Bolsas de hielo seco de alta calidad: ¿cómo mejoran la logística de la cadena de frío??

Introducción: Shipping temperature sensitive goods across long distances requires high quality dry ice packs. These ultra cold packages ensure medicines, seafood and other perishable products arrive intact. En 2025, demand for dry ice is growing while carbon dioxide supply lags, so understanding pack design, proper handling and the latest trends is crucial. This guide explains what makes a premium dry ice pack, how to select the right one, and the innovations reshaping cold chain logistics. It draws on recent data and industry research to provide practical advice.

What defines a high quality dry ice pack? Learn about materials, design and performance criteria.

How to choose and use dry ice packs effectively for different shipment durations and product types.

Requisitos reglamentarios y de seguridad when handling and shipping dry ice.

2025 tendencias e innovaciones, including smart sensors, sustainable materials and alternatives.

Real world tips and case studies to help you protect your cargo.

What Makes a Dry Ice Pack “High Quality”?

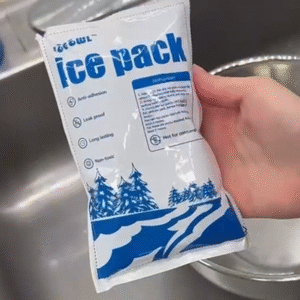

A high quality dry ice pack must maintain ultra low temperatures, resist leaks and provide consistent cooling. Premium packs use durable, puncture resistant materials such as water activated polymers or expanded polypropylene. Hidratar bolsas de hielo seco, por ejemplo, are lightweight yet freeze rapidly and maintain cold for up to 72 horas. High performance packs also use eco friendly, reusable materials and are designed to withstand rough handling.

High quality packs typically feature:

High performance polymers that absorb water and freeze quickly.

Robust insulation layers to slow sublimation and maintain cold.

Leak proof seams and reinforced walls, preventing bursts during transit.

Reusable or recyclable materials, Reducir el impacto ambiental..

Materials and Design Choices

Hydrate dry ice packs are made from water activated polymers. Después de un breve remojo, the polymer absorbs water, freezes rapidly and stays cold for up to 72 horas. This makes them ideal for seafood, meat or dairy shipments where extended hold times are needed. Tempk’s durable packs use puncture resistant materials and offer extended cooling, ensuring both pharmaceuticals and food remain protected. Material de cambio de fase (PCM) packs provide stable temperature regulation, which is critical for vaccines and biological products. Polipropileno expandido (PPE) cooler packs provide excellent insulation and impact resistance, combining eco friendliness with durability.

| Tipo de paquete | Características clave | Duración del enfriamiento | Lo que significa para ti |

| Hidratar la bolsa de hielo seco | Water activated polymer; lightweight and compact | Arriba a 72 h | Ideal for seafood and meats; eco friendly and easy to use |

| Paquete de hielo seco Tempk | Puncture resistant, robust materials | Extended cooling | Protects vaccines and fresh foods during long shipments |

| Paquete de hielo seco PCM | Materiales de cambio de fase; control de temperatura preciso | Long term stable | Perfect for vaccines and sensitive biotech products |

| EPP Cooler Pack | Expanded polypropylene with superior insulation | Prolonged | Sustainable choice; high impact resistance for rugged logistics |

| Gel Based Pack | Non toxic gel core; reutilizable | Short term (12–24 H) | Great for snacks or cosmetics; quick freezing and cost effective |

Consejos y consejos prácticos

Evalúe su envío: Determine product sensitivity and shipping duration. Hydrate packs suit multi day seafood shipments, while gel packs serve same day deliveries.

Use multiple packs for large loads: Combining packs increases cooling longevity.

Elija opciones reutilizables when possible to reduce waste and cost.

Caso del mundo real: A specialty seafood exporter switched to hydrate dry ice packs and extended the freshness window by two extra days, eliminating 15% of spoilage claims.

How to Select the Right High Quality Dry Ice Pack?

Selecting the right pack depends on product temperature requirements, shipment duration and container size. En la cadena fría, shipments range from ultra low (–70°C) to chilled (2–8 ° C). Dry ice packs sublimate at −78.5 °C (-109,3 °F) and prevent water leakage. Here’s how to determine your needs.

Sensibilidad a la temperatura: Vaccines and biologics often require ultra low temperatures; choose PCM or hydrate packs. Seafood and meats may use regular dry ice blocks or hydrate packs. Para productos refrigerados (2–8 ° C), gel packs or phase change materials at specific melt points are better.

Duración del envío: Para envíos de duración 24 horas, plan for 5–10 pounds of dry ice per 10–15 pounds of product. Para duraciones más largas, add extra packs. High performance packs can last 48–72 hours.

