Todas las empresas alimentarias quieren que los kits de comida lleguen frescos y seguros. Usando un hoja de paquete de hielo seco para preparación de comidas Puede mantener sus alimentos preparados congelados sin el desorden del agua derretida.. Estas láminas flexibles encapsulan dióxido de carbono sólido que se sublima a –78,5 °C (–109,3 °F), Permitir que los envíos permanezcan a temperaturas ultra frías durante días.. En esta guía aprenderá qué es una lámina de hielo seco., como funciona, las diferencias con los paquetes de gel, y cómo planificar sus envíos para mantener la calidad. También cubriremos las últimas 2025 tendencias y ofrecer consejos prácticos para tú Puede gestionar la logística de la cadena de frío como un profesional..

¿Qué es una hoja de hielo seco para preparar comidas y cómo funciona?? – entender la ciencia detrás de la sublimación y por qué mantiene los alimentos secos.

¿Cómo se utilizan las láminas de hielo seco para las entregas de preparación de comidas?? – aprende paso a paso las instrucciones de embalaje y calcula cuánto hielo seco necesitas.

¿Por qué elegir láminas de hielo seco en lugar de paquetes de gel? 2025? – explorar beneficios como una vida fría más larga y cero humedad.

Consideraciones de seguridad y medioambientales. – evitar la congelación, respetar las normas, y comprender la eliminación de las entrañas de los paquetes de gel.

2025 innovaciones y tendencias del mercado – descubrir sensores inteligentes, Refrigeración híbrida y cómo está creciendo el mercado de refrigerantes de cadena de frío..

¿Qué es una hoja de compresa de hielo seco para preparar comidas y cómo funciona??

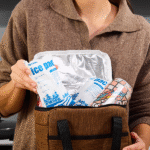

Una hoja de compresa de hielo seco para preparar comidas es una solución flexible., Bolsa sellada al vacío llena de gránulos o bloques de CO₂ sólidos que se subliman directamente en gas., manteniendo sus productos ultra fríos sin derretirse. Las bolsas de gel tradicionales se congelan 0 °C y se derrite lentamente; El hielo seco evita por completo la fase líquida.. Esta sublimación a –78,5 °C absorbe grandes cantidades de calor., mantener temperaturas tan bajas como –78,5 °C durante 24 a 72 horas, según el tamaño de la lámina y el aislamiento. Porque el dióxido de carbono se escapa en forma de gas., Los paquetes permanecen libres de humedad y no hay riesgo de que las cajas se empapen o se dañen las etiquetas..

Las láminas de hielo seco vienen en varios tamaños.. Las minihojas son ideales para kits de comida que requieren –20 °C para 24 horas, mientras que las sábanas desechables más grandes pueden mantener entre –18 °C y –78,5 °C hasta 72 horas. Están diseñados para ser rápidos de activar.: simplemente precongélelos o llénelos con bolitas de hielo seco., luego envuélvalos alrededor de recipientes de preparación de comidas dentro de una bolsa aislante. A diferencia de los pellets sueltos, el formato de hoja distribuye el frío uniformemente y reduce la congelación por contacto puntual.

En qué se diferencian las láminas de bolsas de hielo seco de las bolsas de gel tradicionales

Las láminas de hielo seco y las bolsas de gel entran dentro de los refrigerantes de la cadena de frío, pero sus propiedades difieren significativamente. Hojas de hielo seco Utilice CO₂ sólido para mantener temperaturas bajo cero y no producir residuos líquidos.. paquetes de gel use geles a base de agua que se congelen alrededor 0 °C; se derriten gradualmente y pueden mantener los alimentos fríos (no congelado) durante 24 a 48 horas. Los paquetes de gel son perfectos para productos que deben permanecer entre 2 y 8 °C., como proteínas frescas o medicamentos, pero no son adecuados para comidas que deben permanecer congeladas. Mientras tanto, El frío extremo del hielo seco puede dañar los productos sensibles a la congelación., por lo que es esencial una barrera sellada entre la lámina y los alimentos..

