultrafrío o congelación repentina: Elija pellets

Productos farmacéuticos & Vacunas – Muchos productos biológicos requieren –70 °C o menos. Los pellets ofrecen caídas inmediatas de temperatura.; Los gránulos de alta densidad en envases aislados al vacío pueden mantener las vacunas estables durante 48 horas, reducir el riesgo de deterioro mediante 40 %.

Muestras criogénicas – Las muestras de laboratorio y biotecnológicas a menudo necesitan un almacenamiento ultrafrío.. Los pellets proporcionan un enfriamiento preciso y ajustes de dosis sencillos..

Limpieza Industrial – La limpieza criogénica utiliza pellets para la limpieza de maquinaria sin residuos de agua.. La sublimación rápida es esencial.

Tránsito Medio Frío o Extendido: Elija hojas de paquete

Carne y mariscos – Las láminas de hielo seco son ideales para el envío de carne a larga distancia. Mantienen la carne congelada a –29 °C (–20 °F) sin producir agua de deshielo, preservar la calidad del producto. Con capas adecuadas, Mantienen condiciones de congelación durante 24 a 48 horas..

Alimentos especiales – Postres helados, Los chocolates gourmet o los kits de comida que requieren de –20 °C a –40 °C se benefician de la liberación controlada de CO₂.. El diseño sellado evita la contaminación cruzada..

Logística Reutilizable – Para envíos recurrentes o sistemas de circuito cerrado, Las hojas de embalaje minimizan los riesgos de desperdicio y manipulación.. Su vida útil prolongada compensa el mayor costo inicial..

Refrigeración híbrida: Combina ambos

En 2025 Muchos transportistas están adoptando sistemas de enfriamiento híbridos que combinan pellets y láminas de embalaje con materiales de cambio de fase. (PCM). Este enfoque proporciona un enfriamiento rápido para evitar el sobreenfriamiento., luego temperaturas sostenidas para un tránsito prolongado, y reduce el uso general de CO₂. Una configuración híbrida típica podría colocar gránulos en la parte inferior para la congelación repentina inicial., Paquete de hojas encima del producto., y paquetes PCM para mantener bandas de temperatura específicas. Esta combinación puede extender los tiempos de espera al 25 % reduciendo al mismo tiempo el consumo de hielo seco 18 %.

Fórmulas de tamaño

Para determinar cuánto hielo seco necesitas, considerar la duración del envío, volumen de carga útil, y aislamiento de contenedores. Para pellets, Una regla común es asignar de 5 a 10 kg de hielo seco por período de 24 horas por 100 litros de volumen aislado. Para hojas de paquete, Una hoja de 24 celdas normalmente proporciona entre 8 y 12 horas de enfriamiento.; varias hojas pueden extender la duración hasta 72 horas. Por ejemplo:

| Volumen del contenedor | Peso recomendado del pellet | Cantidad de hojas | Tiempo de espera esperado |

| 10 l | 0.75–1 kilogramo | 1 hoja | ≈ 12 horas |

| 20 l | 1.5–2,0 kilogramos | 2 hojas | ≈ 24 horas |

| 30 l | 2.5–3,0 kilogramos | 3–4 hojas | ≈ 36 horas |

| 40 l | 4.0–5,0 kilogramos | 4–5 hojas | ≈ 48–72 horas |

Siempre enfríe previamente su contenedor aislado y llene los espacios vacíos con material de estiba para minimizar la transferencia de calor.. El preacondicionamiento reduce la tasa de sublimación hasta en 15 %.

Cómo empacar gránulos de hielo seco & Empaque las sábanas de forma segura

1. Preparación & Hidratación

Si utiliza capas de hielo seco reutilizables, Remójelos en agua antes de congelarlos para que las células se activen correctamente.. Congele las hojas en posición horizontal para lograr una forma uniforme..

2. Contenedores de preenfriamiento

Enfríe previamente su caja o hielera con bolsas de hielo o colocándola en el congelador durante varias horas.. Esto reduce el choque térmico inicial y ralentiza la sublimación..

