Logística de cadena de ultra frío: Why It Matters and How to Optimize It in 2025

The global ultra cold chain — the system that keeps biological and frozen goods at extreme low temperatures — is rapidly evolving. En 2025 new gene and cell therapies, mRNA vaccines and premium foods demand reliable ultra low temperatures, while regulation and sustainability goals reshape operations. This guide answers what the ultra cold chain is, por qué te importa, and how to optimize it. Ultra cold chain appears in the first paragraph to anchor the main keyword.

What is the ultra cold chain and how does it differ from standard cold chain logistics? (includes long tail keywords like ultra low temperature logistics and cryogenic storage)

Which market trends will shape ultra cold chain logistics in 2025? (covers automation, trazabilidad digital, demand growth and sustainability)

How can you overcome challenges such as energy usage, packaging and regulation? (integrates long tail keywords like cold chain packaging solutions and GDP compliance)

What practical steps can businesses take to optimize ultra cold chain operations? (discusses IoT sensors, renewable energy and predictive analytics)

Preguntas frecuentes: Answers to common questions about ultra cold chain equipment, temperature ranges and regulatory requirements.

What Is the Ultra Cold Chain and How Is It Different?

The ultra cold chain keeps products at ultra low temperatures like −20 °C, −40 °C or −80 °C to preserve sensitive goods such as biologics, gene therapies and mRNA vaccines. Standard cold chains maintain refrigerated (2–8 ° C) o congelado (−18 ° C) condiciones, but the ultra cold chain operates at far lower temperatures to protect delicate biological structures. Biologics account for more than 40 % of newly approved drugs in 2024, and about 20 % of therapies in development are gene or cell based. These treatments degrade rapidly at higher temperatures and require specialized freezers, hielo seco, y contenedores criogénicos.

Compared with a conventional cold chain, the ultra cold chain requires:

Equipo especializado: Ultra low freezers capable of −70 °C or even cryogenic liquid nitrogen (−196 ° C) almacenamiento. Dry ice and phase change materials maintain temperatures during transport.

Zonas de temperatura múltiple: Modern warehouses often include zones for 2–8 °C, −20 ° C, −80 °C and cryogenic storage to handle diverse pharmaceuticals and specimens.

Redundant power and monitoring: Continuous power supply, backup generators and real time temperature and humidity monitoring to prevent costly losses.

Compliance with strict regulations: Buena práctica de distribución (PIB), Estados Unidos. Ley de modernización de la seguridad alimentaria (FSMA) and WHO guidelines require validated processes and documentation. La FSMA 204 regla, eficaz en 2026, mandates end to end traceability for many perishable foods.

Risk based packaging: Contenedores aislados, paquetes de gel, vacuum insulated panels and active containers help maintain ultra low temperatures during long journeys.

En otras palabras, the ultra cold chain is a specialized extension of cold chain logistics designed to protect high value biopharmaceuticals, research samples and premium foods where even small temperature deviations can cause irreversible damage.

Temperature Ranges and Applications

| Rango de temperatura | Productos típicos | Relevancia para usted |

| 2–8 ° C (Refrigerado) | vacunas, insulina, lácteos | Most common cold chain range; used when goods need to stay chilled but not frozen |

| −18 to −25 °C (Congelado) | carne, mariscos, algunos productos farmaceuticos | Standard frozen range; mainstream cold chain logistics |

| −40 to −80 °C (Ultrabajo) | Vacunas de ARNm, biológicos, terapias génicas | Requires special freezers and dry ice; prevents molecular degradation |

| criogénico (<−150 °C) | células madre, CAR T therapies, biobanking | Stored in liquid nitrogen; extremely sensitive products |

Practical Tips for Handling Ultra Cold Goods

Qualify your equipment: Use validated freezers and packaging tested under worst case scenarios. Consider backup units and remote monitoring for fail safe operations.

Planifica tu ruta: Pre determine transit times, required temperature hold times and contingency steps in case of delays. Real time tracking allows you to intervene before a shipment fails.

Entrena a tu equipo: Personnel must understand how to handle dry ice safely and how to read data loggers. Proper training reduces the risk of accidents and ensures compliance.

Ejemplo del mundo real: Durante el lanzamiento mundial de la vacuna COVID 19, ultra cold distribution networks had to deliver millions of doses kept at −70 °C. One pharmaceutical company invested in modular ultra low freezers, insulated shipping boxes with temperature loggers and GPS trackers. This approach reduced spoilage, ensured regulatory compliance and helped meet vaccination timelines.