| Comparación | Hoja de hielo seco | Paquete de gel | Impacto en la preparación de sus comidas |

| Rango de temperatura | –78,5 °C a –18 °C | 0 °C a 8 °C | Elija láminas de hielo seco para comidas congeladas; paquetes de gel para ingredientes refrigerados |

| Duración del frío | 24–72 horas dependiendo del tamaño de la hoja y el aislamiento. | ~24–48 horas | Las capas de hielo seco ofrecen almacenamiento congelado prolongado durante largos tiempos de tránsito |

| Humedad | Sin residuos líquidos; se sublima en gas | Produce agua de deshielo que debe ser contenida | Mantiene el embalaje seco y reduce el desorden. |

| Consideraciones de seguridad | Requiere manipulación con guantes y ventilación. | Preocupaciones mínimas de seguridad, pero el contenido del gel puede irritar la piel si se filtra | Las capas de hielo seco necesitan un manejo cuidadoso; Los paquetes de gel son fáciles de usar. |

| Reutilizabilidad | Algunos formatos son reutilizables.; otros son desechables | Mayormente reutilizable | Evaluar los costos del ciclo de vida según la frecuencia de uso. |

Consejos prácticos y escenarios

Envío de kits de comida: Para una entrega de 24 horas de 10 lb (4.5 kilos) de comidas congeladas, plan para aproximadamente 10 libra de hielo seco; este 1:1 La relación mantiene temperaturas congeladas por hasta 48 horas. Utilice aislamiento de alta calidad para ampliar el rendimiento..

Recogida de preparación de comidas local.: Si los clientes recogen las comidas dentro de dos horas, los paquetes de gel pueden ser suficientes. Proporcionan temperaturas frías sin el peligro del hielo seco..

Campamento de fin de semana: Un enfoque híbrido (paquetes de gel más láminas de hielo seco) ralentiza la sublimación y extiende el enfriamiento más allá 72 horas.

Caso real: Un servicio regional de entrega de comidas cambió de paquetes de gel a pequeñas láminas de hielo seco para sus platos principales congelados.. Combinando mini sábanas con un forro bien aislado., mantuvieron –20 °C durante 30 horas durante el verano, reducir las tasas de deterioro y mejorar la satisfacción del cliente.

¿Cómo se utilizan las láminas de hielo seco para las entregas de preparación de comidas??

Empacar kits de comida con láminas de hielo seco requiere planificación para maximizar la seguridad y la eficiencia. Comience eligiendo un resistente, Contenedor aislado: espuma de poliestireno o paneles aislados al vacío funcionan bien.. Forrar el recipiente con una capa de espuma de poliestireno. (no hermético) para mejorar el aislamiento.

Prepara tus comidas: Selle los alimentos en recipientes herméticos o bolsas selladas al vacío.. Esto evita la entrada de humedad y evita el contacto directo con el hielo seco..

Activar la hoja: Retire la lámina de hielo seco del congelador o llene las celdas recargables con bolitas de hielo seco.. Use guantes aislantes y protección para los ojos cuando manipule hielo seco..

Colocar la hoja: Coloque la hoja de hielo seco encima de las comidas o envuélvala alrededor de los lados.. Para envíos bajo 12 horas, coloque la hoja encima; Para duraciones más largas, use hojas adicionales o coloque la parte inferior siguiendo las pautas (ver la tabla a continuación).

Ventilación: Asegúrese de que el recipiente o enfriador tenga pequeños orificios o ventilación para permitir que escape el gas de dióxido de carbono y evitar que se acumule presión.. Nunca selle el hielo seco en bolsas de plástico o cajas herméticas..

Etiqueta y marca: Etiquete el paquete con “Hielo seco (Y 1845)”e indicar el peso neto del hielo seco. Las pautas de FedEx establecen que los paquetes deben incluir el nombre de envío adecuado, Número ONU y peso.

Planificar la cantidad: Para envíos al día siguiente, use la mitad del peso de su carga útil en hielo seco; El mismo peso cubre hasta 48 horas, y 1.5 veces el peso proporciona aproximadamente 72 horas de protección congelada.

Deshacerse de manera responsable: Después de la entrega, Deje que el hielo seco se sublime al aire libre y deseche los materiales de embalaje de forma responsable. (más sobre consideraciones medioambientales más adelante).

Guía de cantidad de hielo seco

Utilice la siguiente regla general para estimar la cantidad de hielo seco necesaria según el peso de la comida y el tiempo de tránsito deseado..

| Peso de la comida | < 12 horas | 24–48 horas | 48–72 horas | Consejos |

| 5 lb (2.3 kilos) | 3 libra de hielo seco | 5 libra superior | 10 libra superior | Use una sola hoja en la parte superior para la entrega el mismo día |

| 10 lb (4.5 kilos) | 5 libra superior | 10 libra superior | 15 libra superior | Para viajes más largos utilice dos hojas para mantener –20 °C |

| 20 lb (9 kilos) | 10 libra superior | 20 libra superior | 30 libra superior | Considere la colocación de la sábana bajera para envío en 72 horas. |

| 40 lb (18 kilos) | 15 libra superior + 5 libra inferior | 25 libra superior + 15 libra inferior | 40 libra superior + 20 libra inferior | Los envíos pesados requieren aislamiento adicional |

Consejos para el usuario

Entregas cortas (bajo 12 horas): una hoja encima suele ser suficiente.

