Lechería con temperatura controlada Soluciones económicas en 2025?

Si lo necesitas Lechería con temperatura controlada, soluciones económicas., no estás pidiendo "lo más barato". Estas pidiendo el forma más rápida de proteger la calidad de los lácteos mientras reduce el desperdicio, arrastre laboral, y picos de energía. En la mayoría de las lecherías, Las pérdidas provienen de pequeños hábitos que se repiten a diario.: puertas dejadas abiertas, flujo de aire bloqueado, puesta en escena del muelle “por un minuto,” y rotación poco clara. Repararlos es más barato que equipos nuevos y, a menudo, funciona más rápido.

Este artículo responderá por ti.:

-

Cómo Lechería con temperatura controlada, soluciones económicas. reducir el deterioro sin grandes actualizaciones

-

El mejor Mejoras de cámaras frigoríficas de bajo coste para lecherías. que se devuelven rápidamente

-

A SOP económico de muelle a refrigerador para productos lácteos que evita golpes de calor en turnos ocupados

-

Cómo configurar Monitoreo de temperatura económico para el almacenamiento de lácteos. su personal utilizará

-

Cómo Envío aislado asequible para productos de leche. reduce las quejas por nivel de carril

-

Una herramienta de decisión + Autoprueba para elegir tu próxima mejor actualización económica

¿Por qué las soluciones baratas para lecherías con temperatura controlada superan primero a los “equipos nuevos”??

Respuesta directa: Soluciones económicas para lecherías con temperatura controlada Generalmente superan a los equipos nuevos porque sus mayores costos provienen de fugas de proceso, no caballos de fuerza del compresor. Una nueva unidad no puede arreglar tarimas esperando en el muelle o respiraderos bloqueados por almacenamiento “temporal”.

Explicación expandida: Piense en el margen como un triángulo. Si algún lado es débil, las ganancias se filtran silenciosamente. Las mejores victorias económicas mejoran al menos a una de las partes inmediatamente y no requieren un comportamiento perfecto del personal para tener éxito..

El “Triángulo de ganancias de la cadena de frío” que debes gestionar a diario

| Lado del triángulo de beneficios | lo que parece | arreglo barato | Lo que significa para ti |

|---|---|---|---|

| Estabilidad de temperatura | menos picos cálidos | disciplina de puerta + reglas de flujo de aire | menos reclamos de calidad |

| control de tiempo | corto tiempo de puesta en escena | reglas del temporizador de puesta en escena | menos riesgo de deterioro |

| control de manejo | menos toques | zonificación + carriles claros | menor costo laboral |

Consejos prácticos y recomendaciones.

-

Si tu equipo está ocupado, elegir correcciones que eliminar decisiones, no agregar pasos.

-

Si el efectivo escasea, priorizar puertas + flujo de aire + puesta en escena antes que cualquier “tecnología”.

-

Si estás escalando, estandarice las rutinas primero y luego invierta con confianza.

Ejemplo de caso práctico: Una pequeña lechería redujo el retrabajo semanal después de agregar una regla de tiempo de preparación y publicar una lista de verificación de empaque y mudanza en la puerta de la cámara frigorífica..

Soluciones económicas para lecherías con temperatura controlada: ¿Por dónde deberías empezar??

Respuesta directa: Comience con un 15-auditoría minuciosa usando un cronómetro y un cuaderno. Su primer objetivo es acortar el “tiempo sin frío” y evitar que el aire caliente entre en las habitaciones frías..

Explicación expandida: La mayoría de las lecherías tienen los mismos momentos de riesgo repetibles.: recepción, puesta en escena, aberturas de puertas, y bloqueo del flujo de aire. Si puedes medir y arreglar esos momentos, puede reducir el deterioro y el desperdicio de energía sin comprar equipos grandes.