Market Landscape and Growth Trends in 2025

The ultra cold chain market is expanding rapidly due to innovations in biotechnology, rising demand for high value foods and stricter regulatory requirements. Understanding market dynamics helps you identify opportunities and prepare for change.

Tamaño y crecimiento del mercado global

| Indicador | Valor | Significado práctico |

| Cold chain market value (2023) | ≈ $293.58 billion | The broader cold chain logistics sector, encompassing refrigerated and frozen goods, is already a substantial industry |

| Projected 2032 valor | $862.33 billion | Expected compound annual growth rate (Tocón) ≈ 13 % means major expansion |

| Investigación de precedencia 2025 estimar | $436.3 billion | Illustrates how quickly the market grows from 2024–2025 |

| Mercado de la cadena de frío alimentario 2035 | $1.63 trillion | Food remains the largest cold chain segment; implies opportunities for ultra low freeze for premium foods |

| Ultra low segment growth rate | ≈ 8.5 % CAGR | Reflects increasing adoption of ultra cold storage for biologics |

| APAC region CAGR | ≈ 14.3 % | Asia Pacific is the fastest growing market, driven by healthcare and food exports |

These figures show that the cold chain market is on a steep growth trajectory. The rising share of biologics and cell therapies, coupled with expansion in Asia, underscores the need for more ultra low capacity and resilient infrastructure.

Impulsores del crecimiento

Biopharmaceutical innovation: Over 20 % of drugs in development involve gene or cell therapies, and more than 40 % of new approvals are biologics. These products require ultra low storage conditions.

Vaccine programs: mRNA vaccines must be stored at −70 to −80 °C. Future vaccine technologies may also require similar conditions.

Regulatory demands: La FSMA 204 rule in the U.S. mandates digital traceability for many food products, increasing demand for technology solutions and validated processes.

Presiones de sostenibilidad: Cold chain operations contribute roughly 2 % of global carbon emissions, prompting pressure to cut energy use and emissions.

Expectativas del consumidor: E commerce and home delivery of fresh foods require consistent temperature control, raising the bar for reliability.

Emerging Trends to Watch in 2025

Smart automation and robotics: Actualmente, acerca de 80 % de almacenes no están automatizados. Las empresas están adoptando sistemas automatizados de almacenamiento y recuperación. (ASRS), robotic palletizers and autonomous mobile robots to improve accuracy and safety.

Real time monitoring and IoT: sensores de iot, telematics and cloud platforms provide continuous visibility. Telematics can reduce product loss by up to 30 De % and enable predictive maintenance.

Logística verde: Renewable power sources, biofuels and energy efficient refrigerants help reduce emissions. El Move to −15 °C initiative proposes raising the standard frozen temperature from −18 °C to −15 °C, que podría salvar 17.7 millones de toneladas de CO₂, 25 TWh de energía and reduce costs by 5 12 %.

IA y análisis predictivo: Artificial intelligence analyses data to optimize routes, predict equipment failures and minimize energy use.

Construido para adaptarse a las instalaciones: Outsourcing to specialized cold storage providers that design multi temperature warehouses with redundant systems becomes more common.

Challenges and Risks in Ultra Cold Logistics

A pesar del crecimiento, the ultra cold chain faces significant challenges. Understanding these obstacles helps you plan mitigation strategies.

High Energy Consumption and Sustainability

Operating ultra low freezers demands significant energy. Cold chain facilities account for roughly 2 % de las emisiones globales de CO₂. Además, food waste along the cold chain generates an estimated 8–10 % of greenhouse gas emissions. Utilities costs are rising, and governments are imposing stricter efficiency standards.

What you can do:

Upgrade to modern freezers with better insulation and variable speed compressors.

Implement energy management systems that track consumption by zone and time of day.

Participate in industry initiatives like Move to −15 °C to reduce energy usage while maintaining product quality.

Explore renewable energy options such as rooftop solar and on site battery storage.

Infrastructure Limitations and Capacity Constraints

Many regions lack sufficient ultra cold warehouses and transportation equipment. The supply of dry ice can also be strained during surges in demand, as seen during pandemic vaccine distribution. The industry is working to build more capacity through built to suit facilities and outsourcing. Además, driver shortages and limited skilled workforce challenge reliability.

What you can do:

Partner with third party logistics providers specializing in ultra cold storage.

Invest in training programs to develop a skilled workforce capable of handling complex cold chain tasks.

