Cómo la tecnología de la cadena de frío impulsa cadenas de suministro seguras y sostenibles en 2025

Actualizado: Noviembre 24, 2025

Imagine que sus productos perecederos lleguen siempre frescos e intactos.. That’s the promise of cold chain technology, a network of temperature controlled systems that keep food, pharmaceuticals and other sensitive products within safe limits from origin to destination. tecnología de cadena de frío has exploded in importance because global trade and e commerce demand reliable deliveries; the worldwide market is projected to grow from USD 324.85 mil millones en 2024 a USD 862.33 mil millones por 2032. Keeping pace with these trends means understanding the tools, technologies and best practices shaping supply chains today.

What is cold chain technology, and why does it matter in 2025?

How do smart technologies like AI, IoT and blockchain enhance cold chain technology?

Which sustainable innovations and renewable energy solutions are reshaping the industry?

How do regulations and market forces drive investment, infrastructure upgrades and partnerships?

What emerging trends should you watch as the industry evolves through 2025 y más allá?

What is cold chain technology, and why does it matter in 2025?

cold chain technology refers to the chain of temperature controlled processes and equipment that preserve perishable products from production through consumption. En 2025 its significance is growing fast. Analysts estimate the global cold chain logistics market was worth USD 436.30 mil millones en 2025 and could rise to USD 1,359.78 mil millones por 2034, expanding at a 13.46 % tasa de crecimiento anual compuesta. This expansion is driven by surging demand for fresh food, vacunas, productos biológicos y alimentos de origen vegetal, paired with increasing consumer expectations for quality and safety.

Productores de alimentos, retailers and pharmaceutical companies rely on cold chain technology to reduce spoilage, comply with regulations and protect their reputations. Quick service restaurants in India, Por ejemplo, are projected to grow 20–25 % en el año fiscal 2024, increasing the need for reliable refrigerated transport. Mientras tanto, global dairy and bakery exports are rising, with the US exporting USD 4.21 billion in baked goods in 2022. Sin una cadena de frío eficaz, these opportunities would be impossible.

Key components of modern cold chain systems

Efficient cold chain technology relies on several interconnected components:

| Componente | Que hace | Por qué es importante para ti |

| Transporte refrigerado | Trucks, furgonetas, railcars and maritime containers maintain precise temperatures during transit. The refrigerated light commercial vehicle segment is expected to see the highest growth thanks to lower operating costs. | Ensures your products stay within safe temperature ranges during long journeys and urban deliveries. |

| Cold storage warehouses | Facilities with climate controlled rooms, freezers and humidity control systems. Modernization is vital as many warehouses are over 40 años. | Provides reliable staging points for goods, protects quality and reduces spoilage losses. |

| Monitoring and IoT sensors | Thermometers, humidity sensors and GPS devices transmit real time data on product conditions. The hardware segment led the tracking market, con 76.4 % participar en 2022. | Allows you to respond quickly to temperature deviations, preventing spoilage and ensuring regulatory compliance. |

| Packaging and phase change materials (PCM) | Aislamiento, vacuum panels and PCMs absorb or release heat to stabilize temperatures. These materials are gaining popularity in Europe and other regions. | Provide an extra layer of protection during last mile delivery and reduce reliance on active refrigeration. |

| Information systems and blockchain | Software platforms provide end to end visibility, automate documentation and enable traceability. Blockchain creates immutable records of temperature and location. | Builds trust with your customers, simplifies audits and helps you meet regulatory requirements. |

Practical tips and insights

Start with an audit: Evaluate existing transport, storage and monitoring capabilities to identify weak spots that could compromise product integrity.

Invest in IoT: Deploy sensors that send alerts when temperatures drift; real time data lets you act before a problem becomes costly.

Upgrade warehouses: Replace aging insulation and refrigeration systems to improve energy efficiency and comply with new refrigerant regulations.

Caso del mundo real: A dairy exporter upgraded to IoT enabled sensors and reduced spoilage by 15 %, increasing profits while meeting stricter export standards.

How do smart technologies like AI, IoT and blockchain enhance cold chain technology?

Smart technologies empower cold chain technology operators to optimize routes, prevent equipment failures and maintain product quality. Automation and robotics are transforming warehousing and distribution; acerca de 80 % of warehouses remain unautomated, leaving huge room for improvement. By adopting automated storage and retrieval systems, companies reduce labor costs, improve throughput and ensure consistent temperature control.

