Cómo optimizar su estrategia de precios de revestimiento de cajas aisladas en 2026?

Introducción

En 2026, understanding insulated box liner pricing is vital for businesses involved in cold chain logistics. With growing demand for temperature-sensitive products, optimizing packaging costs without sacrificing performance is essential. This guide provides an in-depth look at what drives insulated box liner pricing, and how you can streamline your purchasing decisions for better cost efficiency and operational success.

En esta guía, We Will Answer:

What factors affect insulated box liner pricing in 2026?

How can you optimize pricing strategy for bulk orders of insulated box liners?

What are the latest trends shaping insulated box liner pricing?

How to evaluate the best suppliers offering competitive pricing?

What Determines Insulated Box Liner Pricing?

The price of insulated box liners is influenced by various factors, each impacting both cost-efficiency and product performance. Key drivers include material selection, liner design, performance requirements, and order volume. Además, freight costs and supplier location can also play a major role in determining the total cost.

Material Selection and Insulation Efficiency

The material used for insulated box liners significantly impacts both performance and cost. Los materiales comunes incluyen:

Foil and Bubble Liners: Ligero, rentable, and suitable for short-duration shipments.

Poliestireno expandido (EPS): Provides moderate insulation, ideal for standard shipments.

Espuma de poliuretano (PUF): Offers high thermal resistance, making it ideal for longer shipping durations.

Paneles aislados de vacío (personaje): Superior insulation for highly sensitive products that require strict temperature control over long distances.

| Tipo de revestimiento | Material | Thermal Resistance | Rango de costos | Mejor caso de uso |

|---|---|---|---|---|

| Frustrar & Bubble | Aluminio + Bubble Film | Moderado | Bajo | Short-duration, local shipments |

| EPS | Poliestireno expandido | Moderado a alto | Medio | Envíos estándar, artículos fríos |

| Espuma de poliuretano | Poliuretano | Alto | Alto | Rutas más largas, bienes congelados |

| personaje | Panel aislado al vacío | Muy alto | Muy alto | Long-duration, productos sensibles |

VIP liners are the most expensive but offer the best protection for temperature-sensitive goods, while EPS liners provide an affordable option for less demanding shipments.

Customization and Features

Custom liners tailored to specific product dimensions or including additional features like moisture resistance or reinforced closures often come at a premium. Here’s how customizations impact pricing:

Tamaños personalizados: Tailoring the liner to fit specific product dimensions increases the complexity and cost of production.

Características especiales: Adding features such as branding, anti-static properties, or moisture barriers increases both material and manufacturing costs.

Freight and Shipping Costs

Shipping costs are another significant factor in insulated box liner pricing. Since many carriers calculate dimensional weight (OSCURO) based on the outer packaging volume, larger liners may incur higher shipping fees. Minimizing packaging size can help reduce dimensional weight charges, ensuring more cost-effective transportation.

Dimensional Weight: The more space your liner occupies in the shipping container, the more you pay. Right-sizing packaging reduces these costs.

Método de envío: Air freight is faster but more expensive, while ocean freight, although slower, is a more affordable option for bulk orders.

How to Optimize Your Insulated Box Liner Pricing Strategy

1. Bulk Ordering for Volume Discounts

One of the best ways to reduce the overall cost per unit of insulated box liners is by placing bulk orders. Volume discounts allow you to secure a lower price per unit, making large orders more cost-effective. Sin embargo, bulk ordering requires adequate storage capacity and cash flow management.

Descuentos por volumen: Purchase larger quantities to take advantage of tiered pricing. Bulk orders reduce the cost per liner significantly, helping you save money.

2. Standardize Liner Sizes

Standardizing the sizes of your liners across different shipments can help reduce costs. When you order in bulk with standard sizes, suppliers can streamline their production process, leading to lower manufacturing costs.

Efficiency Gains: Standardizing liner sizes also simplifies inventory management and reduces complexity in storage.

3. Negotiate Supplier Pricing

Suppliers often offer tiered pricing for bulk purchases. It’s essential to negotiate favorable terms based on your forecasted demand and order frequency. Además, asking for custom pricing based on specific requirements can also help reduce costs.

Long-Term Contracts: If you’re committing to regular orders, negotiate pricing based on long-term relationships, which may lead to better rates.

4. Match Insulation to Actual Needs

Choosing the right material and insulation level is essential. Avoid overspecifying insulation. Por ejemplo, if your products only need 24-hour temperature control, there’s no need to invest in liners designed for 72-hour protection. Tailoring your liners to your specific hold time and temperature requirements will help save costs.

Right-Sizing Insulation: Ensure the insulation level matches the product’s sensitivity and transit time to avoid unnecessary costs.

5. Explore Eco-Friendly Options

While eco-friendly liners may come with a higher initial cost, they can reduce long-term expenses through waste reduction and environmental compliance. Many sustainable options, such as recyclable liners, are available in the market, making them a viable choice for businesses looking to align with green logistics.

Sustainability Premiums: Although these options may be pricier upfront, they help reduce waste disposal costs and contribute to corporate social responsibility (RSE) objetivos.

2026 Trends Shaping Insulated Box Liner Pricing

1. Customization Demand

As businesses seek more tailored packaging solutions, the demand for custom-sized insulated box liners is growing. While these liners come at a higher price, they offer optimized protection and space efficiency during shipping.

2. Sostenibilidad en la logística de la cadena de frío

Sustainability is a growing trend, with businesses increasingly opting for eco-friendly insulated box liners. These sustainable options often come at a premium but provide long-term savings through reduced waste and compliance with environmental standards.

3. Tecnologías de embalaje inteligentes

The rise of smart packaging solutions is influencing pricing. Insulated box liners with embedded temperature sensors allow businesses to monitor the temperature conditions of their products during transit, providing valuable insights and reducing spoilage risks.

4. Production Automation

With automation in manufacturing processes, suppliers can reduce production costs, which may lower the price of insulated box liners in the future. This trend is expected to continue as more companies invest in automated production lines.

Preguntas frecuentes (Preguntas frecuentes)

Q1: Why does insulated box liner pricing vary so much?

The price of insulated box liners varies based on material, rendimiento de aislamiento, y personalización. Premium materials like VIP cost more but offer superior protection.

Q2: How can I lower the cost of insulated box liners without compromising quality?

You can lower costs by ordering in bulk, negotiating with suppliers, and choosing the appropriate material for your needs. Matching the liner’s insulation level to your product’s needs helps avoid unnecessary expenses.

Q3: How do seasonal fluctuations affect insulated box liner pricing?

Seasonal demand can cause raw material prices to increase, affecting the price of insulated box liners. Forecasting demand and adjusting orders accordingly can help mitigate these effects.

Conclusión: Maximizing Cost Efficiency in Insulated Box Liner Pricing

En conclusión, optimizing your insulated box liner pricing strategy in 2026 requires a comprehensive understanding of the various pricing factors and trends. Eligiendo los materiales adecuados, negotiating with suppliers, and matching insulation to actual needs, businesses can save costs without sacrificing product safety or quality.

Paso de acción: Contact a reliable supplier of insulated box liners to discuss pricing options. Consider bulk orders and explore sustainable alternatives to optimize your cold chain logistics for maximum savings.

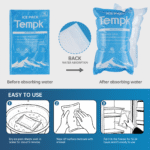

Acerca de Tempk

Tempk specializes in providing high-quality insulated box liners for cold chain logistics. We offer customized solutions that ensure your products stay at the right temperature while optimizing costs and sustainability.

Ponte en contacto: Reach out to us today to learn more about how we can help you reduce your insulated box liner costs and streamline your cold chain operations.