Envío en dos días: Haga coincidir el peso del hielo seco con el peso del producto y monitoree con un registrador de datos..

Envío en tres días: planifique un peso de hielo seco de 1,5 veces y utilice aislamiento adicional.

Estudio de caso: Envío de un servicio de comidas por suscripción 20 lb de comidas preparadas en dos estados utilizadas 20 libra de hielo seco (1:1 relación) y revestimientos térmicos. Los sensores en tiempo real mostraron que las temperaturas se mantuvieron por debajo de –18 °C durante 50 horas, reducir las devoluciones y aumentar la confianza del cliente.

¿Por qué elegir láminas de compresas de hielo seco en lugar de compresas de gel? 2025?

Las láminas de hielo seco se han convertido en el refrigerante preferido para los kits de comida congelada., y 2025 Las tendencias refuerzan sus ventajas.. Mantenimiento en frío extendido es el beneficio más citado: El hielo seco permanece frío por más tiempo que el hielo normal o las bolsas de gel y, a menudo, dura entre 18 y 24 horas por hoja.. Usando varias hojas, Puedes mantener bajas temperaturas durante días..

Otra ventaja clave es sin residuos líquidos. Los paquetes de gel eventualmente se descongelan y pueden filtrar agua que dañe el empaque o contamine las comidas.. El hielo seco se sublima directamente en gas, sin dejar lío. Esta propiedad libre de humedad es invaluable para alimentos sensibles como pasteles o platos principales sellados al vacío..

Las láminas de hielo seco también son eficiencia energética; No requieren refrigeración ni electricidad durante el tránsito.. Esto reduce la dependencia de refrigeradores eléctricos y amplía la entrega a áreas remotas donde no hay energía disponible.. Para envíos internacionales o entregas de larga distancia, El hielo seco garantiza temperaturas bajas constantes y reduce el deterioro..

Finalmente, Las capas de hielo seco son versátil. Se pueden combinar con paquetes de gel para crear sistemas de enfriamiento híbridos que extienden la vida útil de ambos refrigerantes.. Muchas empresas de kits de comida utilizan esta estrategia para entregas de fin de semana., Asegurar que el producto permanezca congelado hasta que los clientes lleguen a casa..

¿Cuánto hielo seco debería utilizar para los kits de comida??

Estimar la cantidad correcta de hielo seco es esencial para evitar un enfriamiento excesivo o insuficiente.. Comience con el relación basada en peso: la mitad del peso de su carga útil cubre envíos nocturnos, El mismo peso mantiene las condiciones de congelación durante 48 horas, y se recomienda 1,5 veces el peso para 72 horas.

Alternativamente, Puedes aplicar las pautas generales de los expertos en envíos.: 5–10 lb (2.3–4.5 kg) de hielo seco para un envío de 24 horas y 10–20 lb (4.5–9 kg) para entregas de 48 horas o más. Sin embargo, Factores externos como la temperatura ambiente., La calidad del aislamiento y la densidad de la comida influyen en la sublimación.. Usar un calculadora de hielo seco o consulte a su operador para obtener recomendaciones personalizadas.

Herramienta de autoevaluación (Sugerencia interactiva)

Para usuarios comprometidos, Una herramienta de autoevaluación interactiva podría ayudar a calcular las necesidades de hielo seco.. Podrías pedir a los lectores que ingresen el peso de sus comidas., tiempo de tránsito deseado y calidad de aislamiento. Luego, la herramienta generará el peso de hielo seco recomendado y la cantidad de hojas de paquete.. Incorporar una calculadora de este tipo en su sitio web fomenta la interacción del usuario y reduce las conjeturas., mejorar las métricas de comportamiento del usuario.

Consejos de seguridad y consideraciones ambientales

El manejo del hielo seco requiere cuidado. Utilice guantes protectores y protección para los ojos. Siempre que manipule hielo seco para evitar la congelación y la irritación.. El contacto con la piel puede provocar quemaduras graves.. Asegúrese siempre de que el embalaje esté ventilado.; Los contenedores sellados pueden romperse cuando se acumula el gas de dióxido de carbono.. Nunca coloque hielo seco en bolsas de plástico herméticas ni en hieleras selladas.; elegir tablero de fibra, cajas de plástico o madera con orificios de ventilación.