AI, IoT y monitoreo en tiempo real

AI-driven route optimisation analyzes traffic patterns, weather and delivery windows to shorten travel times and reduce fuel use. IoT devices transmit location, temperature and humidity data, enabling seguimiento en tiempo real. In the hardware segment, which held more than 76 % of the tracking market share in 2022, these devices are central to maintaining end to end visibility. Predictive maintenance uses machine learning to forecast equipment failures, preventing breakdowns and costly spoilage.

| Tecnología | Cómo funciona | Lo que significa para ti |

| Optimización de rutas de IA | Los algoritmos analizan el tráfico., weather and delivery schedules to determine the most efficient path. | Lower fuel costs, on time deliveries and reduced emissions. |

| Análisis predictivo | AI evaluates historical and real time data to predict equipment malfunctions. | Schedule maintenance proactively to avoid downtime and preserve product quality. |

| IoT tracking and sensors | Los dispositivos conectados monitorean la temperatura, humedad y ubicación, with automatic alerts for deviations. | Immediate notifications help you intervene quickly, preventing product loss and compliance issues. |

| Trazabilidad de la cadena de bloques | Distributed ledgers record every step of a shipment’s journey. | Mejora la seguridad, builds consumer trust and simplifies audits. |

Consejo práctico

Pilot AI tools: Start with route optimisation software on a specific route; measure fuel savings and delivery times to build a business case.

Implementar mantenimiento predictivo: Use machine learning to schedule equipment servicing based on actual use rather than fixed intervals.

Choose interoperable systems: Ensure your IoT devices, software platforms and logistics partners can share data seamlessly.

Caso del mundo real: A logistics provider adopted AI for route planning and cut fuel consumption by 10 %, while predictive maintenance reduced unplanned equipment downtime by 30 %.

Which sustainable innovations and renewable energy solutions are reshaping the industry?

Sustainability is now a core value in cold chain technology. Environmental regulations and consumer preferences push companies to adopt energy efficient refrigeration systems, renewable energy and sustainable packaging. Food cold chain operations account for about 2 % de las emisiones globales de CO₂, and rising energy costs make efficiency a business imperative.

Solar and renewable energy solutions

On site solar panels combined with battery storage can transform energy hungry cold warehouses. The cold storage industry spends over USD 30 billion a year on energy, with electricity representing up to 18 % of total operating costs. Facilities consume up to 60 kWh per square foot annually, four to five times more than typical commercial buildings. Solar energy can cost as little as 3.2 a 15.5 cents per kWh compared with average commercial utility rates of 13.1 centavos por kWh. Solar plus storage systems help operators save USD 20,000 a USD 50,000 per year on energy costs, provide backup during outages and reduce carbon footprints.

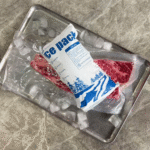

Sustainable packaging is another area of innovation. Companies are adopting recyclable insulated containers, envolturas térmicas biodegradables y compresas frías reutilizables. Materiales de cambio de fase (PCM) absorb or release heat during phase transitions, maintaining stable temperatures without active cooling. These materials reduce energy consumption and extend transit times, making them ideal for last mile delivery.

| Sustainable innovation | Beneficios | como te ayuda |

| Solar plus storage systems | Reduce reliance on volatile grid prices; save USD 20k–50k annually; provide resilience during outages. | Lower operating costs, predictable energy bills and uninterrupted operations even during blackouts. |

| Embalaje ecológico | Biodegradable wraps and reusable packs minimize waste and meet consumer expectations. | Demonstrates commitment to sustainability and can improve brand loyalty. |

| Materiales de cambio de fase (PCM) | Absorb or release heat to keep products within desired temperatures without active cooling. | Extend shelf life and reduce the need for energy intensive refrigeration during transport. |

| Refrigerantes naturales | Ammonia, CO₂ and hydrocarbons have lower global warming potential than synthetic HFCs and HCFCs. | Avoid compliance penalties and align with future regulations that are phasing out high GWP refrigerants. |

Consejos prácticos

Evaluate solar potential: Conduct a feasibility study to determine how much rooftop space you can allocate to panels and whether incentives exist in your region.

Switch refrigerants wisely: Consult experts to retrofit equipment with low GWP refrigerants and comply with upcoming phase down rules.

Adopt reusable packaging: Pilot biodegradable wraps and reusable ice packs on select routes; track customer feedback and cost savings.

Caso del mundo real: A 268,000 square foot cold storage facility in Maryland installed a rooftop solar system producing over 2.5 million kWh annually, reducing energy costs and carbon emissions.

