If you’re learning Cómo usar paquetes de hielo seco, Comience con el tipo, preacondicionamiento, capas, embalaje apretado, y controles de temperatura. Use gel/pcm "paquetes de hielo seco" para contenedores de frío o luz congelada, y el hielo seco de Co₂ real para carriles de pie profundo. Siga las reglas de la aerolínea y el envío, y mantenga la comida en o menos de 40 ° F (4°C) por seguridad. Encontrarás todo lo que necesitas aquí, simple, probado, y listo para usar.

-

Elegir refrigerantes: Cuando gel/pcm beats co₂, y donde cada uno brilla para la cadena fría de larga distancia.

-

Dimensionamiento y tiempo de ejecución: Un estimador rápido para los paquetes de tamaño a la derecha para el tiempo de ruta y la masa de carga.

-

Cómo empacar: Método "capa y separado" paso a paso para evitar daños por frío y extender el tiempo de retención.

-

Reglas y seguridad: 2025 TSA GEL -PACK DISTING y Límites de hielo seco de la FAA explicados en inglés liso.

-

Libros de jugadas del mundo real: Enfriador, parcela, y escenarios de vuelo que puedes copiar hoy.

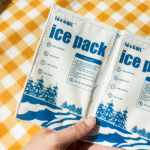

Cómo usar paquetes de hielo seco vs. Gel/PCM: ¿Cuál es la diferencia??

Respuesta corta: La mayoría de los "paquetes de hielo seco" que compra son gel o paquetes de PCM, no sólido co₂. Gel/PCM packs hold a set temperature (for chill or soft‑frozen), son reutilizables, and need no venting. Verdadero hielo seco (Co₂) sits at −78.5 °C/−109 °F, requires vented packaging and airline approval, and is best for deep‑freeze. Use gel/PCM for 2–8 °C holds; choose −15 °C PCMs or CO₂ for frozen lanes.

Por que importa: You protect your product by matching the melt/freeze point to your target zone. Choose 0–5 °C gels for produce and meds, −15 °C PCMs for “freezer‑like” holds without CO₂, and CO₂ only for ultra‑cold or long, rutas calientes. That’s the simplest way to master how to use dry ice packs.

How to use dry ice packs for 2–8 °C or frozen lanes

Pick the refrigerant that melts near your setpoint. PCMs flatten temperature swings while they phase‑change, so your goods avoid spikes. Precondition correctly (8–12 h for 0 °C gels; 24–36 h for −15 °C panels) and add thin barriers between packs and delicate foods to prevent “ice burn.” This is the practical backbone of how to use dry ice packs without damaging contents.

| Opción de enfriamiento | Freeze/melt point | Manejo & normas | Lo que significa para ti |

|---|---|---|---|

| Standard gel “dry ice pack” | ~ 0 ° C / 32 ° F | Sin materiales peligrosos; no vent needed | Ideal for 2–8 °C. Gentle on produce/biologics. |

| PCM freezer pack | −15 ° C / 5 ° F | Sin materiales peligrosos; long pre‑freeze | “Freezer‑like” holds without CO₂. |

| Verdadero hielo seco (Co₂) | −78.5 ° C / −109 ° F | Envasado ventilado; aprobación de la aerolínea | Deep‑freeze and long lanes; gloves and labeling required. |

Consejos prácticos que puede usar hoy

-

Separado & capa: Place a thin cardboard or rack between packs and fragile items.

-

Rodear la carga útil: Lados + top in parcels; abajo + top for frozen coolers.

-

Llenar los vacíos: Towels or dunnage defeat warm air gaps and extend runtime.

Caso en resumen: A pastry shipper used two −15 °C PCMs on sidewalls and two 0 °C gels on top in a 12 L EPS. Después 30 hours and several hand‑offs, center mass stayed below 10 °F, and fruit toppings showed no frostbite.

How to use dry ice packs step‑by‑step for shipping?

secuencia central: Precondition → Layer → Separate → Pack tight → Vent (Solo co₂) → Monitor. That order maximizes hold time and product quality. For gel/PCM “dry ice packs,” venting is not required; para Co₂, it is mandatory. Use a thermometer—don’t guess.

Detailed walkthrough: Confirm pack type; prefreeze to the spec point; Agregar separadores; rodear la carga útil; llenar los vacíos; place a thermometer; and if using CO₂, usar guantes, etiqueta UN1845, and allow gas to escape. This disciplined routine is the safest way to practice how to use dry ice packs at scale.