3. Técnica de capas

Capa inferior – Coloque los pellets o una hoja de embalaje en el fondo del contenedor aislado.. Los pellets proporcionan un enfriamiento rápido; Las hojas garantizan una liberación constante..

Capa de búfer – Utiliza cartón, plástico corrugado o una fina capa de espuma para separar el hielo seco del producto. Esto evita el contacto directo y las quemaduras por congelación..

Colocación del producto – Colocar el producto en su interior., llenar espacios vacíos con materiales acolchados como plástico de burbujas o inserciones de espuma. Minimizar los huecos reduce las bolsas de aire caliente.

Capa superior – Agregue láminas o gránulos adicionales sobre el producto para mantener una distribución uniforme de la temperatura.. Fregaderos de aire frío, por lo que tener hielo seco en la parte superior garantiza un enfriamiento hacia abajo.

Ventilación – Asegúrese de que el contenedor tenga orificios de ventilación o aislamiento transpirable.. Nunca selle el hielo seco en una caja hermética.; La sublimación de CO₂ puede generar presión y romper paquetes..

4. Embalaje & Etiquetado

Etiquete claramente los paquetes con "Hielo seco" o "Dióxido de carbono"., Sólido,” el número UN1845, y el peso neto del hielo seco.

Colocar una clase 9 etiqueta de materiales peligrosos si se envía por vía aérea.

Cumplir con los límites de la IATA: 2.5 kg por bulto en aviones de pasajeros y hasta 200 kg en vuelos de carga.

5. Manejo & PPE

Use guantes y gafas aislantes al tocar pellets o láminas.. Las heladas de CO₂ pueden provocar quemaduras graves en la piel. No ingiera hielo seco ni lo selle en un recipiente hermético.; La acumulación de gas puede provocar explosiones.. Almacene siempre el hielo seco en áreas ventiladas y mantenga el ambiente de almacenamiento entre –80 °C y –20 °C. Rotar el inventario usando el primero en entrar, Sistema de primero en salir para evitar el uso de versiones anteriores., acciones sublimadas.

Consideraciones de costos & Sostenibilidad

Los costos del hielo seco varían ampliamente debido a las limitaciones de suministro. Dado que el crecimiento de la oferta de CO₂ (0.5 % por año) va por detrás del crecimiento de la demanda (≈5 % por año), Los precios al contado pueden aumentar hasta 300 % durante la escasez. Además, El mercado mundial de hielo seco estaba valorado en $1.54 mil millones en 2024 y se prevé que alcance $2.73 mil millones por 2032 (7.4 % Tocón). Para gestionar los costos:

Optimizar el embalaje – Utilice contenedores del tamaño adecuado y aislamiento de alto rendimiento para reducir la sublimación y reducir sus requisitos de hielo seco..

Mezclar formatos de enfriamiento – Paquetes híbridos que utilizan pellets, Las láminas y los PCM pueden reducir el uso de hielo seco al 18 % mientras mejora la consistencia de la temperatura.

Planificar adquisiciones – Asegurar contratos de suministro a largo plazo o unidades peletizadoras locales para evitar la volatilidad de los precios..

Explora las fuentes de Bio CO₂ – Muchos proveedores ahora capturan CO₂ de la fermentación del bioetanol o de procesos industriales., creando un bucle circular. Elegir proveedores que utilicen CO₂ renovable ayuda a reducir su huella de carbono y respalda prácticas sostenibles.

Innovaciones de sostenibilidad

Los actores modernos de la cadena de frío están adoptando medidas ecológicas:

Captura de CO₂ & Recuperación – La captura de CO₂ a partir de bioetanol o de fuentes industriales reduce la dependencia del CO₂ de origen fósil y respalda las economías circulares..

Hojas de hielo seco reutilizables – Las hojas duraderas se pueden volver a congelar varias veces, Reducir el desperdicio y el costo..

Sensores inteligentes & Seguimiento de IoT – Monitoreo en tiempo real de los niveles de CO₂, La temperatura y las tasas de sublimación ayudan a ajustar el enfriamiento y evitar el desperdicio..

Paquetes híbridos – La integración de PCM y revestimientos aislados reduce el uso de CO₂ y la huella de carbono.