How do regulations and market forces drive investment, infrastructure upgrades and partnerships?

Regulaciones, geopolitical events and investor confidence are shaping the evolution of cold chain technology. Geopolitical unrest and trade disruptions have increased transit times and reduced available capacity. Tariffs and new trade agreements are changing trade flows, compelling businesses to improve efficiency and resilience. Ageing cold storage infrastructure—often built 40–50 years ago—needs modernization; regulatory pressure to phase out hydrofluorocarbon (HFC) refrigerants intensifies this need.

Market research shows strong investment and innovation activity. The global cold chain market size was estimated at USD 316.34 mil millones en 2024 y se prevé que crezca a un 19.2 % CAGR de 2025 a 2030. Another report projects the market to grow from USD 416.91 mil millones en 2025 a USD 1,240.29 mil millones por 2033, a 14.6 % Tocón. The sector employs more than 576,300 people and added 26,800 new jobs over the past year.

Investors are pouring capital into cold chain startups, with an average investment round size of USD 56.2 million and more than 1,600 investors participating. Patent filings grew 36.6 % anualmente, y sobre 2,800 patents have been submitted worldwide. En otras palabras, the industry is innovating rapidly.

Market growth and investment trends

| Métrico | 2025 value or trend | Implicación para ti |

| Tamaño del mercado | Dólar estadounidense 436.30 mil millones en 2025, projected to USD 1,359.78 mil millones por 2034. | Signals huge opportunities; early investment can capture market share. |

| Annual growth rate | 13.46 % CAGR 2025–2034; 19.2 % CAGR 2025–2030. | Rapid expansion suggests competition will intensify; focus on differentiation. |

| New jobs | Encima 26,800 jobs added in a year. | Talent demand is rising; invest in workforce training and retention. |

| Patent growth | 36.6 % annual increase with 2,800+ patents filed. | Innovation is accelerating; protect your intellectual property and monitor emerging technologies. |

| Investment activity | Average investment round value USD 56.2 millón; más que 1,600 investors. | Funding is available; partnerships with investors can accelerate growth and adoption of new technologies. |

Consejo práctico

Upgrade facilities proactively: Avoid compliance penalties and take advantage of incentives for energy efficient upgrades and natural refrigerants.

Seek strategic partnerships: Colaborar con proveedores de tecnología, packaging suppliers and logistics networks to improve visibility and share resources.

Monitor policy changes: Stay informed about new trade agreements, tariffs and refrigerant regulations to adjust operations and pricing.

Caso del mundo real: A major logistics company partnered with multiple technology firms to integrate IoT sensors, Análisis de IA y blockchain, Resultando en 20 % faster delivery times and reduced spoilage.

How will cold chain technology evolve through 2025 y más allá?

The next few years will bring transformative changes to cold chain technology. Experts highlight several trends shaping the industry:

Automatización y robótica.

Warehouse robotics: Sistemas automatizados de almacenamiento y recuperación., robotic palletizers and autonomous guided vehicles (AGV) reduce labor costs and improve throughput.

Last mile drones: Emerging temperature controlled drones promise rapid delivery of small payloads, particularly for pharmaceuticals and high value perishables.

Sostenibilidad y eficiencia energética

Eco friendly refrigeration: The shift to natural refrigerants and energy efficient compressors lowers emissions and supports compliance.

Envases biodegradables: Reusable cold packs and recyclable materials reduce waste and meet consumer expectations.

End to end visibility

Real time tracking: IoT devices and predictive analytics provide uninterrupted visibility, permitiendo intervenciones proactivas.

Standardized data: Por 2025, 74 % Se espera que los datos logísticos estén estandarizados., facilitating seamless integration across supply chains.

Modernización de infraestructura

Actualizaciones de instalaciones: Mejora del aislamiento, refrigeration systems and on site renewable energy reduces energy costs and meets new regulatory standards.

Expansion of storage capacity: New facilities near production areas and ports support growth in fresh produce and protein exports.

IA y análisis predictivo

Previsión de la demanda: AI helps predict future demand for perishable goods, reducing waste and improving inventory planning.

Mantenimiento predictivo: Sensors and machine learning anticipate equipment failures, ensuring uninterrupted operations.

Growth of pharmaceutical and fresh food logistics

Pharmaceutical demand: Aproximadamente 20 % of new drugs are gene and cell therapies requiring strict temperature control. The pharmaceutical cold chain market is expected to reach USD 1,454 mil millones por 2029, con un 4.71 % Tocón.

