paquete de 12 Paquetes de hielo seco: 2025 Guía de envío

Si necesita un control fiable de productos congelados o refrigerados, a paquete de 12 paquetes de hielo seco le permite escalar el tiempo de espera desde viajes de un día a carriles de varios días sin tener que hacer conjeturas. En esta guía, dimensionarás el paquete correctamente, evitar daños por congelación, y conocer 2025 etiquetado y normas de seguridad. También verá cuándo elegir gel/PCM en lugar de hielo seco verdadero, además de una lista de verificación rápida para reducir el deterioro a la mitad en rutas calientes.

Nota editorial: Esta página consolida y mejora los tres borradores que proporcionó en un artículo listo para 2025..

-

Elige el derecho paquete de 12 paquetes de hielo seco para congelado vs. carriles refrigerados

-

Calcula cuántos paquetes necesitas para 24-72h rutas

-

Embalar, etiqueta, y ventile de forma segura con pasos listos para cumplir

-

Compare los paquetes de gel/PCM versus Hielo seco realmente seco por costo y riesgo

-

Utilice una herramienta de autocomprobación rápida para eliminar excepciones y reembolsos

¿Cómo funciona un paquete de 12 Las bolsas de hielo seco mejoran el tiempo de espera?

Respuesta corta: un paquete de 12 Las bolsas de hielo seco distribuyen el frío uniformemente, extiende el tiempo de espera, y se adapta a diferentes tamaños de cajas con ubicación modular. Doce unidades más pequeñas rodean la carga útil., reducir los puntos calientes, y mantener las temperaturas estables cuando las puertas se abren o los conductores permanecen. En cargadores aislados típicos, un paquete de 12 puede mantener temperaturas bajo cero o refrigeradas durante 24–72 horas, dependiendo del espesor del aislamiento, calor ambiental, y llenar vacíos.

Por que esto funciona para ti:

Colocar más paquetes arriba Contrarresta la entrada de aire caliente cada vez que se abre una caja.. Revestir los lados y llenar los huecos ralentiza la convección. En los carriles de verano, cambiar de un bloque grande a un 12-diseño del paquete a menudo rinde más, Curvas de temperatura más planas y menos excursiones.. Para SKU refrigerados (0–8 ° C), seleccionar paquetes PCM; para ultracongelados (≤–18°C), use hielo seco verdadero o un híbrido (hielo seco más partición PCM) para proteger cargas útiles mixtas.

¿Cuál es la forma más rápida de dimensionar una mochila de 12 para tu ruta??

método práctico: estimar la ganancia de calor y compararla con la capacidad total de frío, luego agrega un 20–30% amortiguador. Utilice la siguiente tabla para realizar selecciones rápidas antes de la validación completa.

| Atajo de tamaño (meta) | Base | Buffer | Lo que significa para ti |

|---|---|---|---|

| Enfriado 0–8°C, 24–36h | 8–Paquetes de 10 PCM | +2 arriba | Más seguro para bodegas de puertas y muelles calientes |

| Congelado ≤–18°C, 24–48h | 6–10 libras de hielo seco | +25% | Marca UN1845, respiradero, agregar paquetes de carga superior |

| SKU mixtos 36–60h | 6–8 PCM + 4–6 libras de hielo seco | +2 PCM superior | Congelado permanece congelado; enfriado no se congela |

Consejos prácticos para los usuarios

-

Corto, rutas calientes: Usar más paquetes superiores; El calor aumenta cuando se abre la caja..

-

Carriles largos: Actualizar a Forros VIP o reflectantes; reducirá el refrigerante necesario entre un 20 % y un 30 % aproximadamente.

-

Presupuesto ajustado: Cajas de cartón del tamaño adecuado para eliminar las burbujas de aire; menos pulgadas cúbicas = menos carga de calor.

Caso del mundo real: Una marca de kits de comida cambió a un patrón PCM “pesado en la parte superior” de paquete de 12 y agregó un forro de aluminio. Cayeron los reembolsos de verano 28% mientras que el costo del paquete se mantuvo estable.

