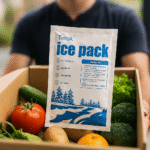

Stop Food Spoilage: Smart Ice Pack Solutions for Cold Chain

Keeping food fresh from warehouse to doorstep requires precision cooling. Discover how modern ice packs protect quality and profits.

Why Food Needs Special Ice Packs

- Temperature Precision: Meat needs 0-4°C, seafood -2°C, produce 4-8°C. Generic packs can’t maintain these ranges.

- Moisture Control: Melted ice soaks packaging, accelerating spoilage. Gel packs leak – PCM technology stays contained.

- Food Safety: FDA-compliant materials prevent chemical contamination. Low-quality packs risk leaching toxins.

PCM Packs: The Food Industry’s Secret Weapon

Material de cambio de fase (PCM) ice packs outperform traditional options by:

- Holding exact temperatures (p.ej., -15°C to +25°C options)

- Lasting 2-4x longer than water or gel packs

- Staying dry – no leakage onto produce or packaging

- Surviving 100+ recharges (VS. disposable alternatives)

Estudio de caso: A seafood exporter reduced spoilage from 8% a 1.5% by switching to PCM packs tuned to -2°C.

Sustainability That Saves Money

Tempk’s food-grade ice packs deliver eco-friendly savings:

- Reusable Design: 120+ cycles cut single-use plastic waste

- Recyclable HDPE: Outer casing meets food-contact safety standards

- Efficient Cooling: Fewer packs needed per shipment → lower fuel costs

Tempk’s Food-Specific Advantages

- Food-Grade Certified: Safe for direct contact with meat/produce

- Custom Temperatures: Match packs to your product’s ideal range

- Non-Leak Guarantee: Rigorously tested for moisture containment

- Stackable Designs: Maximize space in totes and trucks