Mejoras de cámaras frigoríficas de bajo coste para lecherías: la auditoría de 15 minutos

-

¿Por dónde entra el aire caliente?? (puertas, interfaz de muelle, sellos rotos)

-

¿Dónde se bloquea el aire frío?? (palets contra ventiladores, paredes, o ventilaciones de retorno)

-

¿Dónde espera demasiado el producto?? (puesta en escena del muelle, El control de calidad se mantiene, elegir colas)

| Objetivo de auditoría | que buscar | Por que importa | Su comida práctica para llevar |

|---|---|---|---|

| puertas & sellos | huecos de luz, juntas rotas | el aire caliente roba el enfriamiento rápidamente | reemplace las juntas antes de comprar ventiladores nuevos |

| Rutas aéreas | paletas que bloquean las rejillas de ventilación | puntos calientes + descenso lento | marcar zonas de “no bloqueo” en el piso |

| Patrones de escarcha | hielo pesado en bobinas | caída de eficiencia + ciclismo | arreglar el flujo de aire + horario de limpieza |

| Puesta en escena | tiempo de espera sin seguimiento | choques cálidos + pérdida de calidad | agregue un temporizador visible de "fuera de frío" |

Consejos prácticos y recomendaciones.

-

Use cinta para piso hoy. Una zona grabada de "mantenerse alejado" supera a una larga nota.

-

Escribe una regla: “Ningún pallet espera más de X minutos en el muelle”.

-

Mantenga la lista de auditoría breve. Las soluciones económicas funcionan mejor cuando están terminadas.

Ejemplo de caso práctico: Una pequeña lechería redujo el tiempo de preparación a la mitad utilizando un cronómetro y un carril "listo para almacenar".

¿Cuáles son las mejores soluciones económicas de lechería con temperatura controlada para la estabilidad de las cámaras frigoríficas??

Respuesta directa: El mejor Lechería con temperatura controlada, soluciones económicas. Para la estabilidad, centrarse en los “tres grandes”.: flujo de aire, puertas, y puntos de ajuste.

Explicación expandida: El aire frío se comporta como el tráfico. Si bloqueas carriles, creas atascos y puntos calientes. Las puertas son el punto de entrada de calor más rápido. Los puntos de ajuste importan, pero la estabilidad importa más que los ajustes constantes.

1) Disciplina del flujo de aire (la solución más barata de alto impacto)

Errores comunes en el flujo de aire:

-

apilar el producto demasiado cerca de los ventiladores del evaporador

-

empujando paletas contra las paredes

-

almacenar cargas altas que bloquean el aire de retorno

Solución barata: marque “zonas sin apilamiento” y enseñe una regla simple: mantener los respiraderos limpios, siempre.

2) Disciplina de puerta (El calor entra más rápido por las puertas.)

Solución barata: movimientos por lotes y cerrar la puerta entre movimientos. Agregue un cronómetro y un objetivo de “puntuación de puerta” visible por turno.

3) Cordura del punto de ajuste (demasiado frío puede ser caro)

Reducir los puntos de ajuste “sólo para estar seguros” puede aumentar la formación de escarcha y la carga de energía.

Solución barata: Defina su rango de punto de ajuste según las necesidades del producto y manténgalo estable..

| Palanca de cámara frigorífica | acción barata | Nivel de costo | Su beneficio práctico |

|---|---|---|---|

| Flujo de aire | carriles de cinta de piso + señales de “no bloquear” | Bajo | menos puntos calientes |

| puertas | selección de lotes + minutero + hábitos más cercanos | Bajo | menos picos de temperatura |

| Puntos de ajuste | rango de SOP documentado | Bajo | menos deriva y glaseado |

Consejos prácticos y recomendaciones.

-

Si ves escarcha desigual, primero verifique el bloqueo del flujo de aire.

-

Si los compresores funcionan constantemente, revise puertas y sellos antes de comprar cualquier cosa.

-

Si el producto se calienta cerca de las puertas, alejar a los que se mueven rápidamente de las zonas de entrada.

Ejemplo de caso práctico: Una lechería mejoró la uniformidad de la temperatura después de alejar paletas altas de las zonas de ventiladores y repintar los límites de los pasillos..

¿Cómo las soluciones económicas de lechería con temperatura controlada reducen rápidamente los costos de energía??

Respuesta directa: Reducen el costo de energía al reducir entrada de calor y mejorar la refrigeración eficiencia con una “higiene energética” básica.

Explicación expandida: Si entra aire caliente constantemente, Los compresores libran una batalla por la que no necesita pagar. Las victorias más rápidas provienen de las juntas., limpieza de la bobina, y comportamiento de apertura de puertas.