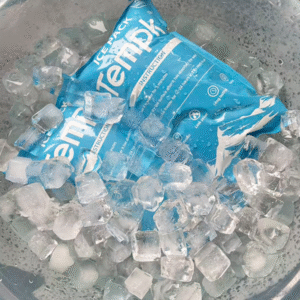

paquete de 12 Paquetes de hielo seco

paquete de 12 bolsas de hielo seco vs.. Hielo seco real: ¿qué deberías elegir??

Final: Utilice el paquete de 12 paquetes de hielo seco (Gel) para productos refrigerados que no deben congelarse; Utilice hielo seco real para productos congelados y ultracongelados.. PCM mantiene una banda constante de 0 a 8 °C sin dañar los SKU sensibles. Verdadero hielo seco (Co₂ sólido, ~–78,5°C) Ofrece las temperaturas más frías y la retención congelada más larga, pero requiere etiquetado, PPE, y ventilación.

Cómo decidir rápidamente:

-

medicamentos refrigerados, producir, chocolate: a 12-paquete PCM El kit previene el choque por congelación..

-

Helado, carne congelada, biológicos: hielo seco mantiene ≤–18°C estable para carriles de varios días.

-

Cargas mixtas: hielo seco sobre SKU congelados; PCM alrededor enfriado SKU con partición de cartón.

Paquete híbrido que reduce el riesgo

Comience con PCM preacondicionado alrededor de los lados., carga útil centrada, hielo seco en la parte superior de un divisor solo para productos congelados. Si el hielo seco se acaba antes, PCM mantiene refrigeración segura hasta la entrega. Esto reduce las excursiones sin añadir agua de deshielo ni limpiezas complicadas..

| Elección | Ventaja principal | Compensación | El mejor ajuste |

|---|---|---|---|

| 12-paquete de PCM/gel | Simple, Sin peligro | Retención por congelación más corta | Enfriado 0–8°C; SKU “sin congelación” |

| hielo seco | Resistencia congelada | Etiquetado, PPE, desfogue | Congelado ≤–18°C, 48–72h |

| Híbrido | Estabiliza ambas bandas. | Ligera complejidad de embalaje | Skus mixto, estancia de fin de semana |

Cómo dimensionar un paquete de 12 bolsas de hielo seco durante 24 a 72 horas?

regla central: Haga coincidir la carga de calor con la capacidad total de refrigerante y agregue entre un 20 y un 30 % de espacio libre. Para PCM, Utilice la especificación de calor latente del paquete.; para hielo seco, Las reglas generales de campo son ~ 5–10 lb por 24h en refrigeradores pequeños, depende en gran medida del aislamiento y los huecos.

Paso a paso desde tu escritorio:

-

Definir carril: horas totales puerta a puerta, ambiente en el peor de los casos, cualquier fin de semana se mantiene.

-

Conoce tu caja: espesor del aislamiento o valor R/U (EPS VS. VIP vs.. forro reflectante).

-

Estimar la carga de calor: U×Área×ΔT×tiempo.

-

Elija PCM o masa de hielo seco: capacidad ≥ carga de calor × 1.25 (buffer).

-

Colocación: 60% de masa fria arriba, equilibrio en los lados; llenar los vacíos.

Minicalculadora (ejemplo, pegar en tus notas):

2025 cumplimiento & lista de verificación de seguridad (si usas hielo seco real)

Elementos no negociables que puede copiar en su SOP:

-

Calificación: "Y 1845, Hielo seco, Neto __ kg" + Clase 9 etiqueta; mantener las direcciones fuera del diamante de peligro.

-

Ventilación: nunca sellar hermético; El CO₂ debe ventilarse para evitar la acumulación de presión..

-

PPE: guantes aislantes y protección para los ojos; Evite la manipulación prolongada.

-

Colocación: hielo seco arriba la carga útil; El frío se hunde mientras se calienta..

-

Documentación: siga la lista de verificación de aceptación actual de las compañías aéreas para el hielo seco como refrigerante.

-

Depósito & seguridad del vehículo: monitorear el aire en espacios pequeños; seguir los límites de exposición ocupacional.