Fresh food logistics: The North American food cold chain market could reach USD 86.67 mil millones por 2025, reflecting rising demand for fresh produce and plant based foods.

Asociaciones estratégicas e integración de la cadena de suministro

Ecosistemas colaborativos: Food manufacturers, packaging suppliers and tech providers are forming partnerships to develop integrated solutions.

Standardization and data sharing: Smart containers and common data standards are enabling seamless integration across supply chains, improving resilience and reducing costs.

2025 latest cold chain developments and trends

Staying informed about current developments helps you make smarter decisions. Key highlights from 2025 incluir:

Crecimiento del mercado e inversión.: Strong CAGR projections and record funding highlight immense opportunities.

Solar adoption: More facilities adopt on site solar and battery storage to manage energy costs and improve resilience.

AI integration: AI powered route optimisation and predictive maintenance become mainstream, cutting costs and improving reliability.

Embalaje sostenible: Rapid adoption of biodegradable materials and PCMs reduces waste and supports regulatory compliance.

Data standardization: Increasing adoption of shared data standards and blockchain enhances transparency and trust across supply chains.

Actualizaciones de infraestructura: Modernization efforts focus on energy efficiency, insulation improvements and compliance with new refrigerant regulations.

Último progreso de un vistazo

Adopción de automatización y robótica.: Many facilities invest in robotic handling and automated guided vehicles to combat labor shortages.

Greener refrigeration: Companies accelerate the transition to low GWP refrigerants and energy efficient compressors.

Expanded solar projects: Large cold storage facilities install rooftop solar systems generating millions of kWh annually.

Market insights show that innovative startups, early stage companies and established logistics providers are racing to develop new solutions. With hundreds of startups and thousands of patents, competition will remain intense, but there’s plenty of room for differentiation through customer service, sustainability and advanced technology.

Preguntas frecuentes

Q1: How does cold chain technology ensure product safety during transportation?

The cold chain keeps goods within strict temperature ranges using insulated packaging, refrigerated vehicles and IoT sensors. Real time monitoring alerts you to deviations so you can intervene quickly.

Q2: What role does AI play in optimizing cold chain technology?

La IA analiza el tráfico, weather and historical data to optimize routes, pronosticar la demanda y predecir fallas en los equipos. This results in faster deliveries, lower fuel costs and fewer temperature excursions.

Q3: Are renewable energy solutions practical for small cold storage facilities?

Sí. Solar panels combined with battery storage offer predictable energy costs even for small operations. Falling costs, government incentives and third party financing make it accessible to businesses of all sizes.

Q4: How do regulations affect cold chain technology?

Regulations require phasing out high GWP refrigerants and enforcing strict temperature control standards. Staying compliant protects your business from penalties and supports sustainability goals.

Resumen y recomendaciones

To thrive in the rapidly evolving world of cold chain technology, you need to embrace smart technologies, upgrade infrastructure and commit to sustainability. The market is expanding quickly, with forecasts calling for double digit growth and increased investment. Focus on real time visibility, AI driven optimization and renewable energy to reduce costs and enhance reliability.

Plan de acción

Evalúe su cadena de frío actual: Identify bottlenecks in transport, almacenamiento y seguimiento. Prioritize improvements that deliver quick returns.

Invertir en tecnología: Adopte sensores de IoT, AI route optimisation and predictive maintenance to improve efficiency and reduce waste.

Modernize infrastructure: Upgrade insulation and refrigeration systems, adopt renewable energy and phase out high GWP refrigerants.

Collaborate strategically: Asóciese con proveedores de tecnología, logistics companies and packaging suppliers to share data and resources.

Mantente informado: Monitor regulatory changes, market trends and emerging innovations to adjust your strategy.

Acerca de Tempk

Tempk is a leading innovator in cold chain technology, specializing in smart sensors, automated storage systems and energy efficient solutions. We leverage decades of industry experience to design integrated cold chain platforms that deliver real time visibility, predictive analytics and sustainable operations. Our customers include food producers, pharmaceutical manufacturers and logistics companies seeking to protect product quality and reduce costs.

Whether you need to upgrade existing facilities or build a new, resilient supply chain, Tempk provides tailored solutions backed by expert support. Our commitment to innovation helps you stay ahead in an industry where reliability and sustainability are essential.

Take the next step

Listo para transformar su cadena de frío? Póngase en contacto con nuestros expertos hoy to schedule a consultation. We’ll help you assess your needs, recommend the right technologies and guide you through implementation. Juntos, we’ll build a safer, greener and more efficient future for your temperature sensitive products.