Mantenga los envíos bien etiquetados. Los transportistas como FedEx requieren que los paquetes muestren el nombre de envío correcto ("Hielo seco" o "dióxido de carbono, Sólido"), Y 1845 número y peso neto. Las regulaciones limitan las cantidades de hielo seco por paquete; FedEx permite hasta 200 kg para envíos generales, mientras que los servicios postales a menudo restringen los envíos nacionales a 5.5 lb (2.5 kilos). Consulte las reglas de su transportista antes de realizar el envío..

Huella Ambiental

Las láminas de hielo seco suelen ser reutilizable y no dejar residuos líquidos. Por lo general, se fabrican con dióxido de carbono reciclado capturado en procesos industriales., apoyando iniciativas de economía circular. En contraste, Las entrañas de los paquetes de gel a menudo contienen poliacrilato de sodio, un polímero súper absorbente que puede irritar la piel y los ojos.. Aunque se considera no tóxico, no se descompone rápidamente, y su eliminación puede obstruir los desagües y contribuir a la generación de residuos en los vertederos.. La película exterior de los paquetes de gel suele ser de plástico LDPE. (#4), que no se puede reciclar a través de programas en la acera y requiere entrega en instalaciones especializadas.

Para minimizar el impacto ambiental:

Reutilizar cuando sea posible: animar a los clientes a reutilizar las bolsas de hielo u ofrecer programas de devolución. Reutilizar las mochilas para acampar, refrigeradores o futuras entregas de comida extiende su vida.

Reciclar responsablemente: Consulte las regulaciones locales para el reciclaje de películas de LDPE y evite verter el contenido del gel por el desagüe..

Optar por materiales sostenibles: Elija capas de hielo seco fabricadas con materiales reciclables o biodegradables y asegúrese de que el CO₂ provenga de captura industrial..

2025 Innovaciones y tendencias del mercado

La industria de la cadena de frío está en auge. Según análisis recientes, el mercado mundial de refrigerantes para envases de cadena de frío, que cubre los paquetes de gel, ladrillos de espuma y productos de hielo seco—fue valorado en Dólar estadounidense 1.57 mil millones en 2024 y se prevé que crezca hasta Dólar estadounidense 1.69 mil millones en 2025 antes de llegar Dólar estadounidense 2.92 mil millones por 2032, una tasa de crecimiento anual compuesta (Tocón) de 8.14 %. El mercado de sistemas de envío de hielo seco para alimentos congelados, valorado en Dólar estadounidense 1.42 mil millones en 2024, Se pronostica que se expandirá a un 7.8 % Tocón a través de 2033. El aumento está impulsado por la entrega de alimentos en línea, Globalización de las cadenas de suministro de alimentos y creciente demanda de comidas congeladas listas para comer..

Últimos avances tecnológicos

Monitoreo de temperatura inteligente: Internet de las cosas (IoT) Los sensores integrados en las láminas de hielo seco envían alertas en tiempo real cuando las temperaturas se desvían.. Los registradores de datos ayudan a verificar el cumplimiento durante el tránsito y mejorar la rendición de cuentas.

Embalaje sostenible: Los fabricantes están desarrollando contenedores térmicos reciclables que mantienen la temperatura durante más de 72 horas y packs de gel utilizando materiales biodegradables. La producción de hielo seco utiliza cada vez más CO₂ capturado en procesos industriales, reducir las emisiones netas.

Transparencia de la cadena de bloques: La tecnología de contabilidad distribuida proporciona trazabilidad del historial de temperaturas y autenticidad en toda la cadena de suministro.. Esto ayuda a verificar que los kits de comida permanecieran dentro de rangos de temperatura seguros..

Refrigeración híbrida: Las unidades de transporte eléctricas e híbridas combinan refrigeración mecánica con láminas de hielo seco, Reducir la dependencia del diésel y reducir las emisiones..

Kits listos para usar: Los kits térmicos preensamblados simplifican la capacitación y reducen los errores de embalaje. Incluyen cajas isotérmicas., capas de hielo seco y registradores de datos, facilitar la adopción para las pequeñas empresas.

Perspectivas del mercado y preferencias del consumidor

Los consumidores valoran cada vez más la sostenibilidad y la transparencia. Las empresas están equilibrando el rendimiento con materiales ecológicos y explorando estrategias neutras en carbono. Materiales de cambio de fase (PCM) y los paneles aislados al vacío proporcionan un control preciso de la temperatura al tiempo que reducen los requisitos de hielo seco. Los servicios de entrega de comidas suelen utilizar minicapas de hielo seco para mantener las comidas congeladas a –20 °C durante 24 horas, mientras que las empresas farmacéuticas dependen de ellos para condiciones de -78,5 °C durante más de 48 horas.