Consider co locating manufacturing and storage facilities to reduce transportation time and risk.

Complex Regulations and Compliance

The ultra cold chain must comply with multiple regulations such as GDP, FSMA, WHO guidelines and local health authorities. FSMA 204 requires collecting key data elements and sharing them within 24 hours of a request. Failure to meet these obligations can result in fines and reputational damage.

What you can do:

Implement digital traceability systems that log temperature, location and chain of custody information for each shipment.

Conduct regular audits and qualification of equipment, processes and suppliers to demonstrate compliance.

Provide comprehensive training so staff understand how to document and handle regulated goods.

Packaging and Transportation Risks

Maintaining ultra low temperatures during transit is challenging. Embalaje pasivo (p.ej., paquetes de gel, contenedores aislados) may not hold extreme temperatures for more than a few days. Active containers with electrical or battery powered refrigeration can extend hold times but are expensive. Dry ice sublimation can create carbon dioxide build up if not vented properly.

What you can do:

Choose packaging based on trip duration and ambient conditions. Para viajes largos, consider active containers or cryogenic dry ice boxes.

Use real time temperature loggers and GPS trackers to monitor shipments. Alerts allow you to intervene if temperatures drift.

Establish contingency plans for delays, including pre arranged replenishment points for dry ice.

Talent and Workforce Challenges

Operating ultra cold chain facilities requires specialized skills, from handling cryogenic materials to maintaining sophisticated sensors. Many businesses face a shortage of qualified staff.

What you can do:

Create educational partnerships with vocational schools and universities.

Develop career pathways that attract younger talent to cold chain logistics.

Automate repetitive tasks to improve efficiency and allow staff to focus on higher level responsibilities.

2025 Desarrollos y perspectivas futuras

Para seguir siendo competitivo, businesses must anticipate and adapt to upcoming innovations. Esto es lo que puede esperar 2025 y más allá.

Technology Highlights

| Innovación | Impacto | Practical Value |

| Digital twin systems | Simulate warehouses and transportation routes virtually to test different scenarios | Allows you to optimize temperature control and energy usage before implementing physical changes |

| Predictive maintenance with AI | Uses machine learning to predict equipment failures | Reduces downtime and prevents product loss by replacing components before they fail |

| Automated high density storage | Robotic shuttles store pallets in extremely cold environments | Increases capacity without expanding footprint and reduces worker exposure to extreme conditions |

| Trazabilidad de la cadena de bloques | Creates tamper proof records of temperature and custody data | Enhances trust and compliance with FSMA 204 and similar regulations |

| Multi temperate packaging systems | Hybrid containers maintain different zones within the same unit | Supports shipments that include items requiring 2–8 °C and −80 °C simultaneously |

Iniciativas de sostenibilidad

Major cold chain operators are committing to net zero targets. Realizing these goals involves:

Energy efficiency upgrades: Mejora del aislamiento, switching to low global warming potential refrigerants and adopting natural refrigerants.

Integración de energías renovables: Installing solar arrays on warehouse roofs and using energy storage to offset peak demand.

Optimización de ruta: AI driven algorithms reduce travel distance and idle time, reduciendo el consumo de combustible.

Product waste reduction: Enhanced forecasting, dynamic pricing and donation programs reduce food waste and associated emissions.

Collaborative platforms: Sharing warehouse space and transport capacity increases utilization and reduces duplication.

Regulatory Evolution

Regulatory oversight will tighten as governments prioritize food safety and pharmaceutical integrity. La FSMA 204 rule becomes enforceable in 2026 and extends digital traceability requirements beyond the U.S. Many other countries are considering similar legislation. Businesses should prepare by standardizing data formats and participating in industry forums to shape best practices.

Market Predictions

Analysts forecast continued double digit growth in cold chain logistics. The proliferation of personalized medicine, expansión del comercio electrónico, and heightened food safety requirements will fuel demand. Mientras tanto, competition will intensify, especialmente en Asia Pacífico, as new entrants build capacity. Companies that invest in technology, sustainability and resilience will gain an edge.

How to Optimize Your Ultra Cold Chain Operations

Here are practical steps you can take now to strengthen your ultra cold chain and improve performance.

Mapee su cadena de suministro: Identify every touchpoint from manufacturing to final delivery. Understand where temperature deviations are most likely and install monitoring devices accordingly.

Implement IoT and real time visibility: Use sensors that transmit temperature, datos de humedad y ubicación. Alerts enable proactive intervention and support compliance.