Tamaño y peso del envío: Los envíos más grandes requieren más hielo seco; oversizing reduces risk. The table below shows recommended quantities.

| Tipo de envío | Cantidad de hielo seco recomendada | Duración | Rango de temperatura |

| Productos farmacéuticos | 5–10 libras por 24 h | 24–72 h | –20 °C a –70 °C |

| Mariscos | 1–2 libras por 24 h | 24 h | –18 °C a –20 °C |

| Muestras biotecnológicas | 5 libras por 24 h | 48 h | –20 °C a –50 °C |

| Entregas de comida | 2–3 libras por 24 h | 24 h | –10 °C a –18 °C |

Planning Shipments with Multiple Packs

High quality dry ice packs can be combined to extend cooling. Using several packs increases the cooling duration and helps maintain consistent temperatures across a large payload. Always calculate the total quantity based on weight and travel time and adjust for external conditions. Por ejemplo, a 30 pound medical shipment traveling for 48 hours may need three 10 pound hydrate packs. Incorporate temperature sensors to monitor performance in real time.

Best Practices for Packaging and Shipping with High Quality Dry Ice Packs

Proper packaging is critical to maximize a dry ice pack’s performance. Aislamiento, pre conditioning and pack placement determine how long a shipment stays cold.

Optimize Insulation and Container Choice

Contenedores aislados: Foam coolers or insulated boxes slow heat gain for short term shipments, whereas advanced vacuum insulated containers extend hold times.

Preacondicionamiento: Pre chill the container before loading to reduce thermal shock and slow sublimation.

Use durable containers: Thick walls and tight seals reduce heat ingress and CO₂ escape.

Pack Layering and Void Reduction

Capas: Place dry ice above the payload so cold air sinks and envelops the shipment.

Reduce void space: Use slices, pellets or insulating filler to minimize empty gaps that allow warm air circulation.

Ventilación adecuada: Nunca selle los contenedores por completo; allow CO₂ gas to escape.

Monitor During Transit

En 2025, IoT enabled sensors provide real time temperature monitoring. These devices alert shippers to temperature deviations, permitiendo acciones correctivas. Investing in smart packaging reduces spoilage and improves compliance.

Herramienta de decisión: Calculadora de bolsa de hielo seco

To streamline planning, use a simple decision tool (spreadsheet or app) where you input product weight, rango de temperatura deseado y tiempo de tránsito. The tool calculates how many high quality dry ice packs are needed. Include a link to the tool on your website to improve user engagement.

Escenario real: A pharmaceutical distributor used an IoT enabled sensor and decision tool to adjust dry ice quantities mid route, ahorro $30,000 in prevented spoilage.

Safety Guidelines for Handling and Shipping High Quality Dry Ice Packs

El hielo seco es extremadamente frío y se sublima formando dióxido de carbono.; mishandling can cause burns or asphyxiation. Proper safety procedures are mandatory.

Protective Equipment and Handling

Utilice equipo de protección: Use guantes aislantes y gafas de seguridad cuando manipule hielo seco..

Manejar en áreas bien ventiladas: Work in areas with airflow to prevent CO₂ buildup.

Evite los contenedores herméticos: Store dry ice in vented containers to allow gas escape.

no ingerir: Dry ice should never be consumed; it can damage internal tissue.

Contenedores de etiquetas: Clearly mark packages containing dry ice and include hazard warnings.

Almacenamiento y eliminación

Guarde el hielo seco en lugares aislados., vented containers and never in airtight freezers. At the end of use, allow dry ice to sublimate in a well ventilated area; never dispose of it in sinks or trash.

Regulatory Exposure Limits

Carbon dioxide exposure is regulated. OSHA sets an 8 hour permissible exposure limit (PEL) de 5,000 ppm and a short term exposure limit of 30,000 ppm sobre 15 minutos. The National Institute for Occupational Safety and Health (Nioh) recommends 5,000 ppm as a time weighted average over a 10 hour shift. Use CO₂ monitors and alarms to keep levels within safe limits.

Caso real: en un 2024 warehouse incident, workers suffered dizziness due to poor ventilation. Installing CO₂ alarms prevented repeat incidents by warning staff when gas levels neared 5,000 PPM.

When to Use High Quality Dry Ice Packs versus Alternatives?

Dry ice remains indispensable for shipments requiring ultra cold conditions. Sin embargo, alternatives are gaining ground for refrigerated goods. Gel packs and phase change materials maintain narrow temperature ranges (2–8 ° C) and reduce supercooling risks. refrigeración mecánica (battery powered containers) offers active cooling for extended shipments but incurs higher costs. Improved insulation reduces the amount of dry ice needed.

Use dry ice packs when:

Temperaturas ultrabajas are needed, such as for vaccines or frozen foods.

Shipments must stay cold for more than 24 horas.

Water leakage would harm the cargo (dry ice sublimates without liquid).

Use alternatives when:

Refrigerated temperature ranges (2–8 ° C) are required – gel packs or PCMs hold steady temperatures.

Regulations prohibit dry ice (some airlines restrict quantities).

Sustainability goals prioritize reusable PCM or gel systems with lower carbon footprints.