Packout estimator (copia)

Estimate the number of 1 kg gel/PCM packs for 2–8 °C holds:

-

CondicionesFactor: 0.8 (frío/sombra), 1.0 (normal), 1.2–1.4 (caluroso/soleado, apertura frecuente)

-

A 1 kg 0 °C gel yields ~one day for ~2 kg payload in a decent shipper; adjust for heat and access.

| Preconditioning guide | Typical point | Prep time | Lo que significa para ti |

|---|---|---|---|

| Paquete de gel estándar | 0 ° C / 32 ° F | 8–12h | Best for 2–8 °C; faster turnaround. |

| PCM freezer panel | −15 ° C / 5 ° F | 24–36h | Longer runtime; freezer‑like without CO₂. |

| Verdadero hielo seco (Co₂) | −78.5 ° C | Buy same day | Deep‑freeze only; always vent packaging. |

Field‑tested packing moves

-

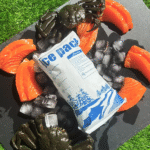

For chilled food: Bottom layer of 0 °C gels, carga útil, one gel on top; keep shaded.

-

Para productos congelados: −15 °C panels on sides + arriba; prefreeze contents; add a gel buffer near delicate items.

-

Para cargas mixtas: Use CO₂ near the deep‑freeze zone and gels/PCMs as buffers near sensitive items; vent outer box.

How to use dry ice packs for flights without hassles?

TSA (gel/pcm): You may carry gel or freezer packs if they’re frozen solid at screening; medically necessary packs can be slushy—declare them.

FAA (Co₂): Max 2.5 kg (5.5 lb) por pasajero/paquete; aprobación del operador; envasado ventilado; proper “Dry ice/Carbon dioxide, solid” marking with net quantity. Build your travel plan around these two rules, and you’ll know exactly how to use dry ice packs on flight days.

Carry‑on checklist

-

Freeze packs solid and place at the bottom of your cooler bag.

-

Expect secondary screening if any pack is slushy; mention medical needs early.

-

Leave vent paths for CO₂ and label perishables clearly for agents.

How to use dry ice packs in coolers for camping and day trips?

For drinks and dairy (2–8 ° C), line the bottom with 0 °C gels, agregar comida, and top with one gel. For frozen meat or fish, run −15 °C panels along the sides and top, and keep a small 0 °C gel between frozen and “chill‑only” items. Limit lid openings, keep a small “day‑use” cooler, and wrap the main cooler if you must store it in direct sun.

2025 cold‑chain updates and trends

Qué hay de nuevo: Reusable PCM systems and curbside‑recyclable liners are expanding fast, as teams cut waste without sacrificing hold time. More lanes pair PCMs with condition monitoring for fewer excursions. The upshot for how to use dry ice packs: smarter hybrids, mejor aislamiento, and clearer audit trails.

Último de un vistazo

-

Transportadores PCM reutilizables: Growing steadily; reduce consumables and total cost per ship.

-

Fiber‑based liners: More curbside‑friendly designs with solid thermal performance.

-

Mainstream IoT monitoring: Temperature loggers now standard on critical lanes.

Insight del mercado: Expect continued 5–9% CAGR in cold‑chain packaging segments through the late 2020s, led by life sciences and e‑grocery. Design for reuse flows and PCM availability when you standardize how to use dry ice packs across networks.

Preguntas frecuentes: Cómo usar paquetes de hielo seco

How much should I use for 24–72 h routes?

Plan ~5–10 lb per 24 h for small parcels with good insulation; add buffer for heat or delays. Test on your route before scaling.

Are “dry ice packs” real dry ice?

Por lo general no. Most are gel/PCM packs marketed as “dry ice packs.” Real dry ice is solid CO₂ and far colder. Check the spec sheet.

Do gel/PCM packs need venting?

No. Venting is only for CO₂ dry ice because it releases gas as it warms.

Is food safe with packs touching it?

Use a thin barrier (towel/cardboard). Keep chilled food ≤40 °F (4 ° C) and confirm with a thermometer.

Can I bring packs through TSA?

Sí, if frozen solid at screening; medically necessary packs may be slushy—declare them.

Resumen & Siguientes pasos

Puntos clave: Confirm gel/PCM vs CO₂, precondition to spec, layer with separators, empacar fuerte, and monitor temperatures. Follow TSA gel‑pack rules and FAA dry‑ice limits, and keep food ≤40 °F (4 ° C). That’s the reliable way to master how to use dry ice packs.

Your action plan:

-

Define the hold zone (2–8 ° C, −15 ° C, or deep‑freeze).

-

Choose packs: 0–5 °C gels for chill; −15 °C PCMs for freezer‑like; CO₂ para ultra fría.

-

Use the estimator to size mass and run a pilot with a logger.

-

Standardize a packout SOP and train teams. Necesitar ayuda? Book a free consult with Tempk’s cold‑chain team.

Acerca de Tempk

We help teams design packout playbooks and data‑driven calculators for perishable food, biofarmacéutica, y productos especiales. Our guidance reflects current TSA/FAA/PHMSA rules and modern PCM options, para que sus envíos cumplan con las normas, predictable, y rentable. We test in real routes and publish brand‑agnostic templates your team can use immediately.

Llamado a la acción: Talk to a Tempk cold‑chain specialist — book a free consultation.