El “barrido energético de 5 minutos” (semanalmente)

-

Inspeccione las juntas de las puertas en busca de huecos y grietas.

-

Verifique los patrones de escarcha para detectar problemas de flujo de aire

-

Confirme que las bobinas estén limpias (o programado)

-

Verifique que las puertas cierren completamente sin pegarse

-

Confirmar que las luces/ventiladores funcionen solo cuando sea necesario

| Fuente de fuga de energía | lo que ves | arreglo barato | Lo que significa para ti |

|---|---|---|---|

| juntas desgastadas | condensación, bordes cálidos | reemplazar juntas | menor entrada de calor |

| Bobinas sucias | descenso lento | horario de limpieza | menor carga del compresor |

| Mal uso de la puerta | picos cálidos frecuentes | movimiento por lotes | menos recuperaciones |

Consejos prácticos y recomendaciones.

-

estaciones calurosas: reforzar la disciplina de la puerta y reducir el tiempo de preparación.

-

Alta humedad: el sellado importa aún más para reducir la carga de escarcha.

-

Equipos más antiguos: la limpieza y el sellado a menudo superan a las actualizaciones.

Ejemplo de caso práctico: Una lechería redujo los picos de energía mensuales después de reemplazar las juntas y aplicar una regla de carga de “etapa previa a la apertura”.

Lecherías con temperatura controlada, soluciones económicas para la eficiencia laboral: ¿Cómo se reducen los toques??

Respuesta directa: Reduzca los toques rediseñando el flujo con zonas, carriles de envío hoy, y ubicaciones claras.

Explicación expandida: Cada movimiento adicional cuesta mano de obra y aumenta la exposición a la temperatura.. Si eliminas solo un toque del manejo de productos terminados, A menudo se ve un alivio inmediato del parto y menos excursiones..

Utilice el método "Touch Count"

Contar movimientos después del embalaje.:

-

pasar a la puesta en escena

-

pasar a la cámara frigorífica

-

moverse a la zona de selección

-

pasar a cargar

Ahora elimine un movimiento con zonificación y diseño de carriles..

| Desperdicio de mano de obra | ¿Qué lo causa? | arreglo barato | Significado práctico para ti |

|---|---|---|---|

| Búsqueda | ubicaciones poco claras | etiquetas de zona + mapa | selecciones más rápidas |

| Movimientos extra | mal diseño | carriles de fecha de envío | menos toques |

| Rehacer | paletas equivocadas | puesta en escena visual | menos errores |

Consejos prácticos y recomendaciones.

-

Equipos pequeños: etiquetas + un mapa de pizarra venció a un software complejo.

-

Muchos SKU: separar los motores A/B/C por velocidad.

-

Canales mixtos: zonas separadas para mayoristas y minoristas.

Ejemplo de caso práctico: Una lechería redujo el tiempo extra después de introducir carriles de “envío hoy” y etiquetar a los que se mueven rápidamente a la altura de los ojos..

¿Qué soluciones económicas para lecherías con temperatura controlada protegen mejor la calidad de los lácteos??

Respuesta directa: Proteger la calidad minimizando cambios de temperatura y reduciendo tiempo fuera de ambientes controlados.

Explicación expandida: La mayoría de los daños a la calidad no son un gran fracaso. Son muchas pequeñas exposiciones cálidas las que erosionan el sabor., textura, y vida útil. Su herramienta de protección de calidad más barata es un límite de tiempo estricto para la preparación y una rutina de muelle repetible..

La “regla de exposición corta” para los lácteos

-

Pon en escena sólo lo que puedas mover rápidamente

-

Evite construir pedidos en zonas cálidas

-

Establecer y hacer cumplir un límite de tiempo de exposición en el muelle

El embalaje y la manipulación también importan

Incluso dentro de una habitación fría, puedes dañar la calidad cuando:

-

Los cartones absorben la humedad.

-

Las etiquetas se desprenden por la condensación.

-

los contenedores son aplastados o desplazados

| Riesgo de calidad | como sucede | arreglo barato | Significado práctico para ti |

|---|---|---|---|

| Problemas de textura | picos cálidos repetidos | límites de estadificación | producto más consistente |

| Daños en el embalaje | patrón de paleta débil | patrón estándar | menos devoluciones |

| Condensación | contacto de pared | espaciado + flujo de aire | mejores etiquetas |

Consejos prácticos y recomendaciones.