2025 Developments and Trends in High Quality Dry Ice Packs

Crecimiento del mercado y desafíos de la oferta

Demand for dry ice continues to rise. Consumption has climbed roughly 5% por año mientras que el suministro de CO₂ crece sólo 0.5%. Este desajuste provoca escasez periódica y volatilidad de precios., con precios al contado subiendo hasta 300%. El mercado mundial de hielo seco estaba valorado en $1.54 mil millones en 2024 y se prevé que alcance $2.73 mil millones por 2032. Los EE. UU.. cold chain packaging market reached $7.97 mil millones en 2024 y se espera que crezca a un 15.6% Tocón de 2025 a 2030. Cold packs specifically are projected to grow 17.6% annually due to meal kit delivery and e commerce. Refrigerants like gel packs and dry ice are expected to grow 16.7% annually because of demand for temperature sensitive goods.

Technology and Sustainability

Sensores inteligentes e IoT: Temperature sensors integrated into dry ice packs provide real time data, ensuring shipments stay within set ranges. Blockchain enhances traceability, ensuring transparency throughout the cold chain.

Materiales aislantes avanzados: Lightweight vacuum insulated panels reduce dry ice consumption by improving thermal efficiency.

Sustainable CO₂ sources: Bioethanol plants capture CO₂ as a byproduct for dry ice production, reducing reliance on fossil based CO₂. en el reino unido, one site provides 30–60% of national CO₂ supply, illustrating the potential of renewable sources but also the risks of over reliance on a few producers.

Estrategias de enfriamiento híbrido: Shippers combine dry ice with phase change materials and improved insulation to reduce overall dry ice use while maintaining performance.

Ideas del mercado

Los EE. UU.. market’s growth is driven by processed and frozen food demand y comercio electrónico. Strict temperature control requirements for vaccines and pharmaceuticals further boost demand. Insulated containers and boxes accounted for 55.2% de ingresos en 2024, and insulating materials held a 58.1% compartir. The fish, meat and seafood segment dominated applications. Key players like Cryopak, Sonoco Thermosafe and Cold Chain Technologies are investing in smart packaging and sustainability.

Preguntas frecuentes

Q1: ¿Cuánto hielo seco debo utilizar para un envío de 24 horas??

Típicamente, 5–10 libras de hielo seco por 10–15 pounds of product is recommended for each 24 hour shipment. Adjust for longer durations or warmer climates.

Q2: How long do high quality dry ice packs last?

Premium packs can remain effective for 48–72 horas en condiciones optimas, whereas economy grade packs may last 12–24 horas. Aislamiento, pack type and ambient temperature influence longevity.

Q3: ¿Es seguro manipular las bolsas de hielo seco??

Sí, if proper precautions are followed. Utilice siempre guantes y gafas aislantes., work in ventilated areas and ensure containers are vented.

Q4: Can dry ice packs be refrozen or reused?

Reusable dry ice packs are designed for multiple uses, while traditional dry ice (Co₂ sólido) sublimates and cannot be refrozen. Hydrate and PCM packs are reusable.

Q5: What are alternatives to dry ice for refrigerated shipments?

Gel packs and phase change materials maintain narrow temperature ranges (2–8 ° C) and may be preferable for chilled products. Active refrigeration units provide longer control but at higher cost.

Resumen de puntos clave

Definition and materials: High quality dry ice packs use durable polymers, robust insulation and eco friendly materials.

Selecting packs: Match pack type to temperature requirements, shipment duration and payload size; plan 5–10 pounds of dry ice per 24 horas.

Mejores prácticas de embalaje: Contenedores de preenfriamiento, reduce void space, layer packs above payload and ensure ventilation.

Seguridad: Utilice equipo de protección, ventilated containers and abide by CO₂ exposure limits.

Tendencias: Demand is rising while CO₂ supply is constrained; sensores inteligentes, sustainable CO₂ sources and advanced insulation are transforming the industry.

Actionable Steps for You

Evaluate your product requirements: Determine the temperature range and shipping duration needed. If you ship vaccines or frozen seafood, invest in high quality hydrate or PCM packs.

Utilice nuestra calculadora de hielo seco: Input weight, transit time and temperature to calculate pack quantity. Incorporate IoT temperature sensors to monitor shipments.

Train staff on safety: Proporcionar guantes, goggles and CO₂ monitors; label containers clearly and follow ventilation guidelines.

Adoptar prácticas sostenibles: Consider reusable packs and explore suppliers using bio based CO₂. Use advanced insulation to reduce dry ice consumption.

Mantente informado: Monitorear las tendencias del mercado, regulaciones e innovaciones; adjust your cold chain strategies accordingly.

Acerca de Tempk

Tempk is a leading provider of cold chain solutions with expertise in developing high quality dry ice packs y contenedores isotérmicos. Our products are designed using eco friendly materials and advanced insulation technologies to ensure reliable temperature control and compliance. With years of experience serving pharmaceuticals, food logistics and biotech clients, nosotros focus on delivering safe, reusable and sustainable cooling solutions.

Llamado a la acción: Contact Tempk’s specialists to discuss your cold chain challenges and find the right dry ice pack solution. Our team can provide personalized recommendations and access to decision tools to optimize your shipping operations.