2025 Tendencias de la industria & Ideas del mercado

El panorama de la cadena de frío está evolucionando rápidamente. Las tendencias clave incluyen:

Dinámica del mercado & Presiones de suministro

El mercado de hielo seco enfrenta estrés en la oferta debido a la disponibilidad limitada de CO₂ y la alta demanda. Los precios al contado se han disparado hasta 300 % durante las crisis de suministro. Los fabricantes están respondiendo construyendo centros de producción localizados y captura de CO₂ in situ para reducir las pérdidas en el transporte.. Los transportistas están diversificando sus estrategias de enfriamiento (mezclando hielo seco con PCM y un mejor aislamiento) para estirar el suministro..

Formato & Consideraciones de rendimiento

Seleccionar el formato correcto (bolita, hoja, bloquear o cortar) afecta dramáticamente el rendimiento. Los bloques grandes se subliman lentamente para envíos largos; Los pellets proporcionan un enfriamiento rápido pero se vaporizan más rápido.; las rodajas finas ofrecen equilibrio y encajan perfectamente en el envase. Diseño adecuado del contenedor: aislamiento de alto rendimiento, minimizando el espacio vacío, y preacondicionamiento: puede reducir la sublimación a 3-8 % por día. Errores como dejar huecos calientes o una ventilación deficiente pueden comprometer la integridad del producto..

Tendencias específicas del sector

Alimento & Procesamiento de carne – Los gránulos y las rodajas más finos permiten un enfriamiento rápido en las líneas de procesamiento, mientras que los bloques siguen siendo el formato preferido para el transporte a granel. Las cajas mejor aisladas extienden los tiempos de espera y minimizan la sublimación.

Farmacéutico & laboratorios – Las nuevas tecnologías de barrera ralentizan la liberación de gas CO₂ para evitar el sobreenfriamiento, y el monitoreo en tiempo real ayuda a proteger las cargas útiles. Los transportistas PCM reutilizables reducen el consumo de hielo seco.

Industrial & Limpieza – Los contratistas de limpieza criogénica obtienen contratos de suministro a largo plazo e invierten en peletización local para evitar perder prioridad durante la escasez..

Innovación & Direcciones futuras

Peletizadores automatizados – Los peletizadores modernos producen pellets de tamaño constante, reducir el desperdicio y mejorar la eficiencia de enfriamiento.

Hojas de hielo seco reutilizables – Las nuevas láminas combinan la flexibilidad de los paquetes con el rápido enfriamiento de los pellets..

Sensores de monitoreo inteligentes – Los dispositivos IoT rastrean los niveles de CO₂ y las tasas de sublimación en tiempo real para optimizar el reabastecimiento.

Embalaje de base biológica – La integración de materiales biológicos o reciclables en los envases se alinea con los objetivos de sostenibilidad.

Sistemas híbridos – La combinación de hielo seco con PCM y aislamiento inteligente reduce la huella de carbono y los costos..

Escenarios prácticos & Consejos para el usuario

Guión 1: Envío de carne congelada al extranjero

Desafío: Un exportador de carne necesita enviar 20 kg de carne vacuna de California a Japón, un tránsito de 48 horas. La carga debe permanecer por debajo de –18 °C..

Solución: Utilice cuatro láminas de hielo seco de 24 celdas colocadas encima y debajo de la carne.. Enfríe previamente el contenedor de EPS y cúbralo con un paquete de PCM a –21 °C. Agregar 3 kg de bolitas de hielo seco encima para lograr una congelación rápida. Asegúrese de que las rejillas de ventilación permitan que escape el gas CO₂. Este paquete proporciona 48 horas de temperatura estable en pruebas, sin descongelar y 60 % Reducción de residuos de envases en comparación con los pellets de un solo uso..

Guión 2: Distribución de vacunas durante una crisis de oferta

Desafío: Una empresa farmacéutica debe entregar vacunas de ARNm que requieran condiciones de -70 °C. Por la escasez de CO₂, el suministro de pellets es limitado.