Automate data collection and reporting: Integrate your monitoring systems with enterprise resource planning (ERP) and quality management systems. Automate compliance reports to satisfy FSMA 204 y requisitos del PIB.

Invertir en infraestructura energéticamente eficiente: Replace outdated equipment with ultra low freezers that have better insulation and refrigerants. Consider phase change materials and vacuum insulation panels for packaging.

Evaluate green logistics options: Participate in the Move to −15 °C initiative where feasible, use renewable energy and optimize routes to cut fuel consumption.

Build strategic partnerships: Outsource to specialized providers when internal capacity is insufficient. Joint ventures or shared cold storage can reduce costs and provide access to advanced technology.

Develop a skilled workforce: Provide continuous training on handling ultra cold materials, safety procedures and regulatory requirements. Offer incentives to attract and retain talent.

Plan for contingency: Create risk management plans for power outages, dry ice shortages and transportation delays. Keep backup systems and redundancy across your network.

Preguntas frecuentes

What temperatures define the ultra cold chain?

Ultra cold chain refers to maintaining goods at −40 °C to −80 °C or even cryogenic temperatures below −150 °C. Standard cold chain ranges are 2–8 °C (refrigerado) and −18 °C to −25 °C (congelado).

Why are gene and cell therapies so sensitive?

Gene and cell therapies contain living cells or viral vectors that degrade quickly when temperatures rise. Maintaining ultra low temperatures preserves their potency until they reach patients.

How long can dry ice keep shipments cold?

El hielo seco se sublima con el tiempo. En un contenedor bien aislado, it may maintain ultra low temperatures for 2–4 days. Para viajes más largos, you may need to replenish dry ice or use active refrigeration.

What are the main regulations affecting the ultra cold chain?

Las regulaciones clave incluyen buenas prácticas de distribución (PIB), la Ley de Modernización de la Seguridad Alimentaria (FSMA), la FSMA 204 traceability rule and guidelines from the World Health Organization. Compliance requires documented processes, trazabilidad y equipos validados.

How can companies reduce energy consumption in ultra cold storage?

Companies can switch to energy efficient equipment, optimize freezer usage, implement demand response programs, integrate renewable energy and participate in initiatives like the Move to −15 °C.

Resumen y recomendaciones

El ultra cold chain is a specialized extension of cold chain logistics designed to keep biologics, terapias génicas, vaccines and premium foods at temperatures far below freezing. Demand is surging due to the growth of biologics (over 40 % of new drugs), terapias génicas (20 % of pipeline products) and mRNA vaccines requiring −70 °C storage. The market is expected to grow rapidly, with global cold chain logistics projected to reach $862 mil millones por 2032. Al mismo tiempo, the sector faces challenges related to energy consumption, embalaje, regulatory compliance and workforce shortages.

To succeed in 2025 y más allá, companies should invest in ultra low freezers, adopt IoT based monitoring, automate warehouse processes and embrace sustainability initiatives such as the Move to −15 °C, which could reduce emissions by 17.7 millones de toneladas y guardar 25 TWh de energía. Building strategic partnerships, training staff and leveraging predictive analytics will further improve resilience and efficiency. Al implementar estas estrategias, you can ensure that temperature sensitive goods arrive safely, cumplir con las regulaciones en evolución, and meet consumer expectations.

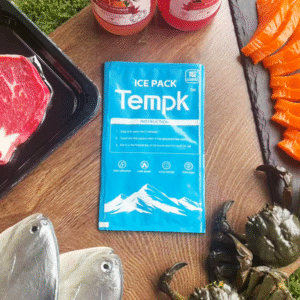

Acerca de Tempk

Tempk is a leading provider of cold chain solutions with expertise in ultra cold logistics. We design and operate multi temperature warehouses that include 2–8 °C, −20 °C and −80 °C zones, along with cryogenic storage for biologics. Our systems use IoT sensors and advanced analytics to ensure real time visibility and compliance with GDP and FSMA requirements. Estamos comprometidos con la sostenibilidad, incorporating renewable energy and energy efficient equipment into our facilities. Whether you need to store mRNA vaccines, gene therapies or gourmet foods, nosotros provide flexible, secure and environmentally responsible solutions.

Llamado a la acción: Contact our experts to explore how Tempk can help you optimize your ultra cold chain. From feasibility studies and warehouse design to end to end transportation and regulatory compliance, we offer tailored services for your specific needs.