-

Si las etiquetas se pelan, Reducir la condensación mejorando los sellos y evitando el contacto con la pared..

-

Si las cajas se ablandan, mejorar el flujo de aire y reducir la entrada de humedad a través de las puertas.

-

Si las quejas se acumulan, mapear de qué zona proviene el producto.

Ejemplo de caso práctico: Una lechería redujo los incidentes de "cartón blando" al cambiar los patrones de paletas y agregar una regla de espaciado simple.

Lechería con temperatura controlada, soluciones económicas para recibir: el SOP económico de la base al refrigerador

Respuesta directa: Recibir necesita un objetivo: Acortar el tiempo entre el camión y el almacenamiento en frío..

Explicación expandida: Recibir es donde la luz del sol, aire caliente, y el tiempo de espera llega primero. La mejora más económica es un POE de cinco pasos con marcas de carriles para que el personal no se detenga a decidir dónde van los pallets..

SOP económico del muelle al refrigerador que puede ejecutar en cada turno

-

Despeje previamente un espacio de almacenamiento antes de que llegue el camión

-

Descargar a un lugar marcado frío primero carril

-

Verifique la temperatura y el papeleo rápidamente

-

Muévase al almacenamiento en frío dentro de su límite de tiempo

-

Excepciones de registro (entonces arreglas patrones, no únicos)

| Paso del POE | lo que controla | Herramienta de bajo costo | Su comida práctica para llevar |

|---|---|---|---|

| Ranura de limpieza previa | evita la espera | tablero de ranura | Las decisiones ocurren antes de la descarga. |

| Primer carril en frío | mantiene las prioridades claras | cinta de piso + señalización | detiene el “estacionamiento temporal” |

| límite de tiempo | reduce la exposición al calor | temporizador o reloj de pared | hace que la rendición de cuentas sea real |

| Registro de excepciones | encuentra patrones | lista de verificación de una página | corrige fallas repetidas |

Consejos prácticos y recomendaciones.

-

Asignar un “capitán de muelle” durante las horas pico para evitar cuellos de botella.

-

Trate el temporizador como política. Un reloj visible cambia el comportamiento.

-

Utilice una barrera de sombra simple si la luz del sol llega a su carril receptor..

Ejemplo de caso práctico: Un equipo redujo la exposición al calor creando dos carriles: “almacenar ahora” y “esperar para control de calidad”,”con reglas diferentes.

Monitoreo de temperatura económico para el almacenamiento de lácteos: ¿Qué deberías medir primero??

Respuesta directa: Empezar poco a poco: monitorear las zonas donde el producto realmente experimenta riesgo: el rincón cálido, el área de la puerta, y la zona de preparación.

Explicación expandida: La supervisión falla cuando crea paneles que nadie controla. Su mejor sistema de seguimiento económico es aquel que genera una pregunta diaria.: “Cualquier excursión hoy?" Entonces desencadena una acción clara..

Dónde medir primero (los lugares de alto riesgo)

-

El rincón más cálido de la cámara fría.

-

Área de la puerta de carga

-

Zona de preparación antes del envío

-

Una ubicación de prueba "principal del producto" durante las pruebas de carril

| Método de seguimiento | Mejor para | Debilidad | Su comida práctica para llevar |

|---|---|---|---|

| Termómetro mín/máx | control diario | sin historia | buena base |

| Registrador independiente | búsqueda de patrones | descargas manuales | perfecto para probar |

| Sensores inalámbricos | supervisión continua | complejidad de configuración | mejor después de que los SOP se estabilicen |

Consejos prácticos y recomendaciones.

-

Coloque los sensores lejos de los ventiladores para que las lecturas reflejen las zonas del producto..

-

Mantener revisión semanal, no "algún día". Los datos no revisados son un esfuerzo inútil.

-

Crear una tarjeta de respuesta: qué hacer cuando las temperaturas cambian.

Ejemplo de caso práctico: Un equipo encontró un pico de calor diario en el cambio de turno y lo solucionó cambiando los hábitos de entrada, no equipo.