Solución: Adopte refrigeración híbrida: 50 % del volumen del contenedor utiliza gránulos de hielo seco para un enfriamiento rápido; el restante 50 % utiliza PCM ajustados a –70 °C y hojas de embalaje reutilizables. Los sensores de monitoreo en tiempo real rastrean la temperatura y la sublimación. Este método reduce el uso de pellets en 25 % manteniendo el cumplimiento normativo. Los contratos a largo plazo con productores locales de pellets garantizan un suministro prioritario durante los picos.

Guión 3: Entrega de helados artesanales

Desafío: Una pequeña empresa envía helados artesanales a través de estados para 24 horas. La satisfacción del cliente depende de la textura del producto y del mínimo desperdicio de embalaje..

Solución: Utilice capas de hielo seco reutilizables combinadas con un único paquete PCM a –18 °C. Preacondicionar el sobre aislado. Porque el helado sólo necesita –15 °C para mantenerse firme, Las hojas empaquetadas proporcionan un enfriamiento constante sin congelarse demasiado., y no hay agua de deshielo desordenada. Los clientes devolvieron las hojas en un sobre proporcionado para su reutilización., reforzar los valores de sostenibilidad.

Tabla de referencia rápida: Selección de formato

| Tipo de envío | Formato recomendado | Razón | Consejo adicional |

| Vacunas & Biológicos | Pellets de alta densidad o híbridos (bandear + PCM) | Alcanza –70 °C rápidamente y se mantiene durante 48 horas | Utilice registradores de datos para monitorear; ventilar los contenedores adecuadamente. |

| Carne & Mariscos | Hojas de hielo seco reutilizables | Garantiza –29 °C a –40 °C sin contacto directo | Hojas de capas arriba y abajo; Rellenar huecos para reducir la sublimación.. |

| Comercio electrónico de postres congelados | Hojas de paquete + PCM | Proporciona refrigeración controlada con un riesgo mínimo de congelación. | Anime a los clientes a devolver las hojas para reutilizarlas.. |

| Limpieza Industrial & Explosión | bolitas pequeñas | Proporcionar una sublimación rápida y una limpieza eficiente. | Asegurar el suministro de pellets a largo plazo para evitar la escasez. |

Seguridad & Cumplimiento normativo: 2025 Requisitos

El hielo seco se clasifica como un material peligroso (Clase 9). El cumplimiento garantiza la seguridad de los trabajadores y evita retrasos en el envío.

Número de la ONU & Etiqueta: Marque los paquetes con “hielo seco” o “dióxido de carbono”., Sólido,” incluir la ONU 1845 número, y especificar peso neto.

Etiquetas de peligro: Clase de afijo 9 Etiquetas de riesgo; Esto es obligatorio para todos los modos de transporte..

Límites de peso: Respete los límites de la IATA: 2,5 kg de hielo seco para aviones de pasajeros y hasta 200 kg en vuelos de carga.

Requisitos de ventilación: El embalaje debe permitir que escape el gas CO₂ para evitar la acumulación de presión..

Documentación: Incluir un conocimiento de embarque o una hoja de datos de seguridad si así lo requiere el transportista..

PPE & Capacitación: Capacite al personal para manipular hielo seco usando guantes y gafas aislantes.. Proporcionar procedimientos de emergencia para la exposición al CO₂., congelación o rotura del contenedor.

Preguntas frecuentes

¿Cuánto duran los gránulos de hielo seco??

Los gránulos suelen durar entre 24 y 48 horas., dependiendo del tamaño del pellet, aislamiento del contenedor y temperatura ambiente. El acondicionamiento previo adecuado y la minimización del espacio vacío pueden prolongar la duración..

¿Pueden las capas de hielo seco reemplazar las bolsas de gel??

Sí. Las capas de hielo seco mantienen temperaturas más frías (–29 °C a –40 °C) durante 24 a 48 horas y no dejar agua derretida, mientras que los paquetes de gel sólo mantienen las temperaturas cercanas 0 °C durante 12 a 24 horas. Utilice sábanas cuando necesite condiciones bajo cero..

¿Los gránulos de hielo seco son seguros para el envío de alimentos??