Para PCM/gel, paquetes de 12: no se necesitan marcas UN1845; todavía incluye claro "No congelar" o "Enfriado 2–8°C"Instrucciones para que los destinatarios minimicen el tiempo de apertura de la puerta..

2025 Tendencias de la cadena de frío y lo que sigue.

Descripción general de la tendencia:

En 2025, Los paquetes modulares dominan: las marcas estandarizan una paquete de 12 paquetes de hielo seco para carriles refrigerados y agregue hielo seco solo cuando la resistencia al frío sea esencial. El abastecimiento de bio-CO₂ y la recuperación de CO₂ mejoran las afirmaciones de sostenibilidad. Los revestimientos reflectantes de bajo costo y los delgados paneles VIP afeitan 20–30% fuera de las necesidades de refrigerante, mientras que los registradores de datos compactos hacen validación rutina para pymes.

Últimos desarrollos de un vistazo

-

Enfriamiento híbrido (hielo seco + PCM): curvas más suaves, menos excursiones con cargas mixtas.

-

Forros reflectantes de "lámina": Fácil adaptación para ampliar el tiempo de ejecución sin necesidad de volver a empaquetarlo..

-

Diseños muy pesados: más masa fría en la parte superior para contrarrestar los picos de calor al abrir la puerta.

Insight del mercado:

E -torcer, biológicos, y los envíos directos a los pacientes siguen impulsando la demanda. Equipos que validan dos o tres kits estándar (24 H, 48 H, 72 H) informan tasas de excepción más bajas y capacitación más simple, especialmente para el personal estacional.

Preguntas frecuentes

¿Cuánto tiempo durará un paquete de 12 Las bolsas de hielo seco mantienen mis productos fríos.?

Con EPS o revestimientos reflectantes, esperar 12–48h para paquetes refrigerados PCM; con hielo seco y buen aislamiento, 24–72h para carriles congelados. Valide su ruta y agregue un búfer del 20 al 30 %.

¿Puedo volar con un paquete de 12 si es gel/PCM?, no hielo seco?

Sí. Los paquetes de PCM/gel no son UN1845. Si agrega hielo seco, aplicar marcas UN1845, peso neto correcto, y una clase 9 etiqueta.

¿Cuántos paquetes necesito realmente??

Comience con el método de carga de calor. Como atajo, usar 8–Paquetes de 10 PCM durante 24-36 h refrigerado a 25°C ambiente; Para congelado, 6–10 lb Hielo seco cada 24 a 48 horas y ajustar para aislamiento..

¿El hielo seco dañará los alimentos??

Puede. Mantenga los alimentos envueltos y separar con cartón; nunca permita el contacto directo.

¿Puedo reutilizar paquetes PCM??

Sí. Vuelva a congelar en plano, Evite apilar mientras se carga, y reemplazar las células perforadas.

Resumen & recomendaciones

Puntos clave: A paquete de 12 paquetes de hielo seco le brinda colocación modular en frío, curvas de temperatura más planas, y escalado más fácil entre tamaños de cajas. Utilice PCM para productos refrigerados de 0 a 8 °C, hielo seco para ultracongelados, e híbridos para cargas mixtas. Cajas del tamaño adecuado, llenar los vacíos, y mantenga más masa fría encima para extender el tiempo de ejecución.

Siguientes pasos (CTA):

-

Elige tu banda objetivo (enfriado vs.. congelado).

-

Elija PCM o hielo seco (o híbrido) y tamaño con un 25% buffer.

-

Validar uno 24 H, uno 48 H, y uno 72 H kit con registradores.

Habla con Tempk para obtener una hoja de trabajo de empaquetado y un plan de validación carril por carril.

Acerca de Tempk

Diseñamos soluciones de cadena de frío que son fáciles de ejecutar a escala. Nuestro validado 12-empacar kits PCM, revestimiento reflectante, y los paquetes congelados le ayudan a cumplir las especificaciones con menos refrigerante y menos excepciones. Lo respaldamos con procedimientos operativos estándar de capacitación y calculadoras rápidas para que su equipo dedique menos tiempo a apagar incendios y más tiempo a realizar envíos..

Listo para optimizar sus paquetes? Contáctenos para una evaluación rápida y una configuración lista para la ruta.