Preguntas frecuentes

Q1: ¿Cuánto duran las hojas de hielo seco para preparar comidas?? Las capas de hielo seco suelen mantenerse entre –78,5 °C y –18 °C durante 24 a 48 horas, y las sábanas desechables más grandes pueden extenderse hasta 72 horas cuando se utiliza con aislamiento de calidad. paquetes de gel, en comparación, Ofrecer entre 24 y 48 horas de temperaturas frías..

Q2: ¿Puedo reutilizar las láminas de hielo seco?? Sí. Algunas capas de hielo seco son recargables: simplemente inserte bolitas nuevas en las celdas.. Otros están diseñados para un solo uso.. Inspeccione si hay daños después de cada uso y siga las instrucciones del fabricante..

Q3: ¿Las láminas de hielo seco son seguras para la entrega de comidas a domicilio?? El hielo seco es seguro si se manipula correctamente. Usar guantes, asegure la ventilación e indique a los destinatarios que permitan que el hielo seco restante se sublime al aire libre. Proporcionar instrucciones claras con el paquete..

Q4: ¿Cuál es la diferencia entre las láminas de espuma de hielo seco y los ladrillos de espuma?? Los ladrillos de espuma son bloques refrigerantes reutilizables que se congelan alrededor de –20 °C; Son adecuados para productos refrigerados, pero no tan fríos como la espuma de hielo seco., que alcanza –78,5 °C. Los ladrillos de espuma son más pesados pero más seguros para uso doméstico.

Q5: ¿Cómo puedo reducir el impacto ambiental del uso de láminas de hielo seco?? Utilice sólo la cantidad de hielo seco necesaria, Elija productos fabricados con CO₂ reciclado y materiales biodegradables., y reutilizar o reciclar los envases. Evite verter las entrañas de los paquetes de gel por el desagüe y siga las pautas de reciclaje locales para la película de LDPE..

Resumen y sugerencia

Las láminas para bolsas de hielo seco para preparación de comidas brindan un rendimiento de enfriamiento inigualable para kits de comidas congeladas. Mantienen de –78,5 °C a –18 °C durante 24 a 72 horas sin residuos líquidos. Siguiendo pautas basadas en el peso: la mitad del peso de la carga útil durante la noche, Peso igual durante dos días., y 1,5 veces el peso para envíos de tres días: puede planificar envíos con confianza. Utilice siempre contenedores aislados., Etiquete los paquetes claramente y asegure la ventilación.. Las capas de hielo seco son superiores a las bolsas de gel para alimentos congelados, aunque los paquetes de gel todavía tienen un papel para los productos refrigerados.

Para optimizar tu cadena de frío, Evalúe el peso de su comida y la duración del tránsito., Elija el tamaño adecuado de la capa de hielo seco e invierta en aislamiento de alta calidad.. Considere usar una calculadora para estimar la cantidad de hielo seco y adoptar el monitoreo de temperatura de IoT para lograr transparencia y cumplimiento.. Finalmente, manténgase informado sobre 2025 tendencias: materiales sostenibles, Sensores inteligentes y refrigeración híbrida: para mantener una ventaja competitiva..

Acerca de Templ

En Templ Nos especializamos en soluciones de control de temperatura de alto rendimiento.. Nuestro Hojas de paquete de hielo seco y los productos de espuma proporcionan temperaturas ultrafrías sin humedad, asegurándose de que sus kits de comida, Los productos farmacéuticos y biológicos llegan de forma segura.. Diseñamos sábanas reutilizables y desechables., cajas aisladas y herramientas de monitoreo de IoT para satisfacer sus necesidades específicas. Nuestro compromiso con la innovación y la sostenibilidad significa que obtenemos CO₂ de la captura industrial y exploramos materiales biodegradables.. Ya sea que necesite ayuda para seleccionar una hoja de hielo seco para preparar comidas o desee construir una cadena de frío resistente, Nuestro equipo está listo para brindar soluciones personalizadas..

Siguientes pasos: Póngase en contacto con nuestros expertos para analizar sus requisitos de cadena de frío o solicitar un paquete de muestra.. Utilice nuestra herramienta de autoevaluación para calcular sus necesidades de hielo seco y explore nuestra base de conocimientos para obtener más guías..