El hielo seco es seguro si se manipula correctamente. Evite siempre el contacto directo con los alimentos colocando una capa amortiguadora o utilizando láminas selladas. Ventile los contenedores para evitar la acumulación de CO₂ y etiquete los paquetes correctamente.

¿Cuál es la huella de carbono del hielo seco??

El hielo seco tradicional se produce a partir de CO₂ fósil. Sin embargo, Muchos proveedores ahora capturan CO₂ del bioetanol y de los procesos industriales., reducir las emisiones de gases de efecto invernadero. La elección de estos proveedores apoya las economías circulares.

¿Cómo calculo la cantidad de hielo seco necesaria??

Utilice entre 5 y 10 kg de gránulos de hielo seco por 24 horas por 100 L de volumen del contenedor. Para hojas de paquete, estimar una hoja de 24 celdas por 12 Horas de enfriamiento; ajustar según la duración del tránsito.

¿Cuáles son las alternativas al hielo seco??

Las alternativas incluyen paquetes de gel., PCM y refrigeración mecánica. Los paquetes de gel no son peligrosos y son reutilizables, pero solo mantienen 0 °C a –20 °C hasta 24 horas. Los PCM ofrecen rangos de temperatura personalizables y duración extendida, A menudo se utiliza en combinación con hielo seco.. Los contenedores activos proporcionan refrigeración pero son costosos y requieren energía..

¿Puedo reutilizar las láminas de hielo seco??

Sí. Las hojas de embalaje de alta calidad se pueden volver a congelar y reutilizar varias veces., reduciendo el desperdicio. Inspeccione si hay fugas o daños antes de reutilizarlo y siga las mismas pautas de seguridad..

¿Por qué es importante ventilar??

Mientras el hielo seco se sublima, El gas CO₂ se expande significativamente. Sin ventilación, La presión puede acumularse y romper los contenedores.. Asegúrese siempre de tener orificios de ventilación o aislamiento transpirable..

Resumen & Recomendaciones

Los gránulos de hielo seco y las láminas de hielo seco son herramientas indispensables para el envío ultrafrío. Los pellets proporcionan enfriamiento rápido y precisión para aplicaciones farmacéuticas e industriales., mientras que las hojas de embalaje ofrecen tiempos de espera más largos y un manejo más seguro para envíos de carne y alimentos.. En 2025 La industria del hielo seco enfrenta desafíos de suministro y presiones de sostenibilidad., impulsando la innovación hacia sistemas de refrigeración híbridos, Captura de CO₂ y sensores inteligentes. Para optimizar el rendimiento y el coste:

Elige el formato correcto – Pellets para una rápida, necesidades ultra frías; hojas de paquete para enfriamiento de rango medio extendido.

Utilice soluciones híbridas – Combine hielo seco con PCM y aislamiento de alto rendimiento para extender la duración y reducir el uso de CO₂..

Siga las mejores prácticas – Contenedores de pre-enfriamiento, capa correctamente, ventilar los paquetes y cumplir con las etiquetas de peligro.

Invertir en sostenibilidad – Obtenga hielo seco de proveedores de bioCO₂., adoptar hojas reutilizables e integrar monitoreo inteligente.

Planificar adquisiciones – Contratos de suministro seguros y opciones de peletizadoras locales para navegar en mercados volátiles.

Siguiendo estas pautas, puedes mantener la integridad del producto, Minimizar el coste y el impacto medioambiental., y manténgase a la vanguardia de las innovaciones en la cadena de frío.

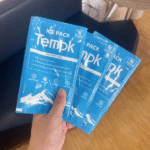

Acerca de Tempk

Tempk es líder mundial en soluciones de control térmico y embalaje de cadena de frío.. Somos especialistas en pellets de hielo seco., Hojas de embalaje y tecnologías de aislamiento avanzadas que mantienen sus productos congelados o refrigerados desde el origen hasta el destino.. Nuestra R&El equipo D desarrolla materiales ecológicos, Dispositivos de monitoreo inteligentes y sistemas de enfriamiento híbridos para ayudarlo a cumplir con los requisitos regulatorios y los objetivos de sostenibilidad.. Contáctenos para obtener orientación personalizada sobre cómo optimizar sus operaciones de cadena de frío.