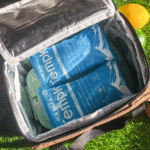

Envío aislado asequible para productos de lechería: ¿Cómo se clasifican los carriles por niveles de forma económica??

Respuesta directa: No envíes todo de la misma manera. Usar niveles de carril para que gastes más sólo donde el riesgo es alto.

Explicación expandida: Muchas fallas en el envío se deben a un embalaje deficiente: demasiado espacio vacío, bolsas de hielo en el lugar equivocado, o retrasos lentos en la carga. niveles + las fotos empaquetadas son baratas, correcciones escalables que reducen las quejas rápidamente.

Niveles de envío basados en carriles

| Nivel de carril | Cuando usar | Movimiento de embalaje de bajo coste | Su comida práctica para llevar |

|---|---|---|---|

| Nivel 1 (bajo riesgo) | rutas locales cortas | cartón del tamaño adecuado + 1 embalar | controlar el espacio vacío primero |

| Nivel 2 (riesgo medio) | rutas regionales | agregar revestimiento aislante + 2 paquete | margen para retrasos |

| Nivel 3 (alto riesgo) | rutas calientes/largas | transportista más fuerte + más paquetes | utilizar sólo donde sea necesario |

Consejos prácticos y recomendaciones.

-

Enfríe previamente el producto antes de empacarlo; no lo "enfríe con paquetes".

-

Estandarice las fotografías de empaque para que cada turno empaque de la misma manera.

-

Mantenga corto el tiempo de empaque y realice un seguimiento como un KPI.

-

Colocar paquetes arriba y al lado lácteos para una mejor cobertura.

Ejemplo de caso práctico: Una lechería redujo las quejas sobre los meses cálidos después de cambiar a niveles de carriles y fotografías de paquetes estándar.

Autoprueba interactiva: encuentre sus mejores soluciones económicas de lechería con temperatura controlada en 10 minutos

Puntuación de cada elemento 0–2

0 = no es cierto, 1 = parcialmente cierto, 2 = consistentemente cierto

-

Tenemos un límite de tiempo de preparación y lo cumplimos.

-

Realizamos selecciones por lotes y reducimos el tiempo de apertura de puertas.

-

Los carriles de flujo de aire están marcados y protegidos.

-

Los sellos de las puertas se inspeccionan mensualmente.

-

Las bobinas tienen un programa de limpieza real

-

Los puntos de ajuste son estables y están documentados.

-

Zonamos el almacenamiento por fecha de envío o velocidad de SKU

-

Utilizamos un patrón de paleta estándar por tipo de producto.

-

Tenemos una "regla de retraso" para recogidas tardías

-

Revisamos las quejas mensualmente y ajustamos los SOP.

Tu puntuación total (0–20):

-

0–7: Comience con la disciplina de la puerta, límites de estadificación, carriles de flujo de aire

-

8–14: Agregar zonificación, patrones de paletas estándar, rutina de mantenimiento

-

15–20: Centrarse en el seguimiento, mejora continua, actualizaciones de entrenamiento

De cómo: implementar soluciones económicas de lechería con temperatura controlada en 7 pasos

-

Establezca un límite de tiempo de preparación y publíquelo en la puerta de la cámara frigorífica.

-

Cree un carril de "envío hoy" y etiquételo claramente

-

Marque las zonas “sin apilamiento” del flujo de aire con cinta para piso

-

Seleccione lotes y cierre puertas entre movimientos

-

Inspeccionar y reemplazar juntas dañadas.

-

Programe la limpieza del serpentín y regístrela

-

Revisar excursiones/quejas mensualmente y cambiar una variable a la vez

La “regla de una variable” mantiene las mejoras baratas

Si cambias cinco cosas a la vez, nunca aprendes lo que funcionó. Cambiar una variable, medir resultados, luego ciérrelo.

| Paso | lo que cambias | lo que mides | Significado práctico para ti |

|---|---|---|---|

| Límite de preparación | tiempo afuera frio | frecuencia de eventos cálidos | menos fracasos |

| Dosificación de puertas | tiempo de apertura de puertas | picos de energía | facturas más bajas |

| Zonas de flujo de aire | diseño de almacenamiento | reducción de puntos calientes | mejor estabilidad |

Ejemplo de caso práctico: Una lechería mejoró su consistencia después de publicar una foto de paleta “estándar de oro” en el área de preparación.

2025 Últimas novedades y tendencias en soluciones económicas para lecherías con temperatura controlada.

En 2025, Los pequeños y medianos productores de lácteos se están inclinando hacia prácticas de “cadena de frío eficiente”.. El foco no es primero la tecnología sofisticada. Es una ejecución predecible con una prueba simple..

Última instantánea del progreso (2025)

-

Tableros SOP visuales: fotos y diagramas reemplazan manuales largos

-

Monitoreo basado en muestreo: Unos pocos sensores revelan la mayoría de los problemas.

-

Envío por carriles: gastar más sólo donde el riesgo es alto

-

Microauditorías: 15-Los controles semanales minuciosos reemplazan las raras y grandes auditorías.

-

Entrenamiento basado en hábitos: disciplina de puerta y reglas de puesta en escena que se enseñan temprano

Insight del mercado que puede usar

A los clientes no les importa lo cara que sea su refrigeración. Les importa la coherencia. Es por eso Lechería con temperatura controlada, soluciones económicas. ganar: Reducen la variabilidad más que la temperatura..

Preguntas comunes (Preguntas frecuentes)

Q1: ¿Cuáles son las soluciones económicas más rápidas para lecherías con temperatura controlada??

Comience con la disciplina de la puerta, protección del carril de flujo de aire, y un límite de tiempo de preparación. Estos reducen los picos calientes sin equipo nuevo..

Q2: ¿Pueden las soluciones baratas realmente reducir el deterioro??

Sí. El riesgo de deterioro a menudo aumenta con la exposición repetida al calor y la puesta en escena prolongada.. Una exposición más corta y un mejor sellado reducen el riesgo rápidamente.

Q3: ¿Cuál es la forma más económica de reducir el costo de la energía de refrigeración??

Reemplazar juntas dañadas, mantener las bobinas limpias, y reducir el tiempo de apertura de puertas. Estos reducen los ciclos de recuperación y el tiempo de ejecución..

Q4: ¿Cómo sé si el flujo de aire es un problema??

Busque heladas desiguales, deriva en una zona, o emisiones repetidas de la misma área de almacenamiento. Luego verifique si hay rutas de retorno bloqueadas..

Q5: ¿Qué debo realizar un seguimiento mensual en una cadena de frío de una lechería??

Seguimiento de eventos cálidos, violaciones de puesta en escena, patrones de puerta abierta, y quejas por SKU y zona. Los patrones son donde viven los ahorros.

Resumen y recomendaciones

Soluciones económicas para lecherías con temperatura controlada funcionan porque atacan las causas reales de la pérdida: entrada de calor por puertas, flujo de aire bloqueado, puesta en escena inconsistente, y reelaboración evitable. En 2025, Las mejores mejoras de bajo costo son disciplinadas y repetibles.: carriles de flujo de aire, lotes de puertas, puntos de ajuste estables, controles de juntas, rotación FEFO, y un seguimiento sencillo que desencadene la acción.

Plan de acción (borrar CTA)

Elegir dos actualizaciones para implementar esta semana:

-

límite de tiempo de preparación + regla del temporizador visible

-

zonas sin flujo de aire + foto POE

Medir eventos cálidos y quejas por 30 días. Si los resultados mejoran, bloquear el proceso y pasar a la siguiente solución.

Acerca de Tempk

En Templ, Ayudamos a los operadores de la cadena de frío a mejorar el rendimiento con sistemas prácticos de embalaje y flujo de trabajo.. Nos centramos en rutinas repetibles., control de temperatura estable, y diseño de SOP fácil de capacitar, para que su equipo pueda ejecutar de manera consistente bajo presión real. Si estás construyendo Lechería con temperatura controlada, soluciones económicas., Le ayudamos a priorizar las actualizaciones que generan retorno de la inversión antes de invertir en equipos más grandes..

Siguiente paso: Comparte el tamaño de tus instalaciones, frecuencia de envío, y el mayor punto doloroso (energía, deterioro, mano de obra, o cumplimiento). Trazaremos una hoja de ruta de mejora de bajo costo adaptada a su operación.